Forum Replies Created

-

AuthorPosts

-

Dillen

ModeratorThe problem could be that the plunger gets permanently magnetized, and it will

stick to the metal bracket.

I have seen this a few times.

Take it apart and demagnetize it.Martin

Dillen

ModeratorWhere do you plug the CD player in?

Does the CD player play in both channels if connected to a different amplifier?Martin

Dillen

ModeratorBeogram 3000 was produced with two different mechanics (one has the start relay box), but the motors are all identical to the one in Beogram 2000 (5244).

Same goes for the record deck in Beocenter 3500, which is identical to Beogram 3000.If the pad is this one:

https://www.beoparts-shop.com/product/pad-for-idler-wheel-lifter-arm-beogram-beocenter/

Read the description and look at the photos.Martin

Dillen

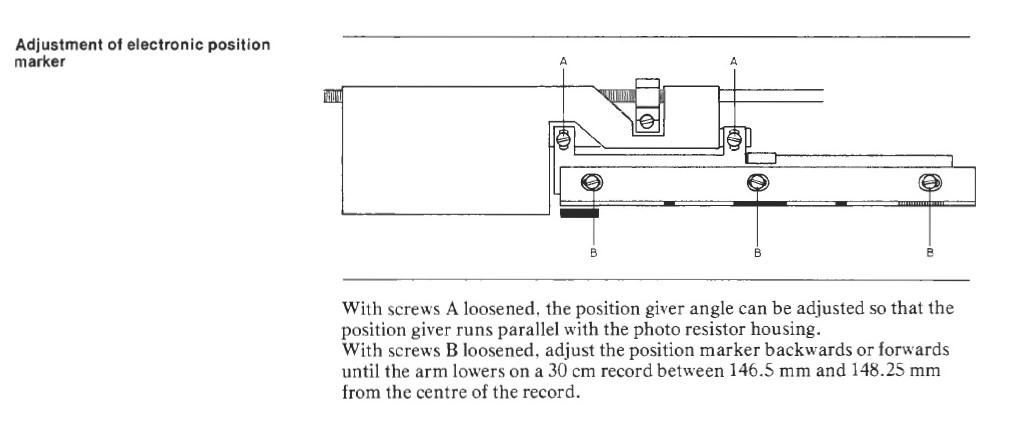

ModeratorDid you try the adjustment mentioned in the service manual?

Martin

Dillen

ModeratorFound, I believe… 🙂

Martin

Dillen

Moderator…Here’s what B&O did to ameliorate the resonance of the air chamber created under the hard dust cap of their midrange, which is just the same woofer, just modified pole-piece.

The driver with the ventilated magnet is not a midrange!

Both drivers were custom produced to each their specific jobs here.

Personally, I don’t believe much of it before I see some form of documentation.

No, you cannot just listen. – You can measure much more than you can hear.

If you sat down and took some readings, you will see that

the midrange and woofer drivers have quite unique T/S parameters, and you would also see that those parameters go out the door, when you fit rubber surrounds.

It’s a fact. It can be measured and calculated – but most people will actually be able to hear that something is out of normal.

Look at a scope, enlarge waveforms, analyze distortion and its source.

And that comes based on decades of experience with all matters B&O audio

and lots of speaker experiments, measurements and whatnots.

All facts.And – as a moderator – I have also been weeding out posts that went into audiophoolery.

Beoworld forum is not for buying or selling snake-oil.Why don’t you give us the readings, so we can see, that what you are doing are in fact improvements?

Martin

Dillen

ModeratorThere should be no pairing.

If you are sure, that the Beo4 is working, it’s most likely, that the remote receiver is not

longer working in the BeoSound 2000.

If the latter is the case, I made this kit:https://www.beoparts-shop.com/product/beosound-century-ir-remote-control-pcb-service-kit/

Martin

Dillen

ModeratorBeomaster 6000 4-channel?

Martin

Dillen

ModeratorDillen

ModeratorThey are not 1970s – but then again, there weren’t that many LEDs in 1970s B&O.

Martin

Dillen

ModeratorGood job, and thanks for the feedback!

Martin

Dillen

ModeratorQuestion is not why something works.

Question is why something doesn’t work.

In your case, – where things basically works when commanded from outside but not

from its own operation panel, there must be a problem getting the commands from the panel to the processor.Most problems of this sort are caused by cables, connectors, solder joints and

stuck switches. However, the keyboard reading circuit could also be at fault.

If the display on the front panel is also garbled, perhaps some circuit shared by those

two functions should be looked at.Martin

Dillen

ModeratorWhen you fit the black subplatter to the hub, make sure to match the

three “protrusions” on it with the three small indentations on the hub.

If you don’t the subplatter will ride too high.And you have the platter upside up – right? Your photo shows its downside.

Martin

Dillen

ModeratorFront panel cable/plug correctly seated?

One or more buttons stuck down?Martin

Dillen

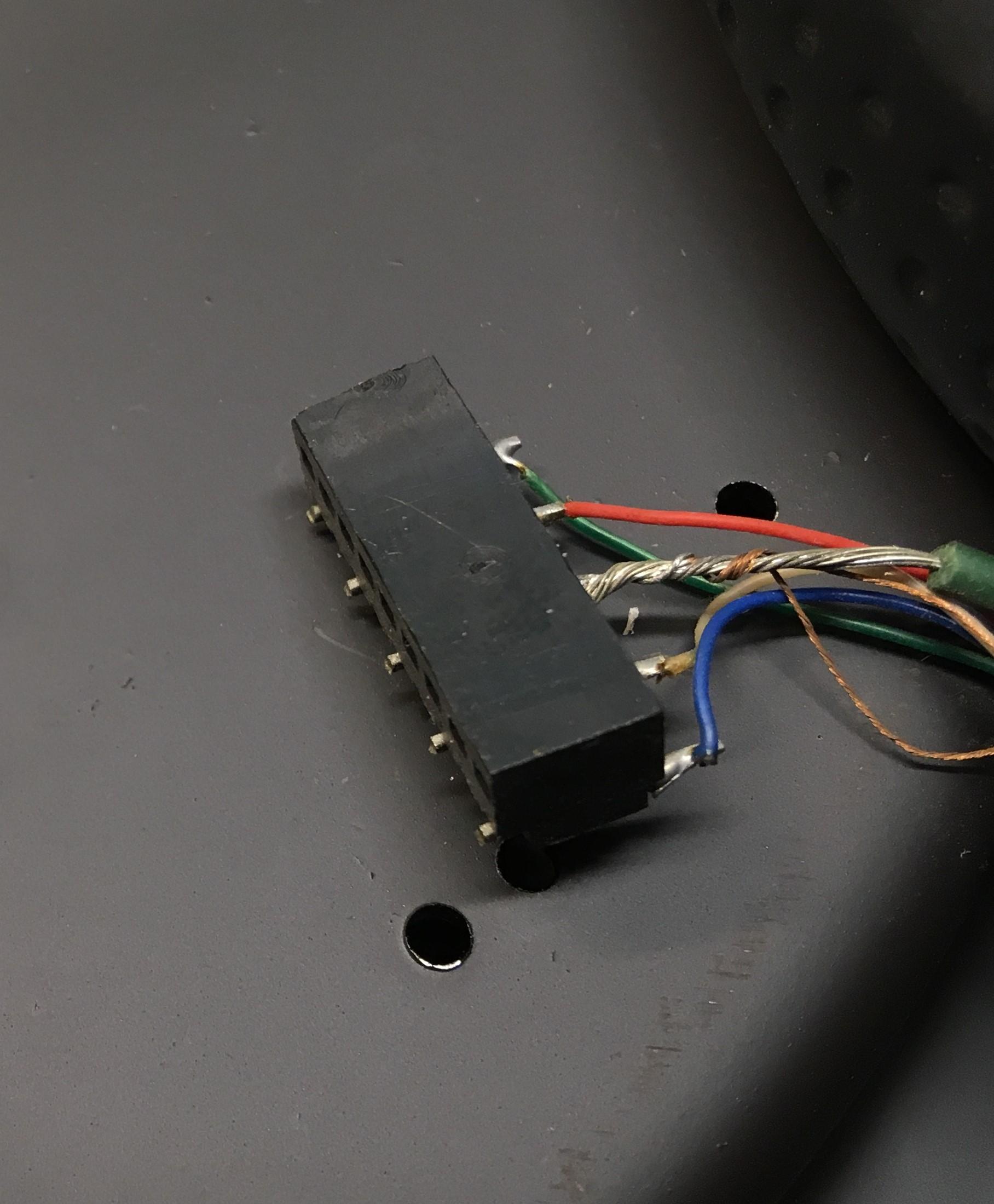

ModeratorYou should be able to find out the other leads as well using an ohmmeter / continuity.

Martin

Dillen

ModeratorA handrule is that the “warmest” color is always right.

If your cable has red and white, red is right and white is left.Martin

Dillen

ModeratorIf the relay is chattering, it could be the diode inside the housing has shorted.

I have seen this happen a couple of times.All fine inside the relay housing? – Check the adjustment and position of arms and levers

and that the small wire spring on one of the relay box arms is still present.Martin

Dillen

ModeratorGreat progress! I would measure the woofers as the doped cones will likely change the parameters causing a crossover modification.

I agree. Even a few grams usually make quite a difference.

– And even more so will the change to rubber surrounds.

I tried it a few times, but when I measured and compared T/S I found them

to be far out compared to the original specs, so I ripped the rubber off

again and changed it back to foam. After a few hours playing time, allowing

the new foam to losen up a bit, everything was spot on, back where it belongs.

I never used rubber again, where foam was used originally.But of course it can be done if you really MUST have rubber.

A compensation for the lack of cabinet volume

needed to satisfy the T/S with rubber (I seem to remember them requiring

8-10 liters) could perhaps be made by introducing a filler driver of some sort, though

driving it right phase-wise could be quite a task and would almost

definitely require a bit of signal processing – not least because it would

almost definitely need to be rear-facing due to lack of front area.

A passive radiator would require a too large area to have any effect, – far

more than what is available – as would surely a bass reflex system,

– and we must not forget that if both the midrange and woofer drivers

are changed to rubber surrounds, both will need compensating, and

not necessarily in the same way.

But why? – When you can just fit foam.I am looking forward to seeing the frequency response and new filter calculations.

Martin

Dillen

ModeratorIf some lights come on, but nothing more happens, it could point to the

CPU not running or not being reset correctly.

Most like a capacitor problem.Check power supply voltages and look for excess ripple from dying filter capacitors.

Martin

Dillen

ModeratorWrong wattage lamp for the FM1 indicator?

Yes, they are critical.Martin

-

AuthorPosts