Forum Replies Created

-

AuthorPosts

-

BRONZE Member

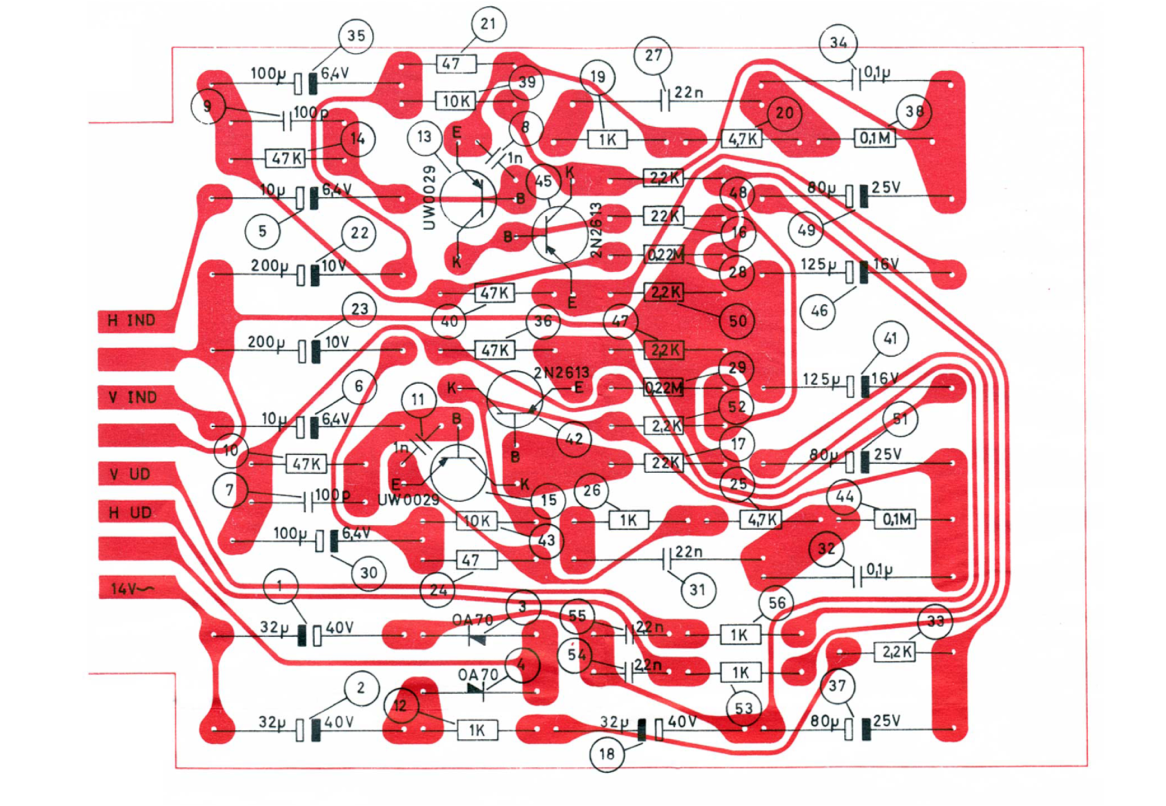

BRONZE MemberNow making the full components list, I run into some questions. Obviously, a RIAA pre-amp of the B&O BeoGram 1000 and the SP cartridges are built to be matching with each other. So I want to make sure that I am selecting the right components. And if needed, to select an alternative that works.

So please help me out with this ….

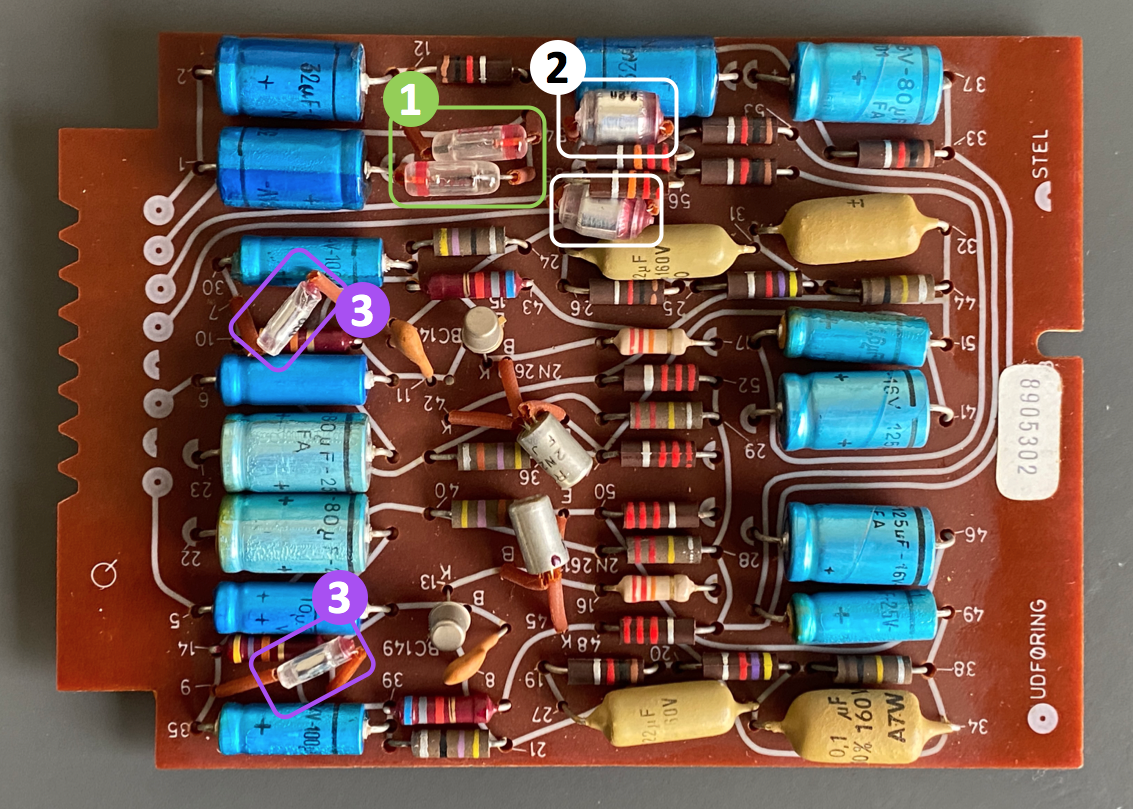

(1) Component 3 & 4 (green box marking in the picture) have type name OA70, and looking at the symbol they seem to be shockley diodes.

Q: Is this indeed a shockley diode? Should I order exactly the same, or is a modern replacement recommended?

(2) Component 54 & 55 (white box marking in the picture) seem to be non-polarised capacitors with value 2,2nF.

Q: What exact type of capacitor is this? Should I order exactly the same, or is a modern replacement recommended?

(3) Component 7 & 9 (purple box marking in the picture) also seem to be non-polarised capacitors but with value 100p.

Q: What exact type of capacitor is this? Should I order exactly the same, or is a modern replacement recommended?

I would be grateful if you add an URL to components you suggest. Thnx!

Att: The PCB picture above, is a horizontal mirror of the schematics below!

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

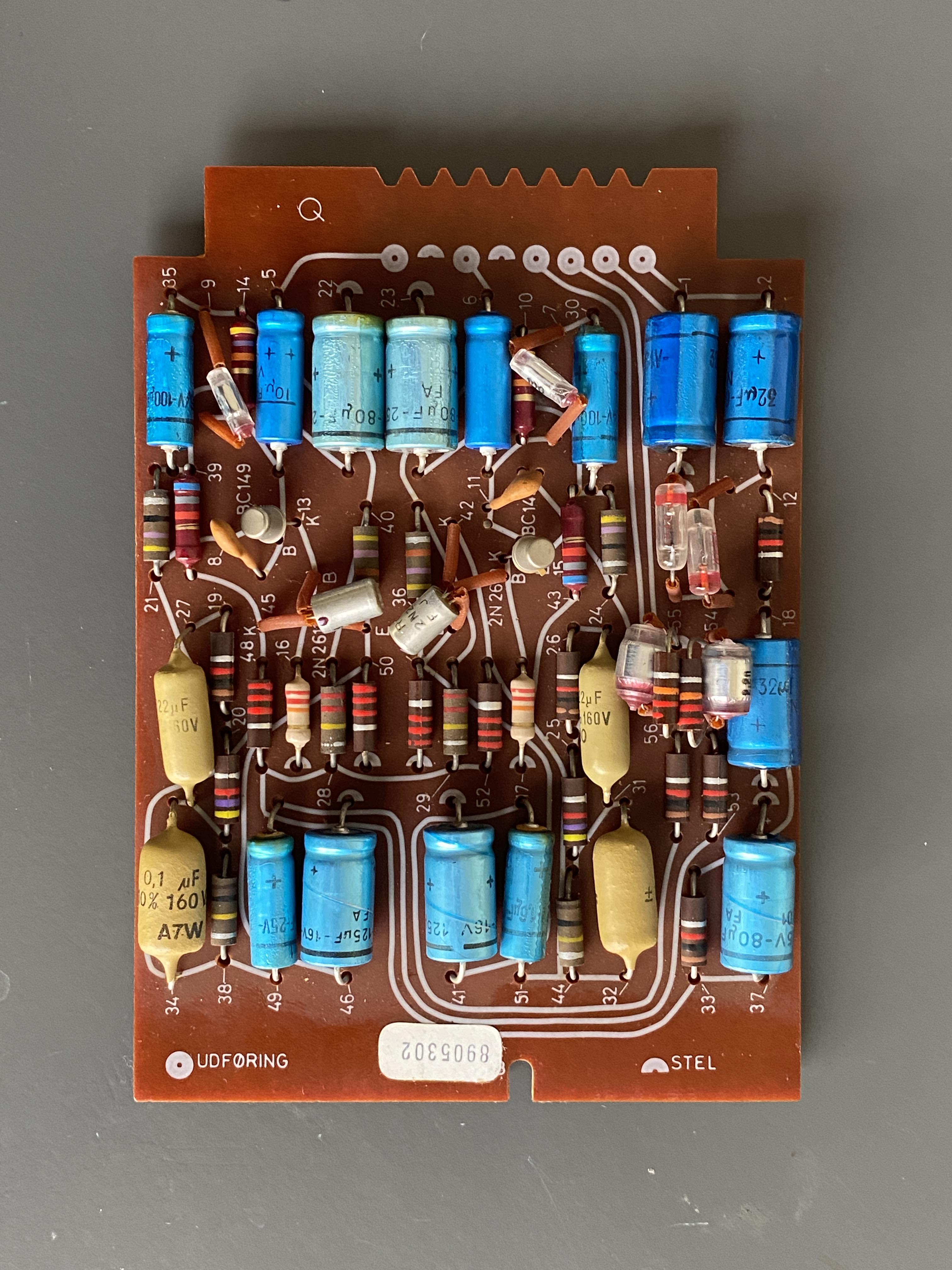

BRONZE MemberThanks for sending the bottom view picture!

Yes, I am aware that my trace image has to be mirrored.Question

The board side that sticks into the slot (so where the 8 tracks in a row are), has 8 notches.

Can you please let me know how deep they are?I think they are a little less deep than the 6mm notch on the other side of the board.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

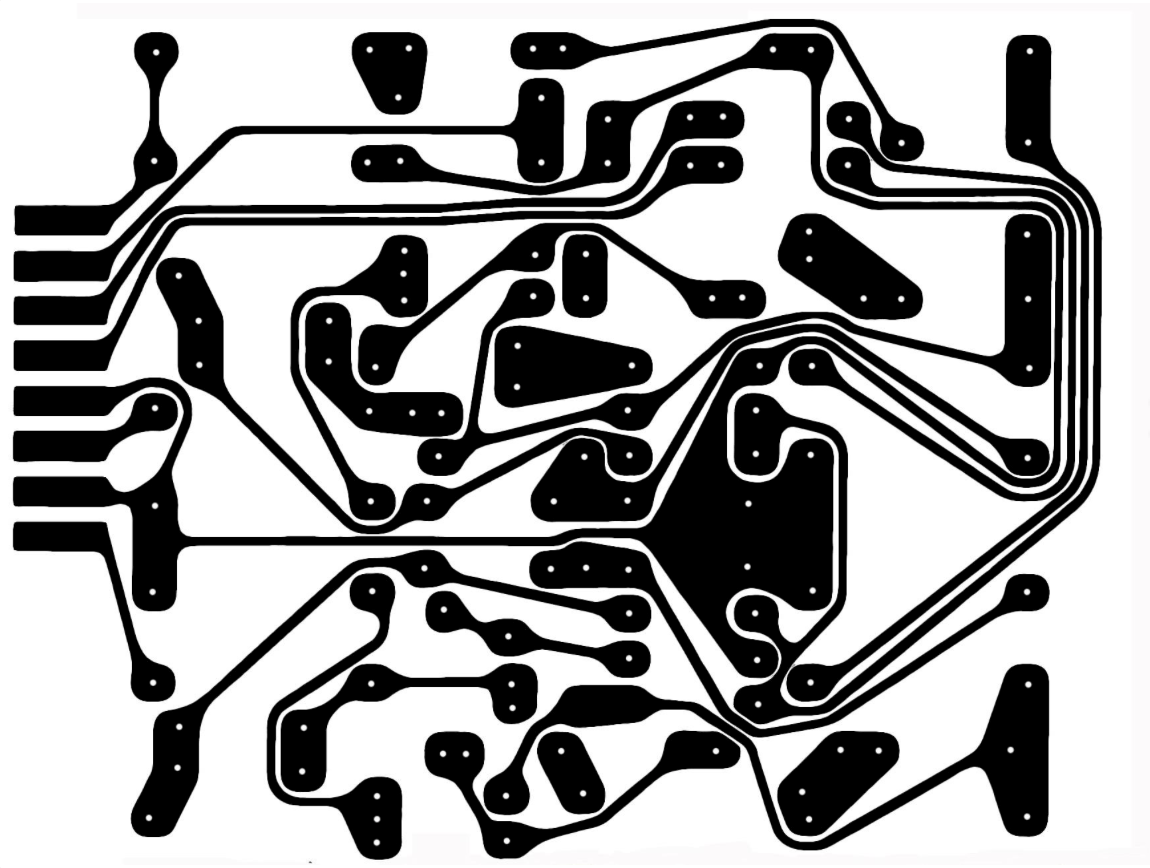

BRONZE MemberAt the moment I am in preparation of making the PCB. My first step is to get the copper traces on a board.

Therefor I have to position and size the image of the copper traces perfectly. I have that picture (see picture below), but it has no outer/PCB border lines, so I have to find out how to size and position this image. (Obviously to get size and proportion equal to the original PCB)

Questions

- Does anyone have such picture of the copper traces pattern, including outside/PCB border lines?

- @Mexking: do you have a picture of the bottom side of the pre-amp board?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberUpdate:

I have now collected most information to reproduce the original B&O BeoGram 1000 RIAA pre amp extension board.

- PCB layout (including drawing of the copper traces)

- Components & specifications

- All dimensions in mm of the PCB board

1 & 2 in this post.

3 in this thread:About components, I will continue in the next post in this thread.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberThis is perfect information, thanks so much !!!

I will start to re-produce the original BeoGram RIAA preamp.

Fantastic!

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberThat is a way of course. Measuring the slot size, and calculating the other dimensions from there.

Maybe I will post a seperate question for measurements. I guess someone on the forum will have a board, to measure all sizes. If I find those, I will post here what it is.

Thnx

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberThanks very much for sharing these pictures! That makes it a lot easier to try to make one myself!

Question

Since I do not have a pre-amp board at hand, do you have the outside dimensions of the PCB?Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberThanks all for your responses and contributions!

I have been questioning that myself too. If I look at pictures of the pre-amp board, it seems it is not unthinkable to re-make it. Even in the same look & lay-out as the original. It even makes me wonder if maybe someone did that … (?)

That’s a good suggestion! I will check with Dillen.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberThanks for referring to Peter Pan’s diagrams Guy, that made it clear!

I like the visual way of understanding the pin layout. In the end, it’s easy to make a mistake if you don’t understand the interpretation of sides: male/female and pin/hole side or solder side.

So a picture like Peter Pan is using, helps a lot:

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberJust to be sure …

When looking at the picture you added about the pin-numbers and what they mean:

- Is the view of this picture, the male connector from the backside (soldering side)?

- Are the ground wires (of the input and output cables that I need to combine to the DIN), combined on PIN 2?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberI would also be interested, and to know of there’s an English version.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberOf course, I understand its Steve’s business. 🙂

But I do not have to know how the cable has been configured internally.I just want to understand if this is only a Mini-Jack-to-DIN cable …

Or that it comes with something else for the 5-volt/trigger signal.@Steve: maybe you like to respond to this?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE Member@Steve

Very interesting the Mini-jack to RCA cable also has a trigger signal.

But for my understanding, the trigger signal needs to be 5v on Pin 4.

Where do you get the 5v to be used on Pin 4 to activate the B&O speaker amp to get from stand-by to active? Hoe does that work with this cable?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberDid you connect a Powerlink or RCA cable to one of the connectors?

what do you see and hear when you do that?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE Member@Steve

Great comment Steve.

How does the (for instance) Apple Airport generate a trigger signal for the BeoLab?

By the way. Is it possible to see the linked product when your website is temporarily closed?

I understand your not 24/7 available to follow-up on everything. Though I can imagine that you keep all informative parts of your website accessible, and close ordering and contact form. Would that work for you?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberHi Lawso,

1) What do you prefer; a) to have an external device to add streaming capabilities, or b) an internal integrated solution?

2) To which B&O model would you like to add these capabilities?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberThanks for your replies guys!

I mainly wanted to know if the pin 3 & 5 and pin 2 & 4 would work simultaneously. So thanks for confirming.

Concerning the cable … the one I need will look a little bit different. I need to split from DIN to a) mini-jack and b) RCA female. But that’s no issue for me, to make one myself.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberWhy I would do so > Cause I need the turntable and the cassette deck connected to the BeoSound for both recording, as well as for playing via speakers connected to the BeoSound.

Is it possible to simultaneously:

- Connect a turn-table via the Auxiliary Pin 3 & 5 and play vinyl

- And connect my cassette-deck via the same Auxiliary Pin 2 & 4 and record the music from the turn-table

Comment: I would say so, cause normally with RCA connections this AUX would be two RCA connectors for Line IN, and two RCA connectors for Line OUT. So, isn’t the DIN a combination of these sets of RCA connectors in one plug?

Question

Please comment on my ‘Is it possible to simultaneously …’ question.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberSo here’s an additional question …

Is it possible to simultaneously:

- Connect a turn-table via the Auxiliary Pin 3 & 5 and play vinyl

- And connect my cassette-deck via the same Auxiliary Pin 2 & 4 and record the music from the turn-table

Is this possible?

(Assuming of course that a made a splitter cable which can handle that)

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberThnx to all, this is a great experience to have such great responses so quickly on the BeoWorld forum!

Additionally I should mention, the external recorder is non-B&O. It will be a vintage Nakamichi 600 cassette deck.

Not being able to control this external recorder as a B&O device is not an issue. For me it is just important that there is a L & R channel OUT, that I can pick up via the Auxiliary connector on the back of the BeoSound 3200.

So from all your information I conclude it is possible and will work. As long as I use:

- Pin 1 > Left out

- Pin 2 > GND

- Pin 4 > Right out

As mentioned and described in the response and picture of Matador.

Thanks!

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

-

AuthorPosts