Home › Forums › Product Discussion & Questions › BeoSound › BeoSound Century – Dead CD Drive

- This topic has 21 replies, 6 voices, and was last updated 3 months, 1 week ago by

GEORGIOS HATZIPETRIS.

-

AuthorPosts

-

19 December 2024 at 02:42 #61724

BRONZE Member

BRONZE MemberSo, following on from the success repairing the IR board on a BeoSound Century, and my subsequent impression of what a great unit these are, I’ve acquired another one, this time for my own use! The first one now resides in my Mother’s bedroom, and she’s loving it!

This one is the same model as before, 2652. The CD drive is dead, as in the motor doesn’t spin the disc at all, and there’s no audible sound indicating laser carriage movement.

Are there any initial things I could check out?

Thanks!

Attachments:

You must be logged in to view attached files.19 December 2024 at 09:11 #61734I can’t remember whether you have the service manual – available on site for Silver and Gold members!

If you do have the manual, page 5-8 has details of the CD Test Mode – with information that is more comprehensive than most service manuals and may give a good indication of the fault. It will also allow you to switch on the laser without CD fitted so that you can observe the light output, if present (view through smartphone camera for safety).

It looks to be in great cosmetic condition, so well worth repairing!

Location: Warwickshire, UK

My B&O Icons:

19 December 2024 at 12:50 #61735When Laser problems, first always check in the technical datasheet that your’s is a genuine kyber crystal. Sometimes it may ruin your CD but it is well know to last long – Like 6 or 10 iterations plus spin-offs.

More seriously, if your CD lens is one of the common ones – Meaning 20$ on the bay – don’t bother but be ready to try one or two before the right one comes. All details on BW II or there.

And in any cases, try the “deep clean method” widely discussed in our colums.

It does not work everytime but has a fair amount of success.Finally, in my experience, the weak link in a CD mechanism is the lens, so CD not spinning, no motor noise, etc… Is in most case due to laser fault.

Someone did once explain me the full CD start sequence and it did make sense.Clean or change the lens.

Good luck.

Location: Paris France

19 December 2024 at 13:14 #61736 BRONZE Member

BRONZE MemberHi – many thanks for the replies 🙂

I have the manual with the test procedure, why didn’t I check this first?!

OK – when in test mode and pressing CD, the display briefly reads 1, then settles at displaying 2, which according to the manual is a focus error. None of the other test modes for the CD give any output. Test modes 40, 42, 43, 44, 45, 46, 47, 48 and 49 do nothing, all I hear is a very quite ‘blip’ from the mechanism, and that’s it. I viewed the lens through my phone, and I couldn’t see anything on my phone screen when trying test mode 40. I’m wondering – if a focus error is returned from the test mode, does that mean none of the other test modes will work?

Thanks again!

19 December 2024 at 13:27 #61737With that Test Mode outcome I would be tempted to disassemble, clean what you can (and manually ‘exercise’ the CD mechanism). Check traces, components (bulging capacitors?), check that ribbon connectors are correctly inserted. Then re-assemble and run the test modes again.

Location: Warwickshire, UK

My B&O Icons:

19 December 2024 at 14:28 #61742billbriscoe

GOLD MemberHi,

First, check to make sure the CD transport locking screws on the back of the unit are loose (turn them counterclockwise to loosen. Then try test mode again, especially 42, 44, and 45. These will test the movement of the assembly.

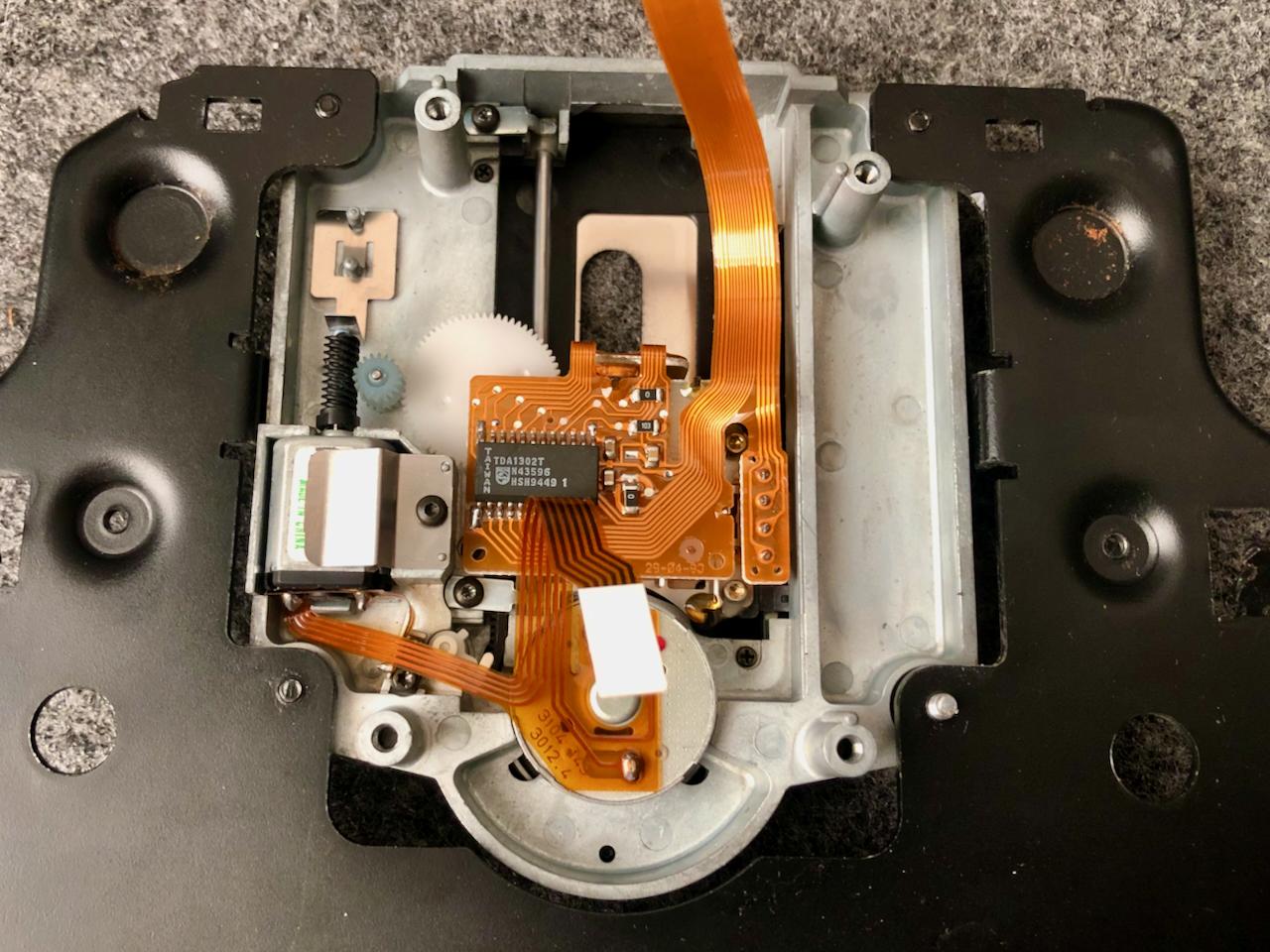

I can’t tell from the photo if the opening for the laser beam is a vertical straight-line going down from the center of the clamper or a curved (radial) opening that’s slightly to the left of center at it’s lowest point. It matters a bit because the laser diode unit (lens) in the straight-line version is less reliable than the radial version.

If you have the straight-line version, it may be that the grease on the rails has hardened and the unit can no longer move at all. It may need to be cleaned and re-lubricated. You’ll want to check this, I think, to ensure that the assembly can move freely up and down the rails if you get a 3 or 4 from the test mode checks. You can “exercise” the CD mechanism manually by turning the large white gear to make the assembly move (as Guy has suggested).

The cd mechanism in the radial units is very robust, and significantly different from the CD Pro model (straight-line version) and it can’t be “exercised” in the same way. You can tip CD assembly unit (while still installed to the base plate after removal from the BS2000) from left to right in your hand to check and see if the laser unit will move along its radial path.

As Guy suggests, inspecting cable connections, looking for obvious component failures is the way to get more information.

These are very nice units and well worth taking the time to get back into working order.

Good luck!

Bill

19 December 2024 at 21:59 #61776 BRONZE Member

BRONZE MemberThanks for the replies 🙂

The drive is the later Philips type, with straight-line tracking. I checked the transport screws, they were in place and were fully unscrewed.

I removed and dismantled the CD drive, then cleaned the lens & mirror as per: https://www.youtube.com/watch?v=qXGubkovMEE

The lens and mirror actually looked quite clean. There was no hardened grease on the tracking drive, and everything is moving freely, including the pickup along the guide rail. No bulging capacitors, or any other visual anomalies on the two boards.

Reassembled, and it’s still no different, returning error 2 when pressing CD in Test Mode. Before reassembly, I manually moved the pickup to the outer most position. When pressing CD, the pickup moved to the inner most position, so it’s fair to say there is at least power! The spindle motor hasn’t once moved though, not even a blip.

I am wondering if someone has been in here before… One of the four screws that secure the drive mechanism to the steel chassis is silver, the other three are black. I could also see what appeared to be some telltale wear to the coating on the black screws.

@billbriscoe I agree, they are great units! I was mightily impressed with the first one I acquired. I’ve just never really noticed the Century before now, thinking (erroneously) they wouldn’t sound that great. How wrong I was! My Mother who’s in her 80s is now enjoying her expanding CD collection. It’s easy for her to use, after I made up some cheat-sheets to guide her 🙂20 December 2024 at 03:29 #61781billbriscoe

GOLD MemberHi,

I just pulled out one of my Bs2000’s with a linear CD drive mechanism (CD Pro) that was working last year. It would not play a CD now so I ran through the different CD options in test mode and was able to replicate your results exactly. I swapped out the complete CD mechanism (transport and servo board) with a known good unit and it worked fine again. While the BS2000 was out of service it was stored in an extra bedroom and properly covered so no dust could get to it (top. bottom, and sides). In this case I doubt that cleaning would help. I would guess from my experience with these units that you need to replace the laser diode. Check Danish Sound Parts (https://www.dksoundparts.com/) for the correct laser module for your unit.

It’s well worth the money to keep it up and running properly.

Bill

20 December 2024 at 06:34 #61785 BRONZE Member

BRONZE MemberSorry to hear that Bill 🙁

I wonder what has failed, given your working unit has been powered down, and was found to be faulty on powering up. Maybe a pronged period of no power, followed by power-up causes a spike / damage?

Did your spindle motor move at all in any of the tests, even a touch, or was it completely stationary? I would be interested to know the start sequence for the drive. I’m wondering, if the laser is faulty, then the spindle motor won’t receive any power.

But then, would a faulty laser also result in no response to the tests, like 44 and 45, which just move the pickup? I note that test 42 states: ‘Turntable motor starts, and the laser switches on and goes into starting position.’ Is this a simultaneous action, or sequential?

So many questions!

20 December 2024 at 13:36 #61798billbriscoe

GOLD MemberWhen I first ran through the tests I had a CD loaded so I couldn’t see what the lens was doing but I could see that the turntable motor was not spinning the disc. The only error code that ever showed up was 2 – focus error. I then removed the CD and ran through again and the lens tried to focus briefly but stopped and the turntable did not move. No test was able to move the turntable. I assume that if the first test (40) results in a 2, no other test after that will work.

I then pulled out a different BS2000 unit that uses the radial type (CDM4 variant) and ran through the tests and everything worked just fine, each test did exactly what it was supposed to do in terms of moving the laser around and moving the turntable. CDs play properly.

Because I had a known working complete assembly to swap in and test I didn’t spend any time trying to diagnose the problem with the bad unit. I suspect a bad laser module as I’ve replaced many of these linear type units over the years in BS2000s, BS3000s, and BS4000s. In every case a new laser module solved the problem. I’ve never had any luck with the deep cleaning process restoring the module but I can see how it would in some cases where significant dust buildup would be a problem.

Good luck with yours

20 December 2024 at 21:52 #61808billbriscoe

GOLD MemberToday I installed a new laser module in the defective assembly I swapped out yesterday and installed it in the BS2000 and that complete assembly works again. I can’t guarantee that a new laser module will fix your problem but I suspect it will.

Good luck getting in up and working!

21 December 2024 at 02:29 #61809 BRONZE Member

BRONZE MemberThanks Bill!

That may suggest a failed laser precludes the carrying out of the CD tests. Did you replace just the pickup, or the main assembly, with spindle & tracking motor?

I see both the pickups, and the assembly are available for very little money, yet others are multiple times those prices. Does anyone know the difference, given they haven’t been manufactured by Philips in years AFAIK?

I have read the new ones are less reliable, and more fussy in terms of media.

Thanks 🙂

21 December 2024 at 09:51 #61810Although you have stated that the CD drive is linear, and the later Philips type, there are still a couple of model variations, and you will probably only determine the exact type when you dismantle.

Danish Sound Parts offer two laser types for the Century – see here: https://www.dksoundparts.com/product-category/beosound/beosound-century/

I purchased the CDM12.4 version from Danish Sound parts for my BC2300 (linear tracking) – it didn’t cure the faults alone and I had to also replace the capacitors on the servo board.

When I repaired my Beosound 1 (CD/FM radio model), also linear tracking, I had to source a CD Pro 2. At the time, I don’t think Danish Sound Parts offered this so I took a bit of a risk and purchased this one on Amazon: https://www.amazon.co.uk/gp/product/B0D2D47SR8 This cured the fault without any capacitor replacement.

I suggest that you dismantle, have a look at the exact laser pickup module and make a decision from there – Danish Sound Parts will be able to offer advice once you have checked the laser type.

If you want to research further, I found this site very useful for some of the Philips CD mechanism history: https://www.hifi-advice.com/blog/classics/digital-classics/marantz-philips-classics-2/philips-cdm-mechanisms-page-3-cdm-12-and-cd-pro/

(the hifi-advice link is to page 3 where linear tracking first appears, but pages 1 and 2 cover early mechanisms such as CDM4 and 9)

EDIT: Sorry, I realised that you have already fully dismantled – hopefully you will be able to identify whether yours is CDM-12 or CD Pro 2.

Location: Warwickshire, UK

My B&O Icons:

21 December 2024 at 10:08 #61813I am wondering if someone has been in here before… One of the four screws that secure the drive mechanism to the steel chassis is silver, the other three are black. I could also see what appeared to be some telltale wear to the coating on the black screws.

Further to my message above: If someone has ‘been in there before’, don’t rule out the possibility that they have fitted the incorrect laser!!! Use that ‘hifi-advice’ link to check the layout of the CD servo board also, because those are different between types (photos at the link).

Location: Warwickshire, UK

My B&O Icons:

21 December 2024 at 12:04 #61816 BRONZE Member

BRONZE MemberThanks!

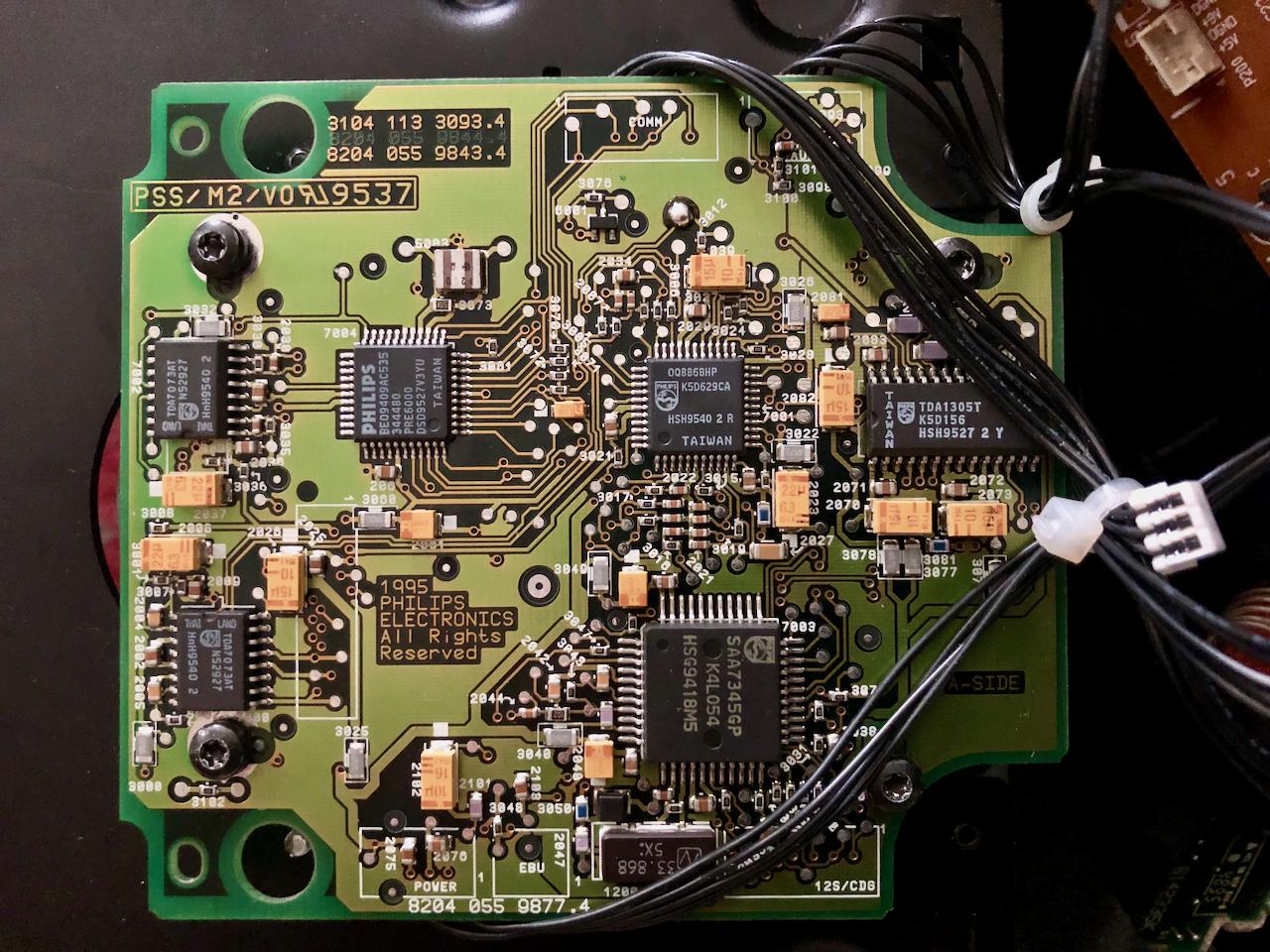

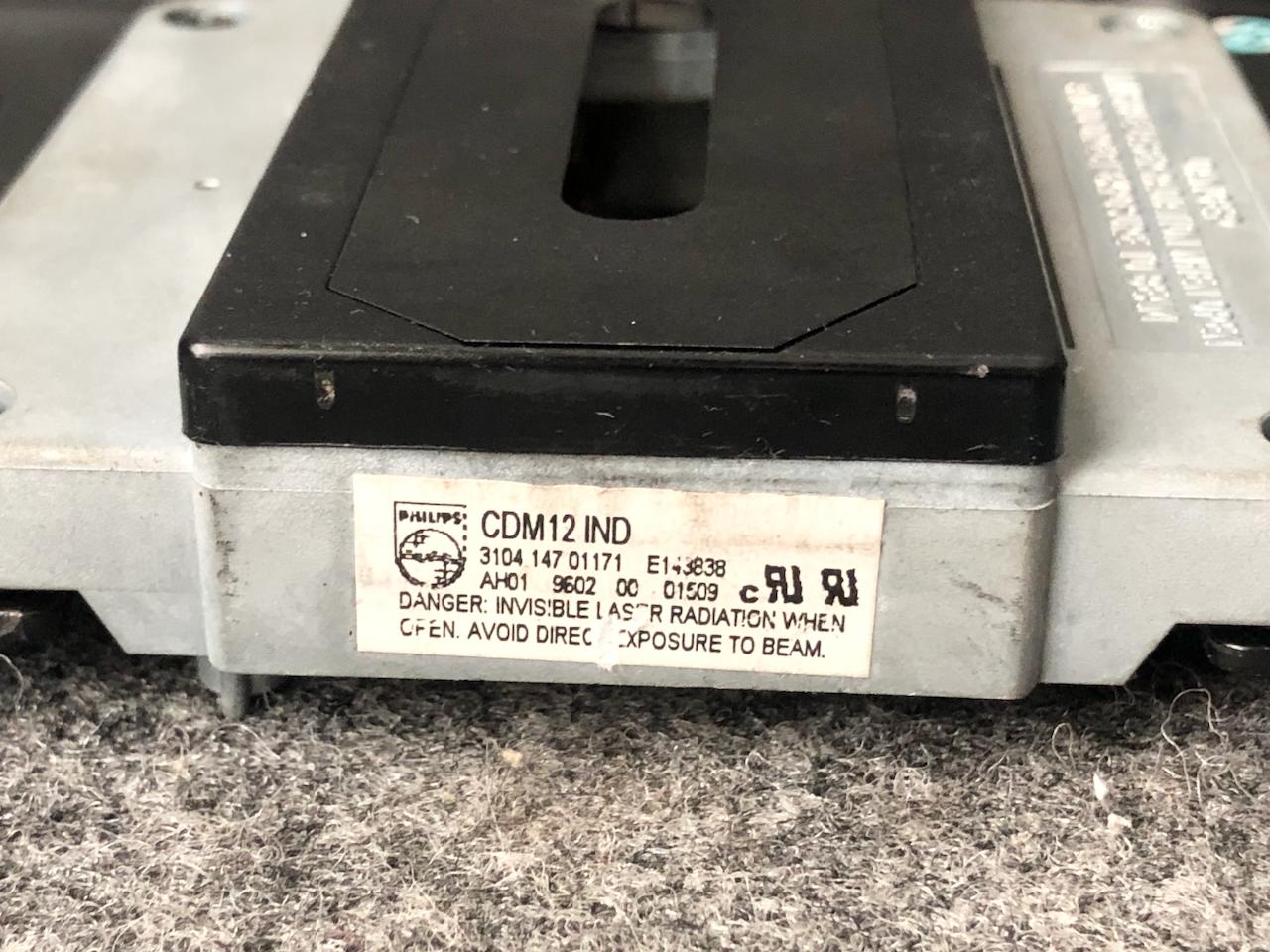

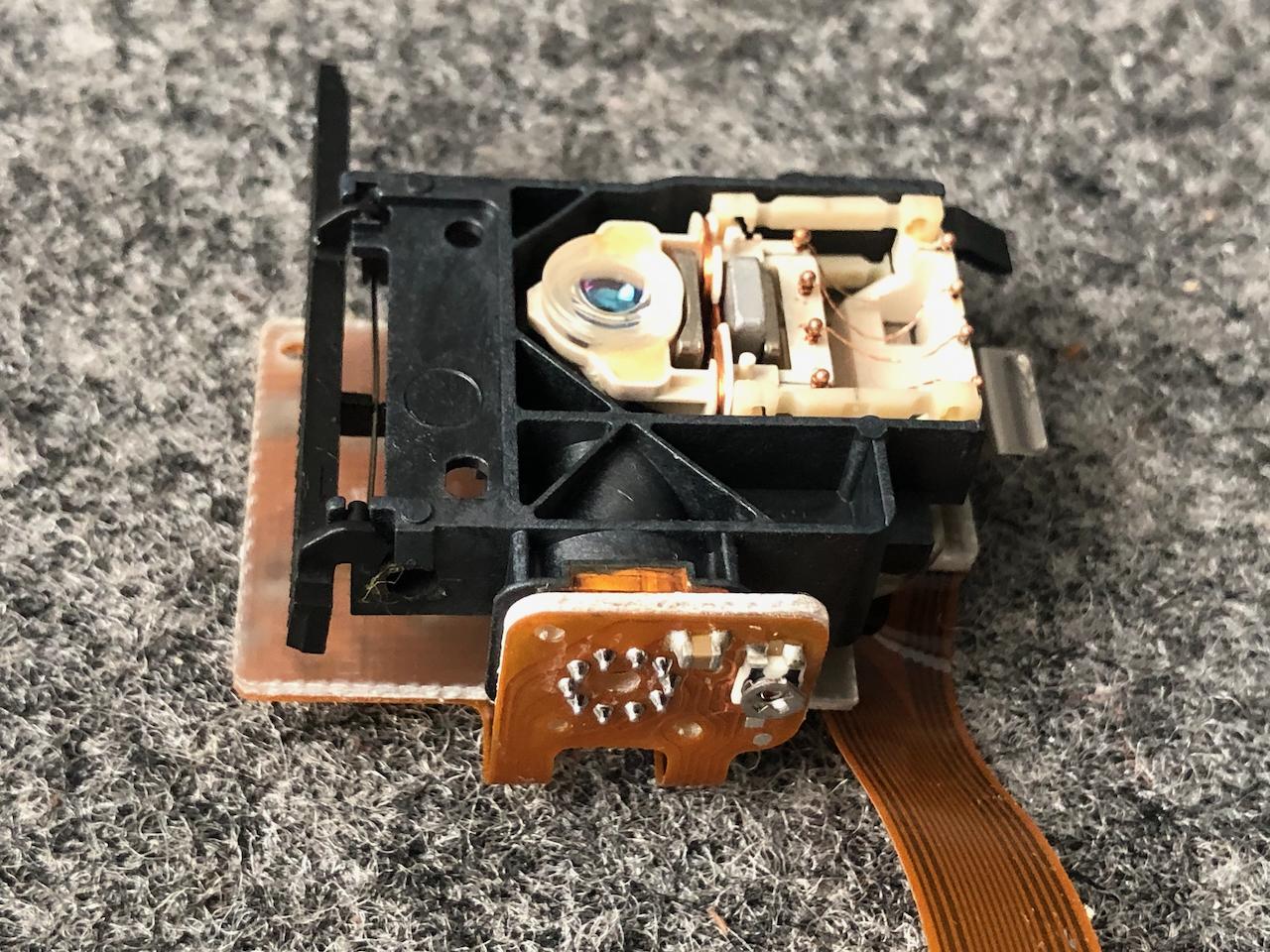

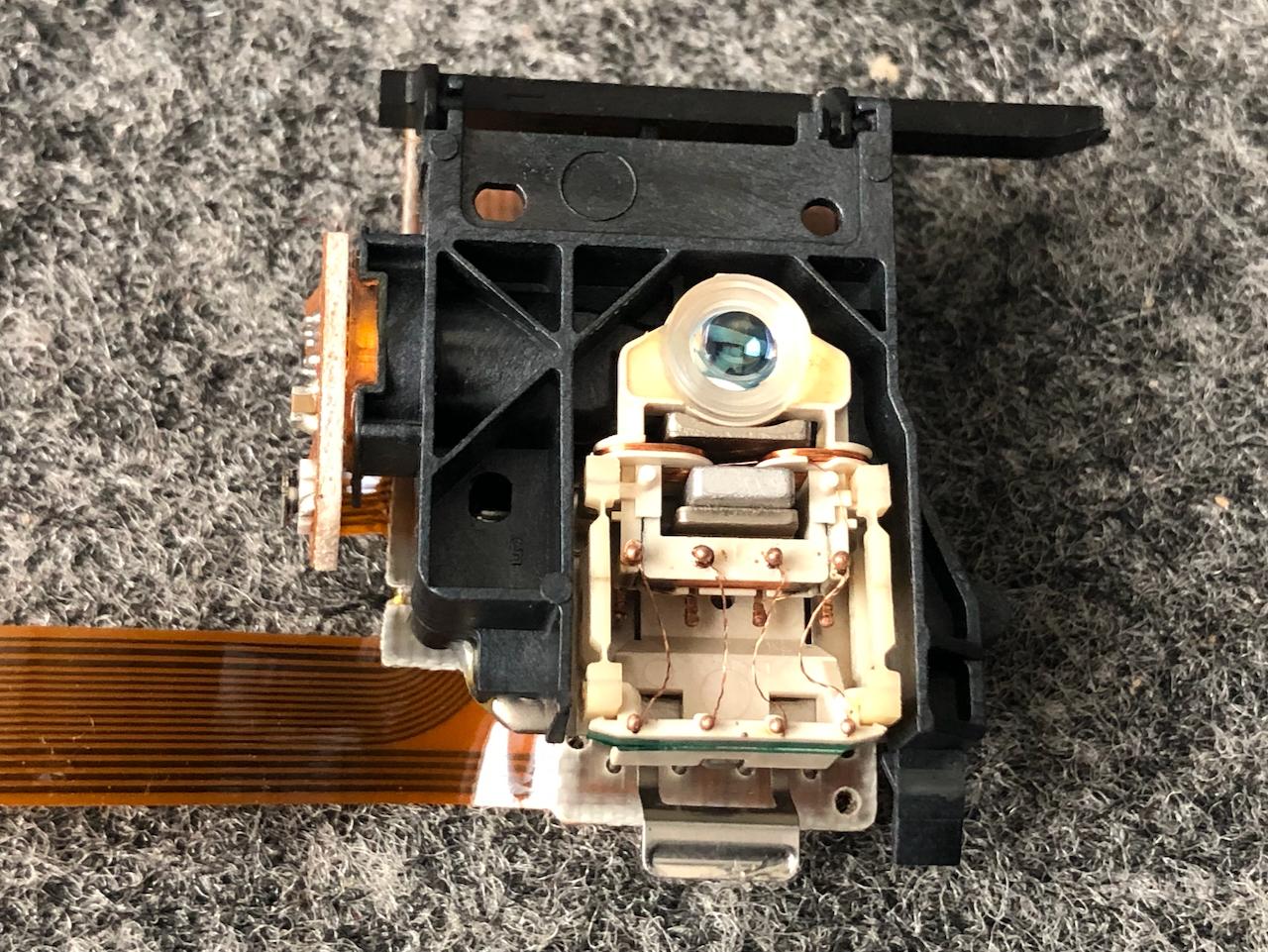

I’ve just removed and dismantled the drive again. It’s a CDM12 IND (Industrial). Looks to have the correct laser pickup?

BTW – just joined as a ‘Silver’ 😃

21 December 2024 at 12:22 #61819I’ve just removed and dismantled the drive again. It’s a CDM12 IND (Industrial). Looks to have the correct laser pickup?

Useful photos – thanks for sharing.

In that case I think you could replace the laser with the Danish Sound Parts CDM-12.4 version. If this doesn’t solve the problem at least you will have a spare laser for future B&O fixes!! 😀 Plus it’s always worth saving some P&P by ordering a few other parts (belts etc) from Danish Sound Parts!

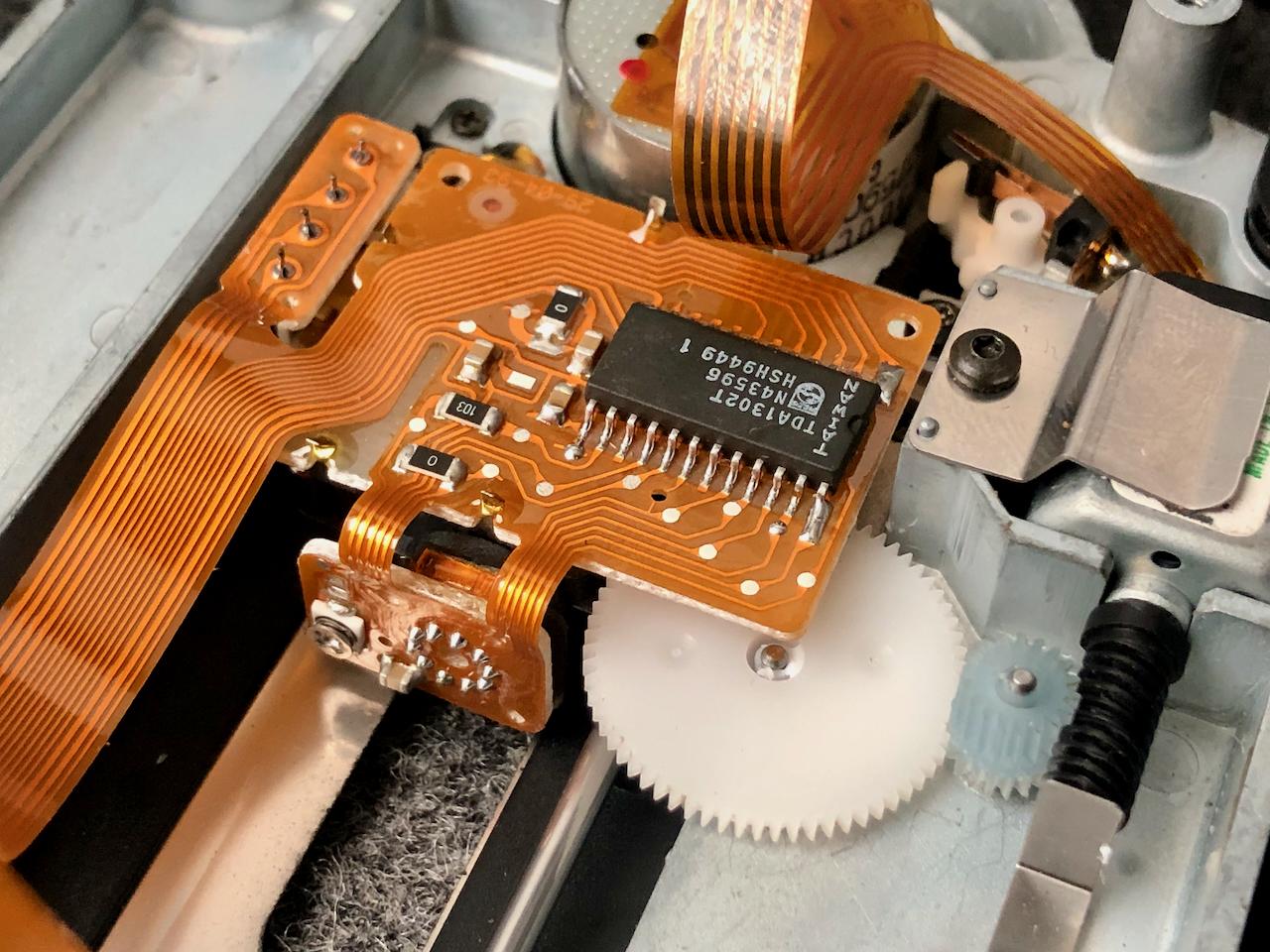

However, in your last photo the four solder joints on the right look a bit suspect. I have seen reference in the past to fixing CD problems by re-flowing solder joints so that could be worth a try. Maybe check for continuity between the 4 contacts on the laser head with the end of the ribbon cable. Have a check though a microscope (or microscope function on iPhone) to check other solder joints or for breaks in track.

EDIT: Also I think on that servo board there should only be 6 capacitors to replace, if you decide to go down that route. You can see my experience of changing capacitors here: https://forum.beoworld.org/forums/topic/beosound-ouverture-cd-not-working/page/2/#post-50390

Location: Warwickshire, UK

My B&O Icons:

22 December 2024 at 23:12 #61867 BRONZE Member

BRONZE MemberThanks Guy

I continuity checked those joints, whilst flexing the ribbon, they were all good.

I may well replace the servo capacitors, and I’ve got a surplus of capacitors for the IR board, so they’ll certainly be replaced!

I’ve got a replacement pickup on the way.

26 December 2024 at 17:58 #61931AlfJ

BRONZE MemberSorry for hi-jacking the thread. I have the same issue with a Beosound Overture.

This thread incicates that both Ouverture and Century has the same CDM12 IND(ustrial) laser unit (Laser moving in straight line).

can someone confirm this?My symptoms:

– CD completely dead. Nothing moves. Nothing spins.

– Error 2 in service mode. No other errors

– Everuything else, doors, tape and radio work fine.A few years ago I replaced the laser pickup with a cheap one from Amazon as the old one couldn´t focus. Disc was spinning, but it would not play most of my CDs.

After replacement it worked fine until recently when it didn’t start at all.

Now I got a new laser pickup from Amazon, but it didn´t help this time. Still dead.

Next I tried with the original non-Amazon laser. Now completely dead.Any ideas?

I´m thinking of getting a donor from ebay to replace the entire CD unit including the large green PCB (servo board?) that sits on the laser unit.

– What machines are potential donors for my Ouverture?

– Can I use the CD unit from a Century? Probably cheaper on ebay than an Overture.

– Is the older CD unit with the curved laser movement plug-and-play compatible with a CDM12?

– Is the entire CD control unit in the PCB mounted on the CDM12 unit, or could the problem be in som other part deeper in the Overture? The cable from the CDM connects to a PCB behind the right hand glass door…

– I guess there must be some non B&O brands using the CDM12 as well? Looking for a less valuable donor than a B&O.

I belive Marantz used CDM12, but that will not be a cheap spare part.I´m not afraid of mechanical repairs, but not too keen on soldering. If I see a blackened component I can replace it, but I don´t want to start re-soldering random components.

Any input appreciated.

Thanks,

Alf27 December 2024 at 13:30 #61951billbriscoe

GOLD MemberI would guess that it’s the laser and you can very likely get a proper replacement from Danish Sound Parts. That’s the first thing to try. You’ll want to remove your unit to confirm the model so that you order the correct laser. I don’t recommend going the donor route at this point.

The older unit with a “curved”, or radial laser, is not plug and play with a CDM12, it’s a CDM4 (most likely a CDM4/19).

Bill

31 December 2024 at 20:25 #62118 BRONZE Member

BRONZE MemberWell, that didn’t work! On replacing the pickup, and attempting to play a CD, the spindle motor did spin up this time, but my hopes were short lived. After a second or two, the spindle motor stopped, and the CD clamp opened. Placed the unit into Test Mode. It initially gave an error 7 on pressing CD, but now repeatedly gives an error 3. I removed & checked all the connections, but error 3 it is.

-

AuthorPosts

- You must be logged in to reply to this topic.