Home › Forums › Product Discussion & Questions › BeoVox › BeoVox Penta Center Channel Concept

- This topic has 89 replies, 9 voices, and was last updated 6 months, 2 weeks ago by

Evan.

-

AuthorPosts

-

21 May 2024 at 18:06 #55816

Evan

GOLD MemberThe woofer baskets are horribly e-coated and are a nasty greenish-brown. I might mask the speaker and spray them black so they don’t look so sickly when exposed!

Location: San Francisco

23 May 2024 at 21:58 #55915Evan

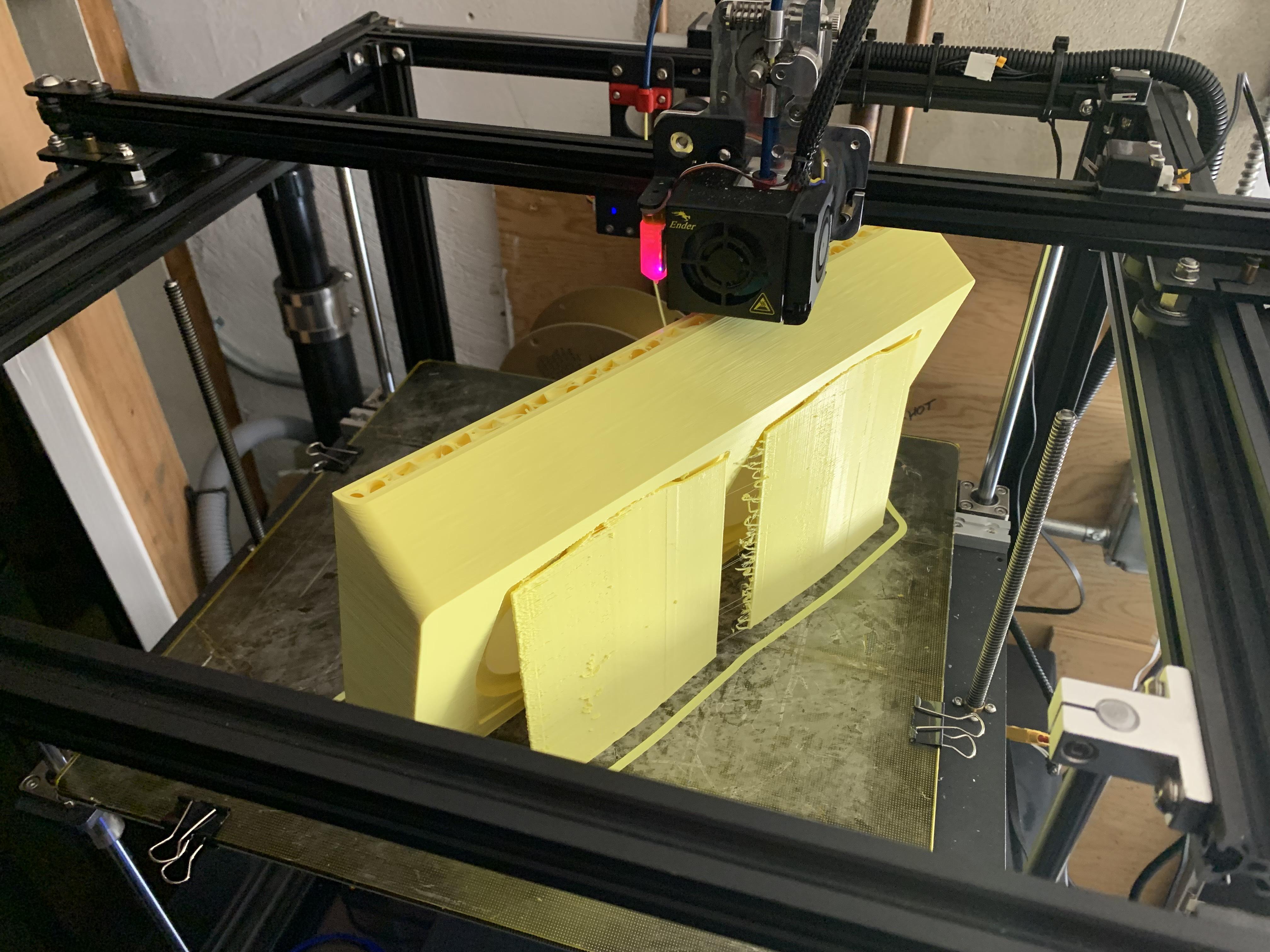

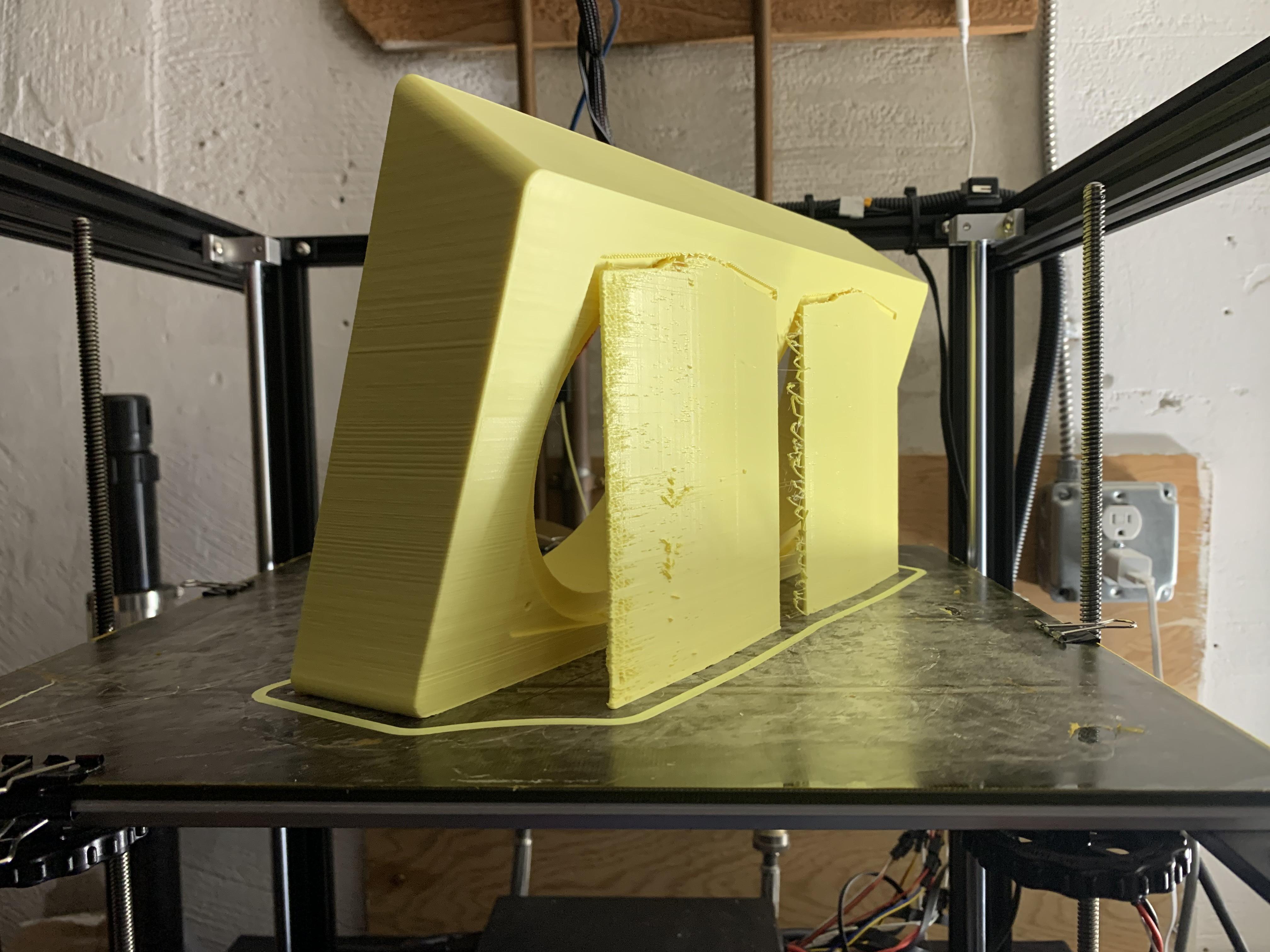

GOLD MemberOk guys – getting caught up. Parents are visiting me soon so I’ve been frantically putting the house together and not spending as much time on this but there are some nice chunks of progress.

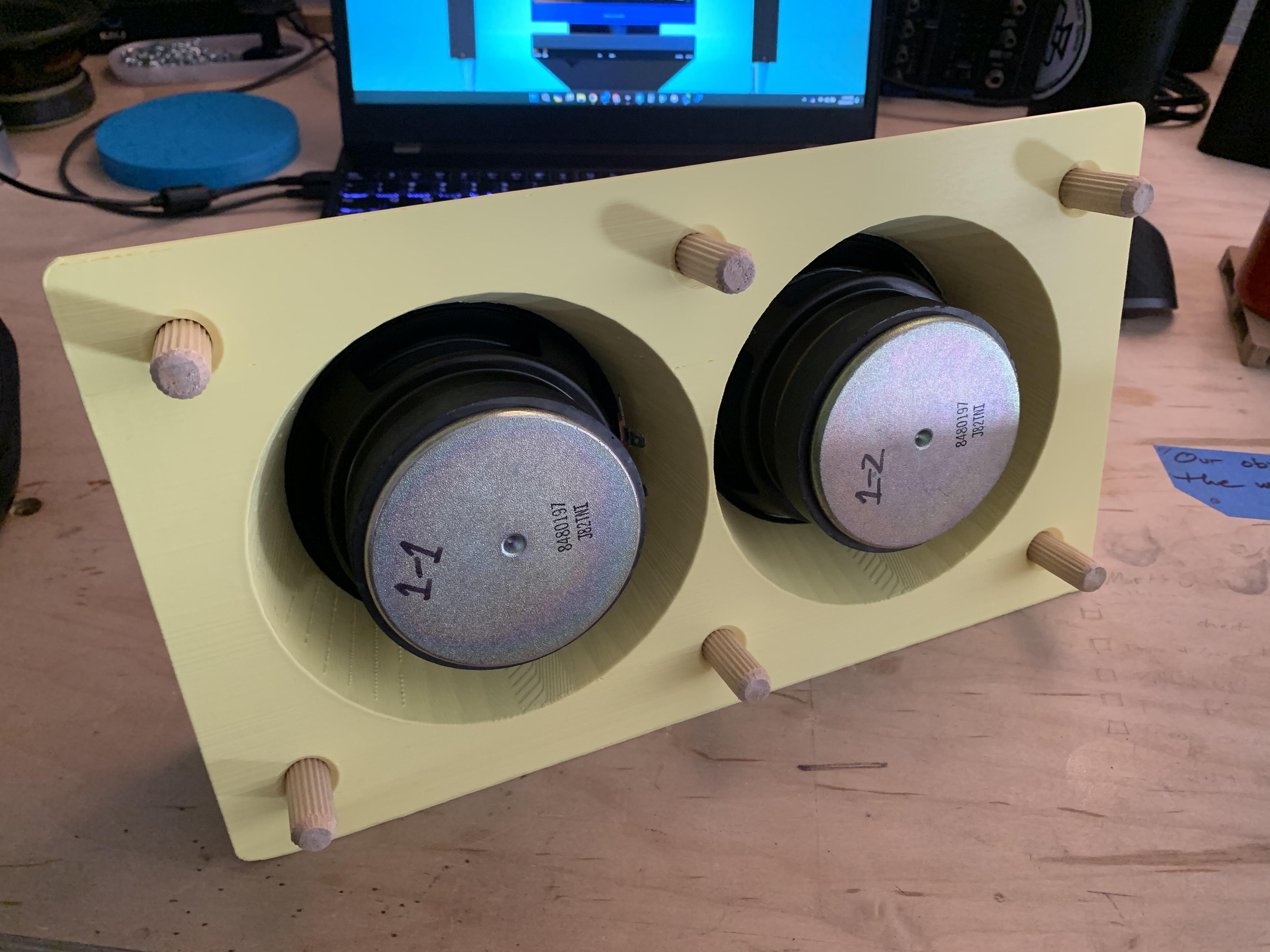

Here is what I’m calling the woofer baffle, being printed for the first time. This is a test for fitment (speakers and fasteners etc) but also a test for the color! Very much a pastel yellow compared to normal, opaque yellow PLA but it should look very nice in situ once my partner and I get the room all put together.

The print was good overall, but I did change some geometry to try and improve the quality. There was one corner that lifted slightly and the banding is quite serious so this part will not get used in the end I think.

Also, since I just changed the nozzle from 0.4mm to 1.0mm, there were some bone-headed slicer oversights so now those are updated as well.

Final print settings are going to be 0.3mm layer height, 18% gyroid infill and 3mm shell. Final printed part should be ~920g. Nearly an entire spool!

Location: San Francisco

23 May 2024 at 22:00 #55916Evan

GOLD Member23 May 2024 at 22:03 #55917Evan

GOLD MemberThe tweemid module will be removeable since it may need to be disassembled in the future for servicing. The woofer baffles however will be permanently bonded (epoxied likely) to a wood baffle so I incorporated 1/2″ dowels into the design. in order to locate the parts during assembly later on.

Location: San Francisco

23 May 2024 at 22:07 #55919Evan

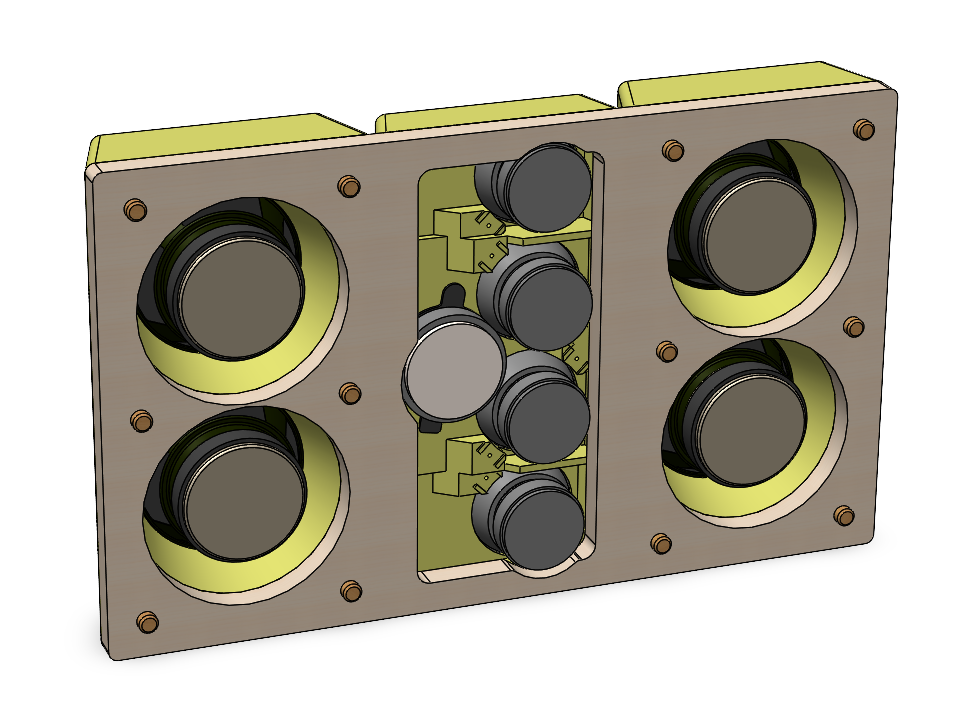

GOLD MemberHere is the baffle sub-assembly design so far. Still need to complete the design of the tweemid baffle and design in the enclosure for the midranges.

Location: San Francisco

29 May 2024 at 00:17 #56048Evan

GOLD MemberHey everyone! Busy weekend here but managed to hustle the printer along to make some progress. 80 hours later, I have two very sturdy woofer baffles ready. These parts need a little bit of clean up but overall they are in great shape.

Looking forward to getting some of this assembled!

Location: San Francisco

15 August 2024 at 09:10 #58295Die_Bogener

BRONZE MemberWhat will be the rear side of the box? The original Penta has a separate “box” for the tweeter and the 4 midrange speakers. You measured the content with around 2 liter volume. But… the Penta is a big speaker, but the volume is still not very big. It is a slim column. B&O separated the midrange speakers from the woofers.

Just be sure, that the midrange box is isolated from the woofers, otherwise the woofers will press air into the midrange box and the midrange speakers will react on this preasure… they will play the sound of the woofers and not the midrange signal. Much bass, less hights…

The Penta has also a breathing hole on the top, the bassreflex tube… where will it be located in the new cabinett? The cabinet for the woofers can be bigger, bigger is no problem. Smaller is a problem, since the breathing of the woofers would/will be limited.

Since you use 3D printing, you can integrate the bassreflex tube in the backside, making it takein-takeout like a horn, not a simple hole. If you have a still operating Penta: play music and touch the bassreflex tube. And listen to the tube, some frequencies produce a breathing sound. It could be possible, that it needs not 1 tube, maybe symmetric 2 of them.

16 August 2024 at 22:03 #58365Evan

GOLD MemberHi Bogener,

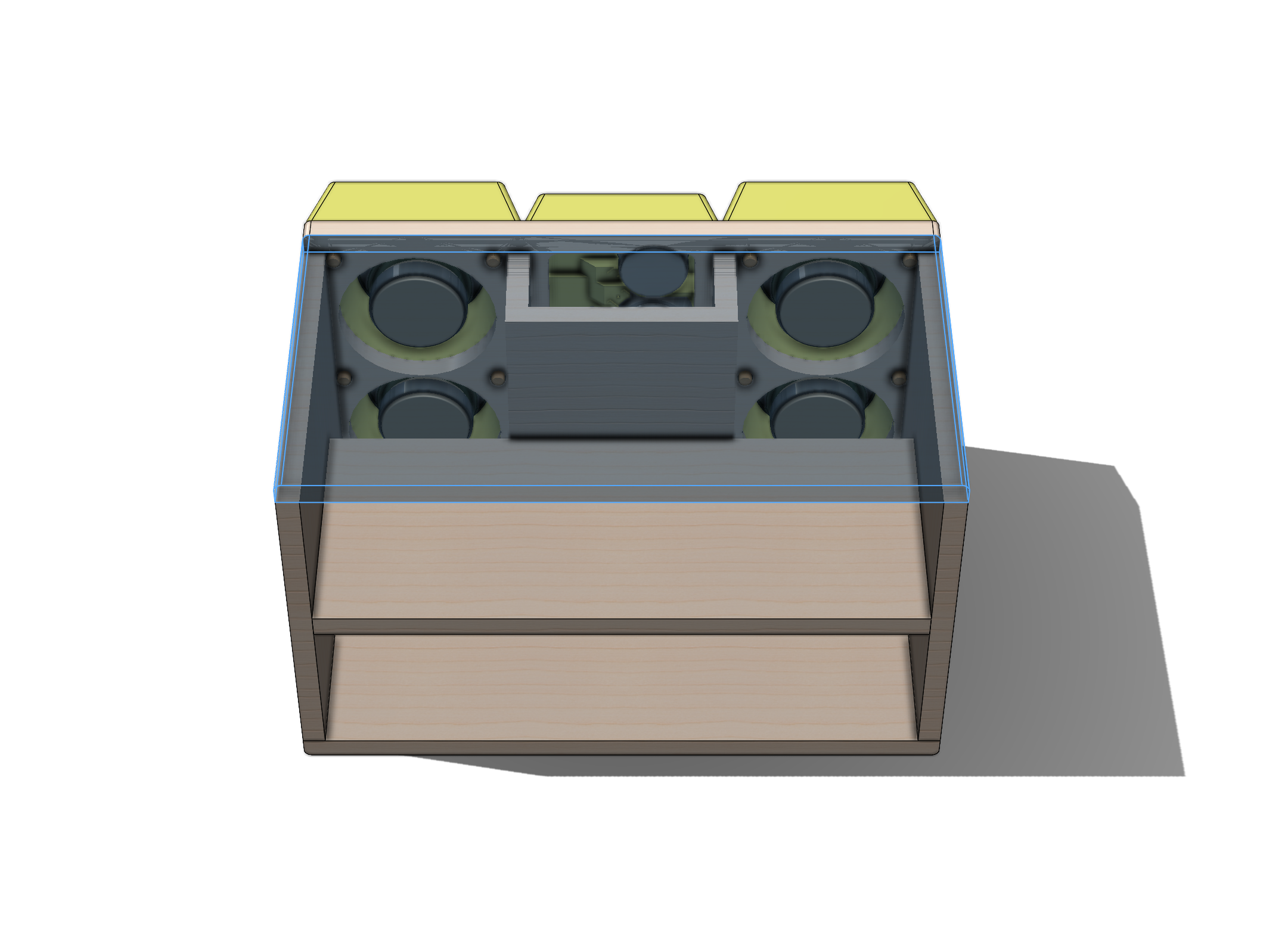

Indeed, there will be a separate volume for the midrange speakers, just like the original Penta design. Overall, the plan is to utilize the extra volume (there is a lot in the current design) I have to try and do away with the port. I prefer sealed speaker designs personally so that will be the initial direction of the acoustic concept. However, all of this still needs to be verified with some measurements. Basic system resonance and overall response still need to be measured before I can make any concrete decisions. If I end up going back to a ported design, I will definitely lean on my 3D printer for it. Time will tell!

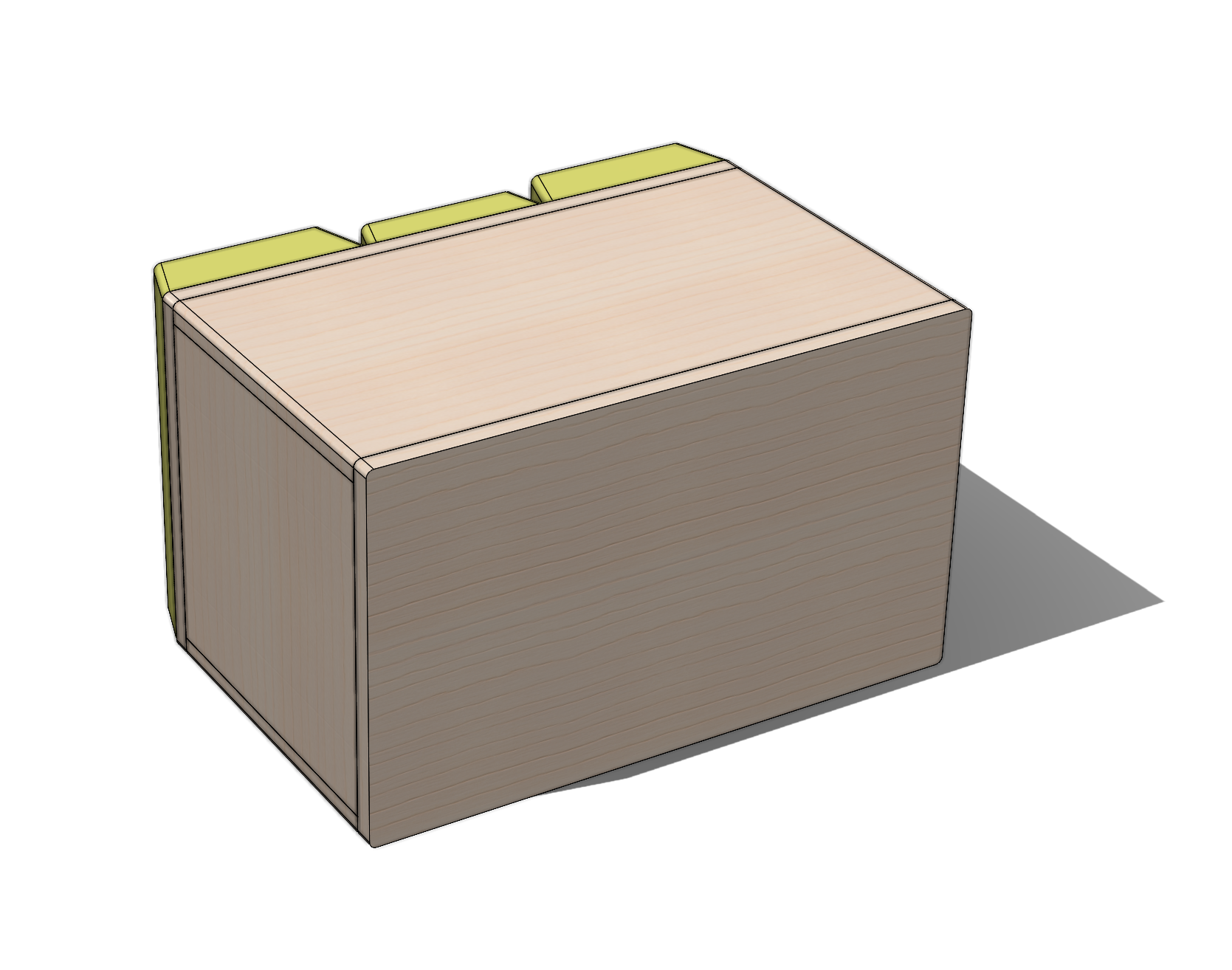

Currently the rest of the cabinet box design is… well…. very box like 😀 The box is intended to made from wood as it is currently modeled below.

Here is the current (but very basic) interior layout of the cabinet. You can see there are a few small vertical pieces that make up the midrange cabinet volume. The horizontal piece is simply there for bracing and stiffness.

I really need to get back into this project! Life has been in my way lately, stealing away spare time. Also the furniture rearrangement in the house has disrupted the need for this speaker altogether so there is currently not a strong household demand for this beast.

Location: San Francisco

22 July 2025 at 12:51 #67573Stereomensch

BRONZE MemberHi Evan,

are there any updates? I’m very interested in your experiences 😀

Did you do some measurements?

Regards

Chris

15 August 2025 at 22:20 #68807Evan

GOLD MemberHey Chris – didn’t realize you had replied! Sorry for the delay.

Sadly no, I had some re-prioritization of projects and had to push this to the back burner. So sadly, there has not been any progress. I will likely pick this back up later in the year.

I will definitely be putting my work here when I resume. Thanks for following!

Location: San Francisco

-

AuthorPosts

- You must be logged in to reply to this topic.