Forum Replies Created

-

AuthorPosts

-

@Stereomensch: Yes! And the fir is perfect to tint.

# Spassmaker: of course. I just dont know how to add an stl file to a post.

Location: Paris France

@matador – can you help, or shall I delve into my boxes???Hi Guy,

I’m afraid I can’t help, I have no spare screen, all the faulty I have are mounted on remotes.

Location: Paris France

Hi Steve,

That is the kind of partnership I was referring to. I should have mentioned it.

Sorry and thank you for your continuous help and support.

Location: Paris France

Hi,

I can’t say if its related to MK’s but early BS3000 have small clamper and later, big clamper.

For the features I can’t say either, sorry.

Location: Paris France

Hi Rudy,

I’m here using my “Moderator superpowers” but be certain I’ talking as an usual member.

Your various announcements are interresting and welcome because they may be useful for the community and specially BV7 or Beolab owners.

But if this enthusiast forum will be used as an advertising, marketing or aftersales support platform, please consider getting in touch with the forum runner and start some sort of partnership.

It’s kind of “unbalanced” to use the large footprint of the forum to make business without “giving back” in return. As a businessman you should know those things have a cost.

In the meantime, post like the three I’ve blocked will be systematically send to moderation for further examination.

I hope you and the other forum members will understand this.

Regards.

Location: Paris France

Usually, it starts with one line of dots that disappear followed by more and more.

And/or the screen contrast fading until being not readable anymore.

And obviously, screen broken or leaking.As you said, pressing the bottom of the screen where the zebra strip is can help sometimes but not always. I tried to carefully clean the strip and tighten it but it didn’t help to bring back some screens to life, so if you have any tip it would greatly help a lot of us I think!

Location: Paris France

THIS IS GOOD BEOWORLD !!!

Location: Paris France

Hi,

Idiot question: did you try with (a lot of very) different discs? If no, maybe it is related to the “density” of data on the disc? I think I’v read somewhere that the specs on CD’s have evolved with time and some early decks may have problems reading more recent discs. I’ve got a deck that is unable to play any burned CD’s that can be read without problem on my BS9000.

Worth a try.

Location: Paris France

When dust is not to stuck, I use a silk brush for painting that as no other purpose that sweeping B&O stuffs, When the device is old and has already cleaning marks like micro scratches, the microfiber cloth and care.

Location: Paris France

Looks like they sense something that tells the door to stay opened.

Do you know how to remove the doors and the black acrylic panels?

if so, try a good cleaning of all components, doors, panels and the sensors you will immediately see (4 littles black pearls into a trapezoidal housing, pointed to the center of the unit.Location: Paris France

I really can’t get why people is able to come in for the fist time and ask for help without saying at least “hello/thank you”. Sorry it falls on you, but this is something that really wonders me each time.

That said:

– there is no such thing as “closing sensor”. it’s just a timeout. If the sensor that triggers the doors opening doesn’t detect movement or something in their field, the doors will closed.

– you don’t tell us if the doors close when you help them, which will point a mechanical problem.

– Then if they close, that will be, as already said and by easiest to solve, 1-clean with alcohol and carefully lubricate with silicon. 2-change the belt. 3-Align the doors (search old forum for details).Hope this helps.

Location: Paris France

Aïe, Aïe, Aïe, RIAA’s…

Between the cheap Chineses, the expensive ones, the not so convenient and those who should but don’t and on top of that the dark shadow of the “not that audiophile” ones that may ruin the rendering of your expensive MMC. It’s a real nightmare. When you add the grounding problems and even worse, the need to board it in the cabinet.

That said I don’t understand why nobody recreated the B&O RIAA preamp the was optional with some Beograms: Wasn’t it made of common components?

Location: Paris France

3 August 2022 at 18:00 in reply to: Beo4 and Beolink 1000 Remote Shortcuts and Equivalent Button Presses #35843Hi Guy,

I’ve tried to participate to your topic by amending it with Beoline 5000 equivalent.

Unfortunately I stalled after the red button key equivalent 🙂Anyway, maybe a little out of topic do you know how to trigger A.AUX from the 5000?

This is to manually switch the inputs on a Playmaker. Beside auto-detect (that sometimes fails), Airplay is triggered by A.MEM (A.TAPE on the BL5000) and the analog input with A.AUX. and for that last I can’t find any equivalent on the BL5000.

N.B.: I could use a Beo4 but I find so stylish to have that BL5000… 🙂

Location: Paris France

Oh right! That make sense now! Thank you Carolpa!

Location: Paris France

31 July 2022 at 08:40 in reply to: Cannot change Picture Format to 4:3 on my Beovision 7-40 with Beo4 #36506Hi and welcome to Beoworld.

You need to “add” the controls in the beo4 list of soft keys:

Press red dot and list simultaneously, the screen should then display “Option?”.

Press List again, the screen should then display “Add?”.

Press Go, now you can cycle all the soft keys available by pressing the List key.

When you have found the soft key you’re looking for, press Go.

The control will now be available by pressing the List key.You can also reorder the soft keys by moving them to the top one by one.

The Beo4 manual is widely available on the internet and explain the detailled procedure.

Hope this helps.

Location: Paris France

Further investigations: it seems to be mechanical.

The hooked lever that pushes into the switch doesn’t engage enough at first LIFT button actuation to click in place and keep the platter running. At second actuation it fully clicks in and the starting process goes as it has to.I’ve cleaned it again but I wonder if it’s not related with the rod pushing that lever from the LIFT switch. But I see no adjustment and that rod looks so fragile…

Any idea please ?

Location: Paris France

The cam and cogs have all been carefully cleaned.

Still need two clicks 🙁Location: Paris France

You shouldn’t. These cams MUST run dry and clean. Martin

Thank you Martin,

I felt like I did something wrong. I good to clean it all.

Can this be the cause of the double click problem?Location: Paris France

While waiting for help, I thought someone may be interested in the re-infusing process I used, since it is well explain all over the internet but not often from a beginner point of view.

Disclamer: I know it could have been made better, with better oil, better vacuum device, better skills. But before investing too much, I thought I might give a quick test ride through the full process without any error that can’t be adresse with a little acetone bath.

First step was to take out and dismantle the motor. I decided to take out the full motor assembly before taking it appart. It was in bad shape, rusty, dirty. The rotor itself had rust marks, like drops of liquid that dried on it. I cleaned it and the inner side of the stator, with alcohol.

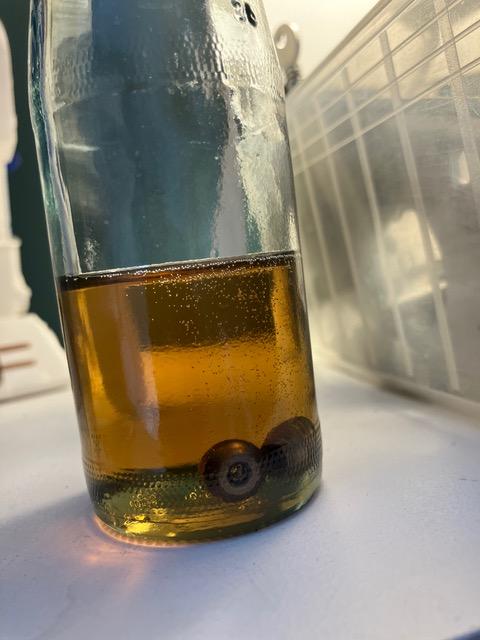

I finally made it to the pearls. Beware, the two pearls are different: one (the bottom one) is a ball, the other (the spindle side one) has a little cylinder part like a jar. Be sure to take pictures at every step.

I thoroughly cleaned the pearls with acetone and let them bath for several hours.

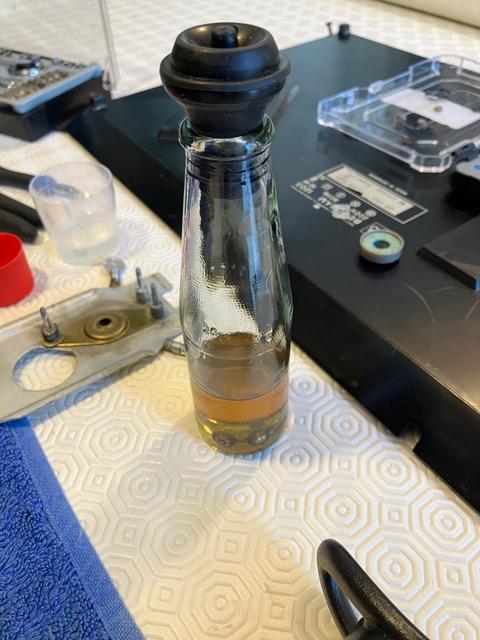

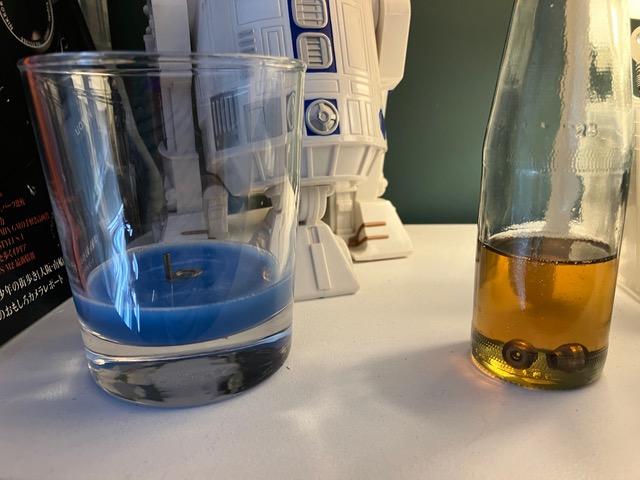

To do the vacuum I used a wine pump and a little bottle. I thought that the smaller the bottle the stronger the vacuum. For the oil I used the first SAE30 I could find: 4 strokes for lawnmower, it come in little container. Put the oil in the bottle, carefully drop the balls (I’ve read they break easily), close the bottle with the special thingy and start to pump.

After few seconds, bubbles starts to form around the pearls.

I pumped a little more from time to time all along the day.

In the meantime, I read somewhere something I thought couldn’t be armful.

So I soaked the idler wheel in fabric softener. for like 10 hours.The balls kept bubbling all night long…

With some magic!

The next day I put it all back together. The deck spins a right speed and silently (it was not so noisy before).

Hope this helps.

Location: Paris France

-

AuthorPosts