Forum Replies Created

-

AuthorPosts

-

BRONZE Member

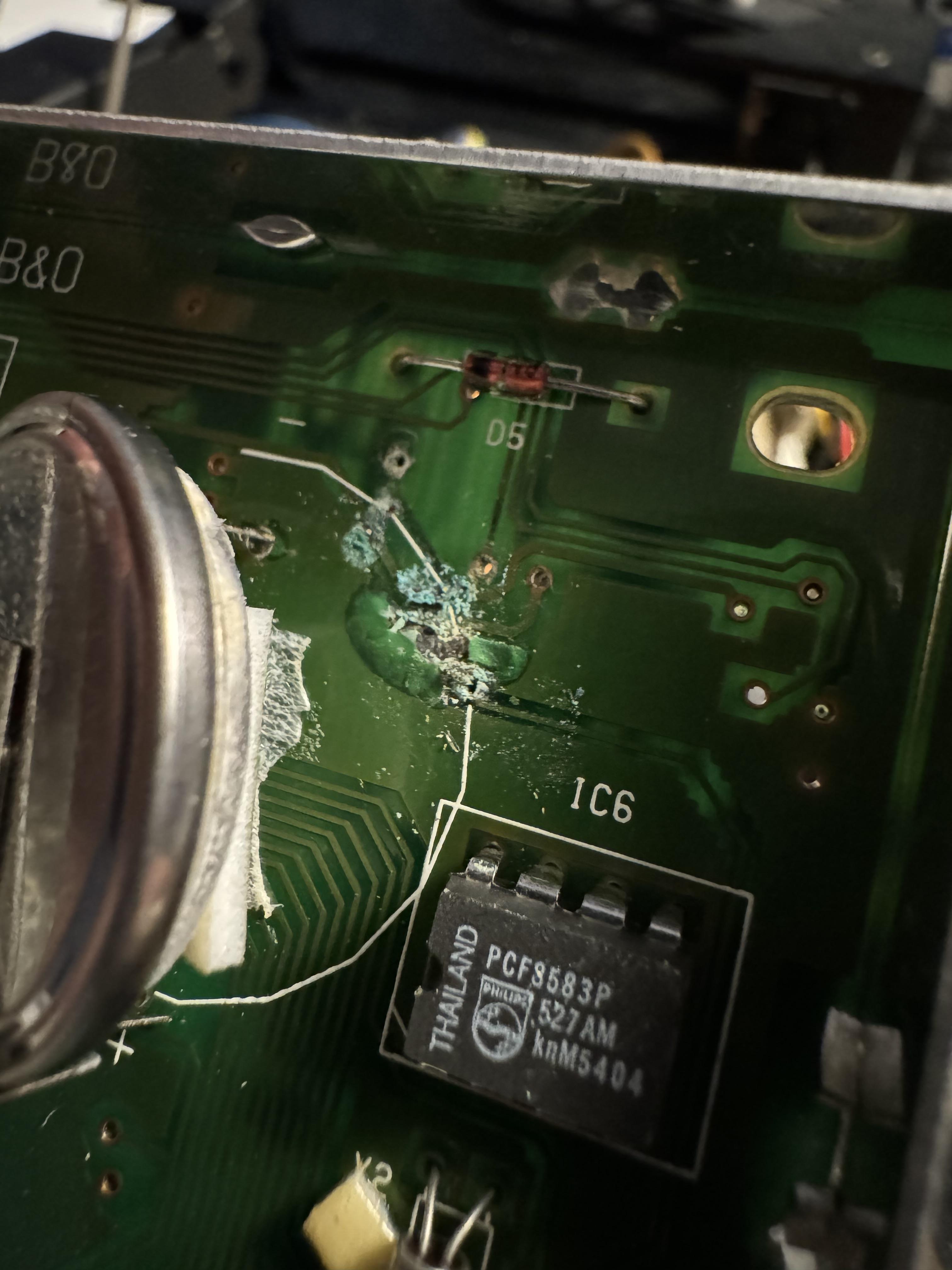

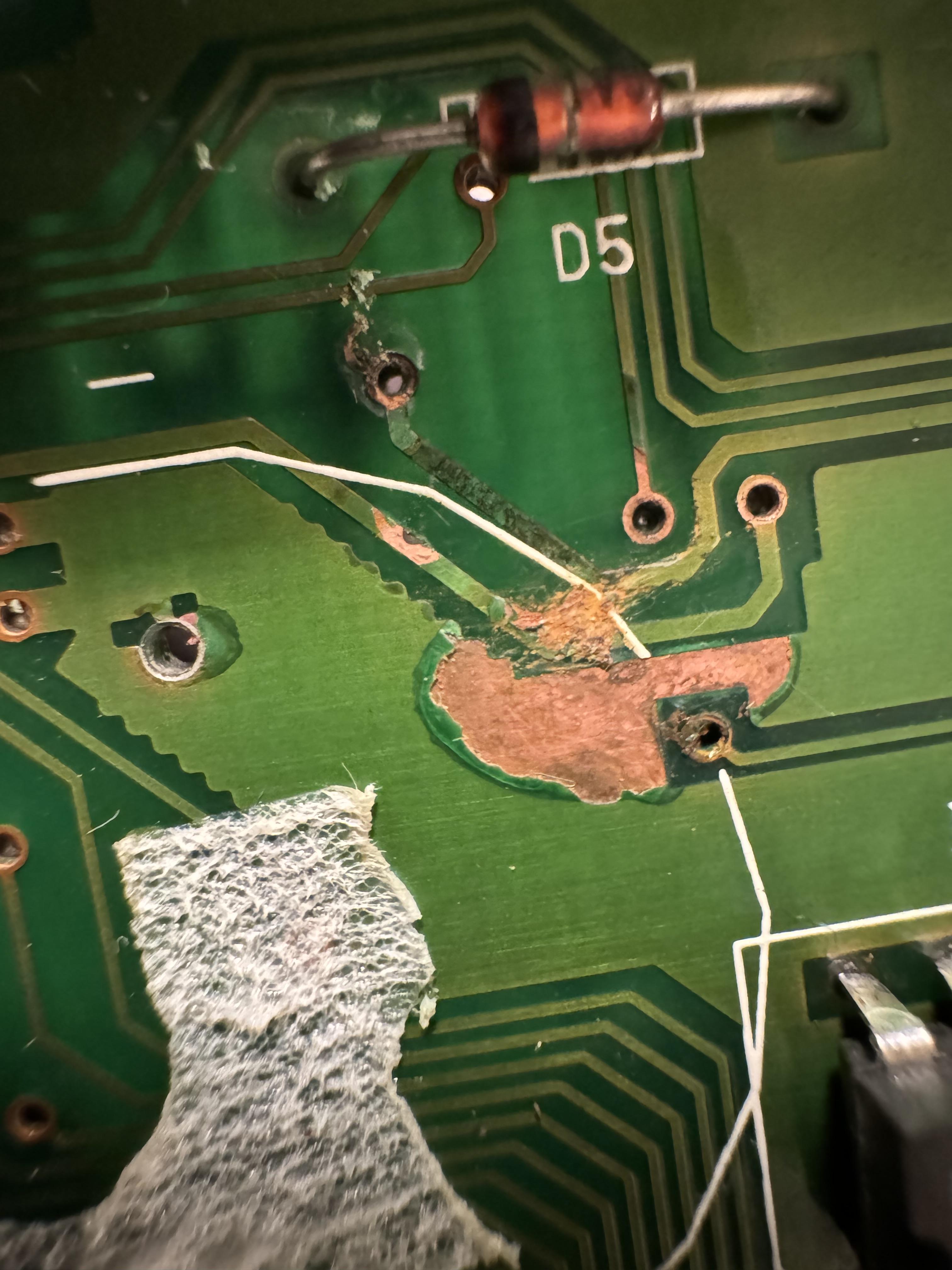

BRONZE MemberI guess I should have started by checking the battery:

There was only one trace that was broken, so I fixed that. Those batteries are a ticking time bomb ?

Location: Copenhagen

BRONZE Member

BRONZE MemberAll fuses were good.

Location: Copenhagen

BRONZE Member

BRONZE Member.

Location: Copenhagen

BRONZE Member

BRONZE MemberIs the relay on the standby board supposed to click? Because mine doesn’t say a click.

Location: Copenhagen

BRONZE Member

BRONZE MemberI have the correct voltages from the transformer. On the standby board I also have correct voltages except for P90 pin 1. It’s supposed to be 7.8V as I read the schematic (it says ‘7V8 unregulated’) but I measure approx. 24V.

Location: Copenhagen

BRONZE Member

BRONZE MemberUpdate: D31 was faulty. After changing D31 and R54, the carriage now behaves the way it should. Nice!

Regarding the motor: it also started working after I pulled it apart, gave it a drop of oil (yes, I know it will not last forever) and changed the order of the small plastic discs.

Now the deck was working kind of great – however, the 45RPM was not stable, and when I tapped the board with the speed relay, it would lower the speed significantly.

So, I decided to take a look at the National relay. I cleaned it with a fiber pen and put on the plastic lid again. After this, the motor only spins one second – and I am not sure what to do.

Location: Copenhagen

BRONZE Member

BRONZE MemberLooks like resistor 1R54 is defect as well as TR17.

Location: Copenhagen

BRONZE Member

BRONZE MemberDepending on the cost of shipping, I may be interested in the front panel (the one that can open and covers all the secondary buttons). I live in Copenhagen, Denmark

Location: Copenhagen

BRONZE Member

BRONZE MemberShould be fixable. But why was it overheating in the first place? Idle current may have been set too high due to corroded trimmers. But as there are parts that actually burned, I suspect a short-circuit may have happened. I am sure other experts here can tell you what happened.

Start with cleaning the board with a clean paint brush to get rid off all the dust.

The damage seems to be only in one area of the board. Find out what the shared denominator is for those four parts to burn up. Then order new replacements. When desoldering on this board, do not use too much heat as you will lift traces. Also – was the transparent plastic holder for the filter capacitors missing, or did you remove it to take the pictures?

Location: Copenhagen

BRONZE Member

BRONZE MemberFirst, check the fuse(s). There is one where the power chord comes in (you need to unmount the bottom of the amp. I don’t remember if there is more than one fuse.

Location: Copenhagen

BRONZE Member

BRONZE MemberI would probably test the fuses first. The fuse holders are known to tarnish, so they will not make any connection. In that case they can be cleaned up with a fibre pen. Also, please take a look at the schematics to see where the source lights get the power from and which voltage. Measure it, and trace it to where it stops.

Location: Copenhagen

BRONZE Member

BRONZE MemberI would suggest cleaning the laser lens and the mirror. You need to open the lens to do this. There is a video in the thread Fixing Beosound 9000 laser.

Location: Copenhagen

BRONZE Member

BRONZE MemberThe main suspect is always C2103 for these types of decks. Once that has been changed, the troubleshooting can go into other capacitors.

Location: Copenhagen

BRONZE Member

BRONZE MemberThank you – will do.

Location: Copenhagen

BRONZE Member

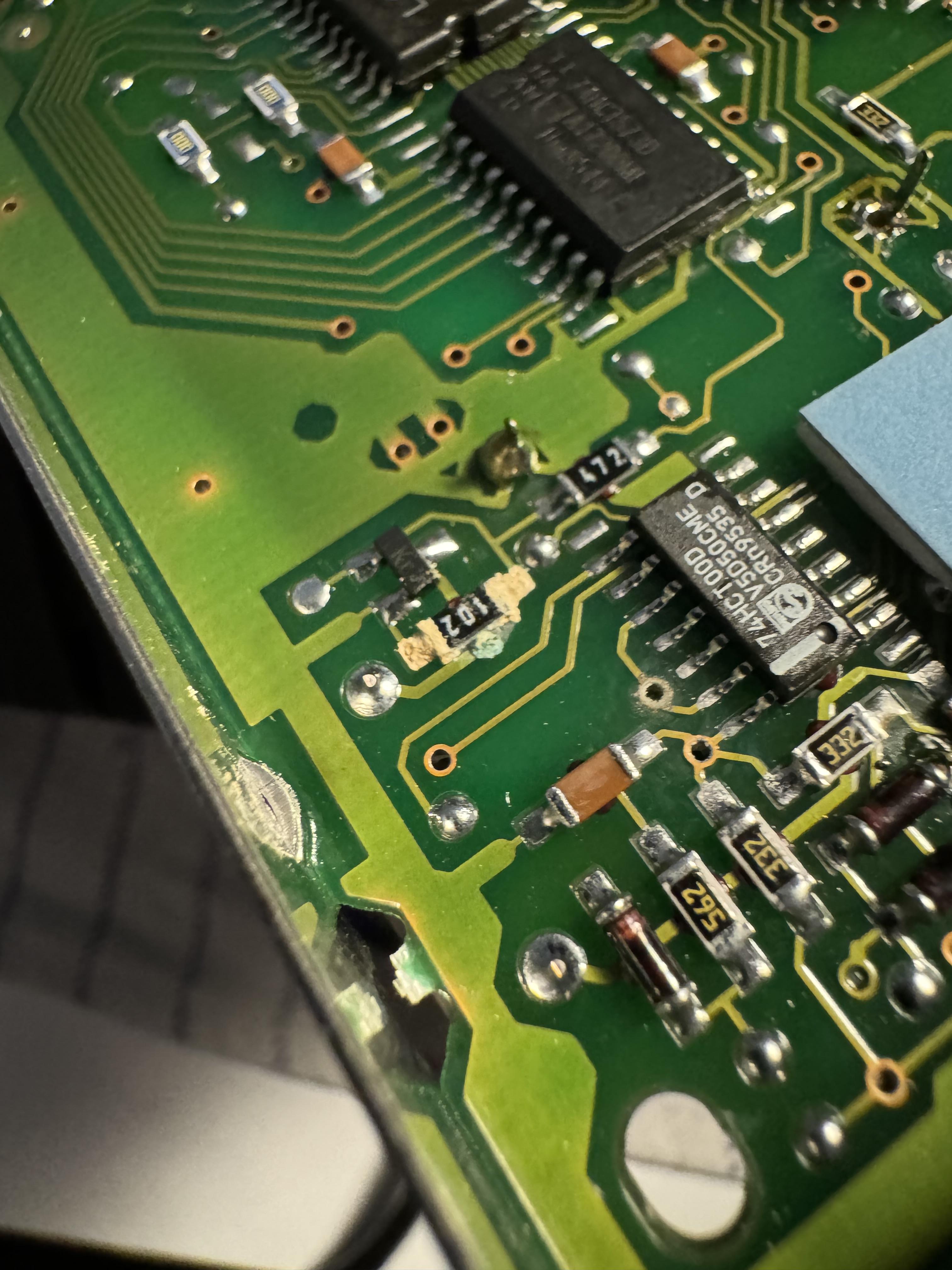

BRONZE MemberYou are on the right track. When I changed capacitors in mine, I changed all 4 or 5 caps but the only ones that were not measuring correctly were actually the two SMD caps. Remember to clean underneath. Also – there may be caps fluid under the chip that is next to the SMD caps, so give the chip’s legs a good clean with IPA.

Location: Copenhagen

BRONZE Member

BRONZE MemberHi – it is a known issue. I presume you mean BeoSYSTEM 7000? In the Beolink 7000 there are two SMD caps that fail. They are not difficult to change but of course you need to know what you are doing.

Location: Copenhagen

19 September 2023 at 19:03 in reply to: Problems with setting radio stations on AV 7000/Beomaster 7000 #48946 BRONZE Member

BRONZE MemberAre you sure the Beomaster is in Option 1? You should be able to tune it with Beolink7000/1000/5000/Beo4

Location: Copenhagen

BRONZE Member

BRONZE MemberWhy don’t you just order new foam surrounds and do the job properly? It really isn’t complicated to do. Cut of the old misalligned surrounds and rinse of the glue with isopropyl alcohol. Order new foam surrounds from a certain store in Holland and do the job properly.

Location: Copenhagen

BRONZE Member

BRONZE MemberWhoever did that refoaming job should have left it to somebody else. Besides the excess of glue, it even looks like the speaker cone is not touching the rubber surrounds. If the other speaker looks anywhere near this, I can totally understand that you would not get the expected sound results.

Location: Copenhagen

BRONZE Member

BRONZE MemberMoving on to the main board. I took a look in the service manual and ordered what I thought would be pretty much all the caps needed. I don’t know what happened – either I totally missed some parts, or I simply made a wrong order – in any case, I still need a lot of caps to change but I think I have done almost half of them. Of all the caps that I have pulled out, only very, very few have actually been in working order. The majority of them have shown Open Line on my multimeter, and I think 5 of them have been within spec – but I have changed them also. Finally, I had a chance to remove the tuner board(s) – they were a hazzle but I managed. This gives a bit more space.

Location: Copenhagen

-

AuthorPosts