Forum Replies Created

-

AuthorPosts

-

Glitch

BRONZE MemberAdmittedly, I’m not in the target demographic for this product. However, I wonder how many potential customers are out there that would spend that kind of money for “orange and birch”. Is this combination a “latest trend”?

I fully understand the aesthetic appeal of the 72-22. Interesting wood veneers are timeless, as are natural metal finishes.

I could see B&O building this as a bespoke product, but wonder how profitable it will be even as a low volume special edition. Does B&O publish sales numbers on products like this (i.e. 72-22, 4000c, etc.)?

Glitch

Glitch

BRONZE MemberI agree with much of what you wrote. Especially the part about B&O leaning on reference designs for the core functionality. My comments were referring to “value” of the modifications more than “performance potential”.

For example, lets say one starts with a 200€ S45 and installed 150€ of fancy capacitors in it. It is still only a 200€ speaker to most people. It might be worth a bit more to someone that isn’t able (or willing) to do the modifications themselves. It might be worth a lot less to an enthusiast that doesn’t trust the quality somebody else’s work or wants originality. It is most likely worth more than 350€ to the person that made the modifications because it is exactly what they want.

Many people would rather spend the same 350€ on something higher up the product line, say a S75, than take the risk on installing expensive parts without a guarantee that they will like the results. There is less risk with buying the S75 since it could be sold for what one paid for it if they don’t like the performance.

Installing relatively inexpensive electrolytic caps makes more sense to me. A kit can be purchased for less than 18€. One could assemble their own “kit” for less if they valued their money more than their time. The expensive caps could always be tried if one liked the direction of progress (or the speaker sold for 200€ at a small loss).

Glitch

Glitch

BRONZE MemberI did find a technician who was able to fix the problem causing my speaker amp to overheat.

That’s good news. IMHO, Pentas are worth the effort to keep running.

I expect that someone will provide good suggestions on what to try to repair the CD player. “Recycling” the player should be a very last resort. Any B&O gear has value, especially if it is in nice cosmetic condition.

Glitch

Glitch

BRONZE MemberActually, refoaming surrounds is not that difficult. The smaller the speakers the more easy it is.

I used to think the same thing until I started measuring the performance of the drivers that I restored. It is pretty easy to make the drivers “look” better or sound better than with totally rotten foam. Matching the T/S parameters of a original/new driver or building a perfectly matched set is a different matter. I guess it all depends on what one’s goals and expectations are…

Glitch

Glitch

BRONZE MemberI agree that a vintage speaker’s value is best preserved by keeping it stock. However, I don’t quite understand the logic in some of the statements above.

Why is it any different to install boutique foil capacitors than to swap the tweeter (per the OP’s question)? Either modification will (arguably) change the voicing of the speaker from the original.

Glitch

Glitch

BRONZE MemberPreviously I haven’t give it much thought but upon measuring I found that the BeoMaster 7000 measures 40° celcius at the heat fins on the back of the amplifier. Granted it is warmer today at measurement.

Just to be clear, you are talking about the temperature when the Beomaster is in full standby, or essentially as “off” as it can be?

Do you have the ability to measure the current draw from the outlet? That would be more definitive for any comparisons than trying to measure temperature.

Glitch

Glitch

BRONZE MemberThe problem _could_ be a poor connection between the turntable and the amplifier, but why would it _always_ push sound through the LH channel at needle drop & needle rise only?

It is a long shot, but if there is a crack or loose connection then the tracking force (or tone arm angle change) might be enough to open it up.

Another possible test is to measure the resistance between the pins of each channel at the connector on the rear of the turntable. Each should start close to 0.0 ohms and jump to 740 ohms when the stylus drops and the muting relay opens. The reading should switch back to zero when you raise the stylus.

Glitch

Glitch

BRONZE MemberThe encoder is a Calt PD30-8G1000BST5. I believe that you can buy it on Amazon (mine was purchased elsewhere). The brass adapter to mount the encoder wheel on the motor or capstan shaft and the magnetic mounts for the encoder pickup where both custom fabricated.

Glitch

Glitch

BRONZE MemberI’m so glad you discovered a way around using a Dremel. That will same a bunch of time and effort.

It also avoids creating metal dust around the motor magnet. This kind of contamination is very difficult to remove.

Can you go into detail of what you did for your performance measurements?

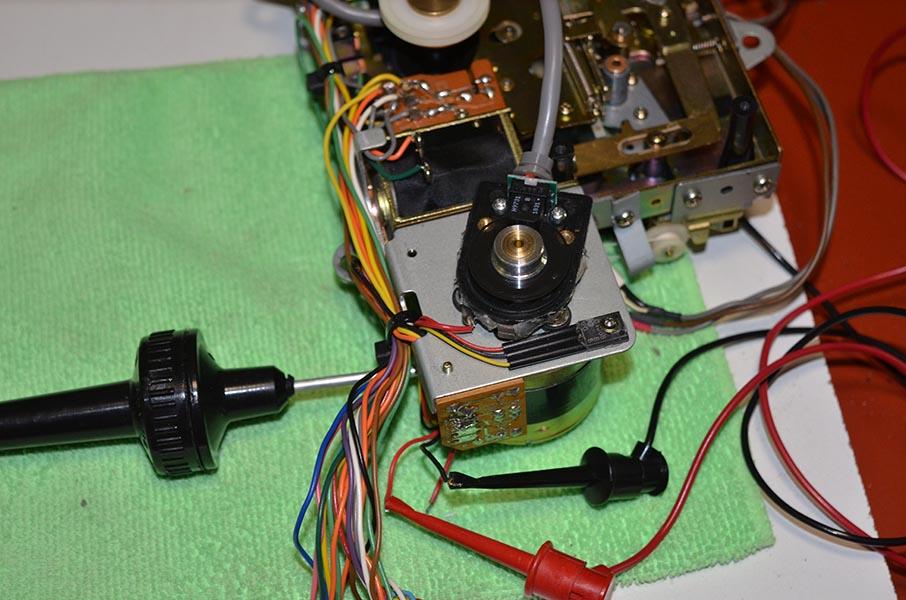

I tried many different things. I did the obvious stuff like measuring motor current. I also added an encoder to measure motor speed. The brass encoder adapter is also machined to attach to the capstan shaft. For the motor vibration, the simplest setup was a mechanics stethoscope coupled to a microphone.

The data from the various sensors is logged and post-processed offline. I tried to run a variety of experiments, like comparing the “drop of oil” method against the “vacuum oiling” method. Unfortunately, my number of samples is statistically insignificant so it is hard to make truly conclusive statements without caveats.

I can go into a lot more detail, but it would be helpful if you had specific questions. It is hard to provide the appropriate level of detail without understanding someone’s interests and technical background.

Glitch

Glitch

BRONZE MemberI ended up buying a couple of dead Beocord 8000’s. I want to experiment on something appropriate before tearing into my beloved Beocord 9000. I learned quite a bit in the process. I won’t go into the whole story since there are a lot of details. However, I thought that people might be interested in a few highlights…

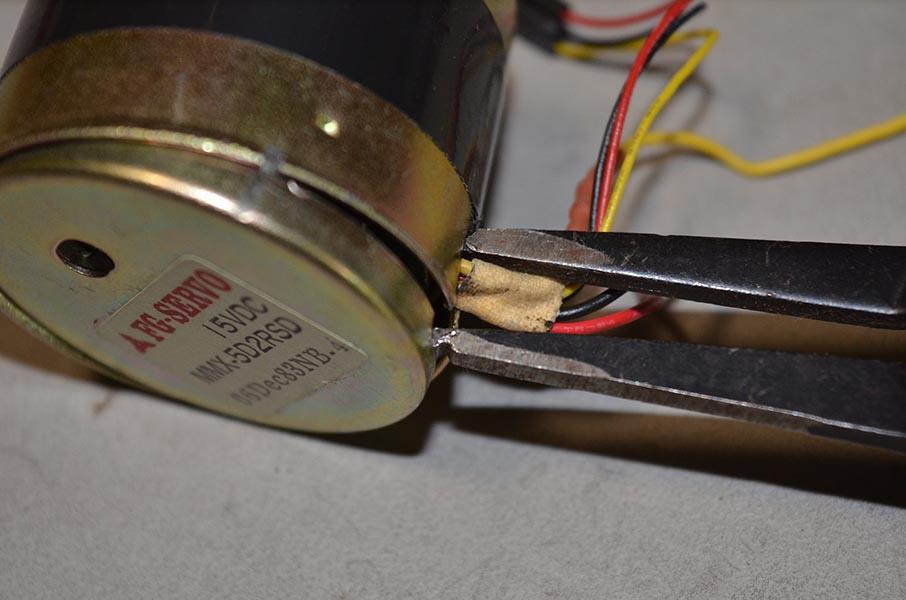

1) I found it is not necessary to do any Dremeling to get the motor lid off. I used a pair of snap ring expansion pliers to pop off the lid. The lid can be pressed back on without leaving any indication that work was done.

2) My motors were the same as in sonavor’s pictures. The motors themselves were surprisingly easy to take apart. The only things to be careful with are to not break the plastic clips holding the motor together and to pay attention to the white plastic spacer on the armature shaft. The motor tachometer is nothing like a Beogram 400x motor. The wire arrangement is such that one would have to try hard to break the thin wires.

3) The motor bearings are not like the Beogram bearings. They are different sizes. The bearing retention is similar. Making a tool for crimping the bearing retainer is easier than what is shown on the Beolover site. A simple piece of wooden dowel will work.

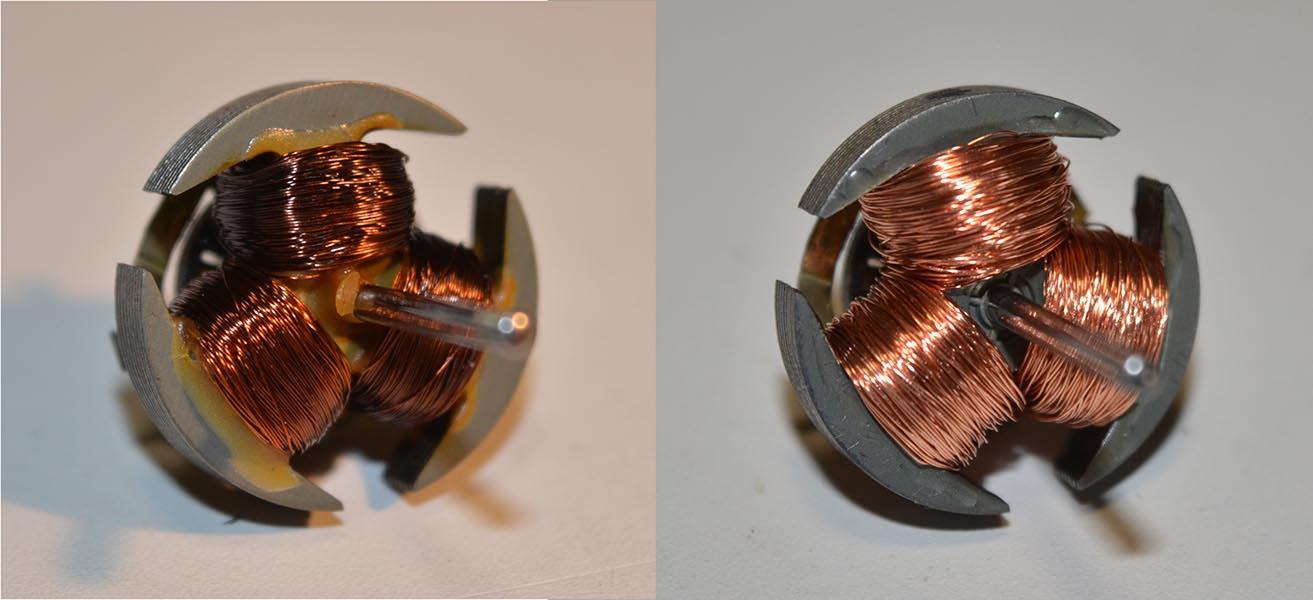

4) The windings in one of the motors were burnt up. Rewinding the armature is possible.

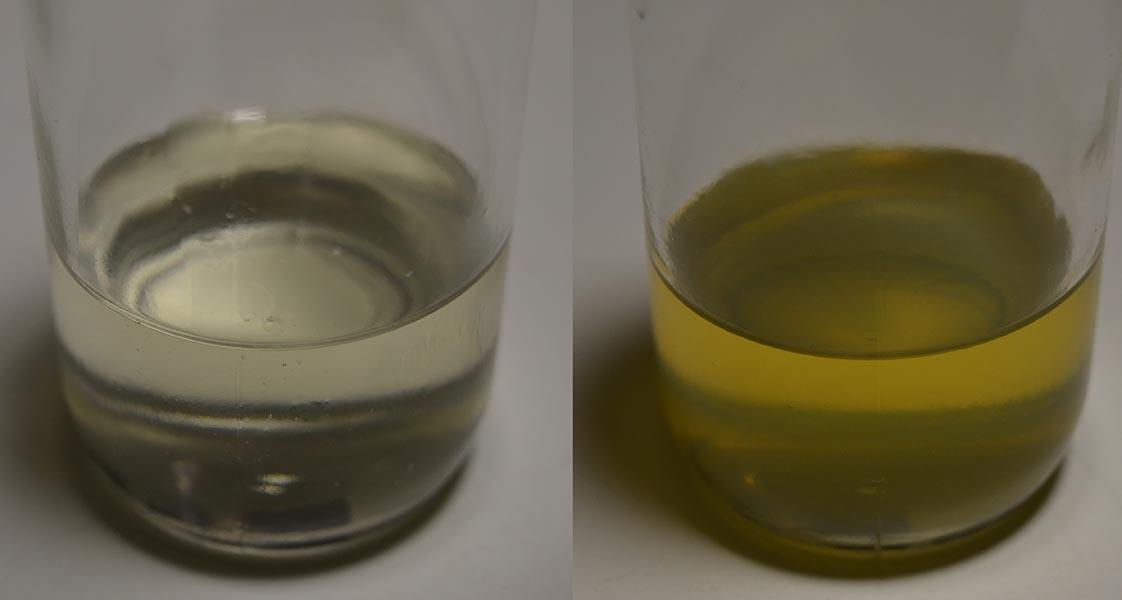

5) Bearing cleaning in preparation for vacuum oiling isn’t critical. I tried to thoroughly clean one set of bearings and skipped the prep work on another. Either way, the before/after of the oil bath was the same. I attribute the change of color to the old amber colored oil coming out of the bearings.

6) I ran a some experiments to refine the process for vacuum oiling. This is beyond what I would want to describe in this post. One thing that I will mention is that I’m skeptical about being able to a good job at vacuum oiling without a proper vacuum pump.

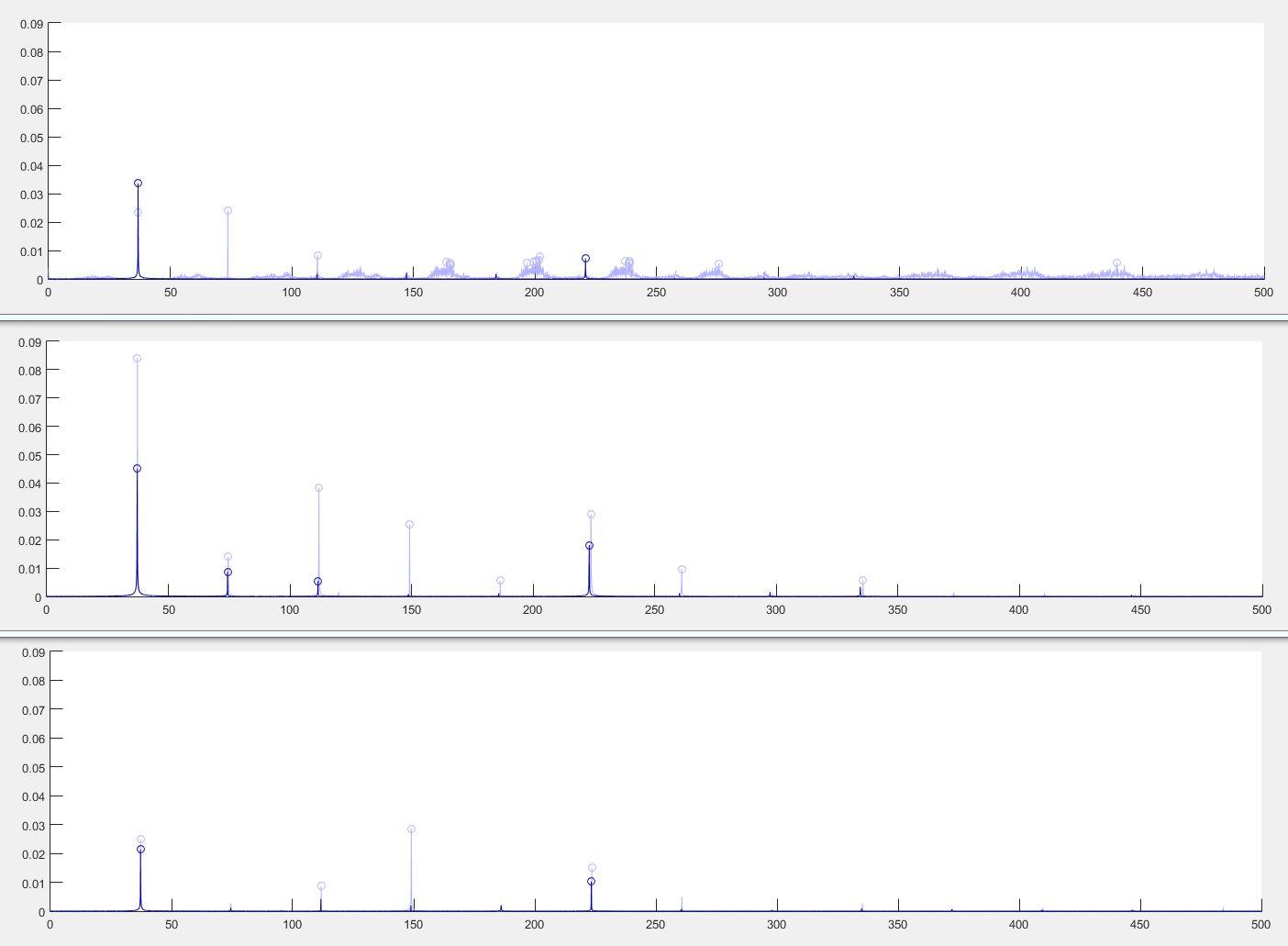

7) I measured the performance of the motors using several methods. The plots above are FFT’s of the motor vibration. The motor in the first plot was obviously noisy. The motor in the second plot was the one with the burnt armature, but was quiet. The third plot was from my BC9000 which started in very good condition. The light blue is before, the dark blue is after vacuum oiling. All three motors are now performing more similarly. I have a more data, but I assume that I’m the only one that geeks out on data analysis.

8) I also vacuum oiled other sintered bearings from the tape transport. I weighed all the bearings before and after to get a feel for how much oil that I added to the bearings. There were things that I found very interesting in the data analysis, but the bottom line is that a well done vacuum oiling is worth the effort. …but you already knew that!

I was able to repair both of the broken Beocord 8000’s and get them 100% working. I did the normal stuff like replace a few bad caps, new belts, rubber tires, LED display rebuild, reflowed solder joints, etc. Now the hard part… figuring out what to do with extra tape players ;-).

Glitch

Glitch

BRONZE MemberThat sounds like a good plan. Dillen is correct when he says that the odor may never fully go away.

I see the telltale rings that look like the speakers were used as a plant stand. Moisture from watering the plants may be the original cause of the mold. It appears that there was enough moisture for the cabinet seams to separate. There is some good info on audiokarma about how to handle this particular repair if you don’t get suitable suggestions here. Search for GD70 (Glenn) as he usually posts good descriptions/pictures of the repairs.

After you have the speakers repaired put them on tilted speaker stands. I don’t know if the tilt actually does anything for the sound, but it does keep your partner from putting plants on the speakers :-).

Glitch

Glitch

BRONZE MemberYou might be able to salvage the damping material by removing it and placing it in direct sunlight. The UV rays in the sunshine can kill the mold spores and the fresh air will dilute the odor. The same goes for any other speaker parts that might be damaged by a liquid based fungicide. Of course, the effectiveness will depend on the species of mold and how deep the UV rays can penetrate.

2) To take out drivers + crossover, and scrap the rest + buy another set of S45-2.

This seems a bit extreme. It is certainly worth trying the least invasive methods and work your way up to a total loss ;-).

Glitch

Glitch

BRONZE MemberPerhaps Keith can modify the quote script to add a “stop quote” by default? That might be easier than trying to train everyone to add it on their own.

Glitch

Glitch

BRONZE MemberI have just had my ~1989 MMC4 re-worked / re-furbished

Can you provide more details about this? Probably the most significant info is how was your cartridge was tested it before was returned.

All of the measurements of you cartridge appear to be correct. Are you sure that it is not something simple like not fully seating the cable between the turntable and the receiver?

Is the cartridge deflecting the right amount when you place it on the record? Have you measured the tracking force?

You may also want to look for other problem sources like cold solder joints and cracked traces.

Above is a picture of a cracked trace that was causing an bad connection. The crack was at the edge of the solder flux and was impossible to see until I removed the flux and cleaned the area with a scratch pen. Something like this could result in the symptoms that you are describing.

Glitch

Glitch

BRONZE MemberWhat kind of new material can I use instead? And what amount to use? Or should I just ignore?

If you want the speakers to sound exactly like stock, your best bet is to replace the material with what was in there before. If that is not available, consider something like Acousta-Stuf Polyfill.

How much to add depends on what material that you use. For the same material, go by weight (unless there are unusual circumstances like the stuffing being wet). If you change materials, then you will need to go by either rule of thumb or by listening and adding and removing material. Check out some of the DIY speaker forums as the people there are enthusiastic about experimenting with things like this.

You could always just ignore it. However, if it is mold, it might spread to more than just the damping material. Also, keep in mind that the speakers will not sound right if you simply remove the material.

The underlying question is why does the material smell bad? This should be understood and addressed.

Glitch

Glitch

BRONZE MemberIt’s not that I don’t like it, but like I stated above, I feel like it could be improved over, also how can I check wherever the ferrofluid is still good?

I don’t know if the S45’s use ferrofluid (FF) in the tweeters. Hopefully someone else can comment on this.

The only way I know of checking if the FF has gone bad is to take the driver apart. I would only do this if I knew for sure that the driver had FF and the driver was sounding dull and lifeless. The FF should be a clear brown viscous oil. The viscosity can vary depending on what the manufacturer used. Bad FF can be muddy or even crusty looking.

I only have one pair of B&O speakers left in my collection. They are Penta2’s. Originally, I thought that they were somewhat dull and lacking impact compared to the other speakers that I own. However, the midrange seemed to do something special. I ended up making a bunch of modifications including changing the tweeter FF to one that was less viscous and modifying the crossovers to remove the “tilted down” signature. I like them enough now that I can’t imagine re-homing them.

If you can describe what you find lacking with your S45’s it will be easier for people to make suggestions for modifications.

Glitch

Glitch

BRONZE MemberI’m not averse to modding speakers. However, you might want to consider restoring the speakers to original condition before trying modifications. Verify that the capacitors in the crossover are good, the surrounds are in good condition, the cabinet is properly sealed, etc. The tweeters might have ferrofluid that has gone bad.

The S45’s are generally regarded as a nicely voiced speaker. If you don’t like the sound of a well restored speaker, by all means hack away. But keep in mind that it is pretty hard to improve upon a well designed speaker.

What specifically do you not like about the speakers?

Glitch

Glitch

BRONZE MemberA more conservative approach would be to test the resistance of the relay contacts as a first step. Look for another source of the problem, like a dirty potentiometer, if the contacts test OK.

Cleaning the contacts as part of the debugging process seems counterproductive. The contact plating on most relays is very delicate and improper cleaning will destroy it. Once the plating is damaged the relay will be much more susceptible to contact failure. Put another way, improper cleaning may provide a short term improvement, but in the long term, the relay will fail. Attempting to clean a good relay simply adds the possibility of damaging it.

IMHO, improper cleaning is using any method that damages the plating or leaves a residue. The proper cleaning method depends on the contact material. Abrasives will remove oxidation or arcing marks, but also remove plating. Contact cleaners that clean by acid (or base) can work. The tricky part isn’t getting the chemical reaction started, but getting it to stop. Contacts are designed to be clean and dry. Any cleaner that leaves a oily film is asking for trouble.

I typically don’t use anything more abrasive than a piece of smooth white paper. I’ll start with dry paper. I retest the contact resistance between steps. Next paper soaked in red Deoxit, followed by paper soaked in clean solvent (i.e. acetone), then dry paper. Next step up would be fine abrasives. However, at this point I’m just trying to get the relay working well enough to continue with other debugging while I’m waiting for its new replacement to arrive ;-).

Sorry for long winded reply. I’m a bit too passionate about this topic. 😉

Glitch

Glitch

BRONZE MemberThis is a excellent guide …But the only problem is getting the blue wall plug…

Rubber or silicone hose might work instead. Using a metal “support” threaded into the frame will improve the odds of a long term fix.

Glitch

Glitch

BRONZE MemberDo you have the broken off pieces?

-

AuthorPosts