Forum Replies Created

-

AuthorPosts

-

BRONZE Member

BRONZE MemberThank you very much for sharing your experience. I haven’t had the opportunity to compare all the BeoGram models, and experience their differences.

So, this information is welcome!

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberInteresting comment.

How would you rate the BeoGram 4000 series, compared to other (later) linear tracking turntables, and radial tracking turntables?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberA warm welcome to you Michael !

Great you got the virus too. And by the way, your story brings back to me the ‘triangle of top designers’.

- Braun design s became famous because of (the great) Dieter Rams.

- Apple’s top designer Jonathan Ivy was inspired by the designs of Dieter Rams. There’s a famous list of Apple products derived from Dieter Rams’ / Braun designs: https://sl1nk.com/fVgIa

- Jonathan Ivy also was inspired by the B&O designs, especially with aluminum, which is obviously recognisable in most Apple products.

So, going from loving Braun to loving B&O is quite logical. Enjoy it!

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberDear Daphne,

I get that.

Your Beolab 8000’s were manufactured in 2002.

With this serial number, they are MK1. (serial number 1699 2475 and above are MK2)Best,

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberI took my BeoGram 1000 out of storage to check how my platter gets disassembled.

With my BeoGram 1000 it’s a 2 step:

- Remove the C-clip to remove the inner (plastic) plate with the strobe markings.

- Remove 3 screws on the main plate, to lift it from it’s holder (see the 2 pictures).

In your case, the 3 screws are rivets. So lifting the platter won’t work the way it does for me.

Though:

- If you need to check the suspension, the platter doesn’t have to be removed. For suspension you need to get the acces via the bottom of the plinth.

- If you need to replace the driving belt, there are ways (not the easiest ones) to do that with the platter in its normal position (for instance as described here after point 11)

- If you need to get the platter out of its way: since it seems to be attached to an assembly including the platter axes, there should be a way to release this axes from the shaft. But this can only be done from the bottom side.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberAre you able to rotate the platter, or is it stuck?

For your information, the platter you are trying to remove, looks like this from the bottom side:

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberIf I remember well, you should be able to lift the platter up/out.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberI had the same the first time. But look very closely.

There is a C-clip that sits on the axel-pin in the middle (seen from the top). Remove that, but be careful that it doesn’t jump away.

When removed, you can lift the inner disc with the strobe markings.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

9 April 2025 at 16:18 in reply to: VAM1250 for BeoSound 9000 MK3: who knows a reliable source to buy > SOLVED #65043

9 April 2025 at 16:18 in reply to: VAM1250 for BeoSound 9000 MK3: who knows a reliable source to buy > SOLVED #65043 BRONZE Member

BRONZE MemberInterestingly, the item on eBay mentions ‘VAM1250/21′ and the main picture shows the exact same box (and VAM1250’ on the white sticker on the box) as the unit I got from Keith Saunders.

If I would have to get one now, I would try this.

(I am not guaranteeing for you, it’s always your own risk)

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

9 April 2025 at 10:55 in reply to: VAM1250 for BeoSound 9000 MK3: who knows a reliable source to buy > SOLVED #65041

9 April 2025 at 10:55 in reply to: VAM1250 for BeoSound 9000 MK3: who knows a reliable source to buy > SOLVED #65041 BRONZE Member

BRONZE MemberVery sorry to hear the VAM1254 does not work.

Though, even if they look almost the same, they are not. I read a lot of info about OPU’s. The VAM1250/21 that you need belongs to the ‘CDM-12 Pro’ family of OPU’s. Others are: VAM1204, VAM1205, VAM1206, VAM1252 and VAM1254. They all share comparable specifications, which also means there are differences. Unfortunately, you just found out about that.

The OPU you have in your BeoSound is a VAM1250/21, like I had. I was lucky to find one with the help of Keith Saunders. Although it is a VAM1250 (not /21), I know this one works.

You can try to contact Keith, but if I remember weel, he sent his last unit to me.

I made a quick check on eBay and found this one: https://www.ebay.com/itm/363230316872

It is a VAM1250, but I don’t know how reliable the advertisement/advertiser is. Maybe you can try to contact them.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

4 April 2025 at 08:03 in reply to: VAM1250 for BeoSound 9000 MK3: who knows a reliable source to buy > SOLVED #64933

4 April 2025 at 08:03 in reply to: VAM1250 for BeoSound 9000 MK3: who knows a reliable source to buy > SOLVED #64933 BRONZE Member

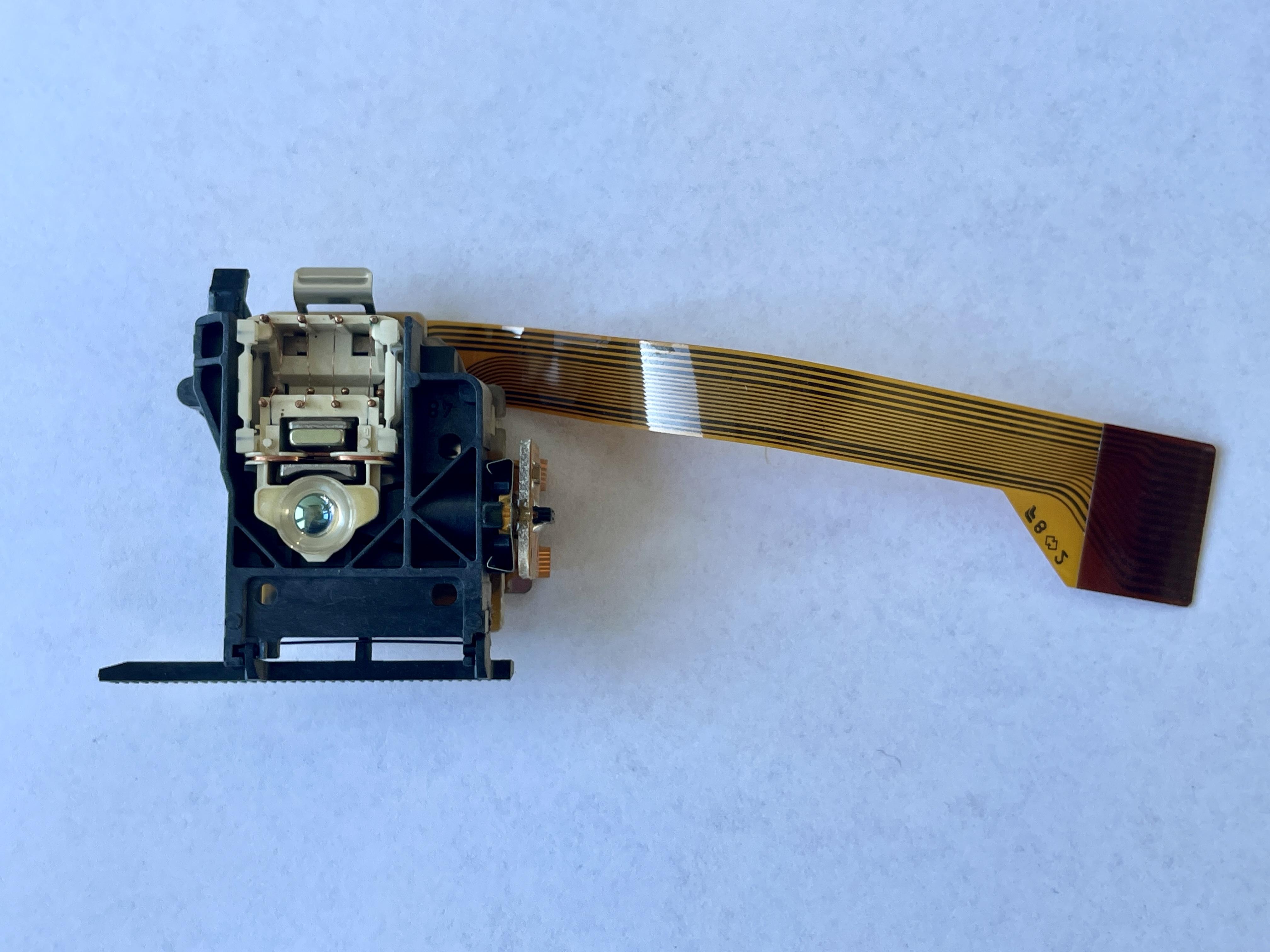

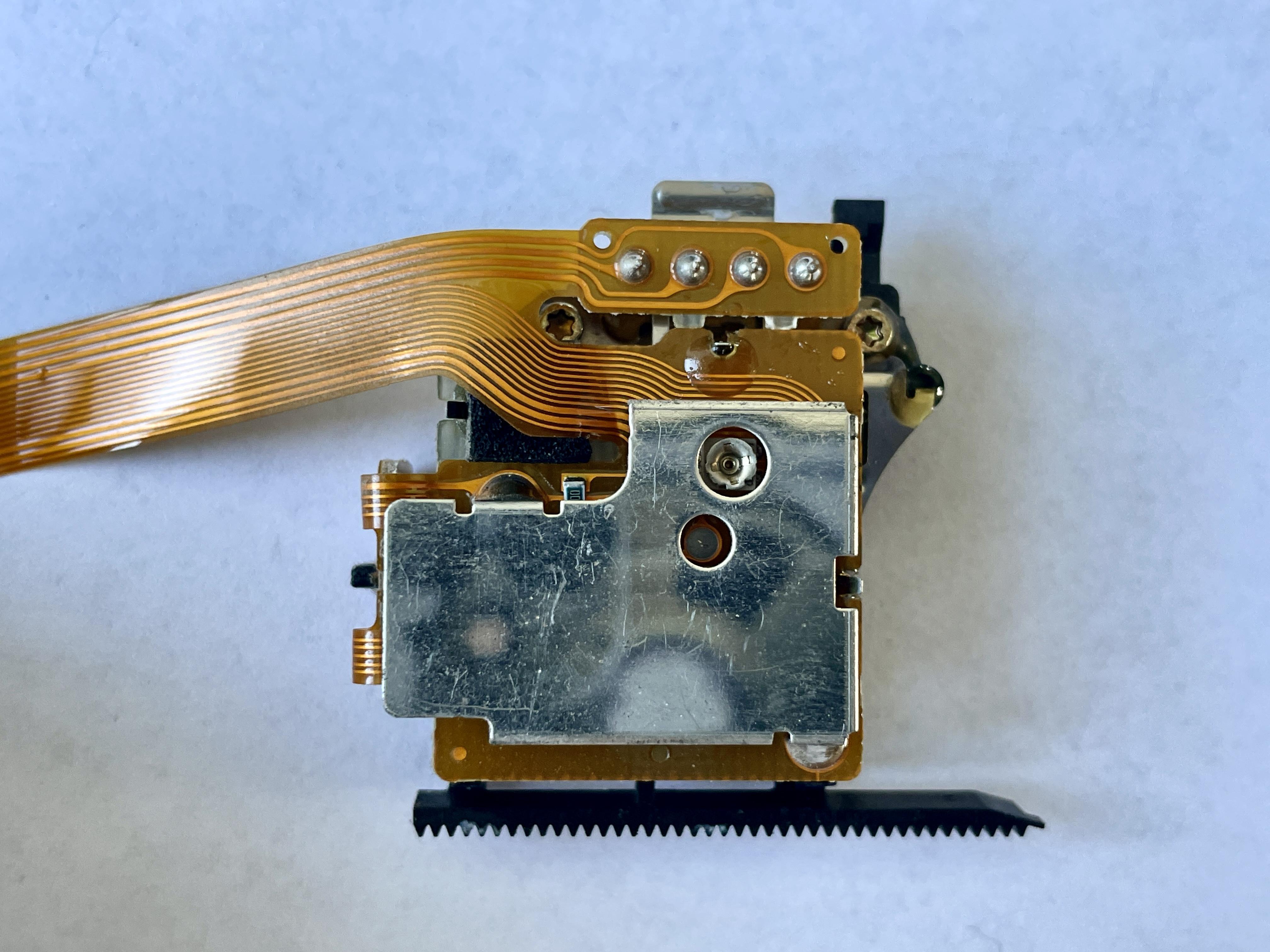

BRONZE MemberThanks for adding the picture. It confirms that your laser unit (in the MK2) is exactly the same, as mine (in a MK3).

This type is a little bit hard to find. I made a picture of the packaging on my replacement laser unit (see below). It does not contain any manufacturer/supplier specific text unfortunately. ( The Chinese characters mean ‘Chinese New Year’s Eve) And the barcode number is not leading to specific and right product or manufacturer information.

Though, the looks of the packaging might help you to find the right laser unit.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

3 April 2025 at 19:55 in reply to: VAM1250 for BeoSound 9000 MK3: who knows a reliable source to buy > SOLVED #64923

3 April 2025 at 19:55 in reply to: VAM1250 for BeoSound 9000 MK3: who knows a reliable source to buy > SOLVED #64923 BRONZE Member

BRONZE MemberHi Igor,

Can you share a picture of the sticker you refer to?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

3 April 2025 at 13:40 in reply to: VAM1250 for BeoSound 9000 MK3: who knows a reliable source to buy > SOLVED #64914

3 April 2025 at 13:40 in reply to: VAM1250 for BeoSound 9000 MK3: who knows a reliable source to buy > SOLVED #64914 BRONZE Member

BRONZE MemberFortunately, I was able to find a VAM 1250 through one of our respected members in the BeoWorld community: Keith Saunders (many thanks to him).

Also I got the laser unit with original packaging. And I think I remember that packaging from a Chinese manufacturers webshop page.

When I have time I will go check that again, because I guess there will be more people in need of this type of laser unit.Best regards,

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

13 March 2025 at 15:21 in reply to: BeoLab 8000: Broken plastic leg supporting PCB > which glue ? #64486

13 March 2025 at 15:21 in reply to: BeoLab 8000: Broken plastic leg supporting PCB > which glue ? #64486 BRONZE Member

BRONZE MemberWhere can I find it Frog?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

11 March 2025 at 08:16 in reply to: VAM1250 for BeoSound 9000 MK3: who knows a reliable source to buy > SOLVED #64435

11 March 2025 at 08:16 in reply to: VAM1250 for BeoSound 9000 MK3: who knows a reliable source to buy > SOLVED #64435 BRONZE Member

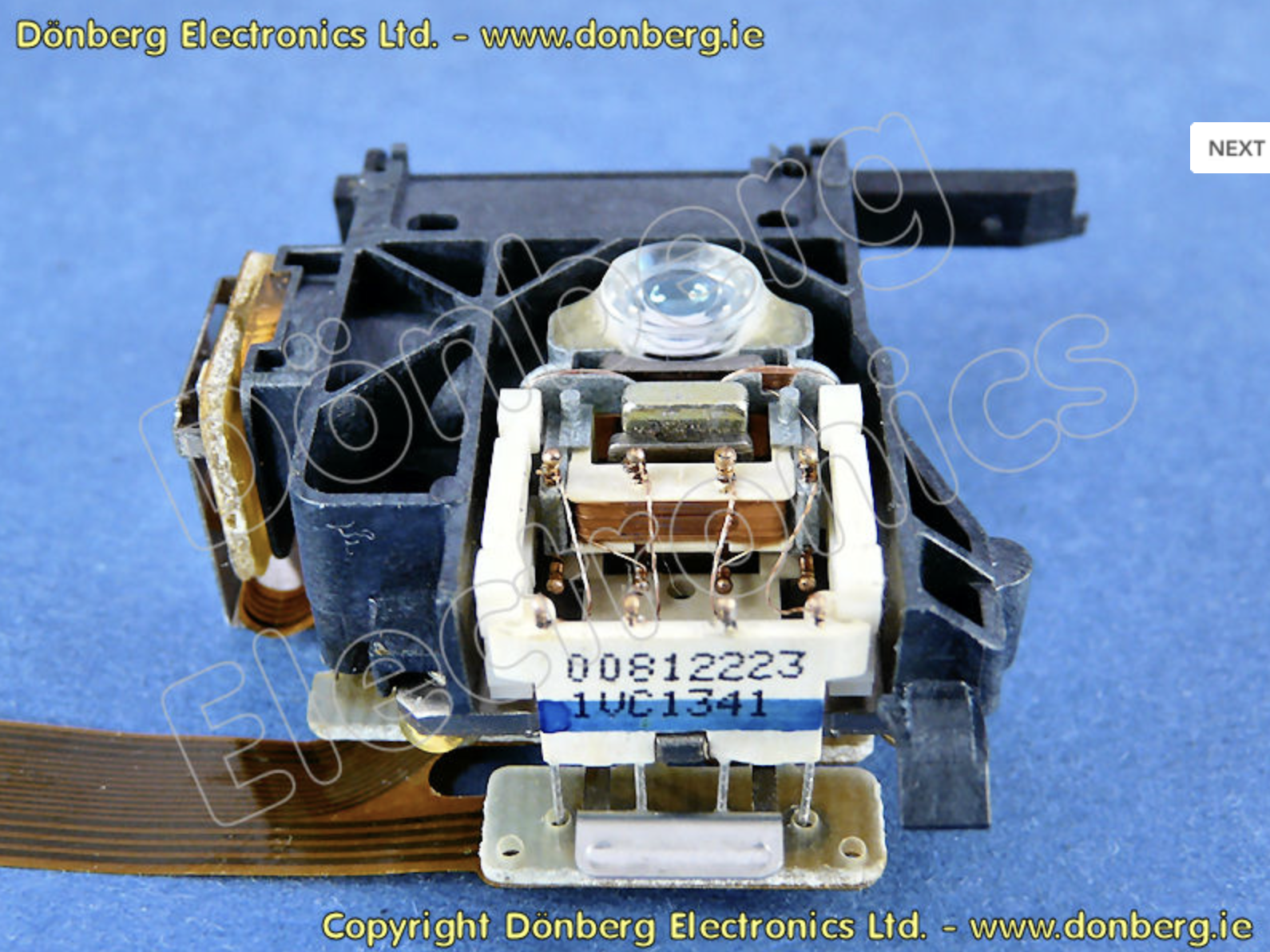

BRONZE MemberIn the meantime I did find a VAM1250 at Dõnberg Electronics in Ireland:

https://www.donberg.co.uk/catalogue/vam_1250.html

But it doesn’t have the addition ‘/21’. So, I am not sure if this is the right one (Dönberg also doesn’t know if it will work.

Question

- Does anyone know if this VAM1250 will work in the BeoSound 9000 MK3?

- Are there any other laser units that are compatible with the VAM1250/21?

The VAM1250 at Dönberg Electronics:

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberFound one at DKSoundParts.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

4 March 2025 at 15:29 in reply to: BeoSound 9000: Torx screw in glass-door hinge stuck ? > SOLVED #64309

4 March 2025 at 15:29 in reply to: BeoSound 9000: Torx screw in glass-door hinge stuck ? > SOLVED #64309 BRONZE Member

BRONZE MemberThanks @B&O Orlando

I did find out in the meantime that the replacement for the BS9000 MKIII, is a VAM1255.

But also I found out that there are not that many available. Some form the US (too far/long shipping time cost) and some in Europe. In the end I ordered at http://www.DKSoundParts.com. They had the right one and reasonable pricing and shipping cost.Curiosity / question

For getting to the sticker on the CD module. Can you give me some direction what should be disassembled?

Can you point put with these pictures?Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

3 March 2025 at 08:01 in reply to: BeoSound 9000: Torx screw in glass-door hinge stuck ? > SOLVED #64281

3 March 2025 at 08:01 in reply to: BeoSound 9000: Torx screw in glass-door hinge stuck ? > SOLVED #64281 BRONZE Member

BRONZE MemberMakes 2 of us.

I should have know too.😉

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

2 March 2025 at 16:45 in reply to: BeoSound 9000: Torx screw in glass-door hinge stuck ? > SOLVED #64274

2 March 2025 at 16:45 in reply to: BeoSound 9000: Torx screw in glass-door hinge stuck ? > SOLVED #64274 BRONZE Member

BRONZE MemberDear M.

Thanks so much for your extensive reply; very helpful suggestions!

The good news is that I solved getting the hinge screw loosened!

When taking another and closer look with a magnifier, I got the impression that it wasn’t a Torx screw. So, I just tried an allen key wrench on it, and immediately felt it made a perfect fit with good grip. So, I concluded it wasn’t a Torx screw but an allen key screw.

It was still very much stuck, but I was able to loosen it that much to get the glass panel out!

So this part is solved, thanks for all the help and suggestions: @Matador & @B&O Orlando

By the way, I checked with the owner. He bought the BS9000 brand new, and gad no service or repair on it. So it remains a mystery to have two different screws in the hinges.

Laser unit for BS9000

Thanks for the advice. I will first get the existing laser unit out and check which type it is. And then look at your tips for sourcing possibilities .

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

1 March 2025 at 11:24 in reply to: BeoSound 9000: Torx screw in glass-door hinge stuck ? > SOLVED #64237

1 March 2025 at 11:24 in reply to: BeoSound 9000: Torx screw in glass-door hinge stuck ? > SOLVED #64237 BRONZE Member

BRONZE MemberGood point M,

I have been very careful with using the soldering iron, and therefore I am sure nothing has melted.

My main focus has been on trying to get the ‘WD-40 anti corrosion lock lubricant’ to pull in. But with no result so far.Question

Again, if this doesn’t work, I might have to drill the Torx-screw out, but then also replace the hinge (part) in which it sits.

But:- Is this a possibility?

- Is the hinge part available?

- About the CD Laser Pickup: the Service Manual mentions ‘CD VAM 1250 from serial no. 15143261’. So this means I need a VAM 1250 for this BeoSound 9000 MK3?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

-

AuthorPosts