Forum Replies Created

-

AuthorPosts

-

On a turntable that old, if its motor is not turning then the grease has hardened and bearings dried out. You never posted what is actually not working.

That is simply a chassis ground.

I’m not sure which wire you believe is totally missing. If you are referring to the Red/Black twisted pair in the first picture that appears unconnected, that is normal for 1000’s not equipped with a phono PC board. Yours simply has the jumper board that directly connects the tonearm cable to the output cables which then go into a preamp’s phono inputs. What is actually not working?

That capacitor is not your problem. You say you don’t have voltage at the 01C1 5V regulator. Does this mean that you measure 0V at both its input and output? If that is the case can you check the continuity of the F1 fuse? If it is good that means you have no output out of the diode bridge and its supporting capacitors. That’s where I would focus.

Your problem is not simply the knob. That amount of damage would have destroyed the arm bearing so that even if you could get the knob in the arm would damage records.

Thanks for the pictures. I’m afraid that level of tonearm bearing damage is not repairable.. You will need to replace the tonearm to restore the turntable. Many of these have bad motors so you may find one for parts that you can use its tonearm.

Dieter, I’m not following your description. Assuming you have a 1200, the rear counterweight when screwed fully in is factory to the tracking force as there was no user adjustment on that model. Perhaps you can post a picture.

Looks like someone did a nice hack job. Here is a link to a picture with all the wires on the correct pads: https://archivedforum2.beoworld.org/cfs-filesystemfile.ashx/__key/CommunityServer.Components.PostAttachments/00.00.12.47.75/bg8000_5F00_din_5F00_pcb_5F00_01.jpg

You need to connect the black lead to a chassis ground which is available many places. For example, the negative terminal of C24 or C27.

First I would double check that All of the replaced capacitors are in the correct polarity. After plugging in, you should see a red dot in the display. If you are not getting that I would check that you have 5VDC at pin P6-1 which is powering the CPU, then work backwards to the Zener and regulator.

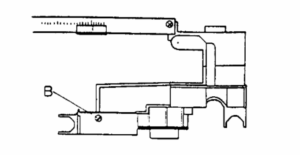

It appears that the arm is being blocked from moving inward once it lowers. I would check with it open and lowering the arm to the right of the platter. It should move freely the 1/2 inch to the sensor arm. Sometimes the optical shutter is sticking or has be rotated so it hits its stop prematurely.

As Dillen replied 0TRi is mounted on a metal block heat sink screwed to the bottom and connected to the board on the solder-side. You can easily measure the voltage across it while pressing the start button to see whether it is passing 22V which is shorthand for “22 volts”. This is my last message to you on this as your combative responses and insistence that you did nothing to cause this non-operation are preventing a successful diagnosis and my help.

There is no harm in adding that jumper as it is simply connecting two ground points together. These boards being single-sided used jumpers all over the place to connect grounds together.

Paul, yes the LED you posted in the second picture is an OP160 IR LED; however, I was addressing the Beolover picture that you posted earlier and the visibly lit areas. This LED however, is not the source of your problem. If you are not getting any response from pressing Start then you are likely not getting 1TR1 turning on 0TR1 so that 22v is sent to activate the arm motor circuit. If you are looking for a troubleshooting flowchart, you can upgrade your membership to Silver and get access to the 4002 service manual which has that chart.

Paul, we appear to have a language issue as I don’t understand what you mean by “plugging in the tray into a 20-Volt outlet”. There are no IR diodes in this model as the end fixed arm light logo and the tonearm movement optical shutter all use incandescent bulbs.

I previously asked you to perform specific tests which you have not reported on and I need this info to assist further. If after plugging into the wall and pressing Start nothing happens, then you may have blown a fuse which is located in the back right hand corner in a black plastic box.

You have done things to the table that are totally unnecessary such as removing the control panel and its PC board and the result can be breaking something. It is also easy to misalign the board connectors and cause problems. How much experience do you have working on electronics and reading and understanding circuit diagrams?

Paul, in your first post you stated that you just purchased this turntable and it worked until you began taking it apart and lubricating it. Can you please confirm the details as to what worked on it and how you reached that connclusion.

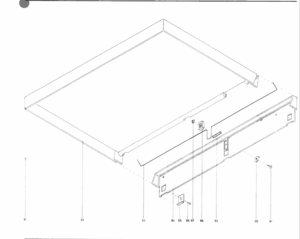

NEXT, as I have stated earlier, no lights should be coming on when you plug the turntable in. On that model nothing should happen until you press the Start button. If you Press and Hold the Start button the arm should move to the center of the table and then reverse and come back. During that process the platter speed will change from 33 to 45. Please put all the belts and platters on and perform this test and report back the specifics of how it behaves.

NEXT put on a record and Press and Release the start button. Report if and where to the arm moves, does the turntable spin and at which speed, and whether the arm lowers.

With the above information, we can begin giving you meaningful directions.

Paul, not sure why you are ignoring my troubleshooting questions. You’ve come here for help and collectively we have decades of experience; however, from what you have posted you are not approaching this systematically. We are trying to guide you by establishing a functional baseline – thus the questions.

Per the manual, there is a relay that switches between speeds based upon either the control panel switch or an optical pulse generated by the tonearm carriage position.

I’d start with replacing C17 as that is too much ripple for a 13vDC line. Are the diodes mounted above the the board? If not then that heat is not normal. How much power is the who player drawing when playing? It should be no more that 20-25W.

-

AuthorPosts