Forum Replies Created

-

AuthorPosts

-

If you lost all power (no lights or movement) then it is possible that you blew a fuse. These are under a screwed cover in the back left corent accessible from the top. Having said that, the fuse likely blew for a reason. That table is 40 years old and likely needs its electrolytic caps replaced. There are service kits available such as this one from beoparts-shop.com. You do need soldering skills.

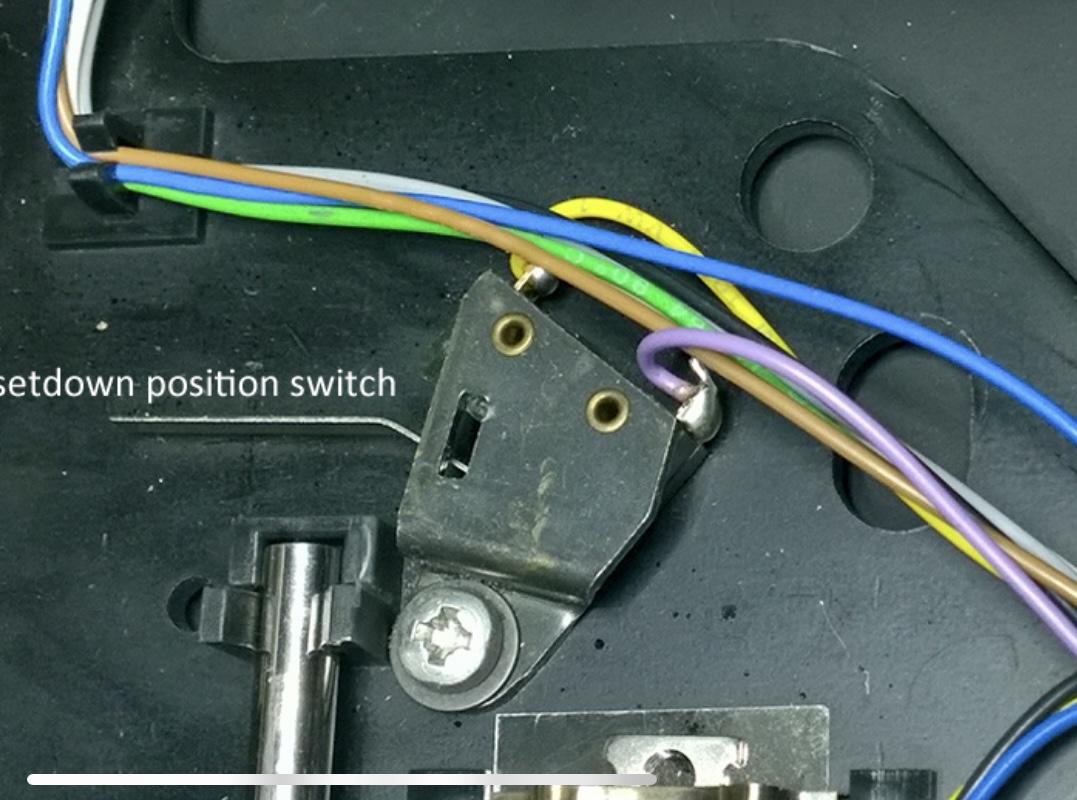

You are missing the set-down switch which those wires connect to. See this picture.

I would also disconnect the cartridge signal cables from the RIAA board and check the resistance between the two signal wires of both channels. Depending on cartridge it should be between 800 and 1K ohms. If it’s open or shorted you’ve got a bad cartridge.

No it is not normal and indicates that your phono preamp does not have sufficient gain or there is an issue with it. You did not indicate what cartridge you are using as the MMC6000 has a lower output for example. It would also help if you had a link to the specs of your preamp that specified its gain. Alternatively, I would try to test the turntable into another receiver to see if you have the same issue.

The arm that has the N and R eccentric is marked as 1606 in the service manual. The problem with the diagram is it leaves out identifying details. That a look at the exploded parts view. As to the platters there were two – one with printed spokes and one with rings.

Yes, that capacitor is important as chassis ground and signal ground must not be tied together in the turntable.

Can you take the back right square cover off by sliding the trim forward and snap a picture of that entire area? It’s possible the chassis ground is not properly connected. Also if you remove the cartridge, you should see a small flexible copper tang coming out of the bottom of the black connector. This connection is designed to ground the body of the cartridge since moving iron cartridges with their relatively low outputs are susceptible to hum. If that was damaged or missing that could also be your problem. Here is a link to a picture of the cartridge holder. If you have an ohm meter with the stylus cover on but the arm lowered, you should have continuity {<1 Ohm) between you ground wire and the cartridge shell.

That type of hum is likely a grounding issue. You did not say what the turntable is connected to. If you are using the DIN->RCA adpater then it must be the phono one which has a separate ground wire or you will get hum. If you are going DIN->DIN it may be a bad chassis ground connection in the TT or amp.

The servo should not activate as the arm is lowering. It sounds like the tonearm needs tracking adjustment. Follow the procedure in the service manual.

That problem is generally the speed selection relay and trimmers need replacement. You can find updated replacements from Beoparts-shop.com (now: Danish Sound Parts).

I’m afraid that reading does not make sense assuming you are measuring mAs. What you are looking for is not the steady-state reading but a current jump as you plug it in. I would use a second meter or Oscope to catch the drop in voltage at the time. At this point given your limits and these imperfect medium, I would replace the regulator just to rule it out as it’s very cheap.

You measure current by putting your meter in series with the circuit. This means disconnecting the regulator output, soldering a jumper and using your probes in series. If you have alligator clip ends even better.

The 7805 regulator can source more than 1A of current if working properly which is more than enough to blow the fuse before its short-circuit protection kicks in. I would confirm by measuring the output current when you plug the TT in and see if it exceeds 1A before dropping. If it doesn’t I would replace the regulator. If it does you are not going to have to start disconnecting 5v loads on the board and testing for 5v.

This is where it gets tough as you may be hitting your original problem. I would check how much current you are drawing on P6-1 as you may have a bad regulator. Normally F1 (800ma) would blow if there was a large draw due to a shorted transistor such as the Lift driver TR9. Also is it at .5v just plugged in?

Putting C24 in backwards would definitely take out the F1 transformer fuse but could have damaged part of the diode bridge or transformer secondary. Are you getting AC voltages across each transformer secondary? If so when you connect P7 back only, what voltage are you seeing across C24?

Update: I retested the pins you suggested but left the other connectors plugged in. With this setup, pins P7-12 and P7-6 do have continuity. The schematic screenshot below shows where P7-12 leads; P7-6 goes to ground. The bottom-most path is from P-712, leading to D42 and a relay. Would you suggest following both paths and testing each component as I go, or is there a more efficient way to test? Thanks!

Yes, P7 is the only connector you should have removed. I would check for losing the short by selectively removing the gnd sides of D20, 0C1, 0C2 and 0IC1 to find the defect.

I would start by leaving the supply disconnected and measuring resistance on the board side between each pair of windings pins looking for a short. Ex: P7 pins 2 and 4. Then you can desolder to find the shorted part.

To add one advisory to the excellent advice already posted, if you have put in one or more of the electrolytic caps backwards and tried to turn it on, you’ll need to check the fuses, transistors and regulators prior to that as you have effectively shorted them. This is likely why you have not made progress.

1 October 2024 at 06:44 in reply to: Beogram 2402 arm skating and recommendation for good companies to fix #59648It’s likely a missing diamond or mis-calibrated tracking force. I doubt its a cueing mechanism issue.

You can get that one to work by removing the top platter and belt.

-

AuthorPosts