Forum Replies Created

-

AuthorPosts

-

Really no one?😔

Hi Jacope

Did you renew the cap on the prcessor-board (47uF if I remember) in the uPC – can?, quiet important.

Usually there are two flat wires to the front panel.

One is just for the display , the other for the buttons.

The flat wire for the buttons is only sticking in the mainbords connector, so high risk of pulling it out a little bit while handling the boards and there is no connection to one of the outer wires, so please recheck these.

Another fact is when already pulled out to missalign the wires while sticking back into the connector so there are maybe two of them in one hole. Don´t ask me why I know this ;-))

Did you measure the voltage for the LDR in the frontpanel?

This could cause lot of funny problems if not aligned according the SM.

So first is to bring the Beogram back to life, after that we could look for the backspinning, which is quiet usual a little bit as the the unit is plugged in, but not for 3 seconds.

Mine makes just about a 1/4 to 1/2 round backwards when plugged in.

Kind regards

Christian

Hi

Found the screws under the rubber ring, all ok.

Thanks again

Christian

Hi

Thanks for that, I´ ll try next days.

Kind regards

Christian

At first I would replace the platterbelt with a new one, if there is still wow you have to dig deeper.

Listen without amp but record on if there is some scraping noise from platter to other parts inside.

Beoparts (now: Danish Sound Parts) provides the right platterbelts

If you are already working on the turntable maybe you renew the belt for the tangential drive too.

Kind regards

Christian

If you adjusted the pot wich is discribed as MOT you would have chaged the amplitude of the platter motor.

Nothing related to the differential circurit as far as I know 😉

Maybe you puzzeld a little bit at the other pot’s too?

Kind regards

Christian

Hi

I’ll try to help a little bit.

P7 – 12 and P 7 – 6 go to ground because

P 7 – 6 is Ground

P 7 – 12 has a conection to ground via the motor coils ( 0 L 1) related Plug ( P 4 -2; P4 – 5) . Have not measured the coils so far but could be in around 200 or less Ohms.

So desolder one leg of D42 and check for a short.

A common issue, what I had already twice for what reason ever, is D 20.

This is a Z Diode 6,3 V and a protective diode for the 5V of Processor and so on.

In case of a overvoltage of the 5 V line this diode is shorted and the fuse could trip to protect the connected uPC and others.

So check D 20

Kind regards

Christian

Hi Ary

Ordering a capacitor kit from Beoparts (now: Danish Sound Parts)is not stupid, i my opinion it’s the best way to get all caps in a set for a dedicated restauration project.

Beoparts (now: Danish Sound Parts) is providing a PDF with information for your ordered Capacitor kit: “Instructions can be downloaded in pdf-format using link(s) provided in the order confirmation email. ” seen on Beoparts homepage (now: Danish Sound Parts).

About your +21,3 Volt at C29, it is the place where the + 15 and – 15 Volt are generated.

What sometimes happens is that the cap was desoldered and “forgot” how it was mounted, so it could happen that a cap is mounted reversed. The printing on the PCB’s is sometimes simply wrong.

So take care that C29 is looking with it’s MINUS to the anodes of the rectifier D21 – D24 recheck C27 to it’s polarity.

I don´t excactly know, but C 27 is the cap with the 3 pointed ring underneath. These 3 points are connecting 2 GND points on the PCB together. Recheck that the GND points around the two 2200 uF cap’s are ok.

If the two GND points are not connected one point has a”floatig” GND and can cause several issues.

Long story told short:

https://beolover.blogspot.com/2017/05/beogram-8000-recapping-main-board-and.html

Kind regards

Christian

Hi Jordi

The Capacitor that you mentioned is the last I would change because this is the Phase Cap for the Platter Motor mechanism which normally lasts very long.

If you got no LED I would resolder ALL solder joints of the plugs on the PCB’s an performing a recap of ALL electrolytic capacitors on thePCB’s.

Usually after that the BG 8000 will start up again…following issues have to be inspected later.

Here, on Beolovers site, you will find a bunch load to read about restoring the BG 8000

https://beolover.blogspot.com/p/beogram-80008002-restoration.html

let us know about your progress

Kind regards

Christian

Hi Gunnar

My question is if the slowing down is sometimes for a second or slowing down for longer time.

first case from my experience there is a problem with the spark snubber diodes (TVS diodes) in the motor. Find out detailed information here:

https://beolover.blogspot.com/2021/12/Beogram-4002-dc-motor-spark-snubber-replacement.html

second case from my experience are the dryed out motor bearings. Detailed information here:

https://beolover.blogspot.com/2023/11/beogram-4002-dc-platter-motor-restoration.html

and here:

https://beolover.blogspot.com/2021/10/beoparts-dc-motor-bearings-tested.html

Kind regards

Christian

Hi

Did you replace the foam and gaskets? Could be airventilation caused by gaps between the amp module speaker module or top module with pipe.

May be that a PCB is ratteling because of a missing screw or a broken screwpost. Often the screwpost break while tightening the boards or handling, or screw isn’t fully tightened.

Why the ratteling sometimes is audible and sometimes not is quite a mystery.

did you crosscheck the”bad” woofers in the”good” speaker set? For me it’s a bit confusing how you did the test ;-))

If you push gently the bad woofers is there any scratchy feeling?

Try to test the woofers out of the speaker with reduced volume and listen to the bad ones and good ones > any difference?

Good luck

Christian

Maybe you get some more information in this discussion:

https://archivedforum2.beoworld.org/forums/t/10293.aspx

Lot to read and some pictures.

Kind regards

Christian

Hi

1

I could not find any hints in the service manuals (even BG 4002 type 5501) where is discribed to change the fuses to 500 mA, so I would keep the 250 mA slow blow and check it out.

Of course the Ohm’s law says half of voltage means double of current with same power output

= 500 mA

Maybe Martin has further informations from Service manuals which I’ve not seen.

The worst thing what can happen is that one of the fuses is blown and the Beogram stops working.

Tonearm will lift at power fail.

2

Regular glass fuses, slow blow

3

Living in DE so no experience

4

you could use an adapter or mount an UK plug as you like, I would use an adapter so all keeps original. The plug should have no effect to the sound because there are no RIAA amplifiers or somthing active parts like that in a BG 4000. The High end authority would say something else ;-))

Kind regards

Christian

Martin

Thanks for your reply, you’re such a great database ;-))

Checked it out yesterday and the BM 8000 shuts of after about 30 miutes, so all is working.

Thought it would shut off after 5 miutes or so.

Have a nice day

Christian

Hi Derek

Thanks fore information.

I already saw these offers in the www.

In between I desoldered all IC’s from the PCB and tested them on a breakoutboard.

Found one mor defective FCH 131 wich had an steady High level on one output.

I decided to solder all back in and only leave 3 IC 5 open because the there are only two and three inputs of the NAND’s used.

I will try to rewire an CD 4012 an look what will happen….fingers crossed.

Still waiting for deliver the CD4012, when they arrive I will report.

The failing of the IC’s was, in my opinion, caused by the Z Diode 2D4 6,8 Volt.

This diode was loose in the solderjoints by some strange human activity. If it’s loose or not connected anymore, from my knowlege, the voltage on Emitter 2TR6 is raising near to the input voltage Collector 2TR6 (haven’t measured what comes out from the bridge rectifier) and fries the IC’s.

Kind regards

Christian

Really no one ??

Kind regards

Christian

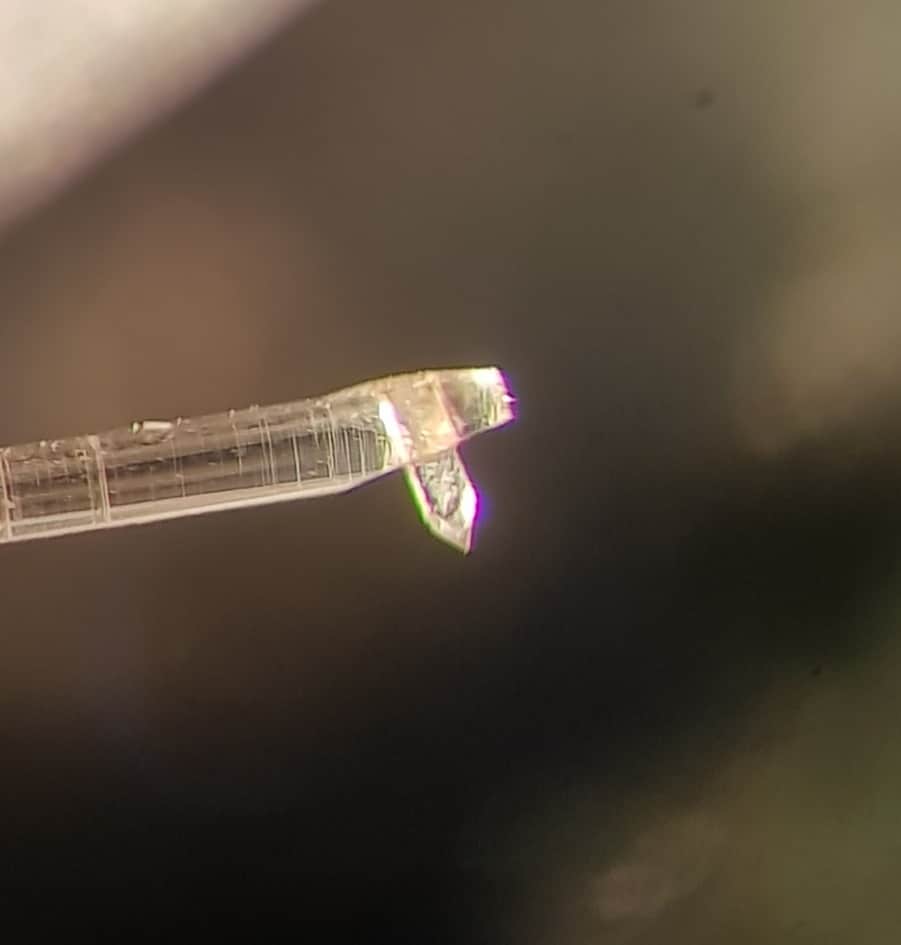

Thanks for the picture

Any further information?

How to?

Where to get?

What about black lettering?

Kind regards

Christian

As I already mentionee

d, it upon your amount of money you will spend for an build in RIAA.

I´ve not heard the one from Beolover but he´s always on top with his development and he makes a great job. He´s not just firing out some products but he is thinking and thinking about to make things better , my opinion an many others I belive.

What I heard about the Zen Phono preamp was that it is a very well made and sounding RIAA, but even this one I´ve not heard.

The Claudius product seems to be grounded on the RIAA from Beogram 4500/ 7000 with some silde variations here and there. He´s doing a fine Job too and will help you kindly and friendly with problems related to his products if you have problems. I´ve had no problems so far.

So there are are mountain of RIAA´s to look for and the choice is yours.

For the external RIAA´s check the several HiFi and HiEnd related Forums. There you can read years and will not find the right one 😉

That´s all from me to say, because it will end in a endless thread ;-))

Put the needle on the record and dont talk about it , listening is believing;-)))

Kind regards

Christian

Hi

Some suggestions about buildt in solutions for Beogram 4002 / 4004/ 6000 :

The solution from “Beolover” is very impressive, plug and play you can buy it on the E-B …. auction platform, search for:

Beogram 4002 and 4004 Phono RIAA Pre-Amplifier – Easy No Soldering Installation.

For more information look on Beolvers Blog.

Have not heard it so far but there are some points where you could adjust the RIAA to you favorite sound I guess, would be very interesting in my opinion.

The second solution for a build in preamp is like this from danish Soeren Claudius:

https://claudius-elektronik.dk/designs-og-l-sninger.html

Have alredy mounted 5 of these for several projects and it’sworking great.

A little bit of soldering needed but no big deal and a good value for the money my opinion.

The third I know about is from Jacob Rungwald, member of facebook group Beogram 400/4002….

https://www.facebook.com/groups/1499233306805847/permalink/6809783595750765

This is a plug and play RIAA version and has implemneted a IR remote function via DataLink

(Beomaster 4500 or similar is needed) so you could controll the Beogram with a BEO 4, Beolink 1000 or similar.

You have to get in touch with Jacob and ask for avaiability and price.

Thousands of extern Preamps a avaiable quality from crap to high end, like the prices from a few Bucks up to somewhere ;-))

So it’s your choice

Kind regards

Christian

Hi

You are right, the spindle is held by a rivet and only to remove with some pulling on the rivet

I’ve a complete spindle / hub in my workshop, all teeth are ok, rivet is attached send me a pm.

Kind regards

Christian

-

AuthorPosts