Forum Replies Created

-

AuthorPosts

-

BRONZE Member

BRONZE MemberISSUES SOLVED !

Thnx for your remarks @matador & @lesbart.

I have been cleaning the two prism sensors already at the beginning, and as described in the Service Manual. (See my first post in this thread, point 3)

Anyhow, I have been able to find out what to do. I was still in the process of re-assembling the unit. The glass door had not yet been put back. After doing that, the ‘CLEANING REQUIRED’ message was gone. Obviously quite logical.

Thanks again for thinking with me. All issues are now solved.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberUpdate

Today I received the replacement Laser Pick-Up for the BeoSound 9000, and placed it.

And the good news is, it works again!So after all checks, tests and cleaning of lenses and mirror, it was the laser unit that did not function well.

My gratitude goes to Ralf Gerner of Gerner Electronics / Lasertrader.de who helped me pick the correct replacement parts. Great service and quick shipment.

Still one issue?

As said the BS9000 plays CD’s again, though one thing still disturbs me. Just before it starts playing the selected CD, the display shows the message ‘CLEANING REQUIRED’.

It surprises me, since the whole Laser/lenses/mirror is completely new and clean.

Questions

- Is this maybe an old notification that has to be reset?

- If so, how do I do that?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberSend him a PM via BeoWorld. Search by ‘beobuddy’ and you will find him.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberOk. Do you know BeoBuddy?

Maybe you can try if he can.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberI can recommend BeoLover, he has a lot of experience in repairing and restoring BeoGrams.

Check his website for contact details:

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberThanks for this info.

I have a BeoLab 8000 that also has a problem when connected via RCA.

It sometimes does switch on (mostly not), but only when I put the input volume high.

Question

- Could this also be caused by a bad IC1?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE Member BRONZE Member

BRONZE MemberHi Peter, no issues with the type of foam in your speakers.

BeoLab 8000 MK I has the improved type of foam, much better resistant to temperatures caused by the internal amplifier and PSU.

So, no problem.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberThnx again @Matador !

I have checken my module and found it has no such connector. Though very interesting to know that this issue can be solved by reflowing on the MK III version.

Since I have done so many checks, tests and cleaning without the wished for result, I have decided to order the replacement laser/mirror/lenses module. I will return after I have received, placed and tested it with my results.

To be continued and thans for ‘travelling’ with me!

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberThnx again @Matador !

Do you know, is there any check I can make, in which:

The laser should be on, and in which I should be able to see it?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberUpdate further testing & checking

In TestMode I now also checked:

#61 Focus ON = CD FOCUS ON = OK

#62 Focus OFF = CD FOCUS OFF = OK

#63 Start of CD turntable motor = TURNTBL ON works but a lot of noise.

#64 Stop of CD turntable motor = TURNTBL OFF works but a lot of noise.

#65 Laser arm is moved to extreme outside position = LIGHTPEN OUT = OK

#66 Laser arm is moved towards the centre = LIGHTPEN IN = OK

#67 Starting the CD = CD ERROR 2 = Focus error, it has not been possible to find focus.So …

At least I know the motor works fine, and the laser arm makes the correct movements.

Starting the CD keeps showing ‘CD ERROR 2’ so still the focus error.In the Service Manual I read that when in TestMode #65 (lighten in outside position), the light pen can be seen. when test mode 65 is executed.

Question

- Does the service manual remark ‘in TestMode #65 the light pen can be seen’ mean that I should be able to see the light of the laser?

- Because I don’t see any light coming from the laser in TestMode #65. If I should, then the laser is defect and needs replacement, right?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberSolution / cause found

The issue was caused by the left cover panel of the sledge. After re-assembling it, I did not put it back the right way. Causing it to be too high to make the sledge move all the way to the end at the 6th disc.

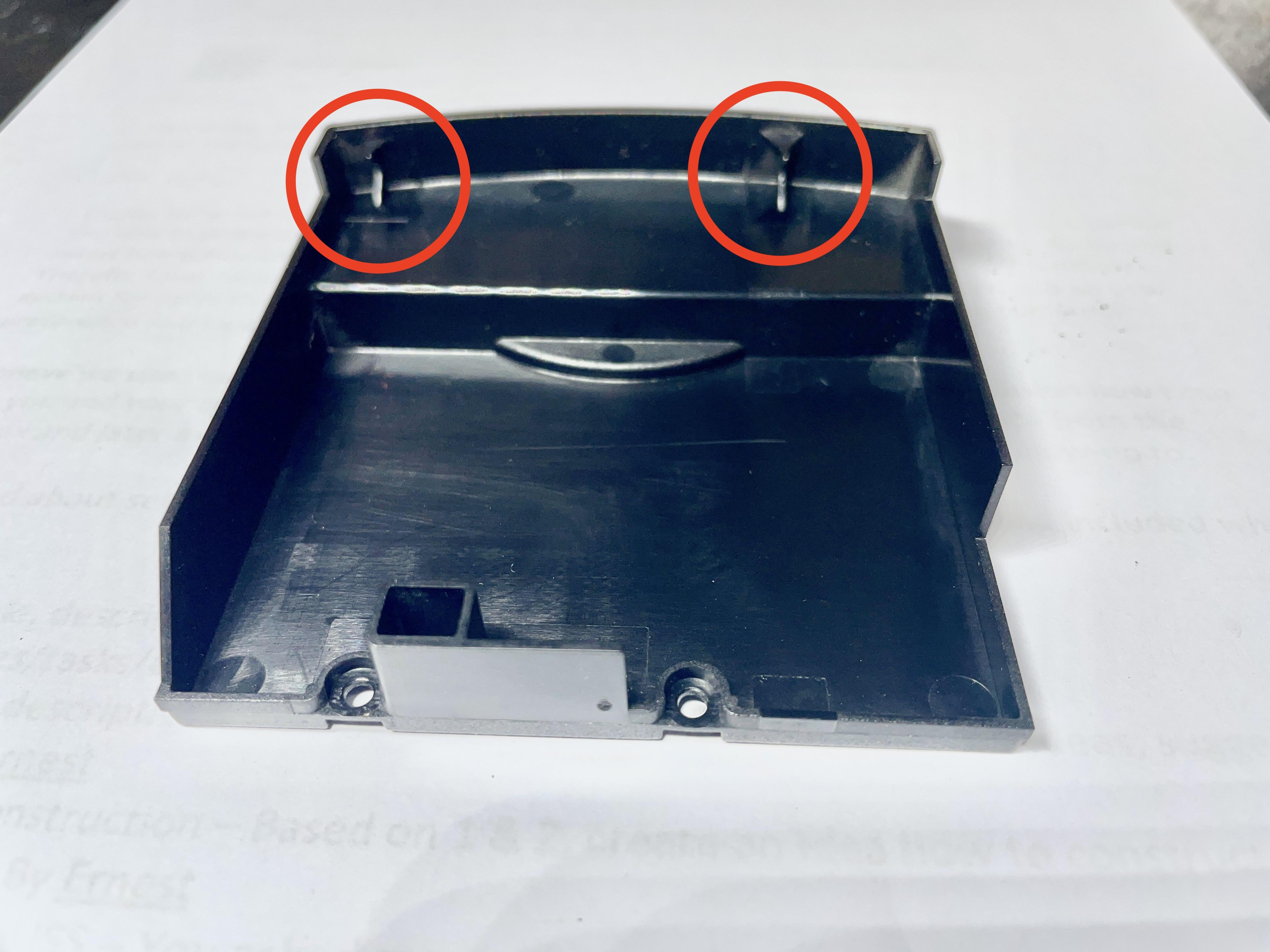

This cover panel has two clamps (see picture) that need to grasp on the edge of the PCB that it covers. If they are positioned right, everything fits well and the sledge can make the normal movements.My advise for re-assembling after working on the BS9000 laser unit is to put this cover back, and then immediately hand-move the sledge all the way left and right (while the sledge is still unblocked). This prevents that you find out later and you have to disassemble and re-assemble again.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberThnx @Matador !

You are referring to the “orange part in the picture”.

Do you mean the orange PCB and its flatcable?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

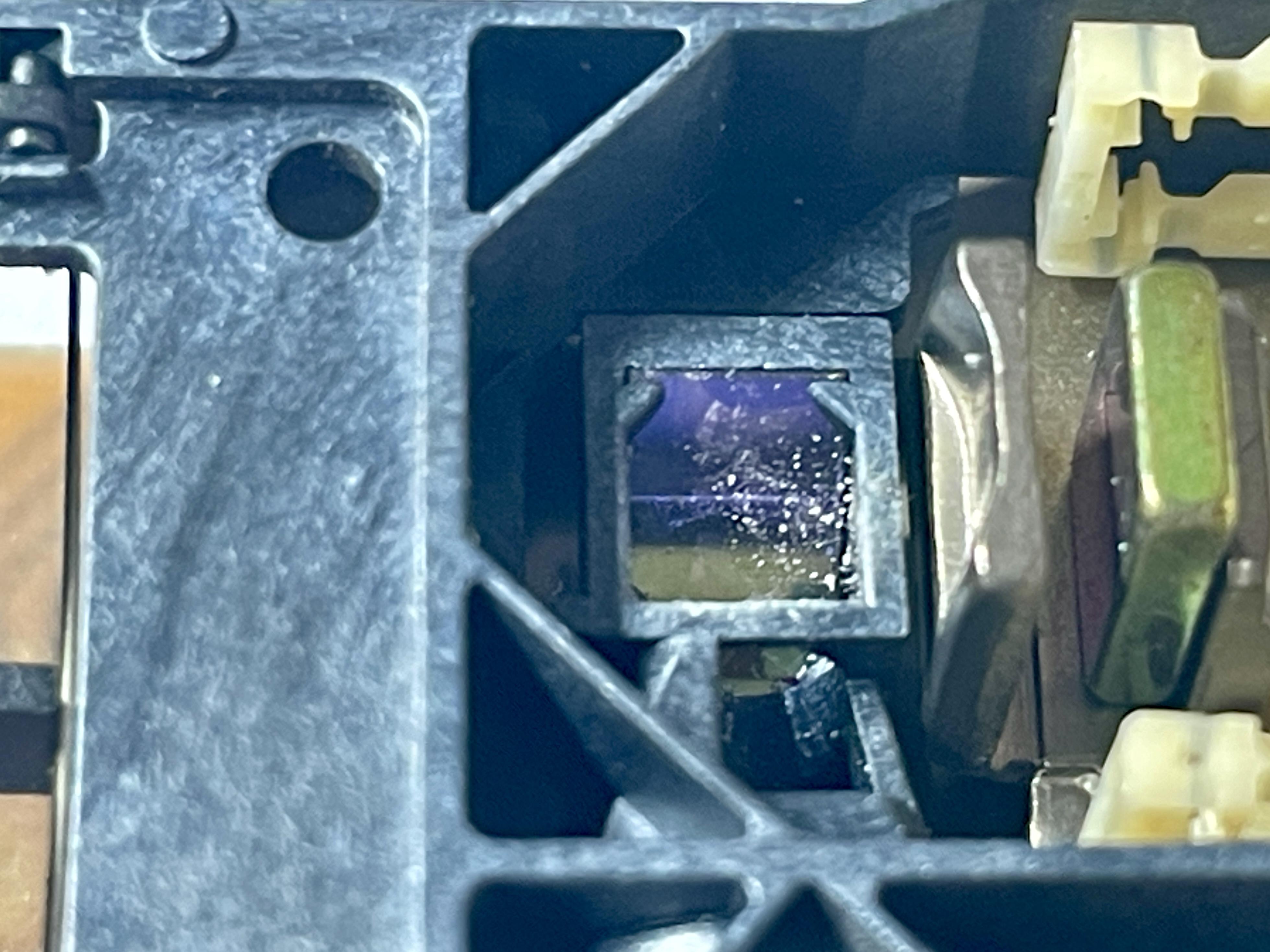

BRONZE MemberI have disassembled the laser/lens/mirror unit, and did a cleaning according to the instructions by japcast in his video on Youtube. By the way, this is a great instruction video!

I did find after disassembly and uncovering the mirror, that it was very dirty. Look for yourself:

After cleaning and re-assembly I did a CD play test, unfortunately with still the same error as when I started.

After that I did a TestMode run #27 again. Interestingly with some different results than when I did this run before cleaning. Here’s the differences:

Before cleaning:

- NO ML ERROR

- 1 IIC ERR104 = The 35IC2 motor processor

- 1 CD ERR 2 = Focus error, it has not been possible to find focus.

- NO SER ERROR

- 1 SLG ERR 31 = microprocessor 35IC2 cannot register pulses from 9PE1.

- NO PLT ERROR

- 1 APS ERROR 15 = it has taken more than 5 seconds to carry out auto positioning. The turntable motor driver might be defective.

After cleaning:- NO ML ERROR

- NO IIC ERR

- 1 CD ERR 2 = Focus error, it has not been possible to find focus.

- NO SER ERROR

- NO SLG ERR

- NO PLT ERROR

- NO APS ERROR

So, it’s positive that most errors are gone. Though a pity that it still doesn’t play.

My questions

- I guess there is only one thing left; replacing the laser/lens/mirror unit. Correct, or are there still other possibilities?

- If I need to order a replacement laser/lens/mirror unit, where can I find it? And where can I trust it is the right one and working? (I need it for a BS9000 MK2, type 2561)

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

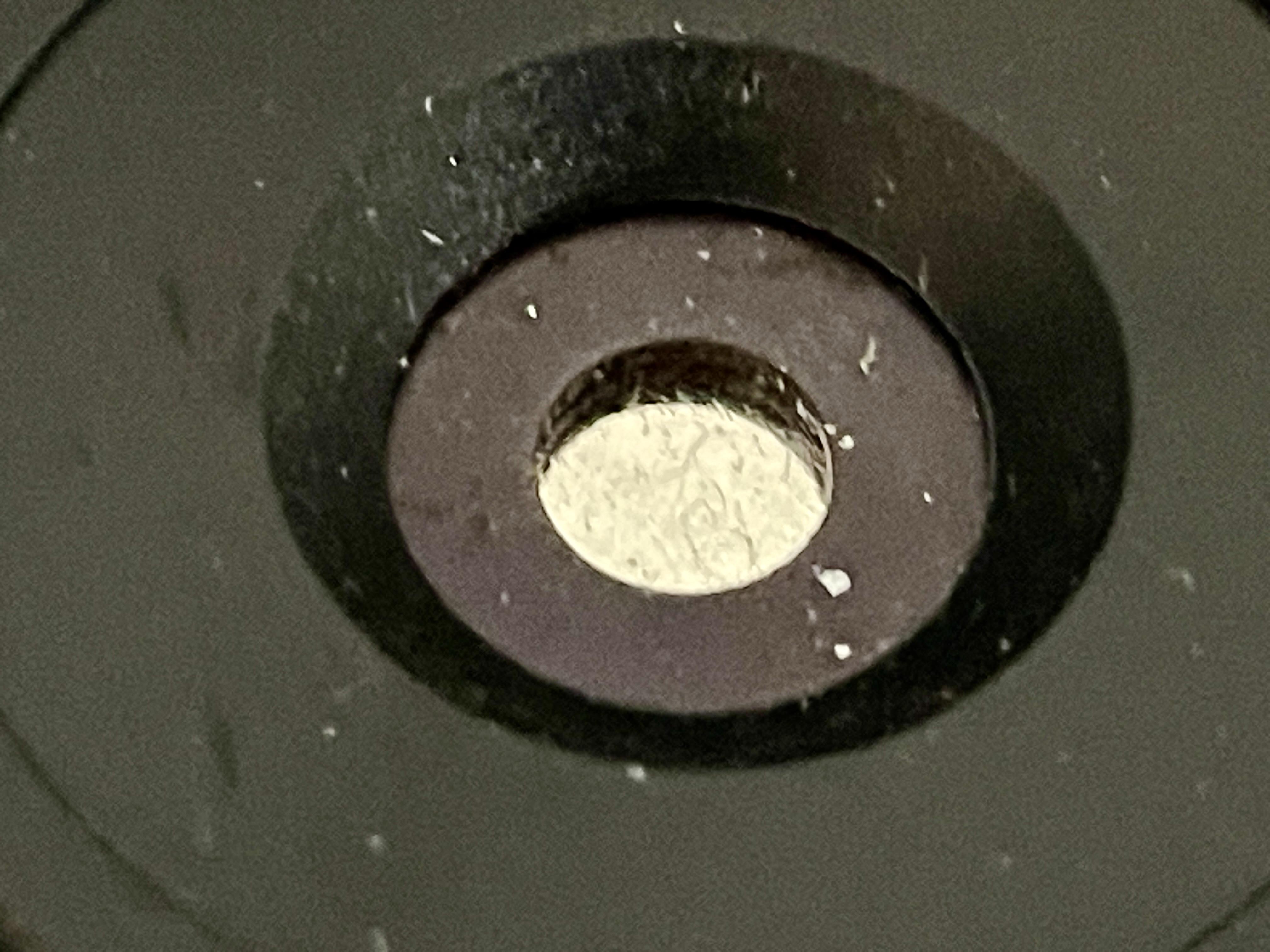

BRONZE MemberI have come to the point that I have disassembled enough to have full access to the laser unit.

What I noticed is this part …

The middle:

The outer ring:

Question 1

It is very dirty. I think this is just the clamp and the dirt does not affect the laser/reading of the disc. Is that right?Laser unit

I have uncovered the laserunit. What I can see is the lens, which I will clean with isopropyl.Question 2

Besides cleaning the lens here, is there anything else I should clean?Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberThnx @Matador !

It’s also my guess that the laserunit needs replacement.

Question

- Is there any other test run I can make in Test Mode, to confirm that?

- Do you know any reliable source to order the right replacement part for this BS9000 MK1 type 2561?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

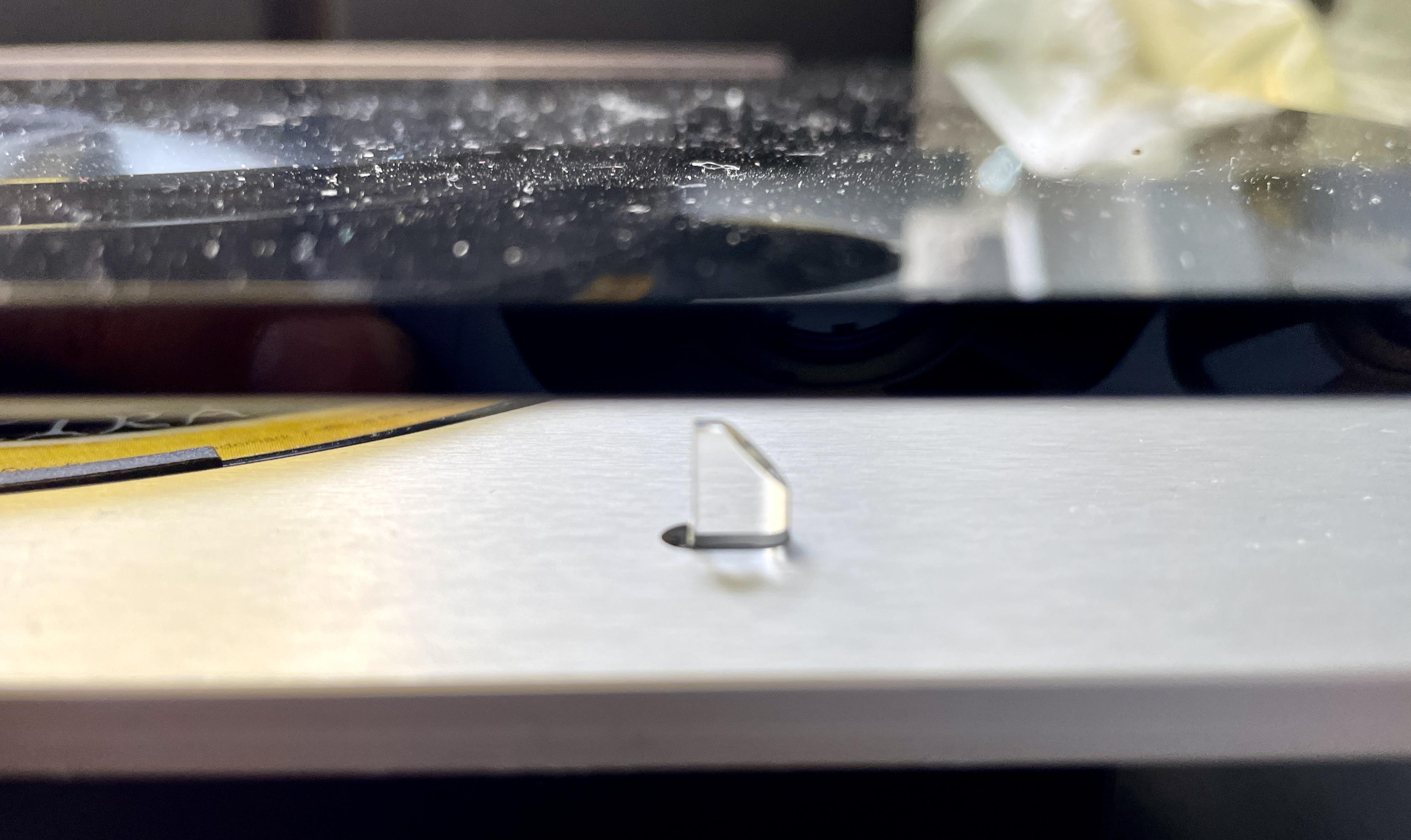

BRONZE MemberThnx @Pestria !

Since I am new to the BS9000, where can I find the two sensors you talk about?

Are these like this (see picture below)?

But I guess the sensors themselves are underneath?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberHi @LPCOLLECT.

I am having the same issue here with a BS9000 type 2561, I believe that’s a Mark II.

Did you find any solution solving your issue?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberWhat input do you use: PowerLink or RCA?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

BRONZE Member

BRONZE MemberI have had experience with rubber rings letting loose once before. Most common causes for that:

– The glue used us a bit old and therefor dried out.

– The adhesion pressing after glueing has not been done enough.

After having done a lot of refoaming, I can conclude that it is a reliable way of repairing/restoring speaker drivers. Nevertheless, the execution has to be done accurately.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

-

AuthorPosts