Forum Replies Created

-

AuthorPosts

-

hcraig244

SILVER MemberThese switches are notorious for failure due to arcing damage…..it’s quite possible the reason for your issue, very difficult to repair/replace too ?

hcraig244

SILVER MemberQuickly moving on…….as the deck came to me bereft of cartridge I fitted one of my own and gave it a test

hcraig244

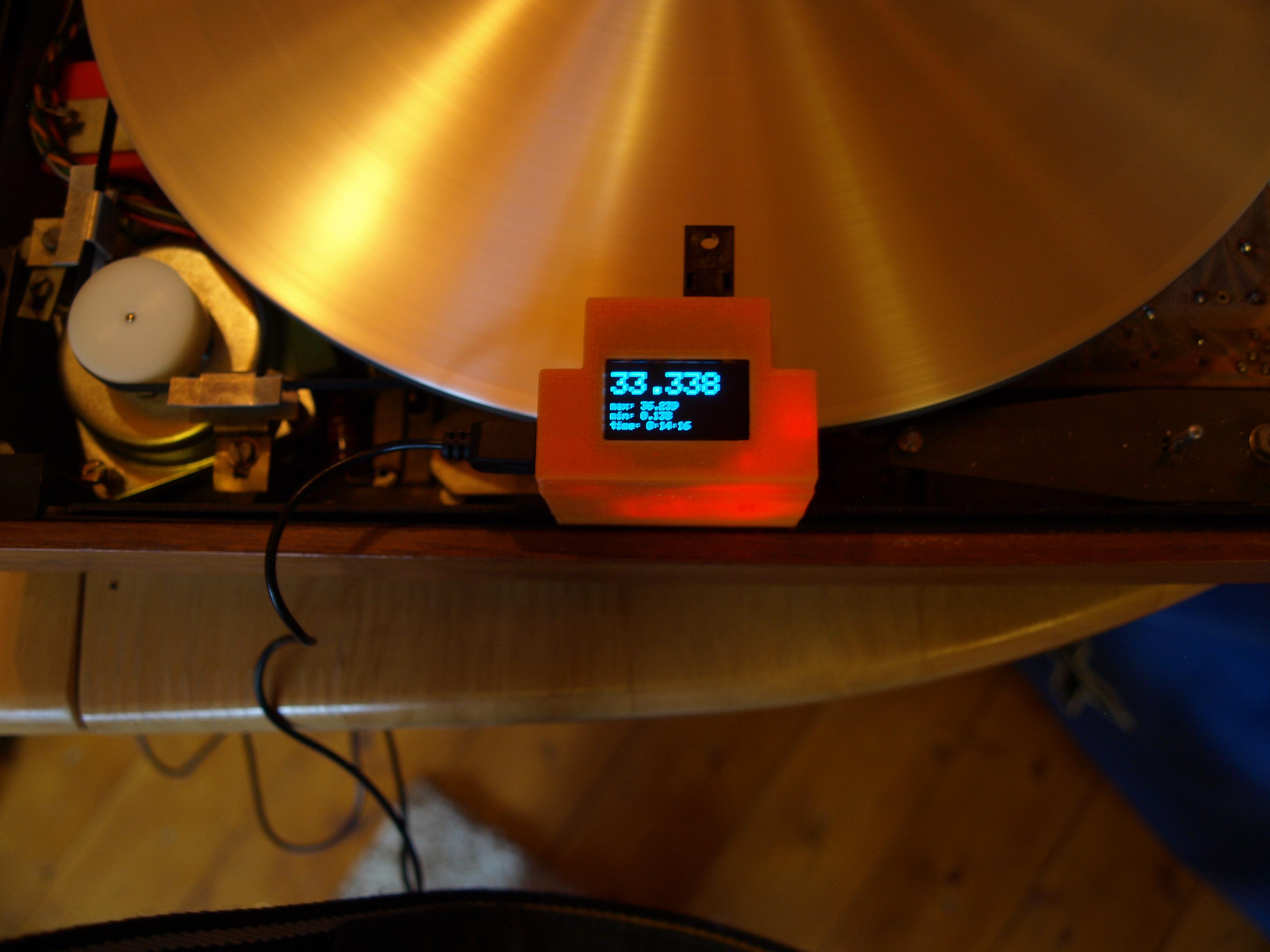

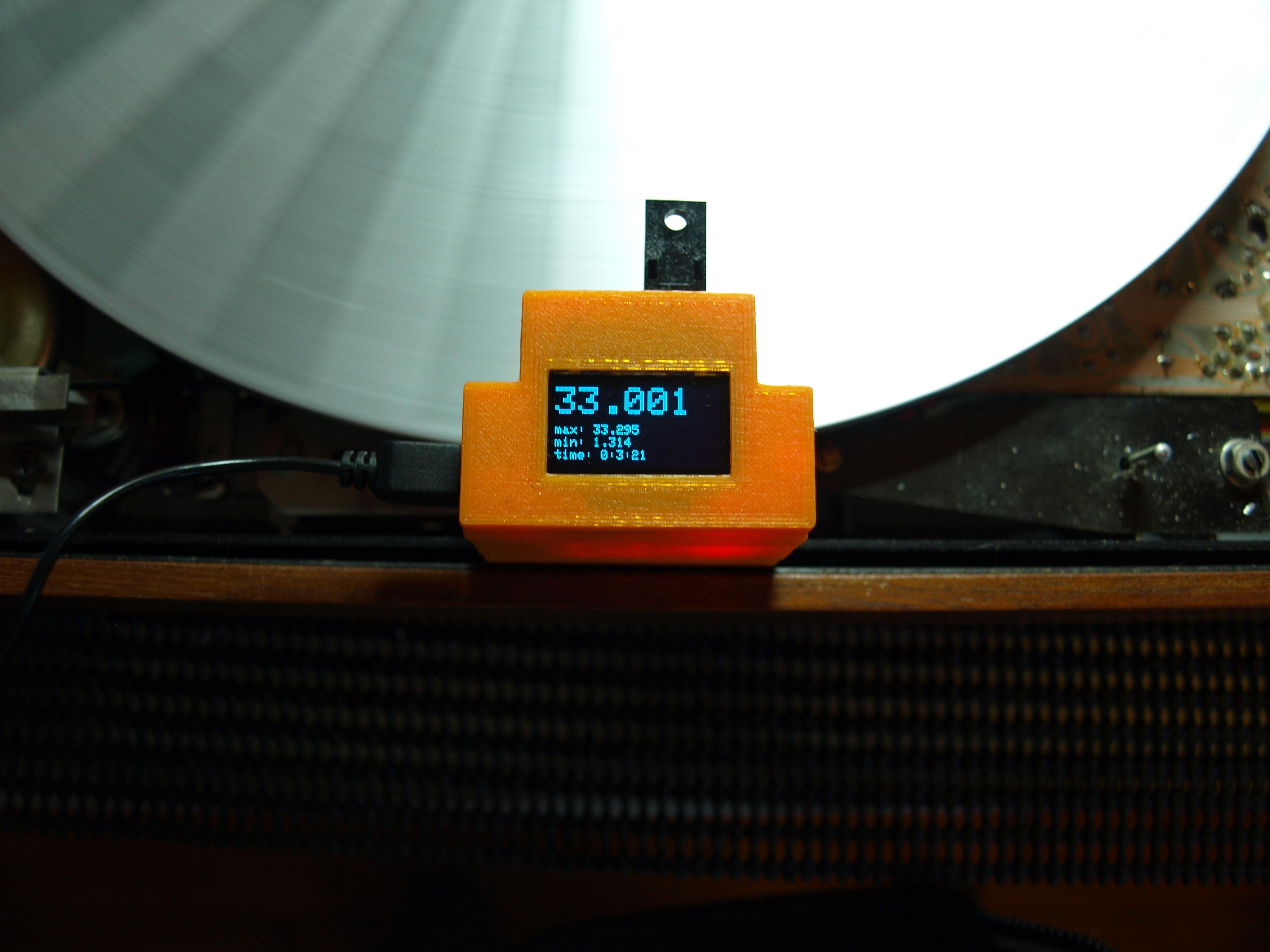

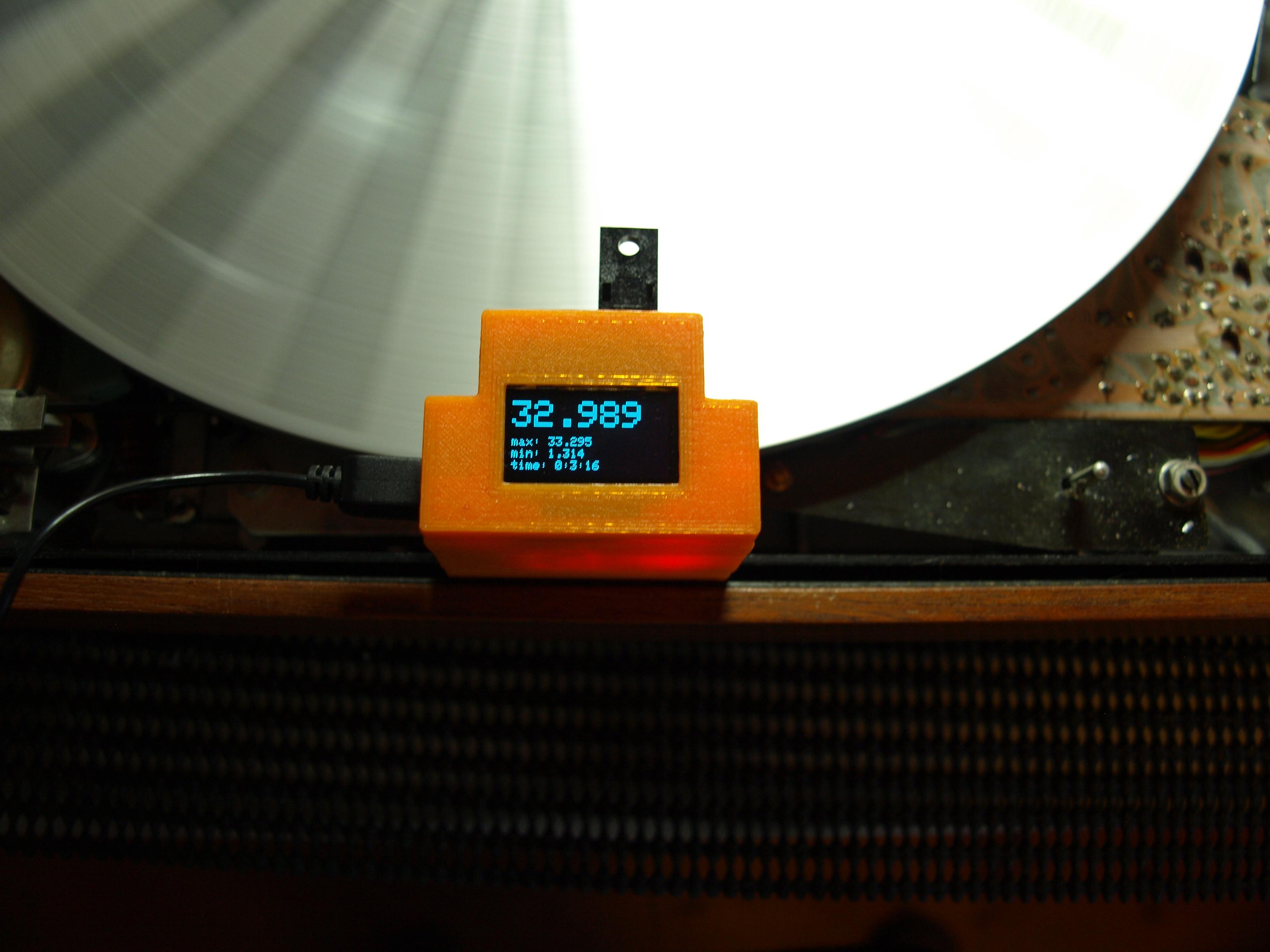

SILVER MemberWell……isnt this a little embarrassing, fortunately Glitch is paying attention and identified the schoolboy error regarding the 33rpm setting. should of course be set to 33.33rpm…the manual identifies the 33rpm setting should be set up using the stroboscope dial which no doubt is calibrated to give a 33.33rpm setting when appearing stationary…..oops

hcraig244

SILVER MemberAll that remains is a period of testing……

hcraig244

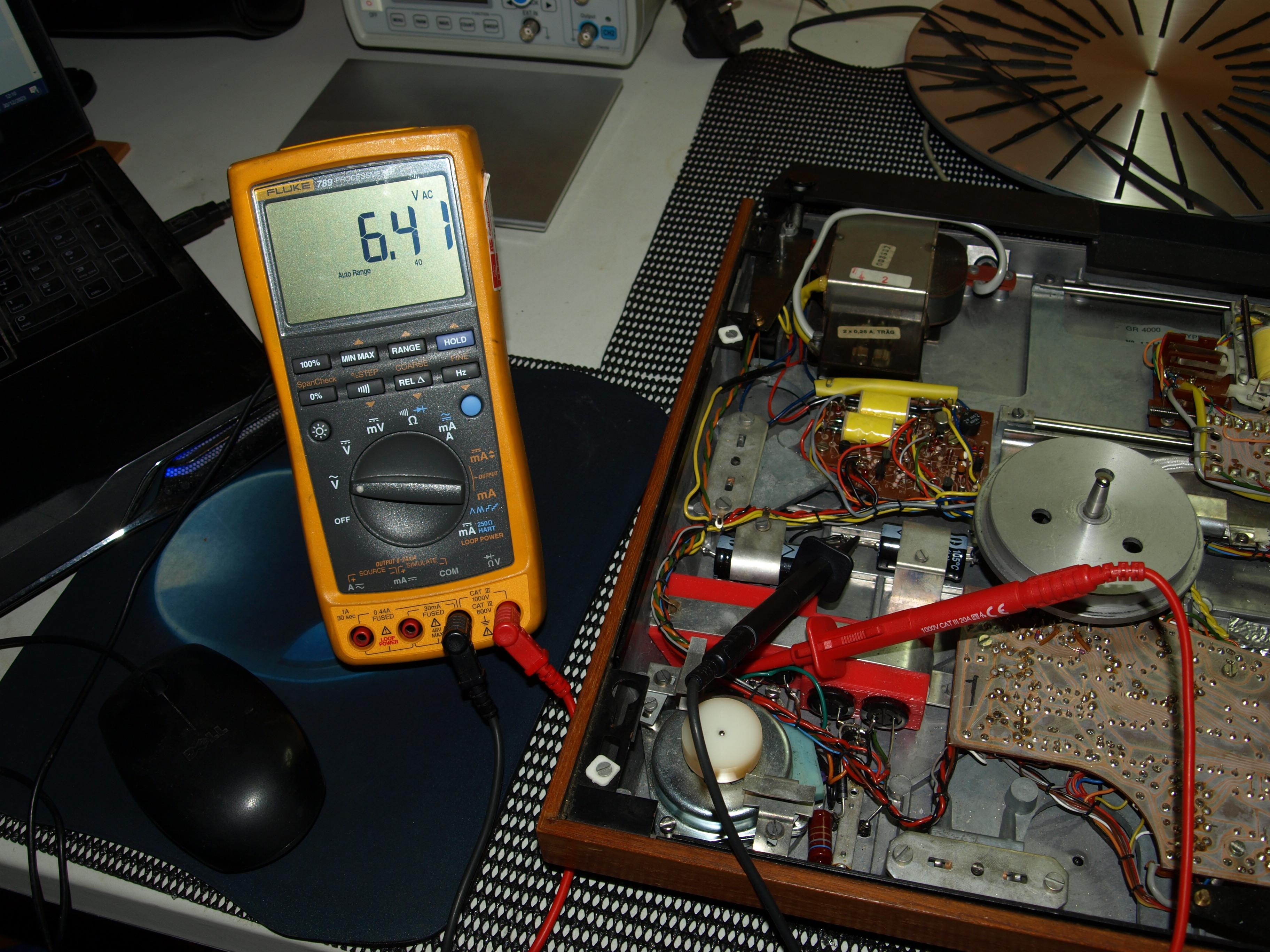

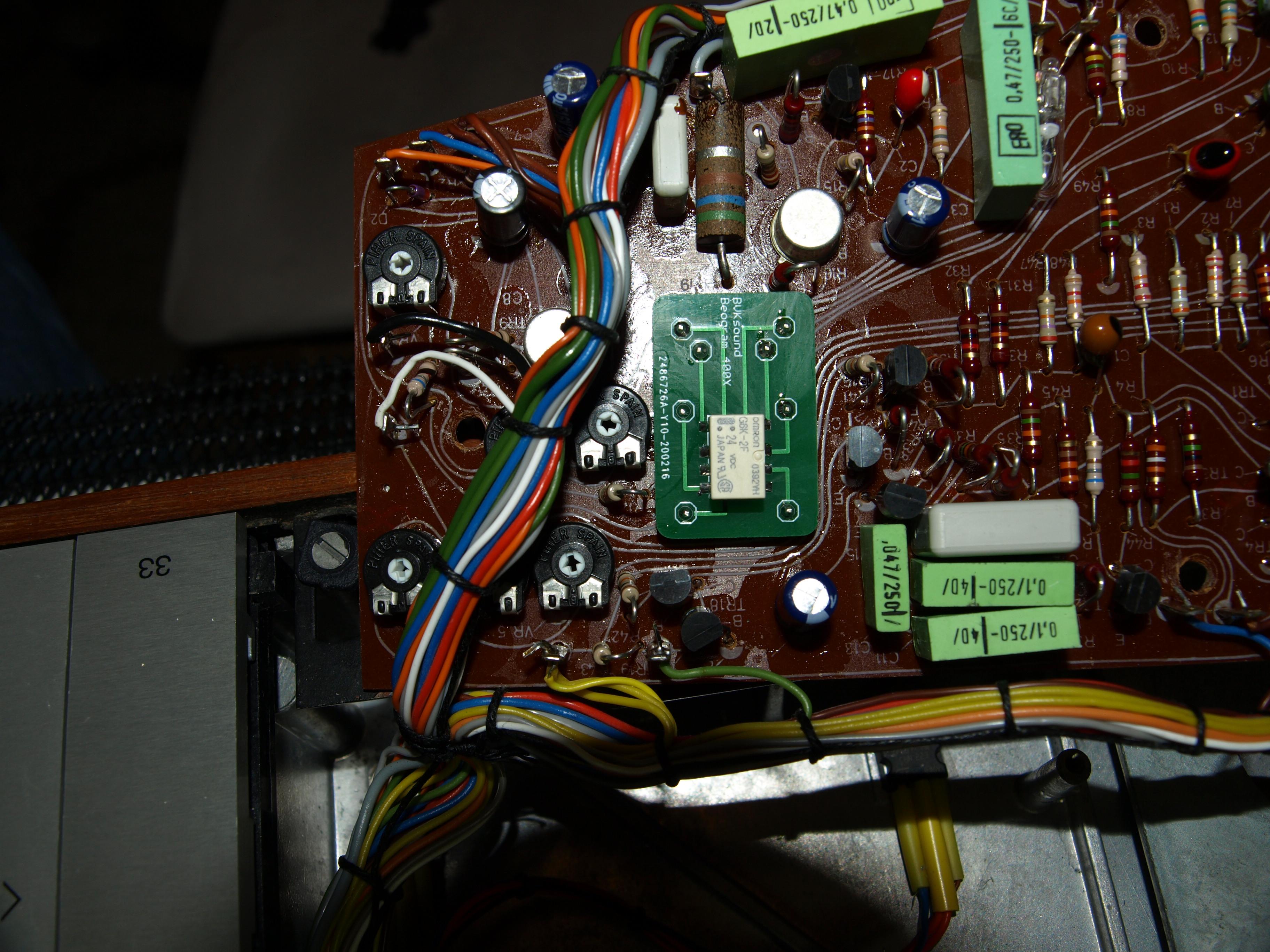

SILVER MemberFairly straightforward with the exception that X is now in a different place due to the modified capacitor arrangement provided by Rudi….the Bi Polar capacitor position is now after the two back to Back capacitors…..measured up fine.

hcraig244

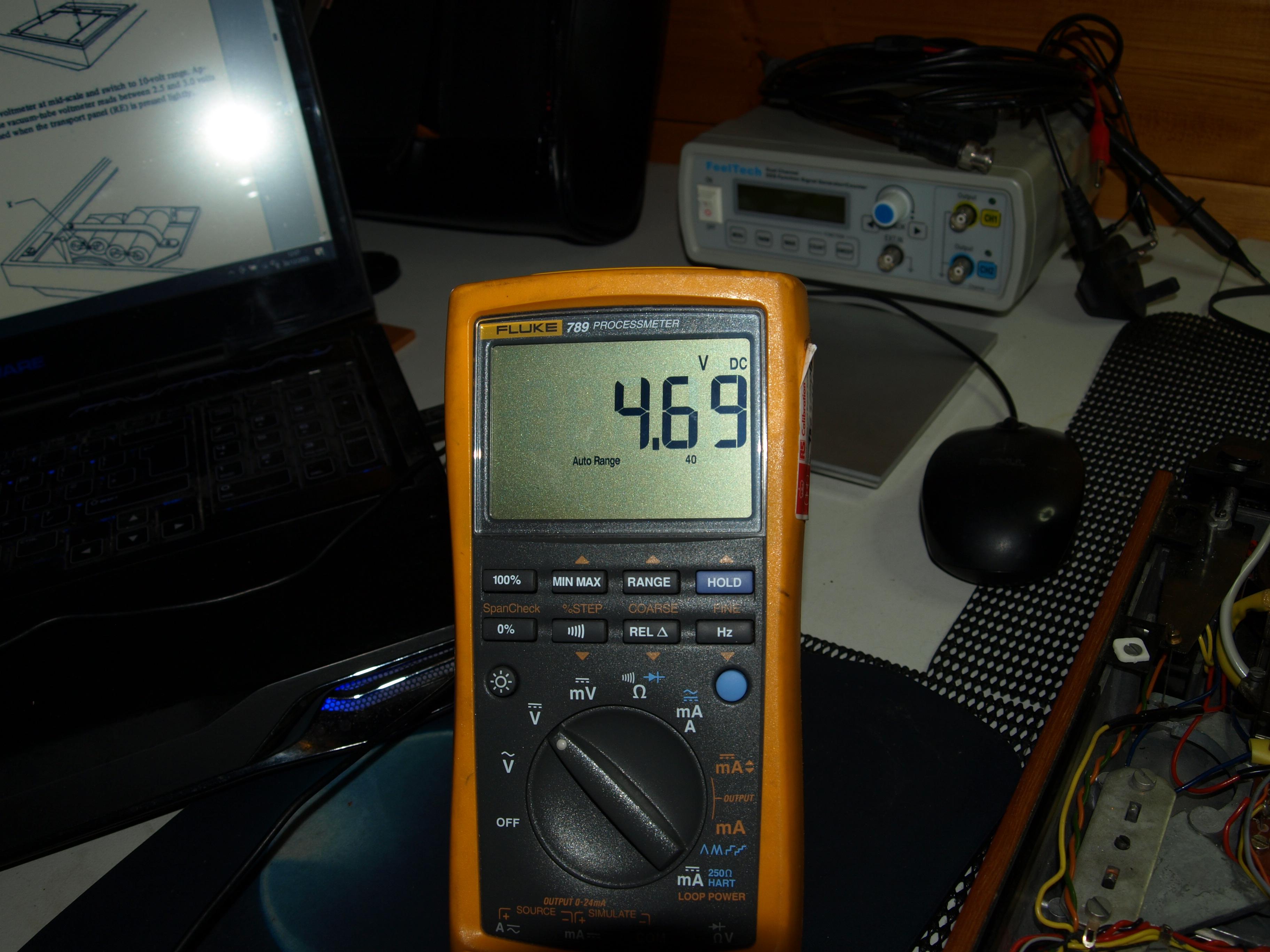

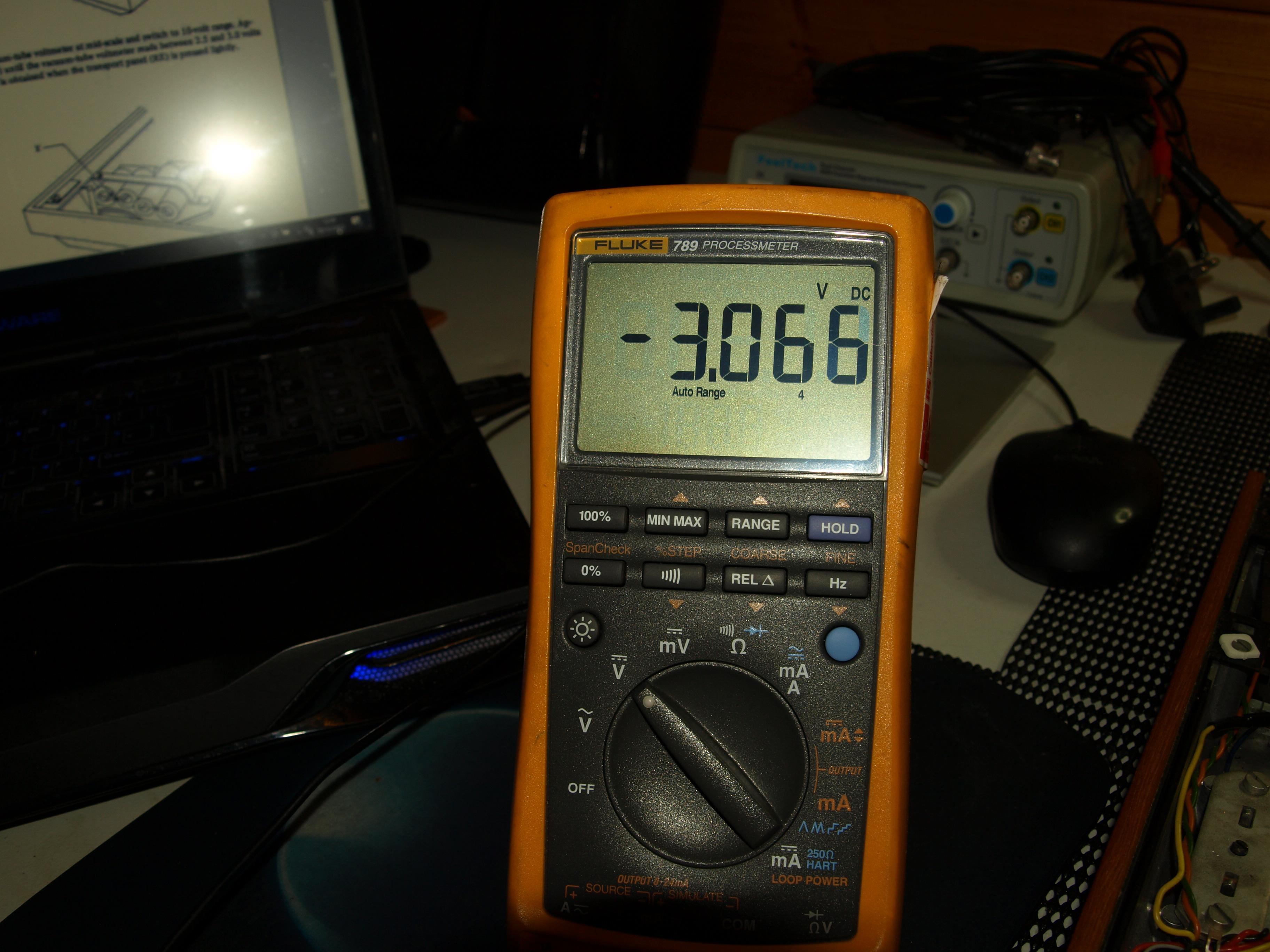

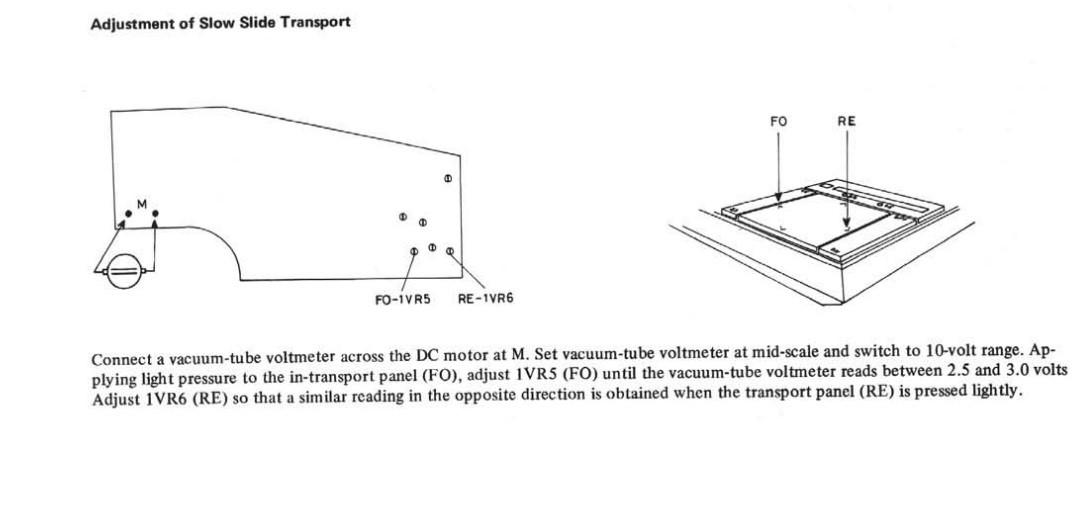

SILVER MemberAdjustment of voltage for drive motor

hcraig244

SILVER MemberReverse was a little off….so had to adjust somewhat, so its always good to check. oh and swapped the probes around.

hcraig244

SILVER MemberThis went well……forward measurement, got the probes wrong way around naturally, measured up fine

hcraig244

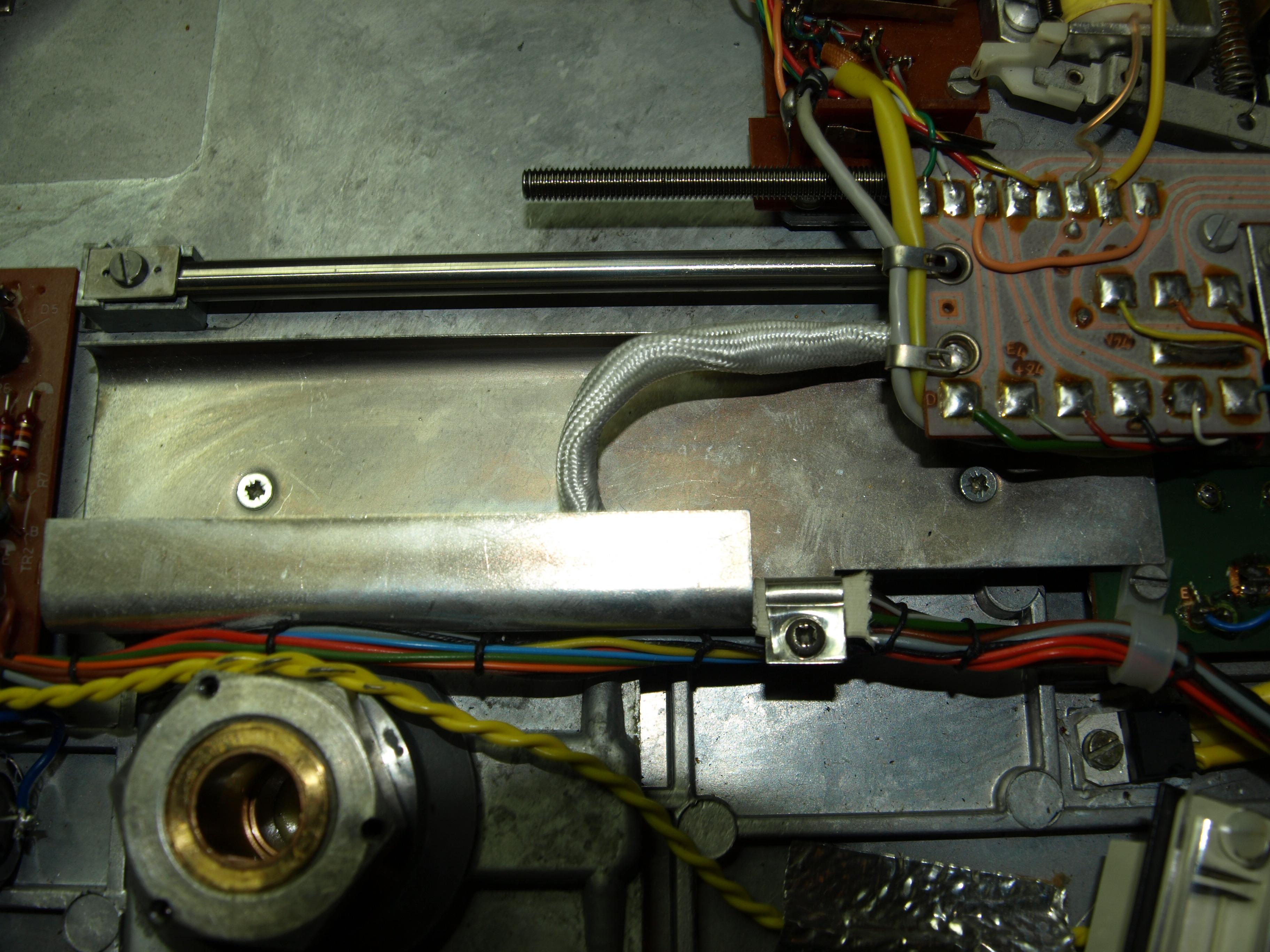

SILVER MemberAdjustment o the slow slide transport……..

hcraig244

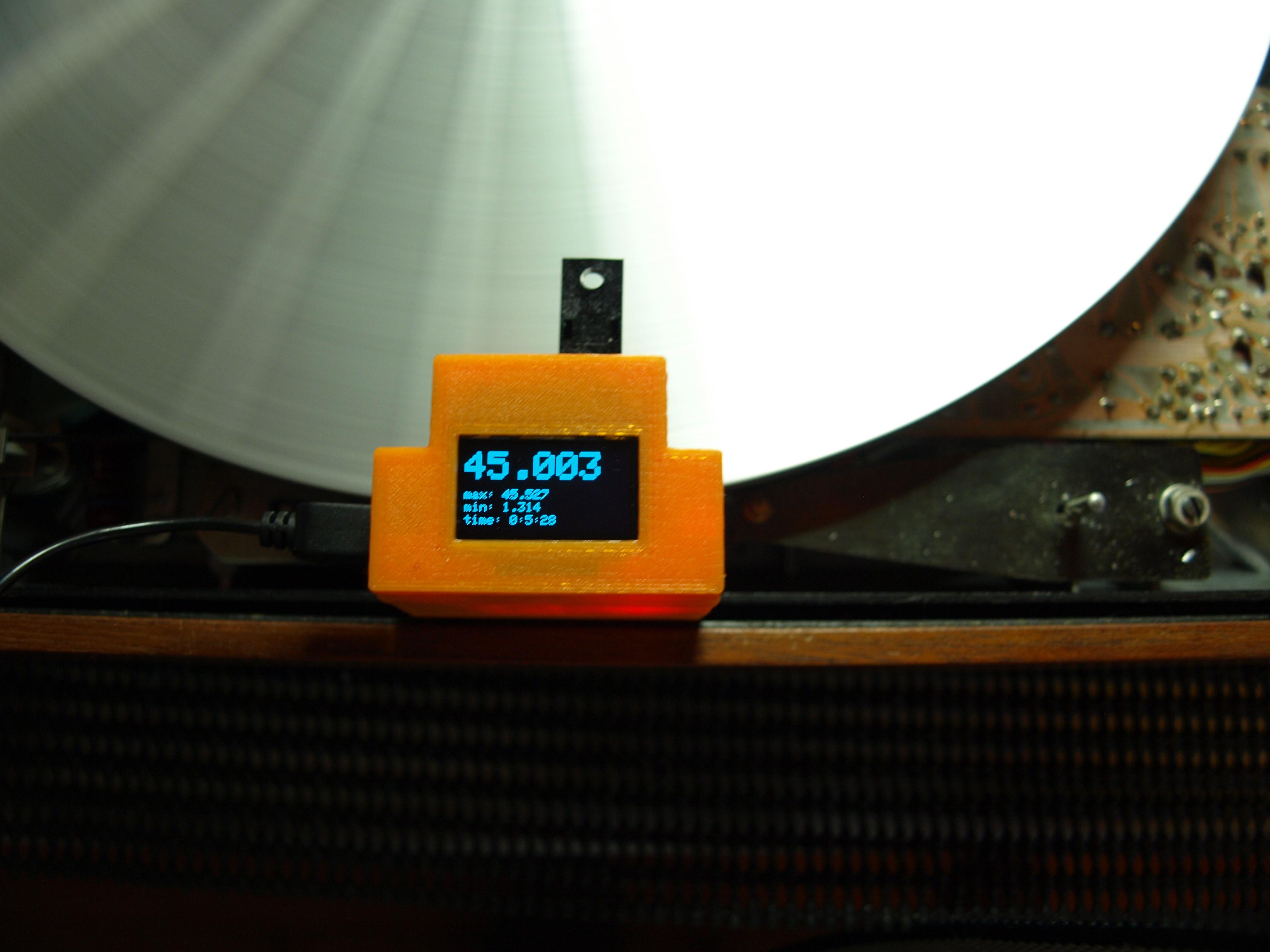

SILVER Member45rpm was a similar story….tweeked that trimmer also

hcraig244

SILVER MemberSo tweaked it in……..

hcraig244

SILVER MemberJust need to do some adjustments following the trimmer replacements…I don’t expect them to be far away as I measured across the relevant legs of each one and set the new trimmers accordingly but doesn’t hurt to check……used Rudi’s digital tachometer I purchased for the very purpose…..seems a shame not to use it. 33rpm up first and it was a little off…

hcraig244

SILVER MemberAnd had a dig around in my box of miscellaneous odds and ends and located some machine screws to fix the PCB in place.

hcraig244

SILVER MemberGot around to replacing the skeleton trimmers today, not that they where suspect in anyway just because they probably will fail at some point.

hcraig244

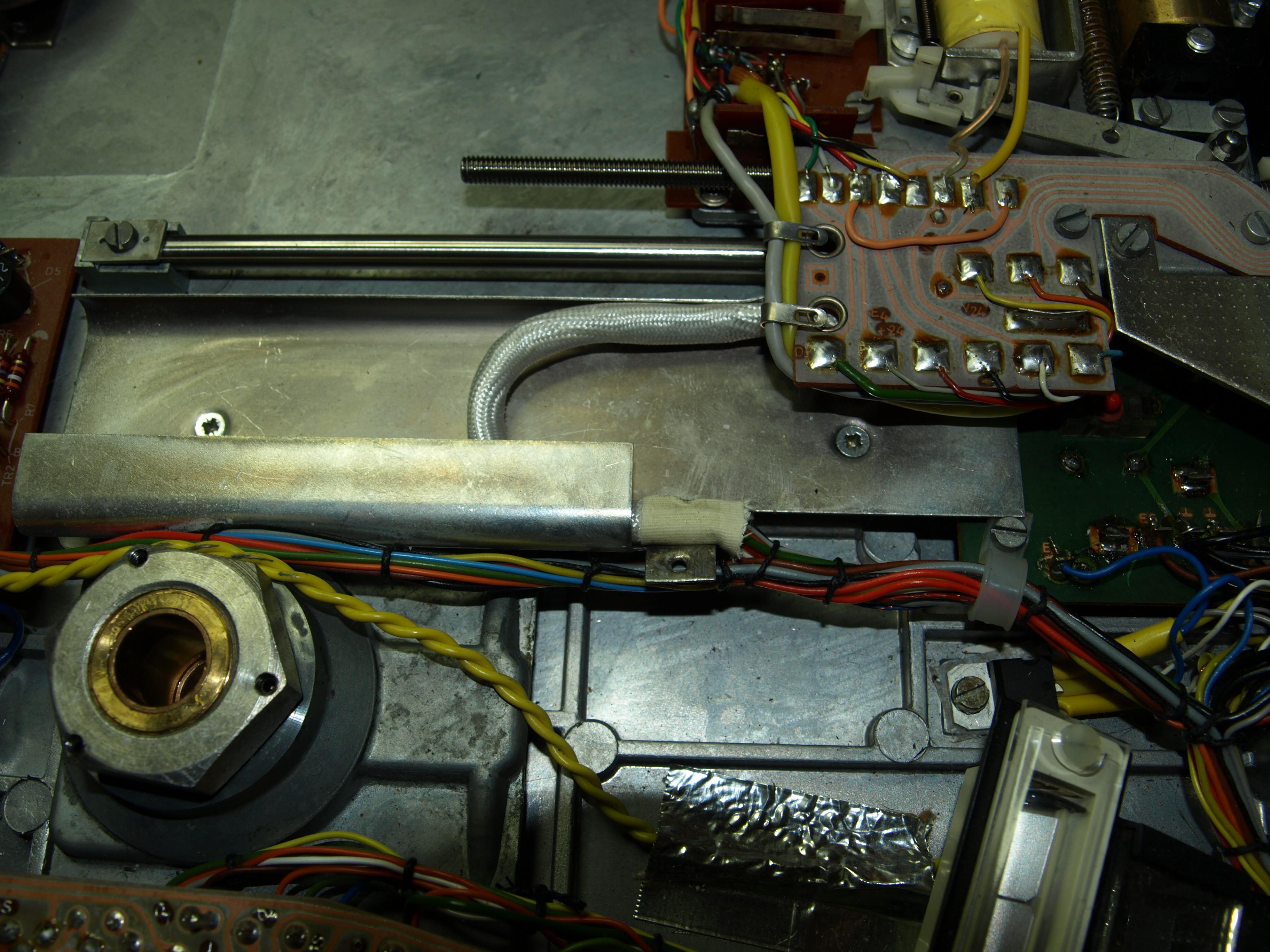

SILVER MemberUnclamped the sock and rotated it to remove the kinks…..this is much happier now, never seen this before……will re secure the clamp and look to replace the trimmers.

hcraig244

SILVER Memberduring testing I found that when the tone arm approached the ES position it was slowing down considerably, when moving forward slowly by nudging the tone arm by small increments to simulate a record on the deck, and more often than not actually stopping short.

I noticed that the drive motor was still running and the belt was slipping….watching this a couple of times i spotted this..the cable containment sock was all twisted and lumpy and the carriage was fouling on it at the end of its travel…

Tht

hcraig244

SILVER MemberRemoved 1TR28 and it tested fine! went ahead and tested all 1TR27/1RT26/1TR29…..all proved good…..put them all back and powered up and needless to say everything worked perfectly…..dry solder joint somewhere? temperamental transistor?

hcraig244

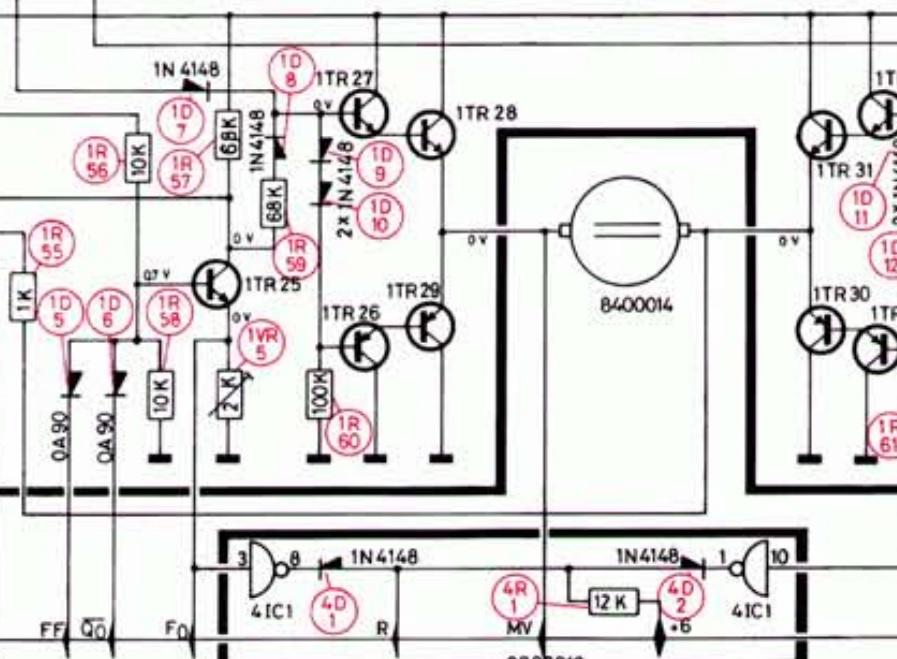

SILVER MemberOk….time for a update, according to solderons training notes when FF is operated the collector of 1TR25 should go high (approx 22v) I was getting closer to 14v at this point….still good.

Also said voltage is fed to the Base of 1TR27…still good…and therafter to the Base of 1TR28 thus causing the motor to rotate in the forward direction…..the 14v was not getting out of 1TR28…..so no rotation.

hcraig244

SILVER Memberfollowing re solder of the transport motor connections powered up again and the following happened….Main motor started to run, Neon lamp illuminated, scale illumination lamps came on as did 33rpm lamp….Solenoid didnt pull in immediately which was also good however no movement of the transport motor.

Operating the FWD switch on the control panel did nothing…so wound the transport carriage forward an inch or so and operated the REV switch on the control panel and the transport was driven to the stop position by the motor…..

Hit start again and nothin happened so wound the transport carriage forward again by hand all the way to the 33rpm drop position and the solenoid pulled in…continued winding until the end point and the solenoid de energised and the transport was driven back to the stop position…big improvement,

Clearly an issue with the transport motor circuit…..will have a look.

hcraig244

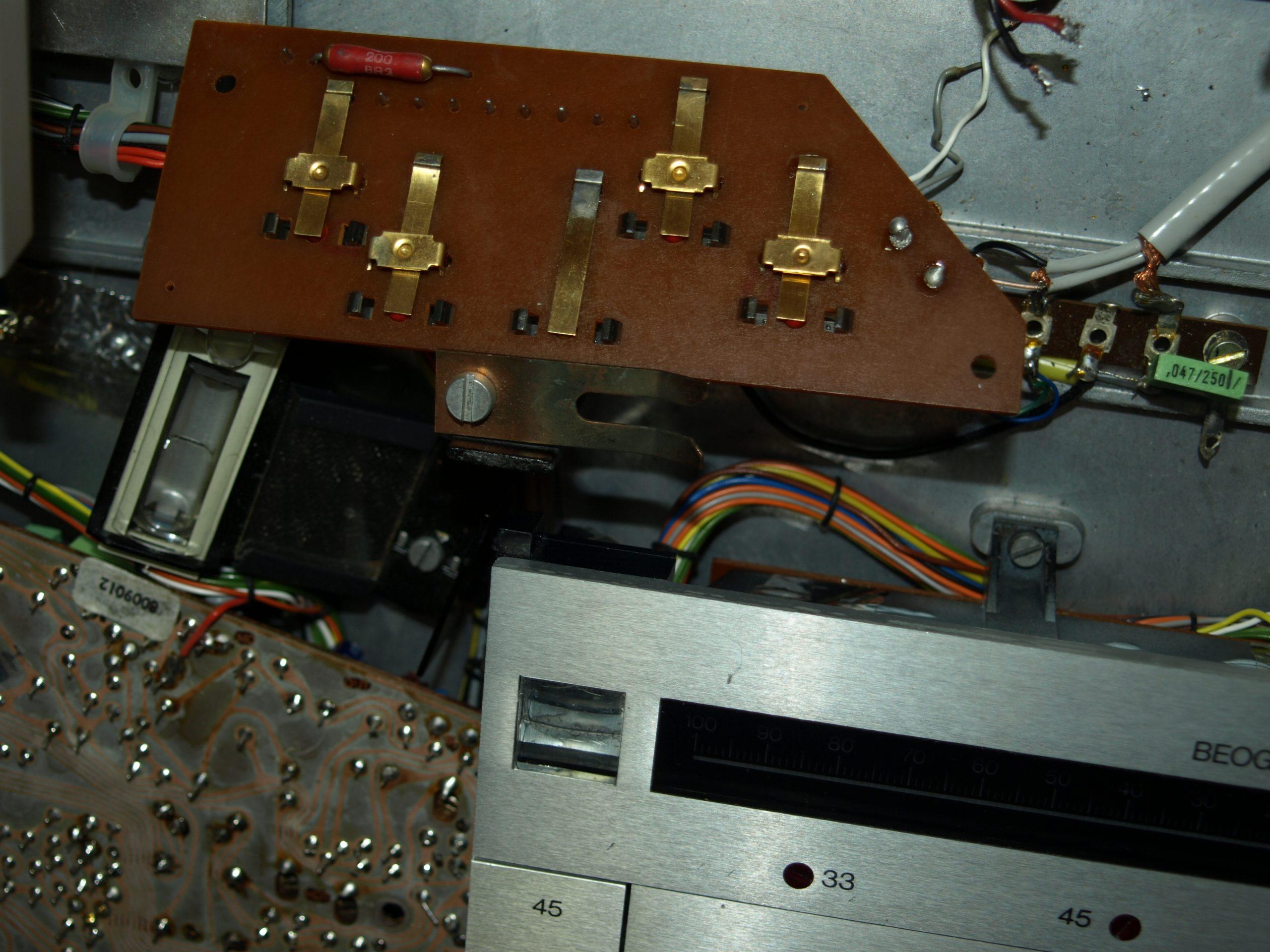

SILVER Memberspent a little time this morning unsoldering and cleaning the transport slide switches, didnt look bad actually….I think someone may have gold plated these ;¬) but cleaned them to eliminate them from any further considerations.

-

AuthorPosts