Forum Replies Created

-

AuthorPosts

-

27 November 2025 at 14:06 in reply to: Beogram 3000 (Linear) – Tonearm gets stuck in Lift/Lower Loop #71562

didier

BRONZE MemberInteresting, I didn’t know Datalink was supposed to work with the matching beosystem! When I bought the Beogram I had some doubts, since I’d owned the Beomaster on its own for a while. But when I plugged them together and everything seemed to behave, I just assumed the link was fine.

Everywhere I looked said the only real difference between the BM2000 and BM3000 was the addition of the remote control module.

Good point about the pins! I set them on my desk and my cat immediately started eyeing them, so I’d better keep those safely out of reach…

25 November 2025 at 23:13 in reply to: Beogram 3000 (Linear) – Tonearm gets stuck in Lift/Lower Loop #71554didier

BRONZE MemberTonight I realized datalink between my Beomaster 2000 and the Beogram was not working, and testing this further I found removing the 2 pins from the phono socket fixes the issue!

Digging through old threads, I found two previous reports of this exact same problem, both unresolved and both “fixed” only by removing the Datalink pins:

https://archivedforum2.beoworld.org/forums/t/45418.aspx

https://archivedforum2.beoworld.org/forums/t/20430.aspx

If anyone has ideas about what inside the BM2000 actually causes the fault, I’d love to hear your theories. I plan to open the Beomaster eventually and see if I can trace the source of the bad Datalink signal.

Happy to report back once I learn more!

didier

BRONZE MemberBonjour de Montréal, chartz!

This is the insides of the motor… you can see the cracked plastic I removed at the top, they were originally on the side of the magnetic ring. I didn’t have to disassemble further

Now I don’t see how I could have reversed the magnet polarities since the shaft can only go back one side (so that the brushes can touch the commutator.)

Similarly the brush plate can only be reassembled back one way since the square hole accommodates the chip on the board…

Or maybe I misunderstood something

didier

BRONZE MemberOkayyy… I removed the broken plastic piece and it now runs smooth and quietly!

But… It runs backward ?

I disassembled again and looking at the way th parts fit into each other, I don’t see how I could have reversed the polarity by mistake.

didier

BRONZE MemberI appreciate the answer Mark, I am waiting for a new solder station and will update

didier

BRONZE MemberThank you for sharing!

I got to the PCB in the motor… I’m guessing I can’t go deeper without unsoldering as you said. Do I need to do all the solder points?

didier

BRONZE MemberFor future reference, the motor in question is a Matsushita mmx-4h2rpb, it seems to have been fitted on:

- Beogram 1800

- Beogram 2000

- Beogram 5000 and 5005

- Beogram 7000

- Beogram RX2

- Probably a few others…

didier

BRONZE MemberI did a temporary fix to get proper clearance for the belt:

Right now the belt is not touching anything but the noise is still there…

didier

BRONZE MemberYou were completely right about the rubber suspensions, on eof them was completely squished, while the others were dried up.

Although, even at no load the bad noise continues, here is a video:

https://www.youtube.com/watch?v=QYMYdzi4Bj8

It is my first Beogram, but I think this is not normal…

didier

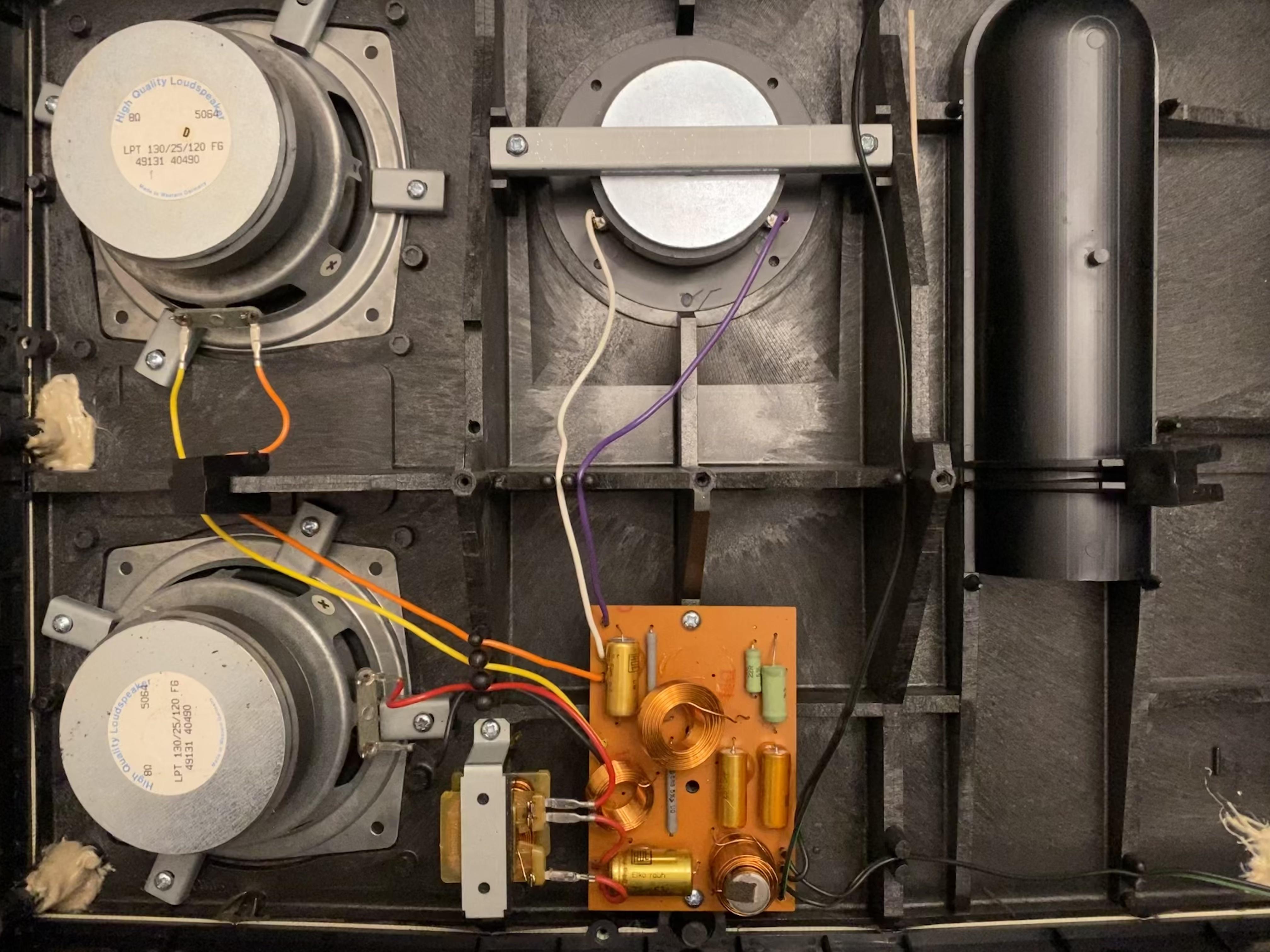

BRONZE MemberI’m refurbishing a pair of Beovox RL 60.2 – one of them had 3 pieces of moulding inside that were broken. They usually hold the screw, so trying to unscrew them would just turn the screw as if the thread was stripped… Fun! Fixed with polyurethane which was what I had available then and I recovered with a new fabric. I have the second one to do now…

I also have a Beomaster 8000 next, but with a hot right heatsink so I’m not in a hurry to get at it. Although I did crack it open to see its state and it doesn’t seem too bad overall.

Then a beogram 2000 low on my priorities, since I’ll need to purchase a cartridge to test further…

didier

BRONZE MemberHi Alf,

I’m looking for the wood veneer in rosewood,

The left spring (under the release rail),

and the lid damper mechanism,

I sent you a pm 🙂

didier

BRONZE MemberThanks Martin,

I will investigate this – and won’t miss to add these in my next order!

-

AuthorPosts