Forum Replies Created

-

AuthorPosts

-

yachadm

BRONZE MemberVery nice idea, but I agree with Chartz –

the overhang is far too long, and does not meet the original specs.

You have a severe problem with the tracking angle.

Shorten the overhang to the original specs, and you may have a winner.

And… where are the connector rods at the rear of the cartridge which insert into the tonearm?

Location: Jerusalem

yachadm

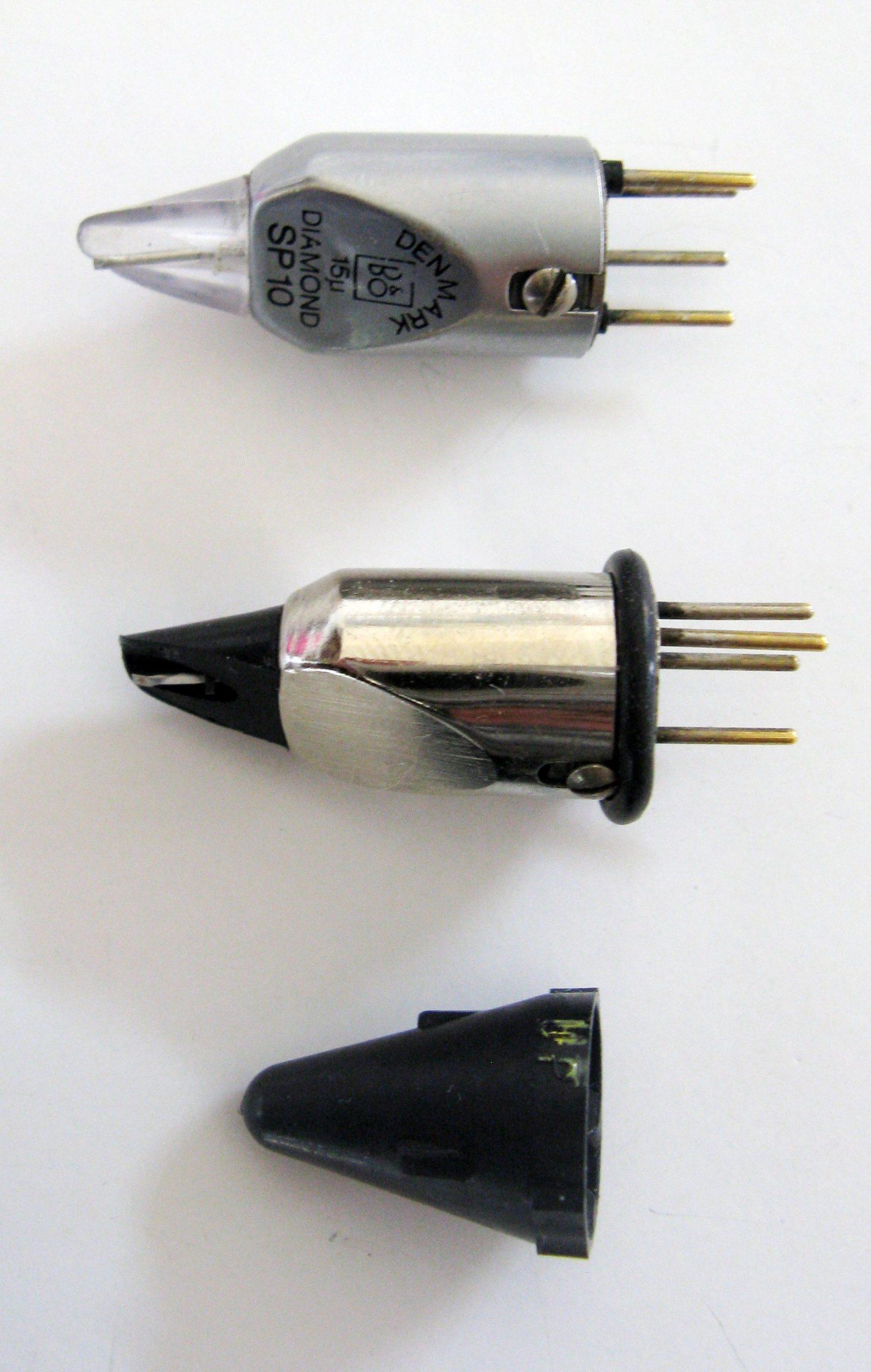

BRONZE MemberHere’s a comparison of the SP10/12/14 (top) and SP6/7/8 etc (middle).

The rubber grommet ensures an aesthetic fit on a BG120x/3000 etc tonearm.

Location: Jerusalem

yachadm

BRONZE MemberI was wondering if I would buy a later SP based Beogram, I could use my newly retipped element on another Beogram like the 3000 or 1800 just for example.

Yes, absolutely – I have done exactly that for other customers.

The early SP6/7 etc stylii fit just fine on a SP12/14 series cartridge, but with a small space, which I fill with a small rubber grommet. It looks just fine.

Location: Jerusalem

yachadm

BRONZE MemberAuric

You’re spot on.

That was exactly the cause of the same problem on one of my repairs about a year ago.

Clean the polished rod at the rear, and install new synthetic oil.

Change the Servo motor belt, for a new flexible type – ID 35-36mm , 1mm square is perfect.

Realign the worm screw to be parallel to the polished rod, and secure it using the bolts behind the servo pulley.

Menahem Yachad

CondorAudio

Location: Jerusalem

yachadm

BRONZE MemberAnother question; are the SP 6/7-8/9-10-12-14 interchangeable between various SP based Beograms?

The stylii themselves are Generally, yes.

Nude contact line elliptical stylus, and I was wondering if this can be used on any other later SP based Beograms.

Short answer – generally yes.

But a Contact Line is NOT an Elliptical.

You have EITHER a Contact Line, OR an Elliptical.

Location: Jerusalem

yachadm

BRONZE MemberI have been buying belts (and other parts) from Martin Olsen (Dillen) for over 20 years.

One BeoCord which I still have, had its belts replaced in 2003. The machine still functions perfectly.

I can’t forecast what the belts would be like in another 20 years, but so far, I’m satisfied with almost 20 years belt-life confirmed on this machine.

I do know that as long as the machine is used every now and then, causing the belts to expand and contract, that reduces the chances of “gooing”.

The other bonus is that Martin’s belts have the correct tension, which does not cause destruction of the fragile sintered brass motor bearings in all these vintage B&O machines. Other belts sold on “e-ay” have a nasty reputation for destroying motors – very expensive repair, if at all possible.

Location: Jerusalem

yachadm

BRONZE MemberHere is a short film of the transport’s behavior during FF and RW

Location: Jerusalem

yachadm

BRONZE MemberHere’s a solution from another enterprising small workshop in Denmark.

RIAA amplifiers to fit different BeoGram models:

https://claudius-elektronik.dk/designs-og-l-sninger.html

Location: Jerusalem

yachadm

BRONZE MemberI’d like to know how they polished the BG4000c Aluminum Platter and Keyboard

Menahem

Location: Jerusalem

yachadm

BRONZE MemberMark thanks

But my question is How to DO it, not “How NOT to do it”.

Obviously Direct heat would damage the plastic ribs.

Mentioned here that a platter arrived separated after heavy handling in transit.

https://beolover.blogspot.com/2018/03/beogram-4000-glueing-delaminated-platter.html

So, it IS possible to separate them, but that method I would not try.

Perhaps a pot of boiling water, and soaking the platter inside?

Location: Jerusalem

yachadm

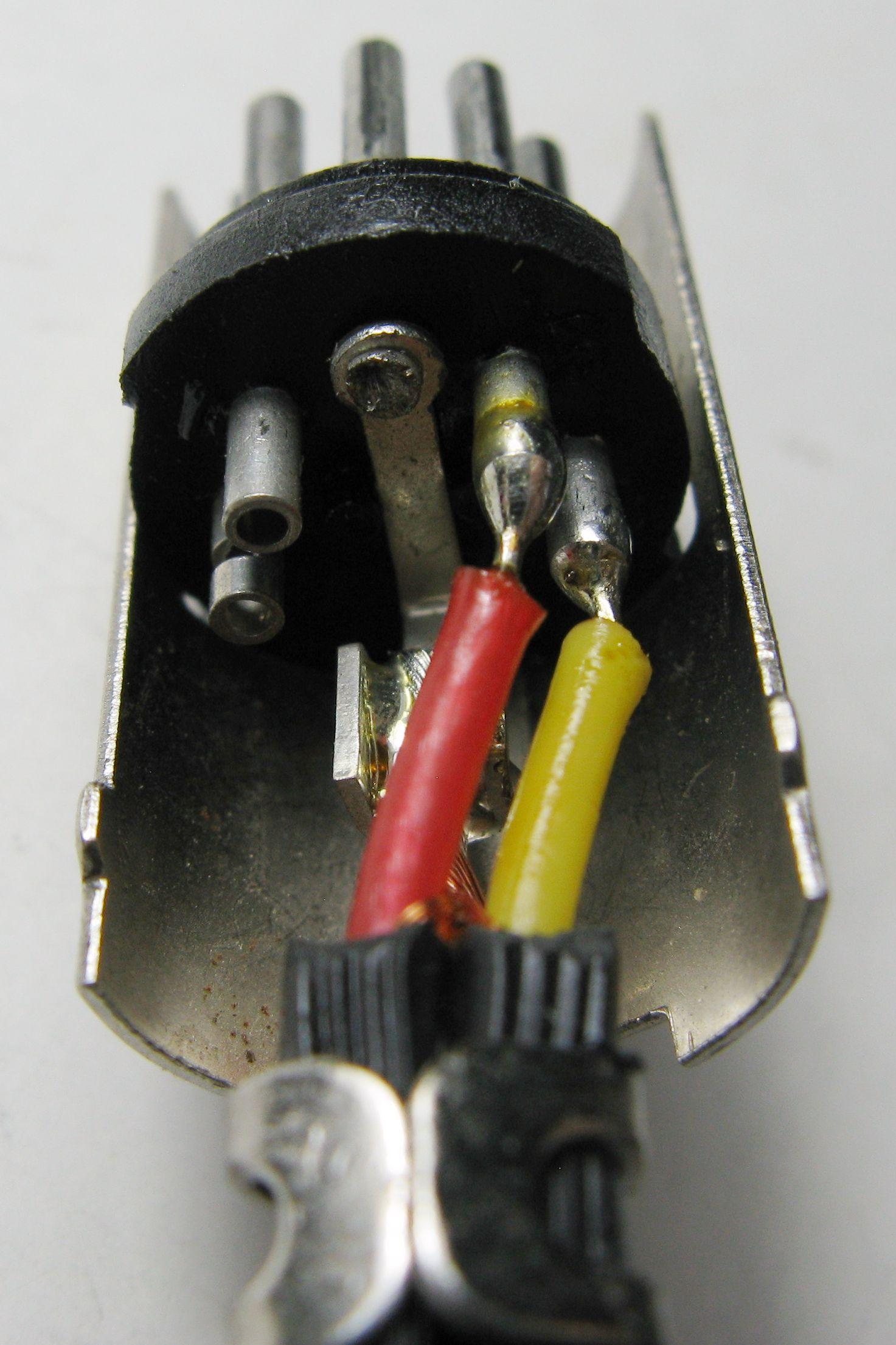

BRONZE MemberCheck this photo

.

Looking inside the 5-pin DIN Male plug.

Center pin – Signal Ground

Pin at 2 o’clock – Signal Right

Pin at 4 o’clock – Signal Left

Menahem Yachad

Jerusalem

Location: Jerusalem

-

AuthorPosts

.

.