Forum Replies Created

-

AuthorPosts

-

Dillen

ModeratorNo.

The small thermo relay has a yellow reset button sticking out the front near the “Overload” printing.Martin

Dillen

ModeratorIf the whole speaker goes silent, failing contact in the safety (thermo-) relay.

Give it a blast of contact cleaner and excersize it a couple dozen times.Martin

Dillen

ModeratorI can’t find any mentioning of this resistor in my notes, but if it sits in series with the

supply to the regulator it is far more likely to be a 4,7ohm or similar value.

And it should be a flame-proof type.Martin

Dillen

ModeratorA 1M resistor would not be a “voltage limiter”, and it won’t be in series with the supply in any way as even the smallest current would result in a huge voltage drop across it.

Could be a bleeder or a coupling to another part of the supply – but don’t worry about this resistor at this point.Set your meter to DC volts.

Clip your meters negative lead to the negative pin on C3.With the positive lead please take readings on

– C3 positive lead

– IC1 all three pins respectively

– TR5 all three pins respectivelyMartin

Dillen

ModeratorIs the problem from all sound sources (FM/Tape/CD)?

Have you checked or reset the sound settings (bass/treble..)?Missing or partly missing speaker outputs, occasionally able to break through at louder volumes – replace the muting relay (Beoparts-shop).

Martin

Dillen

ModeratorSoldering star capacitors have four leads. One center positive and three negative in the outer circle.

You can fit a general purpose capacitor with reasonable specs instead, just make sure to get the

polarity right and connect any negative pads that were previously connected by the original cap.Martin

Dillen

ModeratorWell.. they just always seem to be great performers.

Of the type 57xx family, Beogram 1700 was the newest of the “squares”.

It has the DC-servo controlled motor, it has the slimline tonearm with the round counterweight (read: easier adjustable tracking force) but still carries the good MMC20-series cartridge.

Good platter, and it doesn’t have the operation panel with the somewhat flimsy buttons found on the sloping models.All in all it’s just a stabile and solid build causing few problems.

Only thing you could argue is that it doesn’t have datalink.

Martin

Dillen

ModeratorYes, but it’s neither particularly easy nor apparent how, and not something owners typically mess with.

It’s far more likely to be one of the reasons I listed above.Martin

Dillen

ModeratorWrong tracking force setting?

Bad stylus?Beogram 1700 is a wonderful deck.

Matin

Dillen

ModeratorMany motors will run a bit noisy unloaded.

Have you tried with a belt fitted?Martin

Dillen

ModeratorThe dial wheel can have seized in old lubricants.

It wouldn’t be a first.Martin

Dillen

ModeratorBeocords mains voltage setting configured correctly for 220-240V?

Martin

Dillen

ModeratorCould be one or more of:

Leads broken off the switch at the tapehead bridge.

Bent switch leafs.

Oxidated switch contacts.Martin

Dillen

ModeratorNo need to be like this please. i misread the SM as L1 does need 30Ma. I fitted 80mA lamps and there is no change. Instead of shouting at me EXPLAIN why the lamps are so important. Nobody will learn anything like this, ok? I checked all transistors again. I reflowed more joints and the voltages are steady now (more or less) instead of falling / rising. TR7 reads (FM input, stereo signal): B = 14,85 C = 8,30 E = 7,51 I can check IC1, no problem Bert

Shout?

Sorry. I better let somebody else take over.Martin

Dillen

ModeratorThe discriminator lamps are integrated components in the tuning system.

Look at the schematics and you’ll see how it connects together.Why do you fit 30mA and even 12V lamps when the manual calls for 6V 80mA?

Correct lamps may not be available on every street corner but they are not THAT special, they just

have to stay within certain specs (which means no cheap chinese toy lamps with specs all over the place).And I will ask the two questions again:

Does the voltage on TR7 base also change?

Or is the change in voltage coming from IC1?Martin

Dillen

ModeratorCheck those lamps.

Correct voltage lamps is not enough.

The important thing is the current draw and their “working pattern” with varying voltages.Does the voltage on TR7 base also change?

Or is it coming from IC1?Martin

Dillen

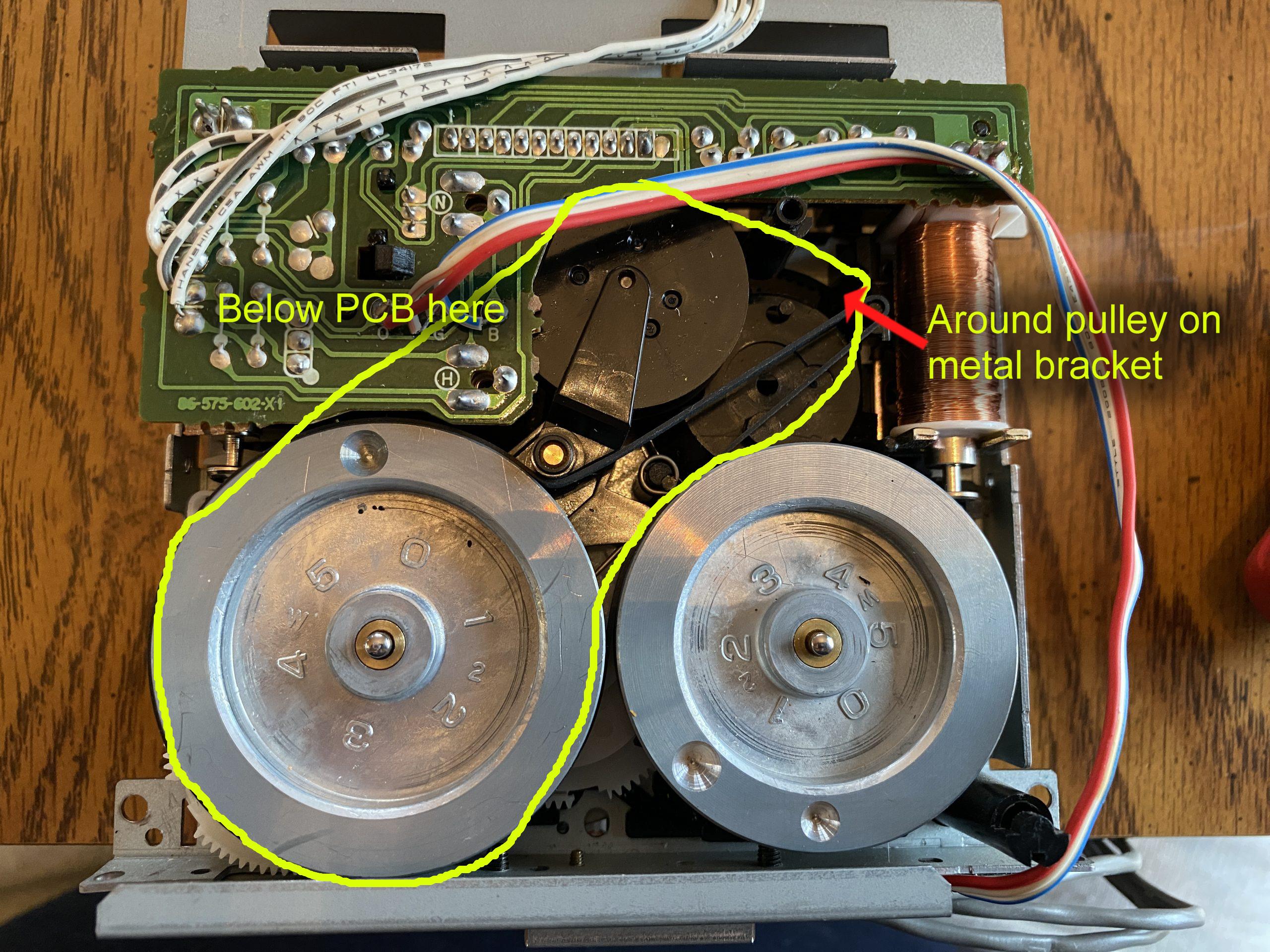

ModeratorWrong belt path.

The belt should run like this:Sorry for this fast freehand, but I think you get the idea.

Martin

Dillen

ModeratorHave you checked the motor suspension?

There is a good chance the motor pulley is rubbing on the metal bracket due to failing suspensions.

Read here:Motor suspension rubber bushing grommet set f. several Beogram Beocenter models

Martin

Dillen

ModeratorAre both your tuning lamps working fine?

And of correct types/wattage?

Note that on this Beomaster model, the AFC-button also activates ST (Silent Tuning = quiet between strong stations).

This could be the key here.

Do you have a good antenna?

Tuner aligned properly?

Will it play with the AFC/ST not activated?Martin

Dillen

Moderator(Thermistor or current limiter…)

Modifying only to compensate afterwards would make little sense in my opinion.Sorry to say it, but I would suggest replacing that lot of capacitors with single cans of good general purpose types.

I would fit can-types rather than PCB-mounts, exactly as B&O chose to do it. They have

a much nicer “oompfh” for this combination of motors, relays, solenoid and (at times sensitive to clean voltage) electronics.

This goes for the DC-motor versions as well.And remember – no low-ESR capacitors in any power supply filtering positions in the classic B&Os.

Also make sure to find a bipolar cap with healthy ripple current specs.

Phasing a motor is hard work for a capacitor.Mains has no reference inside the Beogram.

Chassis ground has no connection to any mains (it would potentially be lethal).

Mains go through the voltage selector and the fuses to the transformer.

Chassis ground is capacitively coupled to signal/electronics ground. If your deck has a three-prong mains plug, the chassis will be connected to the earth pin of the plug.

This means, that you can’t use chassis ground as reference for anything, really – not

for measuring around in the electronics either. Here you must use signal ground for reference.

For convenience I like to clip the meters negative pin to the common negative point of the large cans in the regulator circuit (after your modification no longer accessible in your Beogram).Martin

-

AuthorPosts