Forum Replies Created

-

AuthorPosts

-

Dillen

ModeratorYou need to diagnose the problem before replacing any components.

Make sure that the problem really IS with the idle current before replacing anything.

Chances are that you will only introduce more problems, that could make repairs more difficult – as in f.e. being unable to set the new trimmers right because the original fault is still present, keeping the Beocenter from staying powered up – and even if the original fault is found and fixed the new trimmers setting could be wrong so it still keeps shutting down.I would also leave the capacitors alone for now. At least until the present problem has been diagnosed.

One thing at a time.

Martin

Dillen

ModeratorBad tantals around the Dolby IC. I’ve seen that a couple of times.

Martin

Dillen

ModeratorMark-sf wrote:

B&O made the switch of sides in all of their turntables in the mid 1980’s. They still perform the same record detection function. They became wider to display the speed while the cartridge carrier became narrower to support the smaller cartridges. The older service manuals for the 400x series provide the most detail on the tracking system.—

That’s not quite right;

Earlier Beogram tangentials use the second arm for record detection, and the arm contains an optical sensor system (light, lens etc.).

In order to do this the sensor arm needed to be “in front” of (to the left of) the tonearm.Beogram 5500 and all other type 59xx decks have the extra arm to the right of the tonearm.

This second arm has no sensor and performs no function apart from carrying the speed indicator lights at its outer end. In these decks records are detected by weight.Martin

Dillen

ModeratorSure it’s not something else? A broken lead or a filter problem?

Have you tried swapping with the woofer from the other speaker?

Does it make a very tiny click-sound when you connect your ohmmeter across it?Martin

Dillen

ModeratorThe metal top plate on Beogram TX2 is smaller than on most other type 59xx decks, so the original cover is lighter and the holding springs are different.

Take out the springs, stretch them by hand so they end up apprx 5-6 mm longer than they were, and fit them again.

Martin

Dillen

ModeratorNo. That’s two different transformers.

Martin

Dillen

ModeratorI seem to remember it can be rewired internally. I don’t have the servicemanual at hand now.

Else: https://beoparts.com/2018/11/22/mains-transformer-220-240v-8013312/

Martin

Dillen

ModeratorTapehead cleaner, isopropyl alcohol or carburettor alcohol (same stuff) and cotton buds.

NEVER acetone or paint thinner or the likes.Martin

Dillen

ModeratorIt has nothing to do with it being an export model or not;

Beomaster 3000 build-series 1, 2 and 3 tuned to 108MHz.

From build series 4 it was limited to 104MHz.

You cannot “modify” it. You must replace the tuner module and front panel = easier to find the right Beomaster.Beomaster 4000 was also produced in versions with both ranges.

Martin

Dillen

ModeratorA Beomaster with a bad backup battery can act up in different ways.

If nobody knows which settings and what content is being stored in memory, things really

get quite unpredictable.Martin

Dillen

ModeratorA cracked solder joint, perhaps.

Check around the voltage regulators.Martin

Dillen

ModeratorSC20 is for Beocenter 2000/2002.

You would want a SC77:Martin

Dillen

ModeratorThe tuning lights will only come on with a reasonably good antenna signal.

As will stereo reception (and indicator).Martin

Dillen

ModeratorNot totally correct. The rl140 used foam surrounds, and the rl7000 rubber surrounds. If you compare the crossover they are the same. But the rl60 has a passive membrane and the rl60 w has a bassreflex. Im gonna refoam my rl140’s with rubber you and not with foam. If the flexibility for both surrounds is the same, just take the most durable ones…lesser sensitive to temperature and moist fluctuations. Ok

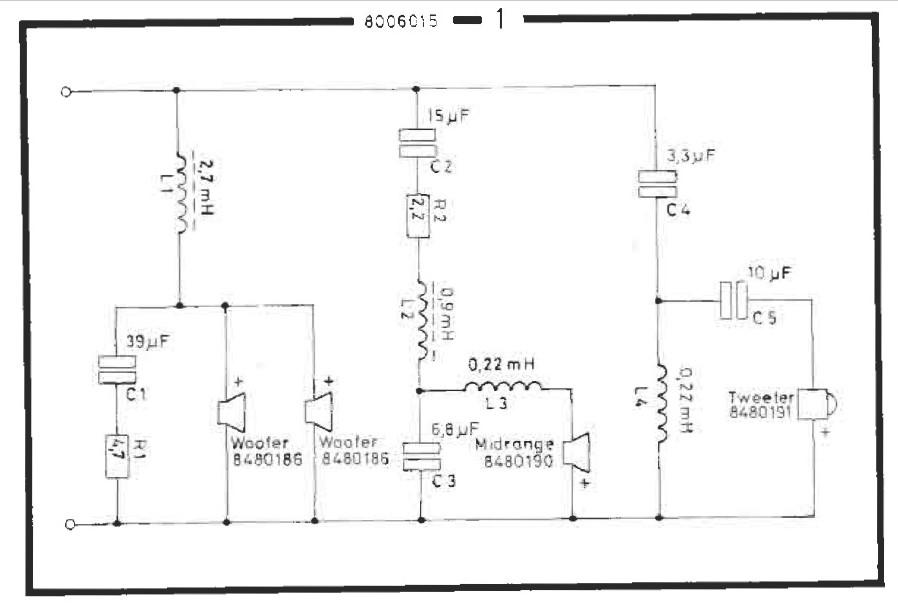

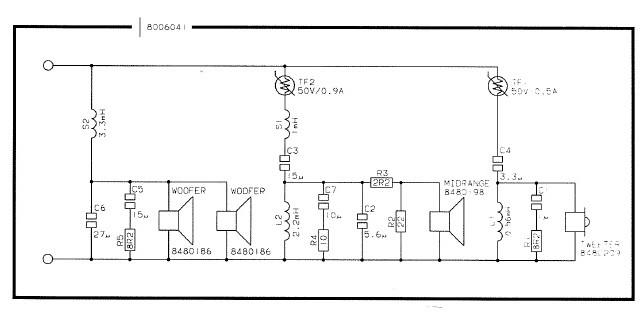

Beovox RL140:

Beovox RL7000:

The woofers are identical. The rest – not quite, I think.

Rubber may last longer (or it may not, depending on the type of rubber),

but if you measure the drivers T/S parameters and compare foam and rubber, you will

be surprised to see how much of a difference it makes.

In some cases it will end up an almost completely different driver.

I would stay with foam where foam was originally used.And keep in mind to let newly refoamed woofers play for some hours before judging/comparing.

They will almost always be a little stiff and sound a bit “stubborn” or “tame” at first, and they will need to losen up a bit to do their job as intended.And don’t compare to how they sounded with the old, partly disintegrated foam, as having the woofers cones flapping around undampened and

uncontrolled, as they would be, will also be far from what was intended with T/S parameter readings everywhere and nowhere.Martin

Dillen

ModeratorBeoworld neither can nor will provide a pin code, and neither can anybody else, sorry to say.

It’s part of Bang & Olufsens anti-theft programme.

Best is to bring the original purchase receipt with you to the nearest dealer, but

as a minimum bring the unit in with the serial number intact and visible, so they

can check against B&Os stolen goods registry.

If everything is fine it won’t take long for them to reset the unit.If it’s stolen, it’s worthless.

Martin

Dillen

ModeratorThese decks have very few problems with lubrication, really.

Unless something is not working as it should, there is really no need to do anything.Martin

Dillen

ModeratorShorted 1C53 (220uF)?

Martin

Dillen

ModeratorIf the cone of the woofer has seized solid (common problem), it can usually be repaired with a little skill.

Before the new forum took over the old forums URL you could look up guidance and tips for repairing your woofer. Several threads in the old (archived) forum discussed and showed how.

Now you will be lucky if google comes up with anything usable.But, basically, it’s a matter of manipulating the magnet and the pole piece.

Martin

Dillen

ModeratorA small amount of teflon-based “oil”.

A seller on Ebay once had something called “liquid bearing”, that’s very good.

Because it’s not really an “oil”, but mainly microscopic teflon balls, it doesn’t really

evaporate and it doesn’t grab and hold dust and dirt the same way an oil will.Don’t use shaver- or sewing-machine oil. It evaporates over hours rather than years, and

most will leave some of its additives etc. behind.Forget WD40. Keep that in the garage for use with rusty cars.

Martin

Dillen

ModeratorSo was I.

Martin

-

AuthorPosts

The woofers are identical. The rest – not quite, I think.

The woofers are identical. The rest – not quite, I think.