Forum Replies Created

-

AuthorPosts

-

Dillen

ModeratorDismounting the servo circuit board from the bottom of the disc drive you must work carefully.

You will have to release the ribbon cable running to the laser block from its socket on the pcb.

This can be tricky – particularly because the cable will almost certainly break at the sharp corner where it’s secured, if pulled.Martin

Dillen

ModeratorCorrection: It cannot be from a 606 due to the different pivot system.

Martin

Dillen

ModeratorIt could be from a GR 605 (1959) or 606 (1960).

Martin

Dillen

ModeratorPut a scope on an output.

Check for oscillation.Martin

Dillen

ModeratorDillen

ModeratorThe modern grey stuff often sold for use with computer CPUs is useless. Some of it dries hard over a week or two.

Silicone pads – some are fairly good, others are junk. I don’t like them, and I throw them away on sight.

The original white heatsink compound, that was also used originally, works best. It will last for decades.Martin

Dillen

ModeratorA drifting idle can be caused by bad thermal contact to the heatsink.

Did you use the proper white heatsink paste?Martin

Dillen

ModeratorA worn and slipping belt can allow the motor to accellerate to easily.

The motor pulley simply slips on the belt at startup.This, coupled with electronics that will accept to lock in at twice the correct speed, causes this.

The cure is to replace the belt.Martin

Dillen

ModeratorI use a “glass-hair”/fiber brush.

But if there is oxidation, you can clearly see it as black flakes.Martin

Dillen

ModeratorWelcome back, Peter!

Martin

Dillen

ModeratorDifficult to say what could be the reason, but if you start working or diagnosing keep in mind that Beomaster 900 has positive ground.

Martin

Dillen

ModeratorTypical sign of aging capacitors. Grab a service kit and replace the lot.

Martin

Dillen

ModeratorDoes your volume control have one or two ICs?

Martin

Dillen

ModeratorThanks Mark.

Martin

Dillen

ModeratorWhat happened to my (long) reply to this thread from apprx. four days ago?

Martin

Dillen

ModeratorThe insulation capacitors are there for a reason.

I would NEVER remove them.

Actually, they are signs of a very high quality circuit design.So what are they, and why are they here?

They are small ceramic capacitors placed in strategic places through the signal path, from the signal path to ground.

They are called insulation caps because they insulate the individual signal path stages HF-wise.

They are here because you cannot put a load on f.e. a power supply, without seeing some kind of reaction on its power output, and

because most OpAmps have a very high slew-rate.If an OpAmp switches fast from off to on (or vice versa), the current it “accellerates” will have to come from somewhere.

In other words, a sudden spike commanded on an OpAmp output will see a corresponding (reverse) spike on its power supply rail(s).

This supply will often be supplying other circuits in the signalpath as well, and these circuits will also see the spike in their supply causing them to instantly produce a spike on their output.

Actually, the OpAmp itself will almost always also cause a spike, as will most semiconductors (and some capacitors).The spike on the power supply rail will of course also affect the very OpAmp that caused it (with a brief delay), and

the (very!) brief power surge will cause a new spike on its output.

The result is a very high frequency “ringing” (fading burst of spikes) until the new current flow situation has settled (throughout

the signal path!).As the spike reaches stages with higher and higher amplification and higher currents involved, the corresonding

spikes on the power supply rails will be larger – again feeding back to the earlier stages.

If the power supplies are not suitably decoupled, due to f.e. tired/sluggish filter capacitors, this could in severe cases end in

self-oscillation and a burned amplifier.Small caps (100nF or so) are often placed directly on OpAmps (and other circuits handling audio signals) power supply pins.

This helps quite a bit when viewed from the power supply side.

But any spike already produced will go on to the next stage, be that tonecontrol, volume or amplification.

If nothing is done, the spike will continue to the next stage and cause the next OpAmp to (attempt) to

reproduce this “signal” which, in case of an amplification stage, would only make matters worse.

The spike will grow through the amplifier, and the more it grows the heavier spikes form on the power supply rail and the

more ringing will be introduced to the signal.This signal could eventually end at the tweeter (as speakers crossovers usually don’t cut off HF), and it can contain quite an amount of energy.

A Zobel-network on the amplifier output would take some of it, but even this small circuit could be put to hard work.

Bad power supply filtering caps (the small 10uF) in f.e. Beomaster 5500 can cause ringing throughout the preamp and output stages,

and the small Zobel network resistor can actually burn from the resulting HF energy contained in the signal.

The output stage will also run warm.Putting an insulation cap (a few pF) on the signal path to ground will drastically improve matters as it will be seen as a

dead short for the very high frequency contained in the bursts.

A capacitance this small will have no influence on anything within the audible frequency range.

Quite opposite in fact, as it will remove spikes and bursts that are not part of the original signal.In some cases, – typically early in the signal path, the OpAmps (or whatever circuit handles the signal) power are fed through

a low-pass filter, often seen as something like 47-100 Ohms in series with the power supply/ies and 100uF to ground.

This is done for all stages individually, of course, – or it would be pointless.

The JAMO Promix 200 which is at first glance simple but, by far, one of the best sounding discoteque mixers, uses this in dozens of places.

Beogram CD5500/6500/7000 does too in the analogue stages.I strongly recommend leaving insulation caps well alone.

It is very high quality circuit design.Martin

Dillen

ModeratorVery nice indeed.

For shipping considerations, it would also be good to know where you ship from.Martin

Dillen

ModeratorDepends on the type of Beovox 3702.

Kits are readily available:

https://www.beoparts-shop.com/?s=3702&post_type=productMartin

Dillen

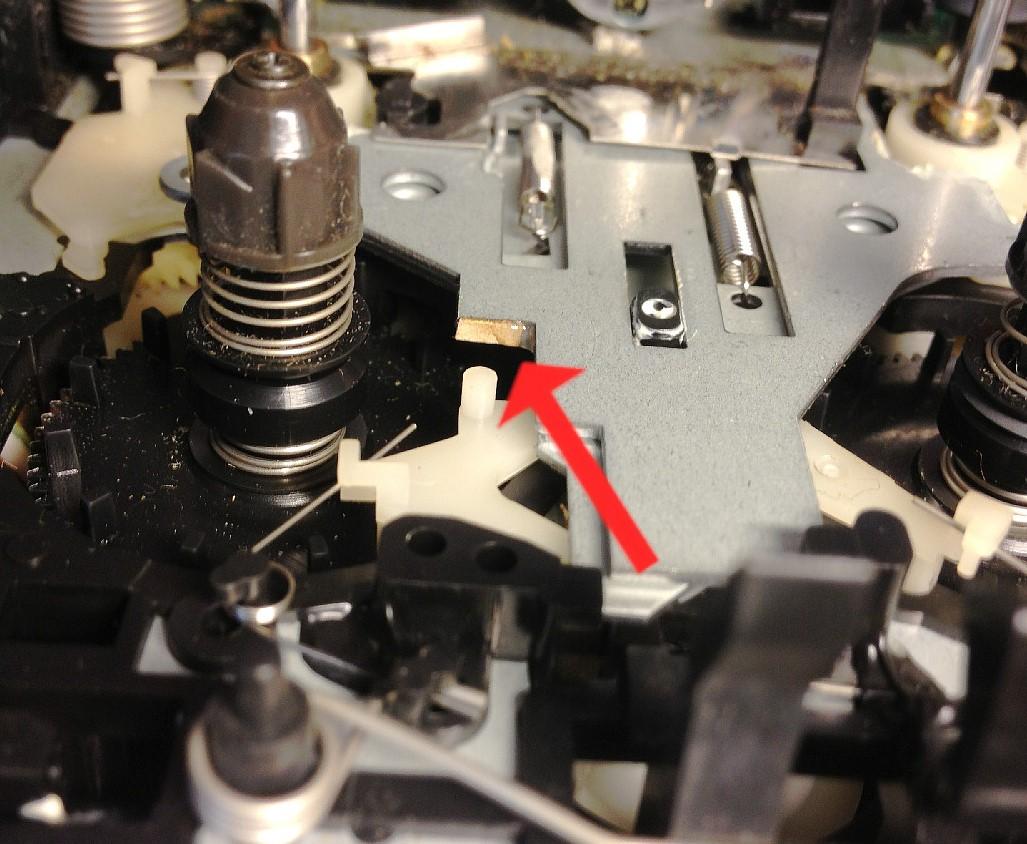

ModeratorIt’s a known problem with this drive type.

Glue in a small piece of carton or plastic card (apprx 0,5 mm thickness) here:You can give the exposed motor bearing a tiny drop of sinter oil.

The belt for the motor must NOT be tight!Martin

Dillen

ModeratorIt’s not uncommon to see the Beocords rubber feet missing as they harden with age.

The outer parts break off, while the inner parts fall inwards where they will often

get stuck between the Beocords bottom plate and the drawer, causing a braking effect.

Look in from the front with a torch light.Martin

-

AuthorPosts