Home › Forums › Product Discussion & Questions › BeoCord › Beocord vx5000

- This topic has 96 replies, 6 voices, and was last updated 2 years, 5 months ago by

-

AuthorPosts

-

12 August 2023 at 17:08 #46485

Die_Bogener

BRONZE MemberWhen i remember right… it’s a defect gearbox.

If you remover the gearbox from the underside… be very very very carefull… it makes PLING and a small plastic ring part will fly away. On the axle of the clutch is a white plastic ring on the top with a crack and it will learn to fly.

The evolution is a brass instead a plastic ring. You have already removed the gear box… still surviving?

Make photo of the clutch.

12 August 2023 at 21:52 #46486 BRONZE Member

BRONZE MemberYeah – that thing flew right off a few times but I found it. I glued it back on.

Here is a pic of the gearbox:

The symptoms are:

- Play works on the left reel but the take up reel does not move, so the tape soon becomes tape salad

- Fast Forward and Reverse do not work. I can hear the motor spinning but the tape does not move.

As a side note: the VX7000 that I received was also eating the tape. The reason was hardened grease under the take up reel. After cleaning and lubrication, the tape is no longer eaten. Anyway, I am not so interested in the VX7000 as its functions are very limited without a suitable Beovision.

Location: Copenhagen

13 August 2023 at 08:53 #46487Die_Bogener

BRONZE MemberThe left wheel is the clutch. The torque is made with a spring and some tissue pressed together. Fast forward/rewind stops if torque is to low.

Clean it with alcohol, the tissue collects something like silicon from the plastic and becomes lower and lower…

Improvement of the to low torque: use some sanding paper. Not in rotation direction, across rotation. The scratches make torque higher… dont exceed with to rough sanding paper, it can make rattle.

Take photos BEFORE disassembly. There are a lot of parts inside. And springs…

I prefer the VX5500. Less heat and less problems than the VX5000 … and more cooling air and space inside. Modified with a switching power supply and removed tuner and unusable analog sound system unit it stays pretty cool. Much work, but worth the uncounted hours of work. I use it still every day for watching satellite TV.

The VX7000 is technically better, but functionality is a pain… especially the unsolved rewinding problem. It stops without any reason by software, starts again like starving… just a pain. And with BEO4 software just worse…

13 August 2023 at 14:02 #46488 BRONZE Member

BRONZE MemberHmm – I tried to do what you wrote. After putting it together there was no change. However, I did have some success – not sure why.

After covering the light sensor, I could see that the take up reel was spinning both during play and fast forward. Maybe there is some misalignment somewhere as the eject mechanism was actually in the up position (as in no tape there). I then put in a tape, and it would fast forward and reverse. Screwing down the eject mechanism, I could hear that the forward motion started to struggle, so I didn’t screw it down completely. Play still chewed up the tape as the take up reel would not move. I ejected the tape. Inserting it again, I could hear the motor spinning when fast forwarding but again the tape would not move 🙁

Location: Copenhagen

20 August 2023 at 11:30 #46489 BRONZE Member

BRONZE MemberSo … I think I have narrowed down what the actual problem is – though I have not found the solution.

If the tape eject mechanism is not in, and I put a tape in the machine, it will play, reverse, fast forward etc. (there is still a wow and flutter problem that I don’t know why is there).

However, when I put in the eject mechanism, nothing really works. It can play but will make tape salad after a few seconds due to the take up real not engaging. Looking at the eject mechanism when it goes all the way down, it will press on the reel drive idler. I presume that due to this, it will stop working – unless this is normal behaviour?

Location: Copenhagen

20 August 2023 at 12:40 #46490 BRONZE Member

BRONZE MemberAnd looking at the VX7000 and VX5000 mechanisms, I now see that there is a crucial difference. The part called Cassette Holder Base is much wider (edit: I meant ‘deeper’) on the VX7000 mechanism, causing it to press on the Reel Drive Idler. I initially thought that the two eject mechanisms were fully the same, except for the materials chosen.

Location: Copenhagen

20 August 2023 at 16:10 #46491Die_Bogener

BRONZE MemberWider? Nooo…

But the metall plate under the cassette itself is a little different acording to the drive…

I just opened a VX5000 and VX7000 and everything is identical but the cassette holder itself is different according to the drive. The trim/cutout is different.

And yes, there seems to be a problem using a 7000 unit in a 5000…

20 August 2023 at 17:25 #46492Die_Bogener

BRONZE Member20 August 2023 at 17:51 #46493 BRONZE Member

BRONZE MemberWider – no. Deeper yes. As you rightly say, the cutout is different.

Anyway, I changed the cassette holder base and put the one from the VX5000 in the 7000 eject mechanism and put the whole thing in the VX5000. Happy to report that play, FF and Rewind are now working.

There is still a wow and flutter problem with the sound so that needs to be fixed. Not sure where to start with that. It comes from small speed ‘jerks’ it seems.

Location: Copenhagen

20 August 2023 at 18:31 #46494Die_Bogener

BRONZE MemberHmmm, is there a difference between old records and new records?

Old= dump, odd, dull, no treble…

New= crisp and clear? But little bit jumpy?

Then it is adjustment of the sound head and/or Tape guide.

But: turned once on the screws it will never be the same…

Have you good old records of the original machine?

20 August 2023 at 19:57 #46495 BRONZE Member

BRONZE MemberHere is a recording: https://www.dropbox.com/scl/fi/mzdzpocwz6rork3kb361g/VX5000_lyd.mp3?rlkey=mc5cz7lzpptfmgp6gtnv1hhka&dl=0

The pressure roller looks dry and slightly cracked. I can replace it with the one from the VX7000 which is in perfect condition but I don’t know if that could be the issue?

I have only tried old tapes so far but they do the same thing. I have not turned any adjustment screws.

Location: Copenhagen

21 August 2023 at 12:41 #46496Die_Bogener

BRONZE MemberUuuups, that is the tape speed control itself… tachometer control?

I had this on several VX, but it was gone with a 100% recap… i dont know which cap is responsible for this… but probably you have not done all of them…

21 August 2023 at 21:45 #46497 BRONZE Member

BRONZE MemberYes – no recapping done yet – except for the capstan motor board – as I first needed to source the eject mechanism and get it working. I guess, I will take it board by board, starting with the main board which has the servo and hifi circuits. Perhaps even the power supply first, though it seems to be working fine.

Location: Copenhagen

23 August 2023 at 21:51 #46498 BRONZE Member

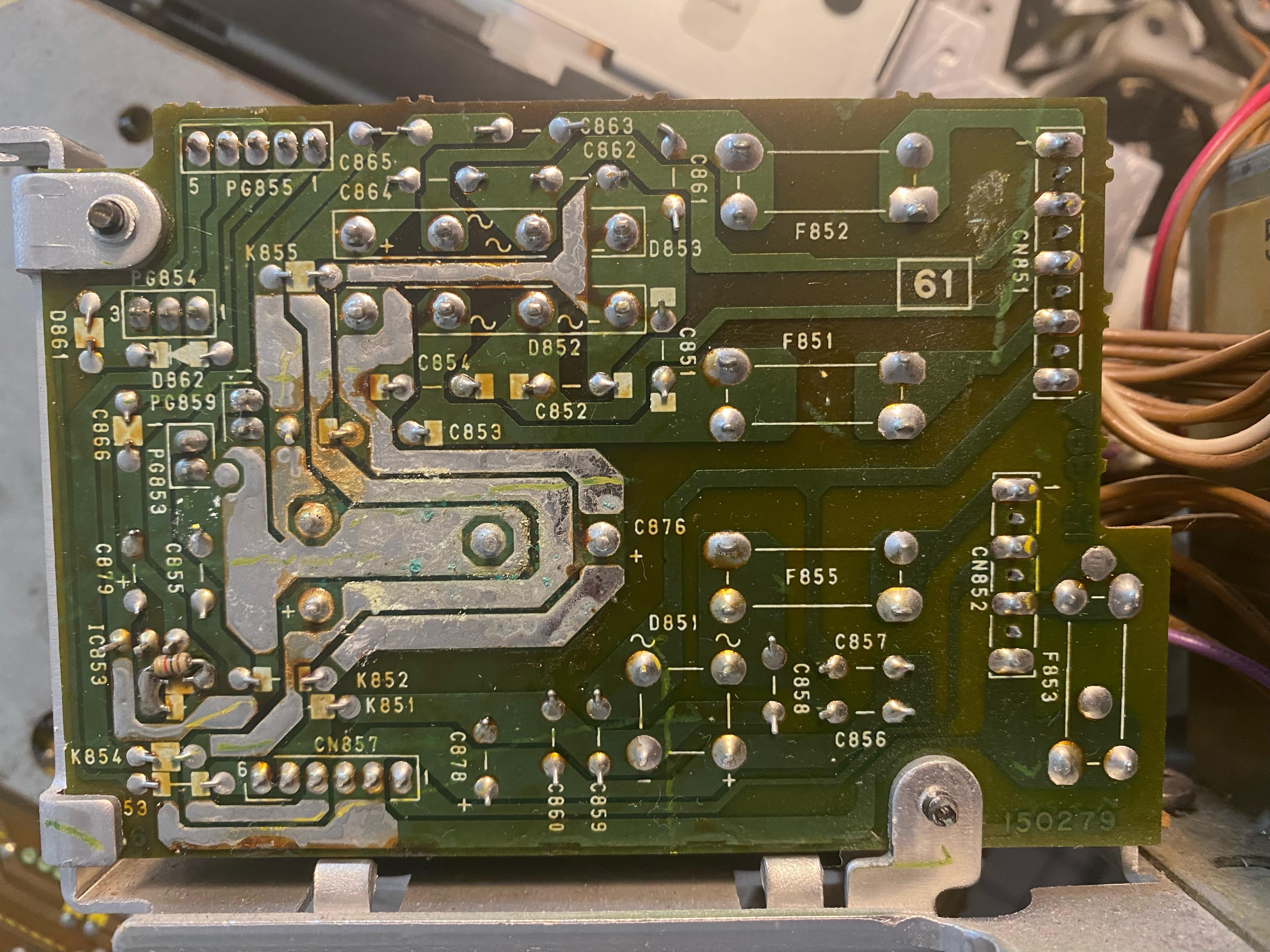

BRONZE MemberPower supply first. Though it seems to work (though perhaps not 100%), I took it out for inspection. Hmm – does look a bit corroded in the middle of the board, so I will start recapping that one first.

Location: Copenhagen

24 August 2023 at 10:37 #46499Die_Bogener

BRONZE MemberC876 lost some acid, the typical dead 220uF C878 and C879 are still alive… you are lucky. This board is a 1% survivor.

25 August 2023 at 15:13 #46500 BRONZE Member

BRONZE MemberI decided that I needed to be able to remote control the unit. Luckily somebody had tossed a transceiver a while ago that I found in the dumpster. It looks an awful lot like the VX sensor so I figured it would be possible to make it work. Sure enough. Green wire was 5+V, White data and brown ground. So now I can remote controle the VX5000 without a Beovision. Still need to fix that sound issue. Of all the caps that I changed on the power supply, the video amplifier and the 12 V regulator, I did not find a single faulty one. (I still need to change a 4700uf cap since my cap pusher only had one). The only faulty one that I discovered was one that was leaking at the right side of the top board. I changed it, and measured that it was completely open.

Location: Copenhagen

13 September 2023 at 12:10 #46501 BRONZE Member

BRONZE MemberMoving on to the main board. I took a look in the service manual and ordered what I thought would be pretty much all the caps needed. I don’t know what happened – either I totally missed some parts, or I simply made a wrong order – in any case, I still need a lot of caps to change but I think I have done almost half of them. Of all the caps that I have pulled out, only very, very few have actually been in working order. The majority of them have shown Open Line on my multimeter, and I think 5 of them have been within spec – but I have changed them also. Finally, I had a chance to remove the tuner board(s) – they were a hazzle but I managed. This gives a bit more space.

Location: Copenhagen

-

AuthorPosts

- You must be logged in to reply to this topic.