Forum Replies Created

-

AuthorPosts

-

pilatomic

SILVER MemberHello,

I apologize for having neglected this thread for the last few weeks. Although I was very quiet here, things were still happening ( albeit a bit slowly ) to run a second batch of kits.

I have received this week all the parts for a new batch of PCB. I still need to program and test these PCB, but I should be able to resume shipments starting from the next week !

Pricing stays at 60€ + shipping.

Just like the previous batch, contact me in PM to order one.

Location: France

My B&O Icons:

pilatomic

SILVER MemberHi lumbergh,

Sorry for the delayed answer, I a bit behind on my mails !

Sadly I’ve sold the latest kit of the first batch, but I’m currently planning to run another batch ( components availability is a bit hit or miss right now, and prices have yet to come down ).

I’ll announce here when the next batch is ready, stay tuned !

Location: France

My B&O Icons:

pilatomic

SILVER MemberHello Yann,

I’m afraid I am not familiar enough with these circuits to offer any meaningful clue on this issue.

I can just wish you to find someone with experience on those.

Best regards

Location: France

My B&O Icons:

pilatomic

SILVER MemberHello YannChris,

I’m a bit late to the party, but after a close inspection of your 1st photo, the bottom right resistor looks suspicious to me.

According to the documentation I have for the CDM 2 ( not for this exact board ), this could be R3108, a 4.7 ohm resistor responsible for filtering part of the +5V rail.

Can you get a closer look ?

Location: France

My B&O Icons:

pilatomic

SILVER MemberHello 69er,

I have assembled a couple more kits this weekend, those are available right now, still for 60€ / piece + shipping.

Please send me a PM with your address so we can arrange the payment and shipping.

Best regards

Location: France

My B&O Icons:

pilatomic

SILVER MemberHi Rudi,

Thank you for chiming in on this thread, and hats off for the original design ! I cannot imagine trying to fit that design is such a tight space 30 years ago !

I do understand that the original issue is a degradation of conduction with the ribbon, but as you stated, the complexity of obtaining a new ribbon and the operations required to bond it properly both to the PCB and to the LCD do not make this path viable.

Also the issue is compounded in many cases by the old ribbon cracking, and the LCD breaking free from the aluminum body due to its adhesive foam failing.

However, this does not seem to be the same issue on the Beo4 screen ( cf Guy’s previous message ), as no ribbon is involved on the Beo4, and replacing the zebra strip does not seem to fix the issue. Any idea what might be happening there ?

Best regards !

Location: France

My B&O Icons:

pilatomic

SILVER MemberOne full line of pixel missing suggests that indeed one electrical connection to the driver chip was lost, so ordinarily I would jump to the conclusion that the zebra strip is responsible for this, but Guy’s experience tells another story !

I am not aware of other common failure modes for this, although damage to the conductive track on the LCD could explain this behavior.

Now I’m getting really curious about this issue ! If you still have one (or more) damaged screen in your possession, and are willing to ship them to France, please PM me.

Location: France

My B&O Icons:

pilatomic

SILVER MemberHi Pilatomic, In my experience Beo4 screens do fail, but replacement is actually quite straightforward because connection to the PCB is via a little rubber ‘contact strip’ – a replacement strip is provided with the new screen.

Can you describe me how the screen fails ?

I think there is a good chance the screen are actually fine, just not making proper contact.The “contact strip” is called a zebra strip, it is commonly used for connecting LCD displays, but the drawback is you now have to keep it under mechanical pressure to ensure a proper electrical connection.

Failure to maintain the correct mechanical pressure is, as far as I know, the most common failure mode for those kind of displays.

Location: France

My B&O Icons:

pilatomic

SILVER MemberBonjour,

Si vous n’avez pas pu obtenir cette information ailleurs, je possède un meuble similaire, les tubes mesurent 15 mm de large par 25 mm.Location: France

My B&O Icons:

pilatomic

SILVER MemberThank you @YannChris for trusting me with your remote !

Sorry @david656 I didnt see your message earlier. I have yet to own any Beo4, is it subject to the same screen failures ?

Location: France

My B&O Icons:

pilatomic

SILVER Member@Pilatomic: thnx! This sounds really helpful. One question. Is it correct that the +/-35v at the C5 capacitor is always available? So also when the BeoLab 6000 is in stand-by/Red LED on?

The voltage across C35 will only be present when the LB6000 is turned on. ( Relay RL1 closed )

If you need a permanent voltage, you can find it across C31. It will probably have quite a lot of ripple, but the DC/DC converter should be able to deliver a stable output voltage nonetheless.Location: France

My B&O Icons:

pilatomic

SILVER MemberHi KolfMAKER,

I checked out the schematic you posted, and at first the circuit around the 5V point was not make any sense. I believe it is rather a 34.5V point ! ( A2 and A5 are definitely 8.6V and -8.6V according to this schematic )

IMHO, your best option is to use the +35V present across the C5 capacitor ( it is the leftmost large red circle on the drawing ). You can find the negative side ( 0V ) by identifying the large white band on the capacitor.

Then use an isolated DC/DC to get a clean isolated 5V (you don’t technically need an isolated supply, but it makes things a lot easier to avoid noise and some issues with different reference potentials).

I would recommend the TMR 4-4811WI, as it accepts inputs from 18 to 75V.

Last advice : You might want to find a bluetooth module with a good quality audio output. Many of them are sub par, and would probably sound like a disappointment on those speakers.

Best luck with your project !

Location: France

My B&O Icons:

pilatomic

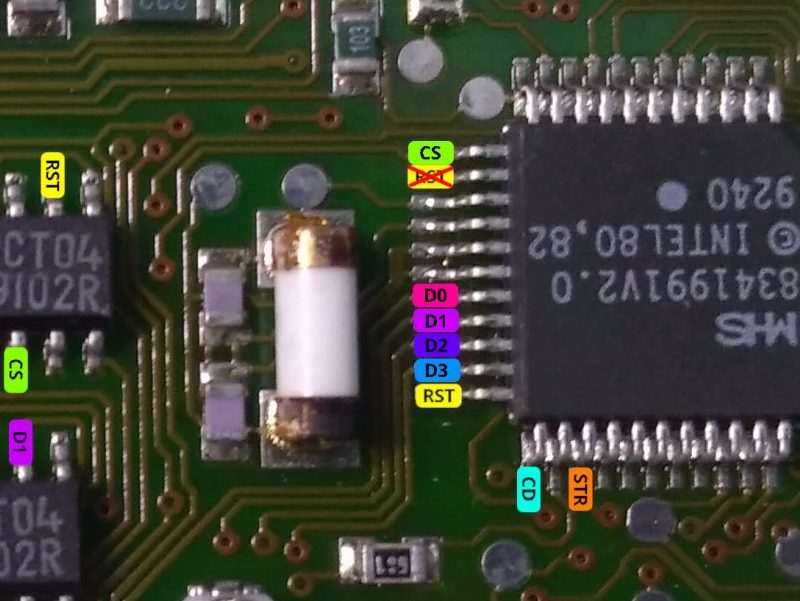

SILVER MemberERRATUM : Bad wiring diagram in installation manual.

There was a mistake in the section 6, about the signals connections on the MHS CPU. The RST pin was incorrectly placed.

I apologize for this mistake !

If you ran a jumper wire to the wrong pin in an attempt to make the connection according to this diagram, it does not seem to cause any issue, but it is better to remove it.

The installation manual v1.1 contains the correct diagram.

Location: France

My B&O Icons:

-

AuthorPosts