Forum Replies Created

-

AuthorPosts

-

Take off the fret and inspect the speakers. Quite sure that they need a refoam job which is quite easy.

Location: Copenhagen

I only use PowerLink but will try to see if I can find a pair of passive speakers somewhere.

I did try the headphone socket, and there is no sound either.

Location: Copenhagen

I would think it is a matter of lubrication turned hard. The tonearm travels on a rod and that rod may need a good cleaning and new lubrication.

Location: Copenhagen

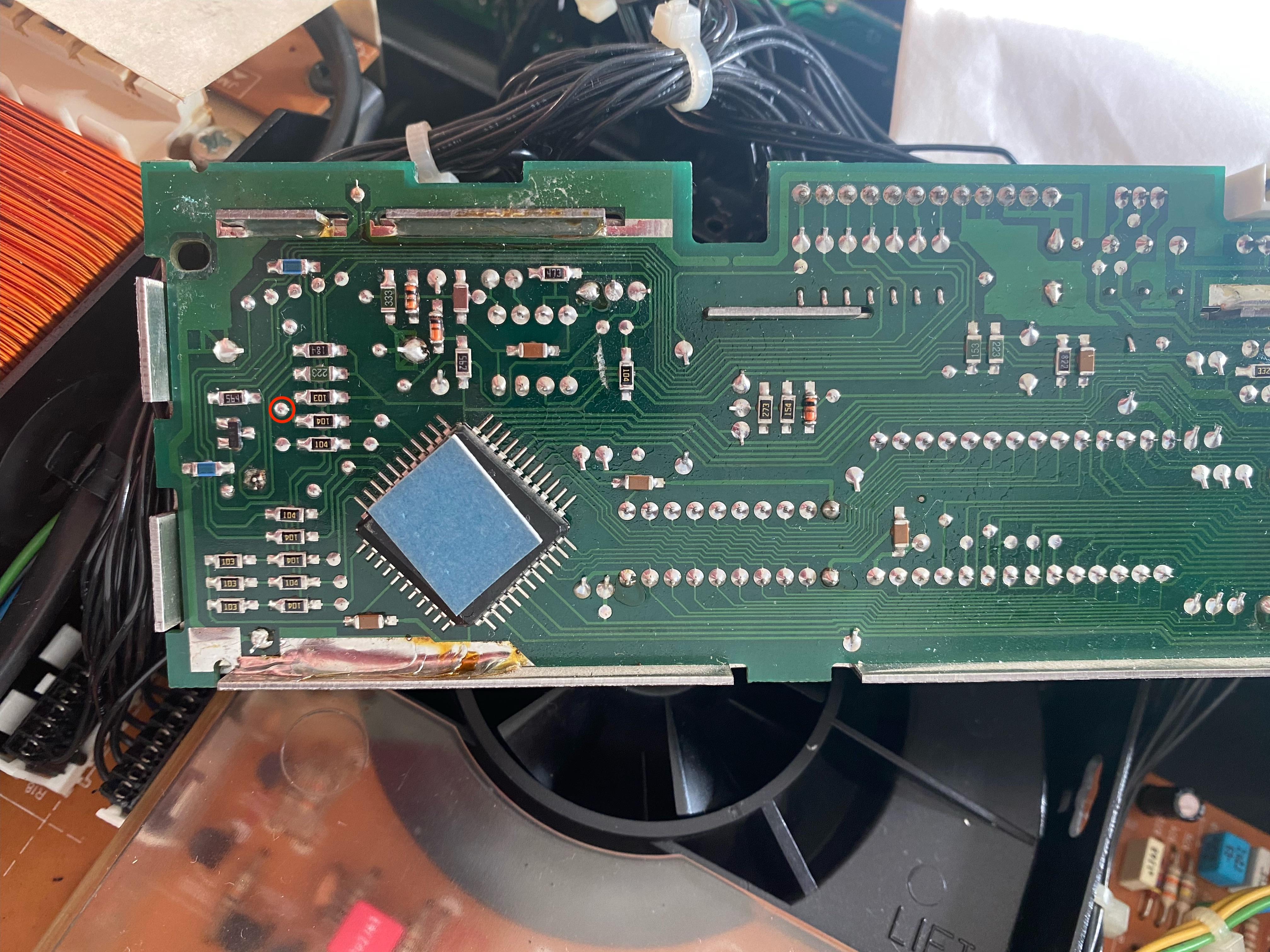

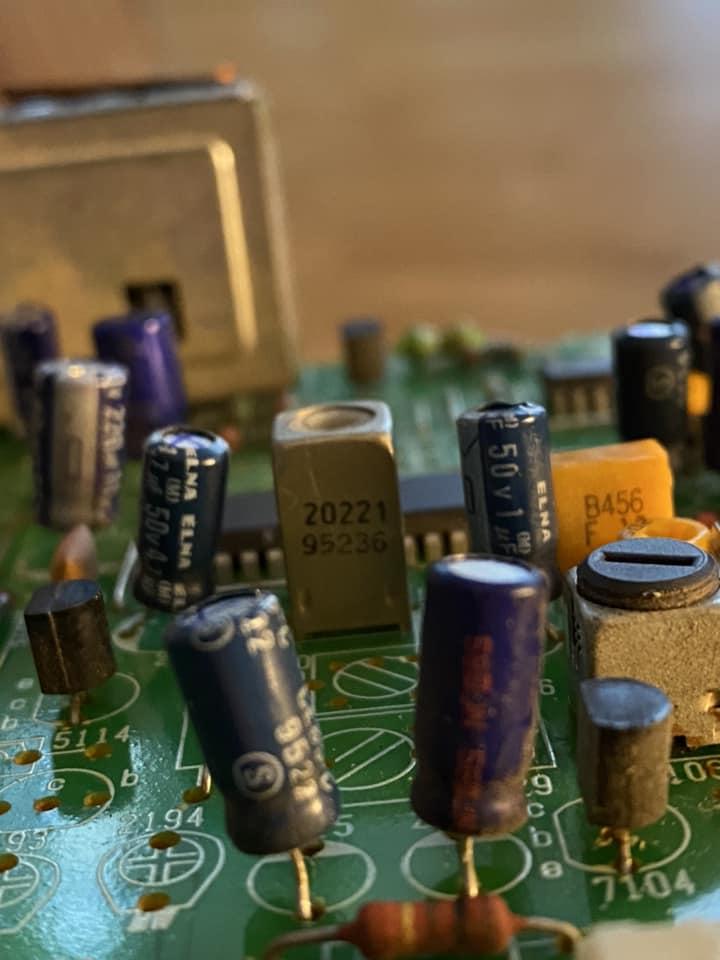

I decided that I needed to be able to remote control the unit. Luckily somebody had tossed a transceiver a while ago that I found in the dumpster. It looks an awful lot like the VX sensor so I figured it would be possible to make it work. Sure enough. Green wire was 5+V, White data and brown ground. So now I can remote controle the VX5000 without a Beovision. Still need to fix that sound issue. Of all the caps that I changed on the power supply, the video amplifier and the 12 V regulator, I did not find a single faulty one. (I still need to change a 4700uf cap since my cap pusher only had one). The only faulty one that I discovered was one that was leaking at the right side of the top board. I changed it, and measured that it was completely open.

Location: Copenhagen

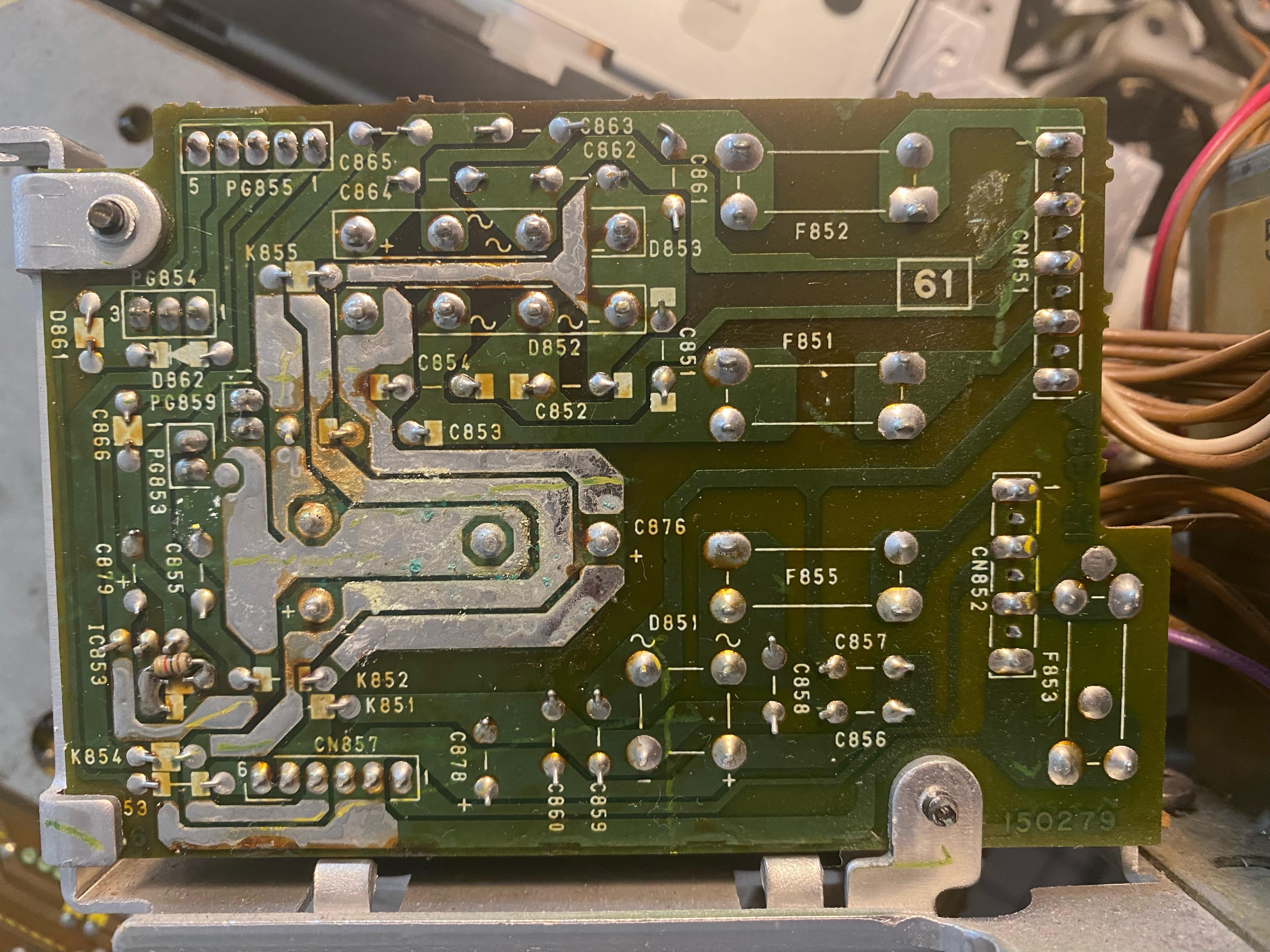

Power supply first. Though it seems to work (though perhaps not 100%), I took it out for inspection. Hmm – does look a bit corroded in the middle of the board, so I will start recapping that one first.

Location: Copenhagen

Yes – no recapping done yet – except for the capstan motor board – as I first needed to source the eject mechanism and get it working. I guess, I will take it board by board, starting with the main board which has the servo and hifi circuits. Perhaps even the power supply first, though it seems to be working fine.

Location: Copenhagen

Here is a recording: https://www.dropbox.com/scl/fi/mzdzpocwz6rork3kb361g/VX5000_lyd.mp3?rlkey=mc5cz7lzpptfmgp6gtnv1hhka&dl=0

The pressure roller looks dry and slightly cracked. I can replace it with the one from the VX7000 which is in perfect condition but I don’t know if that could be the issue?

I have only tried old tapes so far but they do the same thing. I have not turned any adjustment screws.

Location: Copenhagen

Wider – no. Deeper yes. As you rightly say, the cutout is different.

Anyway, I changed the cassette holder base and put the one from the VX5000 in the 7000 eject mechanism and put the whole thing in the VX5000. Happy to report that play, FF and Rewind are now working.

There is still a wow and flutter problem with the sound so that needs to be fixed. Not sure where to start with that. It comes from small speed ‘jerks’ it seems.

Location: Copenhagen

And looking at the VX7000 and VX5000 mechanisms, I now see that there is a crucial difference. The part called Cassette Holder Base is much wider (edit: I meant ‘deeper’) on the VX7000 mechanism, causing it to press on the Reel Drive Idler. I initially thought that the two eject mechanisms were fully the same, except for the materials chosen.

Location: Copenhagen

So … I think I have narrowed down what the actual problem is – though I have not found the solution.

If the tape eject mechanism is not in, and I put a tape in the machine, it will play, reverse, fast forward etc. (there is still a wow and flutter problem that I don’t know why is there).

However, when I put in the eject mechanism, nothing really works. It can play but will make tape salad after a few seconds due to the take up real not engaging. Looking at the eject mechanism when it goes all the way down, it will press on the reel drive idler. I presume that due to this, it will stop working – unless this is normal behaviour?

Location: Copenhagen

Carried out functions 16 and 7. Everything reported back as functional with status 37.

Still no working RDS. I guess I need to measure the 12 and 5 V connections to the RDS board first to see if it is actually getting power.

Location: Copenhagen

Hmm – I tried to do what you wrote. After putting it together there was no change. However, I did have some success – not sure why.

After covering the light sensor, I could see that the take up reel was spinning both during play and fast forward. Maybe there is some misalignment somewhere as the eject mechanism was actually in the up position (as in no tape there). I then put in a tape, and it would fast forward and reverse. Screwing down the eject mechanism, I could hear that the forward motion started to struggle, so I didn’t screw it down completely. Play still chewed up the tape as the take up reel would not move. I ejected the tape. Inserting it again, I could hear the motor spinning when fast forwarding but again the tape would not move 🙁

Location: Copenhagen

Yeah – that thing flew right off a few times but I found it. I glued it back on.

Here is a pic of the gearbox:

The symptoms are:

- Play works on the left reel but the take up reel does not move, so the tape soon becomes tape salad

- Fast Forward and Reverse do not work. I can hear the motor spinning but the tape does not move.

As a side note: the VX7000 that I received was also eating the tape. The reason was hardened grease under the take up reel. After cleaning and lubrication, the tape is no longer eaten. Anyway, I am not so interested in the VX7000 as its functions are very limited without a suitable Beovision.

Location: Copenhagen

Thank you, Martin – but I was lucky enough to get a VX7000 for free today, so I have taken the mechanism from that one.

However, I still have one problem:

The reel drive gear is driving me a bit insane. I cannot get it to touch the take up reel. I have looked in the service manual but there is definitely something that I am not seeing. Any tips? Seems like there is a plastic hook underneeth the right wheel that prevents the change.Here is a video of the problem

Location: Copenhagen

Looking further in the Service manual, it says to carry out functions 16 and 7 in test mode which I have not done. Could that be the reason for RDS not working?

Location: Copenhagen

I managed to fix it. I had to remove the metal shield to get access to 4TP1 and short circuit it to ground. Now the frequencies are correct. RDS is still not working.

Location: Copenhagen

Perhaps the crossover filter needs a recap. Since the sound is not great regardless of using the amps or not, it points to either the crossover filter or the mid foams IMO. The placement and distance to walls can also affect the sound.

Location: Copenhagen

I finally had time to check the FM board. What a hazzle to get it out. Removing 16 screws marked A – some of them quite hidden.

All the caps on the board test fine – that is the good news.

I am pretty sure that the fault lies in the square part 5105 which is just called ‘coil’ in the service manual. It is an IF can with a condenser, and it seems that the condenser in these dies for whatever reason. Since I don’t know the specification, I don’t know if a replacement part can actually be ordered from somewhere, or if it can somehow be repaired by replacing the condenser. Anyone has an idea?

Location: Copenhagen

I will PM you.

Location: Copenhagen

-

AuthorPosts