Forum Replies Created

-

AuthorPosts

-

BRONZE Member

BRONZE MemberThnx Keith, I will di that check and report it tomorrow.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE Member@Keith: thanks, I guess I misunderstood.

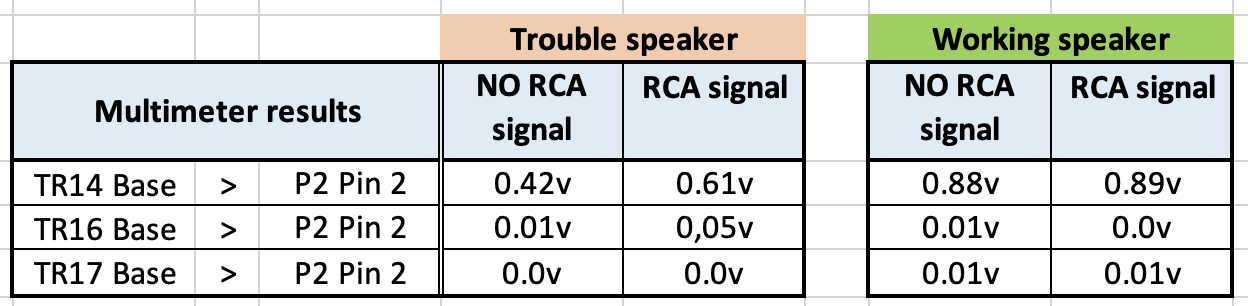

So I re-measured with the multimeter in DC voltage.

Also, I did the same measurement with a speaker that switches correctly on the RCA/Line-in.

This is what you meant?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE Member@Glitch: Thanks for your input and especially the visualization. This helps understand what to look for. So I will check again.

@Keith: Also thanks a lot!

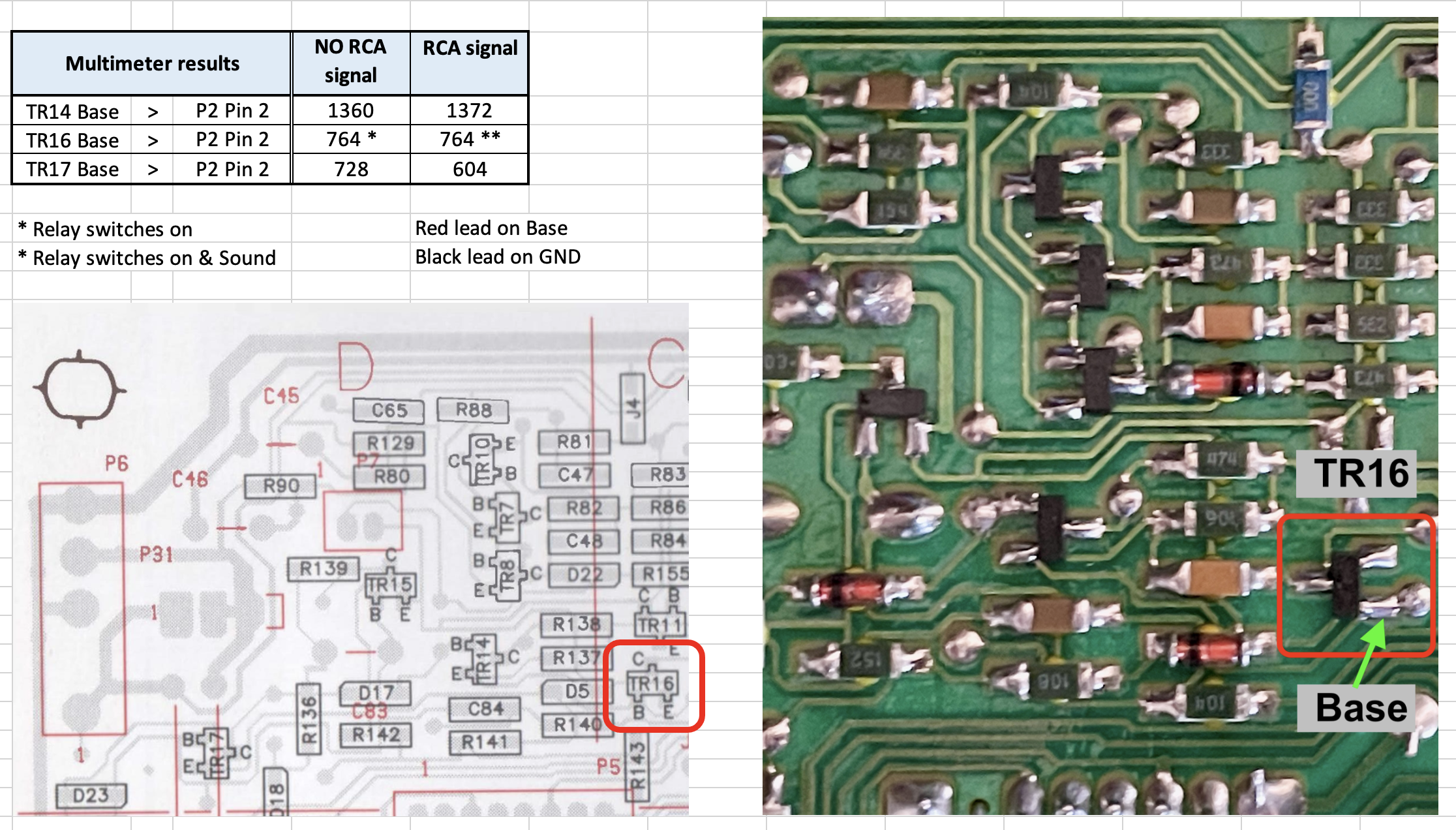

TR14, TR16 & TR17

In the meantime I measured what you suggested. Since I do not have an oscilloscope, I used a multimeter (Voltcraft VC130-1), in diode/continuity mode. IO found out that the direction of TR16 on my PCB is 90 degrees different than the layout in the Service Manual. But I assumed the Base to still be the left leg of the two next to each other.

You can see the results below. In all measurements, no continuity signal but a value measured.

Measuring at TR16 with & without signal on RCA, the relay switched on. With audio signal on the RCA, music was also there.Additional

In the schematics of PCB02, I read that IC1 should measure +15v at leg 8, and -15v at leg 4.

- I measured 29v.

As IC should also measure +15v at leg 8, and -15v at leg 4, I checked that one too.

- Also 29v.

Question:

- What does this mean to you?

- In the meantime I have also received a new IC1. Do you suggest to execute the replacement, or do you have another suggestion?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberIn addition I did a test on the Input selector switch on PCB05, I measured all positions of the switch with a multimeter. And then did the same with a switch on a PCB05 from a working speaker. In comparison all results were the same.

I also swapped a PCB05 from a working system to this speaker. Results the same; in the RCA position the LED stays red.

To be continued when I received IC1.

In the meantime, still open to suggestions that help problem solving.Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberMe too.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

19 November 2024 at 15:15 in reply to: BeoLab 8000: P4 / 230v connector to PSU-PCB broken, replacement? #61048

19 November 2024 at 15:15 in reply to: BeoLab 8000: P4 / 230v connector to PSU-PCB broken, replacement? #61048 BRONZE Member

BRONZE MemberThnx a lot @Glitch!

After checking the connector block close by, I could see the release tabs.

Pulling them a bitt outwards indeed enabled me to pull the wires and the internal terminals.After that I was able to reconnect the terminals better to the wire.

All fine now!Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberI think you’re right that AUX is just AUX.

And that the DIN AUX connector on the BS9000 only has pins 1 – 5.Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

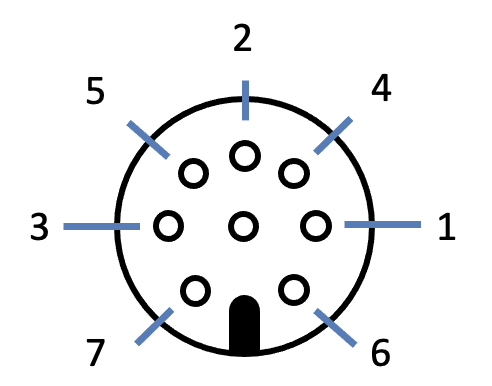

BRONZE MemberThough B&O uses an 8-pin DIN connector, for this purpose you can use a 5-pin DIN connector, using only 3 pins.

It is all about connecting a cable with 3 leads to the right pins, for getting the stereo signal from your WiiM in to the BS9000.

The 3 leads are: (picture show male DIN connector from the back/solder side, or female from the front side)

- Gnd to pin 2

- Right channel to pin 4

- Left channel to pin 1

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberYou can definitely make this work.

I am sure Steve from @soundsheavenly can help.

Can you jump in Steve?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

16 September 2024 at 13:17 in reply to: BeoLab 8000 woofer scratching noise: can it be solved? #59129

16 September 2024 at 13:17 in reply to: BeoLab 8000 woofer scratching noise: can it be solved? #59129 BRONZE Member

BRONZE MemberThnx @matador !

They way you describe it, sounds very much the same to how I experience this.

Cloud you please share the Spotify link to this song?

Please also mention at what point in the song (minutes:seconds) you experience the ‘vibration’.

Thnx in advance

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberHi Laurens. Here’s some things you can check.

(1) Check the Belt: Ensure the belt is in good condition and properly seated. A worn or loose belt can cause speed issues. If the belt is old, consider replacing it.

(2) Speed Adjustment: The Beogram 1203 has a speed adjustment mechanism. You might need to fine-tune this. Use a strobe disc to check the accuracy of the speed and adjust accordingly.

(3) Clean and Lubricate the Speed Change Mechanism: Sometimes, old lubrication can cause the speed change mechanism to stick. Clean out the old lubrication and re-lubricate with a suitable oil, like sewing machine oil1.

(4) Check the Motor Pulley: Make sure the motor pulley is clean and free of any debris. Sometimes, dirt or grime can affect the speed.

(5) Inspect the Electronics: If the mechanical parts are all in good condition, the issue might be electronic. Check for any faulty capacitors or resistors that might need replacing.There’s also a video on Youtube about fixing a slow 1203. I gaven’t fully watched it. But maybe you find something helpful.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberThnx @jacek1313 & @Dillen

@jacek1313: did you find this info for the 8002 in its Service Manual?

(I haven’t found such info for the BeoLab 8000 in its Service Manual)

@Dillen: thanks for sharing this nuance. I understand that a multimeter in Ohm measuring mode, will measure in DC and not in AC. If so, what is the right way to measure the value for the 8000? And what should the value be (for the 8000)?Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberComing back to my addition.

In the meantime I have been able to solve my issue. It had nothing to do with the issue described in this thread. The cause in my case was in air gaps that created a wrong air flow resulting in vibration.

I have added what I have done to solve it in my topic (see the link in the post just above this one).Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberXX

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberWith help of @spassmaker I focused on possible air ventilation/gaps. So I now changed two things since last time:

- I cleaned away every tiny bit of the left glue of the old gasket. To make sure the whole surface is smooth and straight.

- I placed brand new foam (original B&O, placement according to B&O instruction).

Also, I checked the bad woofers by gently pushing them down in the middel, and feel if there was any scratchy feeling? > There is no scratchy feeling or noise.

Result: Happy that I can say that the bad vibrations are gone. Just one remark about that. I have played a list of songs with a bit more heavy and low bass tones. All play well, but only one song keeps disturbing me a bit: Coldplay with Magic. Still, in the first part of the song, the vibration can be heard when the kick drum comes in. But the effect is much less than before, and only at high volume (75% or up). Maybe it is in the song.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberThanks for your input Christian!

Interesting remarks you made. Especially the air ventilation triggered me. So I now changed two things since last time:

- I cleaned away every tiny bit of the left glue of the old gasket. To make sure the whole surface is smooth and straight.

- I placed brand new foam (original B&O, placement according to B&O instruction).

Result: Happy that I can say that the bad vibrations are gone. Just one remark about that. I have played a list of songs with a bit more heavy and low bass tones. All play well, but only one song keeps disturbing me a bit: Coldplay with Magic. Still, in the first part of the song, the vibration can be heard when the kick drum comes in. But the effect is much less than before, and only at high volume (75% or up). Maybe it is in the song.

Your questions

- Did you crosscheck the”bad” woofers in the”good” speaker set? > Yes, the so-called bad woofers did well in the ‘good’ speaker set.

- If you push gently the bad woofers is there any scratchy feeling? > There is no scratchy feeling or noise.

Question to you

- What kind of material do you use for the gasket?

(share a link if you can)

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

8 August 2024 at 09:05 in reply to: BeoLab 8000: Broken plastic leg supporting PCB > which glue ? #58096

8 August 2024 at 09:05 in reply to: BeoLab 8000: Broken plastic leg supporting PCB > which glue ? #58096 BRONZE Member

BRONZE MemberThanks BeoBuddy !

I agree on the ‘brittleness’. The material all over is quite vulnerable after all these years. After it happened with one screw, I put just a bit of WD40 in the other screw holes. Keeping the screw vertical and screwing slowly works quite well. Anyhow, if one screws slowly without too much of resistance, it works well.

For all other cases, it is indeed better to create new brackets/stands. I think I might also do this on my 3D printer.

===

By the way, did you see my PM to you?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberExcuse me for dropping in, I certainly do not want to hijack this topic.

I also have an issue with the woofer drivers of BeoLab 8000. Though I think it is not a scratching noise. In my case I have a vibration that sounds like there is something loose or damaged in the driver. I have just added my topic to the forum right here.

Can you please have a look at this and comment if you recognize this?

Thnx in advance!

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberWhat exactly do you want to know?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

15 April 2024 at 07:44 in reply to: Penta Mk3 display dead and amplifier LED stays orange in standby #54227

15 April 2024 at 07:44 in reply to: Penta Mk3 display dead and amplifier LED stays orange in standby #54227 BRONZE Member

BRONZE MemberHi @Beauvais762

I haven’t worked with Penta’s myself, but I remember reading about issues with them. There’s a lot of info on the forum. Especially in the ‘archived forum’. Though I am currently experiencing errors accessing the archived forum. Probably a temporary issue.

One of the threads that might interesting is this one: https://archivedforum.beoworld.org/forums/p/31993/259129.aspx#259129

I remember that some of the issues with the display can be solved by replacing a capacitor on the display PCB.

Hope this helps a bit.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

-

AuthorPosts