Forum Replies Created

-

AuthorPosts

-

I think it’s fake.

For me, it looks like a cheap Tonar element with some lookalike print on it.

The cartridge misses the transparant protection cap in front.Edit: I missed the cap in the pictures. It’s there. So, I’m baffled as wel.

Location: Utrecht

I’m glad to read that the change has been done for a good reason!

Congrats and wishes of good luck for taking the challenge to expand the business.

Beobuddy.

Location: Utrecht

25 September 2024 at 19:07 in reply to: Reusing speakers from BeoVision Avant 32 (CRT) as active standalone speakers #59404I draw that once 😉

You need a symmetrical powersupply indeed.Location: Utrecht

Is it now possible to connect the Connect Core and H100 through USB-C, to get the best quality of music (B&O with Tidal or using the Tidal app)?

Location: Utrecht

7 August 2024 at 15:53 in reply to: BeoLab 8000: Broken plastic leg supporting PCB > which glue ? #58092My experience with glueing the parts together with supports around etc is, that the plastic is so brittle and it easily breaks again at another place along the pillar.

To prevent breaking I always start to search for the thread and use some grease or just wetting the screw to carefully turn the screw with the minimal amount of force back in its place.

Location: Utrecht

7 August 2024 at 13:01 in reply to: BeoLab 8000: Broken plastic leg supporting PCB > which glue ? #58085Glueing will not work. The first screw that enters, will break it again.

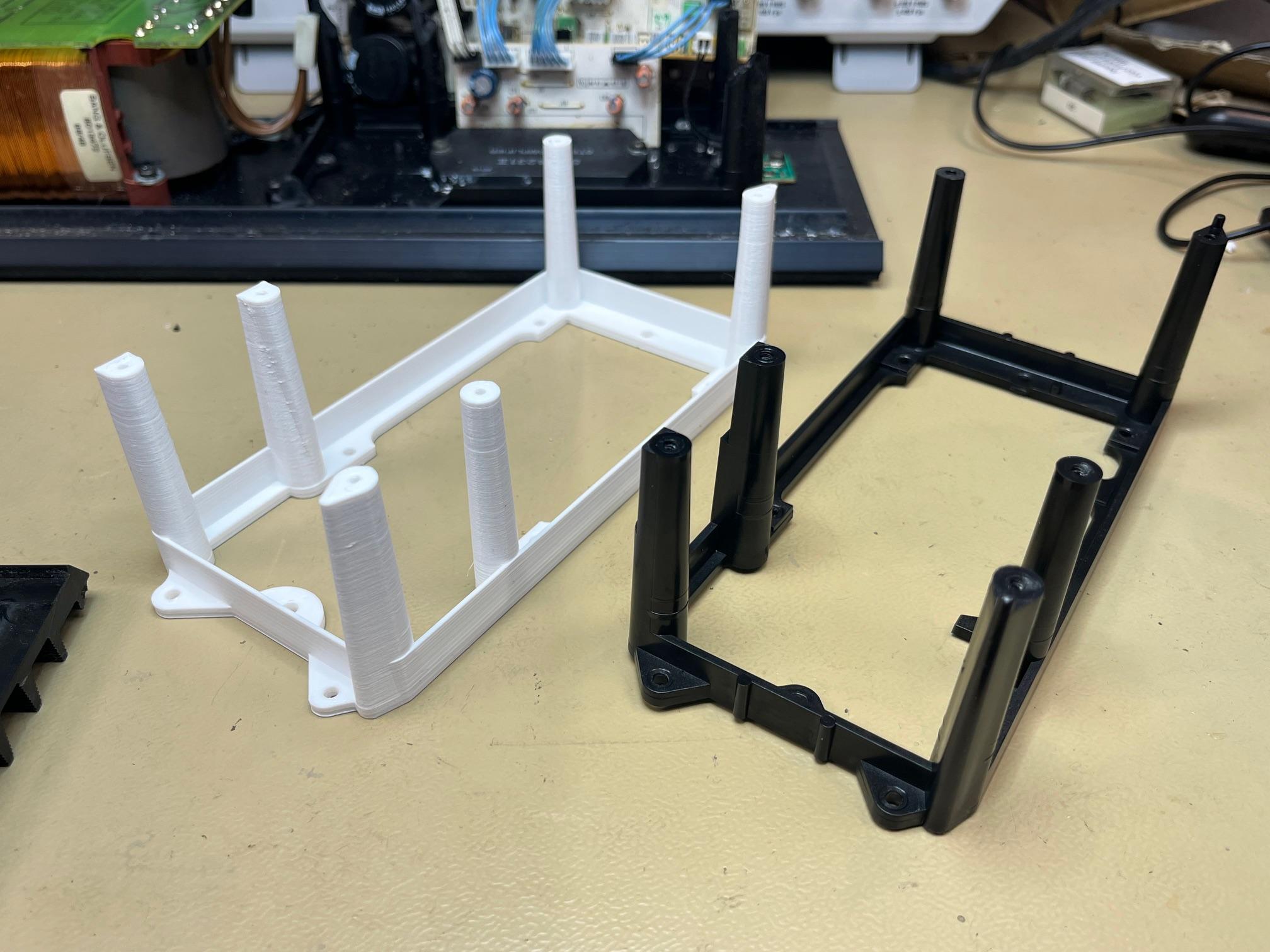

Reproducing these:

Or at the PSU side:

Location: Utrecht

7 August 2024 at 12:51 in reply to: Help with beolab 5 – bang noise when starting on – 165mm woofer #58084By swapping the ICE module it is confirmed that it’s faulty.

Don’t take for granted that it is always caused by a defective module. I’ve had several BL5’s with the same behaviour caused by the DSP.

So, by swapping and eliminating you can often find the responsible part.But be carefull. It won’t be the first driver that has been smoked due to a defective ICE module/amplifier.

Location: Utrecht

5 August 2024 at 10:04 in reply to: BeoSound Essence Mk2 final sw version number? 2.5.55678(170713653) ? #58005Did you ever get any answer from B&O support regarding that issue?

They did answer but I didn’t get it to work – sorry I should have updated that other thread. They advised me to update the software (which I already had) and asked me to confirm the connections – I sent a copy of the NL/ML eye wiring diagram from the ML handbook and they didn’t say it was wrong. I also asked them to confirm when to set A,OPT 1 – once they understood the question they told me that it should be done when the Essence is in ‘Network Standby’ – again, I had already tried this. So I have given up! If there are new SW updates I will check again. Otherwise, it would be useful to know if anyone has got it to work recently, either with the newer JOIN ML IR eye or the older TIMER version that I am trying.

I have 1 used for the bathroom with the newer ir (Join) receiver in the wall.

I remember that I had to change the option setting. But whether it was 1,2 or 4. Just try. The “join”button always works instantly, but responding to the remote (Beo4 in plastic) needed the option instruction. But I can’t remember as it (still) works for the past 5-6 yrs.

Location: Utrecht

Just replace those two paper foil capacitors. As said, it a common thing.

I’ve already done some, these were also boards from BV11’s. But also some psu’s from Essence mk2’s and ML/NL converters.

After replacement the powersupplie will work again.Location: Utrecht

It’s probably most obvious that the BS9000 looses the information about the position of the sledge. It stresses and goes into standby for a restart routine. During that starting routine the sledge moves back to the first position ignoring a possible defective or dirty tacho sensor at the big motor, which moves the sledges.

They aren’t any things a user can do. It has to be opened for further cleaning/replacement which has to be done. But I have to say that the culprit can be on both sensor(s) around the motor or inside the sledge.

The servicemode (sometimes) can tell you more about errors. So, that’s the first thing to explore.Location: Utrecht

What happens when you open the glassdoor and then go from the first to the 6th position?

Does that work?

Location: Utrecht

Hi @beobuddy, Speaker type is 6881 with SW 2.6 (not sure which revision of speakers this is mk1, mk2 or mk3). Yes, speaker stop responding to remote controller commands once it gets warm (after 1..3 hours of normal operation – no loud audio there). I can certainly check if micro is covered with something but how do you draw any conclusions out of it? How would you go about fixing something like that? Do you offer service to fix it? Thanks, Henryk

A BL5 with software 2.6 printed on the label underneath the big disc, is a mk2. mk1’s have software 1.4 or higher, mk2’s have software 2.6 or higher and you can quess that software 3.0 or higher is a mk3. But Afaik there are mk1’s with newer revisioned chassis with upgraded software. But not sure about that. I have seen different components on the mk2 and mk3 when you compare them side by side. I tend to think that mk3’s are a bit more vulnerable for malfunctions. I’ve fixed some mk3 boards on places I haven’t seen happen on the mk2 series.

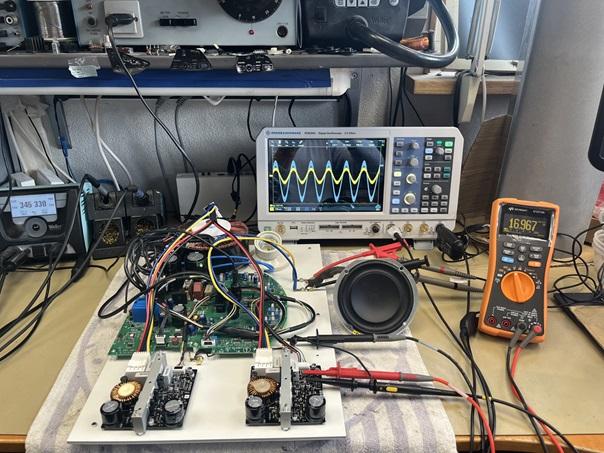

But to answer your question, I offer the service. But. At this moment I’m still examining these kind of behaviour. Due to the fact that the BL5 needs both data and the trigger signal to operate, I’m leaning towards the processor or something in it’s surrounding area. But as these are covered with a special hardened fluid, it is still impossible to measure. It wouldn’t suprise me if there is something happening as with the early BS9000mk1’s and some mk2’s where the processor itself might be the culprit.

Location: Utrecht

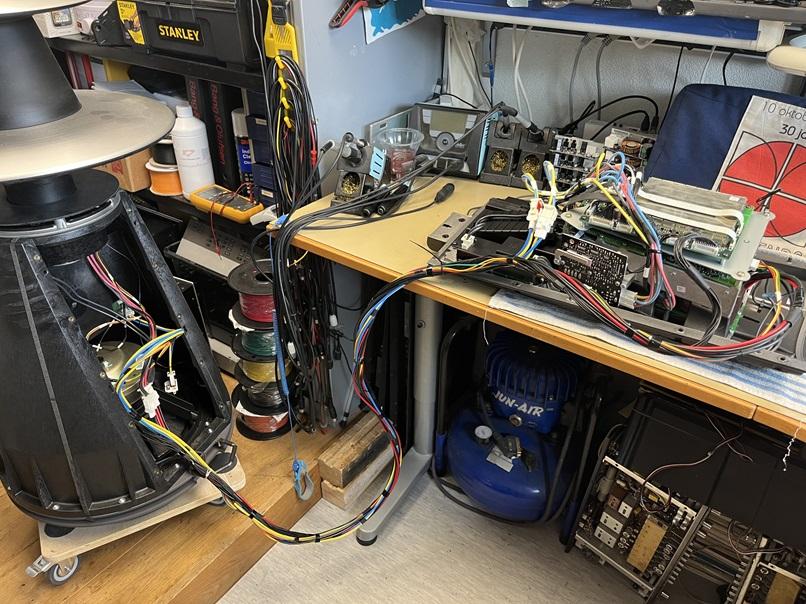

And for testing ICE’s and chassis for a longer period and more heavy load, I have a dedicated BL5.

At the picture you can see the custom made extension cable between the chassis and the loudspeaker itself with the same connectors used by B&O to achieve that reliable connection.

All, again, to get the most reliable test environment and result.

Location: Utrecht

It takes a serious amount of time (and money) to create steady and reliable environment to test and repair modules and BL5’s. To fix a ICE module with just a multimeter will help you, but for more reliable results you need to test them for a longer period of time.

And even despite all the equipment I have, I don’t have all the (software)tools that B&O has when it comes re-program DSP boards.Location: Utrecht

Hi @beobuddy, One more observation from my side. If speaker that exhibits unstable behaviour is cold (in power down state) and I power up whole audio system it works as expected. There are no issues with reacting for commands from Beosound. Issues starts to appear when speaker runs for number of hours and I guess its guts to higher temperature. Is there a chance that some sort of thermal paste that should be present between components and their heatsinks is gone after 15+ years and this causes some issues? Any guidance is highly appreciated. Thanks for your time, Henryk

Temperature is an issue, but not due to old thermal past. If the BL5 doesn’t respond to instructions, then it is most likely caused by the processor on the DSP board. And that is a challenge as the processors on mk2 and mk3 are covered by a layer of resin or some sort of.

Location: Utrecht

@ Gunter.

Does calibration starts with the microphone coming out? If not, then there is another problem.

Most of the time the ICE amplifier for the lower bass is the culprit. But again, look at the movement of the microphone.Location: Utrecht

Just one, to simulate that there are active loudspeakers attached to the BS9000.

Location: Utrecht

You need to replace these 2 SMD capacitors. The picture shows the wrong way of mounting the black plastic strip in front of it. It needs to be turned 180 degrees.

Location: Utrecht

23 February 2024 at 14:20 in reply to: BeoSound 9000 Type 252x (from April 1996) Software Update #52984Just to add.

Types 252x and 256x can have software 2.21a for support NMUSIC and NRADIO.

Types 257x can have software 3.42.

Software 3.x can’t be placed in a 252x or 256x due to different processors.For the housing a TX10 is used and for the hinges a TX8 is used.

Use TM72 in the CD servicemode to release the sledge or during moving the sledge between positions with the glassdoor open, switch of the power. That way the sledge can move freely.Location: Utrecht

Just a small reminder. The BV9 has to be switched on for at leasthalf an hour to be able to activate.

BTW, every panel has it’s own settings, printed on the back of the panel. These settings has to set correct or at least not changed. The camera can adjust the colours of the panel, but probably only for fine-tuning. My panel went a little “greenish”. Had done a lot of hours at that time. But the camera couldn’t compensate that. Although the grey bar was rather greyish from top to bottom.Location: Utrecht

-

AuthorPosts