Forum Replies Created

-

AuthorPosts

-

jfrancis49

MemberAlso there are mechanical parts that need to be cleaned and properly lubricated that may be part of your problem.

John

jfrancis49

MemberHello Karl,

I am not a real savy tech person, but until someone with more knowledge steps in I will give you my thoughts on your problem. You should at least see a light on the control panel, left side for 33 rpm if the table is getting power when you push the start button. If the capacitors have not been replaced, they probably are the first thing to go after 40 some years. There is a fuse box in the back left side under the top plates that you could check. If a fuse was blown there was probably a good reason however.

Depending on where you live, there are people who could service the table, if you have no basic soldering and electronic skills that might be the best course of action.

John

jfrancis49

MemberHello Orava,

There are different places on the internet you can find them, I am not sure the moderators want us to post sources. But if you do a search for “Industrial Drive Timing Belts HTD 3M Pitch Timing Belt Width 30mm Open-Ended Transmission Synchronous Belts” you will find several sources, it is branded 3M but made most likely in China. It is available in different lengths and I would get more than you think you need. You will have to cut the 30mm to around 27-28mm width and cut the length based on an old 1600 belt. Getting a clean cut between the belt ribs for a good splice is the tricky part. That is why I would get more than I need. If done cleanly and straight you then use Gorilla Super Glue Gel and clamp it for 24 hours. I have done two belts and the seem is invisible. You can use WD-40 and a cotton swab to remove small amounts of visible glue.

I plan on posting pictures of the belts when I get the clutch washers installed. I have everything apart replaced the clutch washers, but am having issues putting the rod and parts back in the plastic housing.

John

jfrancis49

MemberThanks Martin, that was a big help! I now have the left side controls taken apart.

John

jfrancis49

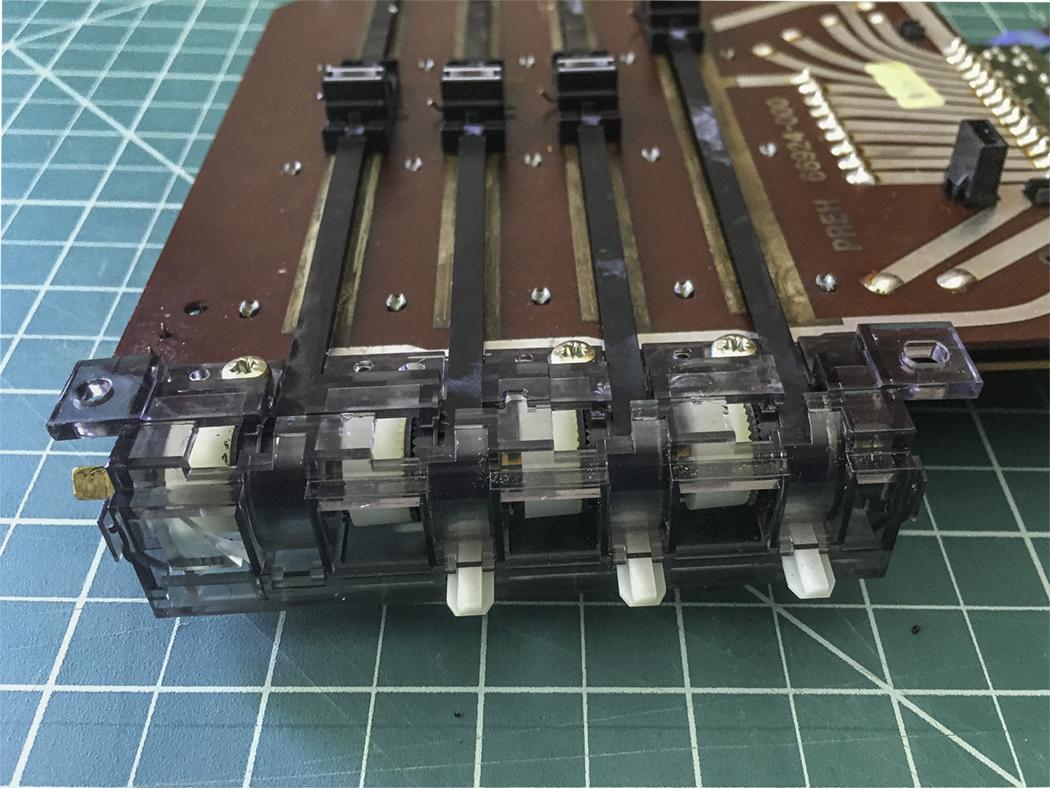

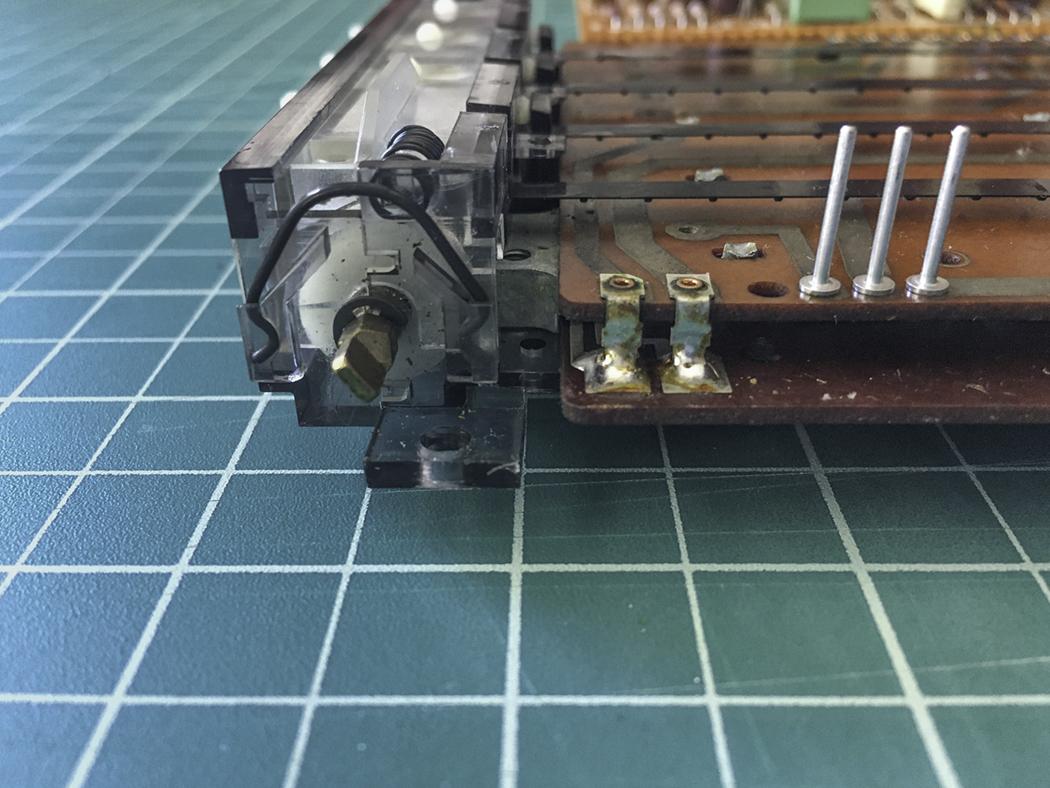

MemberThanks for the reply Martin. I believe I understand that the couplings are the white disks shown in the photo here. But my guess is I need to disassemble this further than I have. Should I remove the screws shown in the first image and the plastic cover and the two clips that would be on each end of the clear plastic enclosure shown in the second image?

Thanks again,

John

26 July 2023 at 23:40 in reply to: Beogram 4002 Tonearm Sets Down at End of Platter With No Record #47868jfrancis49

MemberThank you Mark and Sonavor! You pointed me in the right direction, it was the plastic rule for the sensor that was set to far to the left on the metal guide rail. After reading your posts I remembered that a week or so ago, I reset the rule because the tone arm was no raising automatically at the end play on one of my records. The beginning set down and end point seem to vary depending on the record so I must have over adjusted the ruler.

Thank you again!

John

jfrancis49

MemberHello Thomas,

Unfortunately I don’t have the technical expertise to advise you on this. But before I would trash it or give away the platter I would see if you could find someone to service it. Outside that non-working Beogram 8000 turntables still are worth abut on eBay. Someone else might be able to buy and fix it or use the parts to resurrect another nonworking one.

jfrancis49

MemberHello All,

I just finished adjusting the tracking sensor on this Beogram 4002 and outside of polishing some scratches out of the dust cover I hope it is completed. Thanks to Mark and his help and encouragement I was able to get a few stubborn problems worked out. The 4002 was in beautiful cosmetic condition but had a severely frozen tonearm and a non-functioning board. I was lucky I was able to replace some components and not have some serious trouble shooting.

John

jfrancis49

MemberHello Mark,

Thanks for the reply. So if the tonearm is angled towards the sensor arm when playing, does that mean it needs to be set to be more responsive?

John

jfrancis49

MemberHello,

I unfortunately had some health issues that slowed me down on sorting out the tracking force and arm balancing on my 4002, but I got back to it and hat is now working properly. I ended up taking the tonearm apart and lubricating it and then making sure it was not binding. I have adjusted the 33.33 and 45 rpm speeds and tried out a record. The record plays fine but I notice the tonearm is moving towards the sensor arm and plays at an angle. Is this a tracking sensor adjustment issue? They are both parallel to each other in the up and resting position. It sounds fine, but my other 4002 does not do this when playing a record.

This I believe is my last fix on this turntable.

John

jfrancis49

MemberHello Mark,

Once again, my appreciation. I seem to have an unexpected amount of trouble getting the arm to balance. I will give it a go this weekend.

jfrancis49

MemberI thought maybe I should look at R88 and see if that should be adjusted. And that turned out to be the issue. Now all is working with the speed changes and set down, but I need to do some other adjustments. Balancing the tone arm is next. For whatever reason I have a hard time getting more weight forward to balance without it binding and pulling toward the spindle.

jfrancis49

MemberHello Mark,

I do have the service manual and have looked at the flowchart. Don’t quite know how to follow some of the trouble shooting. I understand how to identify the different legs of a transistor, but not sure where to connect the other multimeter probe to. Afraid of shorting something.

I am currently traveling and won’t be back for a week.

jfrancis49

MemberThanks Mark,

I have an extra board with the photodarlington transistor on it so just switched out that board. No change, the sensor arm still does not recognize where the record set down position should be and does not switch to 45 rpm as it travels toward the spindle. So something may be amiss on the main board still.

jfrancis49

MemberHello Mark,

You were correct, the 45 rpm light does light up when I am able to use the cue button. And the solenoid does function. But the forward and reverse buttons don’t seem to activate those actionsn nor the stop button.

jfrancis49

MemberHello Mark,

Thanks for the reply. Yes, the sensor arm lamp is working and pushed as far down in the sensor arm cavity as it will go. I understand there is some circuit connection here for the fault I am seeing. At start the sensor arm is not finding the record and or switching to 45 rpm as it travels inward. But I was thinking that the 45 rpm button on the keypad though should also function by lighting the 45 dial and turning the motor when pressed.

John

jfrancis49

MemberHello Michael,

I don’t remember who posted it, but someone recommended using just a little baby oil on a soft cloth for the brushed aluminum. I have found that works nicely and just give it a good wipe down with a dry cloth to remove any excess. Regarding the plastic lid, if you have scratches, depending on the severity you will have to use sandpaper or abrasive polishes to remove them. There are several posts in older forums on doing that and some Google searching can lead to others. One thing I have learned is find a product that is an abrasive rather than a wax, the one that are mostly wax just hides scratches. Polishes made for restoring plastic are a good place to start.

jfrancis49

MemberThank you Mark and Adam. Well, I learned something through this experience which is I didn’t think about bulb filament resistance as a factor in my thinking. The good news is I swapped out the tracking sensor today and it is working!

Lucky for me the issues related to this restoration have not required more than switching out a number of parts, soldering new components and adjustments to get this working. Serious trouble shooting is beyond my capabilities.

Thanks for your kind support!

John

jfrancis49

MemberHello Mark,

Thank you for the post. I did have a lamp for the 33 and 45 speed adjustment, so I tried a continuity test on it and it showed no continuity. So I connected a 9V battery to it and it lit up. Not sure why my meter is not showing continuity. Crossing the leads does and my meter squeals like it should. Anyway I took the tracking sensor out of the BG 4002 and connected the leads to the 9 V battery, no light, bad bulb. I tried the other spare sensor I have and the bulb lights with the battery, so I will install that tomorrow and see if that takes care of it. Once again, thanks for your response.

John

jfrancis49

MemberHello Tim,

Sorry for the delay. I very much appreciate the suggestion. I have decided I will first try learning the software to design the wheels based on my 1 good one and 3D print them. I have access to a 3D printer at my university and the software for drawing it is free. I may have found a source for the belts and am waiting for that to arrive. The only other sticking point may be clutch washers. I have not checked those out. But if the 3D printing doesn’t work out I will try your suggestion. Hopefully something good will come out of this I can share with other Beomaster 1600 people.

Thanks again!

John

-

AuthorPosts