Home › Forums › Product Discussion & Questions › BeoMaster › Beomaster 6500 & 7000 improvement of pre-amp circuit

- This topic has 17 replies, 9 voices, and was last updated 1 year, 8 months ago by

Marto.

-

AuthorPosts

-

6 May 2022 at 12:00 #34647

Hi all,

Great to see that Beoworld is slowly coming to life again. It is a wealth of knowledge.

On the old forum, there was a post about changing the pre-amplifying section of the BM6500/7000, and since my own BM7000 is probably soon ready for a recapping, I was contemplating doing this improvement that Die Bogener wrote about here as it would improve signal to noise ratio:

https://archivedforum.beoworld.org/forums/p/2085/14361.aspx#14361

However, as it is lacking pictures, I wonder if anyone still has the the pictures and could possibly insert them in this thread for the joy of others. Thanks in advance.

Here is the German version:

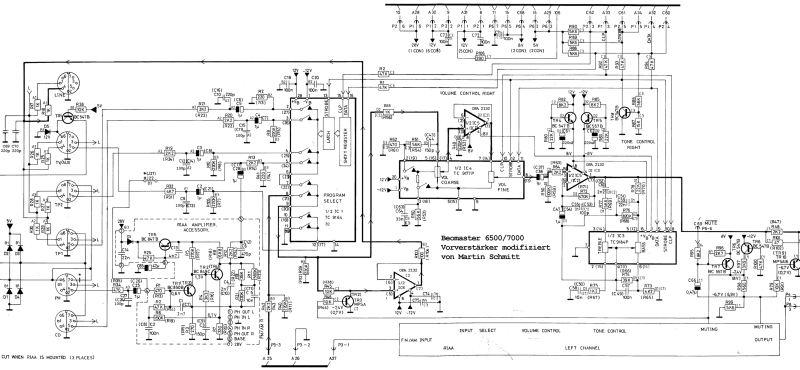

Hier der modifizierte Schaltplan des Vorverstärkers, Stand 25.3.2007 Stand 21Uhr00.

Ich habe IC6 wieder eingefügt, auch die Mute Schaltung für die externen Geräte ist wieder drin und aktiv. Damit können auch niederohmige Geräte wieder sauber getrieben werden. Auch der Line OUT ist wieder aktiv, hier könnte man jetzt auch wieder einen externen Verstärker oder ein anderes Gerät anschließen. Jedenfalls gibt es hiermit einen mutebaren zusätzlichen Ausgang, das ist neu… 😆 😀

Allerdings ist das Line Signal jetzt nicht mehr wie original durch die Line IN/OUT Buchse mehr geschleift, es ist ein reiner Ausgang.

Das hat den Vorteil, dass keinerlei Störsignale von aussen mehr in den Vorverstärker einkoppeln können, auch eine Überspannung könnte nur noch IC6 killen, aber nicht mehr die internen Klangregel IC’s… aber bei einem Blitzschlag wäre trotzdem alles vorbei… so oder so.Vorteil dieser neuen Änderung ist, dass das Tonsignal vom Program Select IC direkt zum Lautstärke Regler geht, externe Störsignale durch den BUS mit Zirpen usw. bleiben aussen vor, auch die langen Kabel zu den externen Geräten haben keinen Einfluss mehr, Impedanzen externer Geräte sind dann auch egal. Auch ein Kurzschluss von den Ausgangssignalen bleibt damit folgenlos, Ein- und Ausstecken wäre u.U. sogar im eingeschalten Zustand folgenlos… wenn man vom BUS auf den DATAs absieht.

Dasselbe Signal vom Program Select IC geht auch zum IC6, wird dort gepuffert und geht auch ohne Störmöglichkeit zum Tape 1+2, TV-Aux usw. BUS-Zirpen wie original sollte damit nicht mehr möglich sein.

So sieht der Vorverstärker jetzt aus:

(IMG:https://img123.imageshack.us/img123/9170/p3250005de6.jpg)

https://img123.imageshack.us/img123/9170/p3250005de6.jpg

Und das ist der überarbeitete Schaltplan:

(IMG:https://img108.imageshack.us/img108/3618/vorverstrkerbm7000modifnw6.png)

https://img108.imageshack.us/img108/3618/vo…000modifnw6.png

Der Rauschabstand hat sich weiter verbessert, selbst bei höchsten Lautstärken ist nichts mehr zu hören, keinerlei Rauschen oder Zirpen. Den Bus hört man erst bei Lautstärken > 74… kein Vergleich mit früher 🙂

Aber Vorsicht beim Ausprobieren… eine falsche Taste und die Scheiben fliegen raus 😉Das Klangvolumen hat sich auch weiter vergrößert. Man merkt, dass im Klangweg deutlich weniger Kabellängen liegen. Original und auch in der Modifikation vom Februar liegen mehrere Meter Kabel am Signal dran, alle Verbindungen zum TV oder Tape 1+2 sind am unverstärkten Signal angeklemmt. Eigentlich ein Verbrechen 🙁

Diese neue Änderung per IC6 eliminiert dieses Problem. Es sind nur “zwei” Brücken (R55/R56) von 2cm nötig, das unverstärkte Signal verläßt den Vorverstärker nicht mehr. Nach “draussen” geht nur noch das per IC6 verstärkte Signal, was auch immer damit passiert, es kann keine Störungen mehr einsammeln 🙂Aktualisierte Teileliste für den Vorverstärker mit Stand 25.3.2006 21Uhr00 :

C66 = 0,47uF Wima… nur optional zu wechseln.

C1, C2, C3, C4, C5, C6, C7, C8, C21, C28, C37, C38, C47, C54 = 1,0uF Wima MKS-2-5

C25, C26 =2,2uf Wima MKS-2-5

C9, C10, C11, C12, C13, C14, C15, C16, C24, C27, (original 220/270pF) = 100pF Styroflex tauschen oder alternativ Wima FKC-2 100pF.

C43, C44 = Wima FKC-2 mit 150pF

C53, C55 = Wima FKC-2 mit 100pF

C69, C70 = Wima FKC-2 mit 220pFC61, C62= Elko 220uF 50V LOW ESR 105 Grad, z.B. CapXon

R17, R18 = 1K

R38, R45 = 10KEs entfallen völlig:

C17, C18, C22, C23, C30, C31, C32, C33, C45, C46, C67, C68, R15, R16, R57, R58, D6, D7, D8, D9Es werden durch Brücken ersetzt:

C35, C36, C39, C40, C41, C42, C48, C56, R36, R37, R55 + R56 (Achtung, neue Position!)R55, R56 = 1K, diese beiden Widerstände werden huckepack gelötet, von den IC6 zugewandten Lötaugen von C31 + C32 zu den Lötbrücken von der ursprünglichen Position von R55, R56. Siehe Bild

Austausch IC2, IC5, IC6 durch OPA2132, AD823, AD712 gesockelt.

/Filip

Location: Copenhagen

7 June 2022 at 15:03 #34648RaMaBo

GOLD MemberHi,

i attached the image i once loaded, but the quality of the circuit diagram is not so good 🙁

But it should be usable. Maybe “Die Bogner” can resend the image in a better quality.

Location: Near Munich

My B&O Icons:

10 June 2022 at 18:13 #34649Die_Bogener

BRONZE MemberI’m back. 🙂

We can make a simple step by step description how to modify the preamp.

Big pictures do not work here… the upload of the circuit plan does not work…

Martin

13 June 2022 at 09:28 #34650Die_Bogener

BRONZE MemberOpen the BM6500. 2 screws on the rear, 2 in the preamp plug section.

Remove the black lower plate, 4 + 3 screws.

Then you have access to the boards. There is no need to remove the boards out of the cabinet. Just unplug the tuner board, the hinge can be removed or unpluged from the cabinet.

Warning!

The boards are made of pertinax, not epoxy. Any overheeting of the solder will destroy them. Do not exceed 320 degrees of solder temperature or the board will seperate the copper layer! There is NO REPAIR!

B&O used a special method to place the parts on the boards before soldering. The part is plugged into the holes, and the wires are angled outwards, fixing the parts for the soldering process. If you just pull the part during the desoldering work then the pad will break off from the board. It will be very hard work to fix this pad again… and the board will not look good any more.

Heat up the pin, use a small screwdriver to straighten the wire in the hot solder and then unsolder/remove it. Any force on the pads will destroy the board.

Clean the board will Isopropanol after your work and during resoldering/replacing parts.

Chapter 1: Parts you do not need.

In the preamp of the BM6500/7000 are some filter caps that do change the sound to dull. The sound will be much clearer without them. Just remove them, they do not need any replacement…

… and removing is simple.

C10, C11, C12, C14, C15, C16, C17, C18, C22, C23, C24, C27, C30, C31, C32, C33, C45, C46, C67, C68, C69, C70

All are small ceramic caps.

13 June 2022 at 14:15 #34651Stereomensch

BRONZE Member@Die Bogener:

Was läuft denn über den Pre-Amp?

** Google translation **

What’s going on with the pre-amp?13 June 2022 at 18:12 #34652Die_Bogener

BRONZE Member@Die Bogener: Was läuft denn über den Pre-Amp?

Die gesamte Tonverarbeitung des Masters mit Quellenwahl und Lautstärke/Klang.

14 June 2022 at 08:59 #34653Stereomensch

BRONZE MemberOk danke,

ich hatte mal gehört, vielleicht rede ich jetzt auch Quatsch, dass Dillen hierfür sogar ein Set zusammengestellt hat, dass man bei ihm kaufen kann. Ich hab aber keine Ahnung wie der aktuelle Stand ist, ob das nur eine Idee war oder nicht. Er war ja hier im Forum schon seit Ewigkeiten nicht mehr unterwegs und bei Ebay macht er auch nichts mehr.

14 June 2022 at 17:44 #34654Die_Bogener

BRONZE MemberNaja, guck mal nach dem Datum dieser Bauanleitung. Das habe ich 2007 in der Deutschen Workbench gepostet… seitdem ist viel Zeit vergangen und etliche Ideen dazugekommen.

Dillen hat wegen der vielen Reaktionen darauf einen Recap- und Teilesatz angeboten…

14 June 2022 at 18:33 #34655@Die Bogener: Was läuft denn über den Pre-Amp?

Being in the general section of the forum and the original question being in english, could you please keep it that way for the understanding of alls? Thank you.

Location: Paris France

14 June 2022 at 18:38 #34656I’m back.

We can make a simple step by step description how to modify the preamp. Big pictures do not work here… the upload of the circuit plan does not work… Martin

Hi Die Bogener and thank you for coming back and making it again!

Pictures never have been easier to insert compared to the previous forum. I’m not aware of size limitation and I always reduce the pictures I post to around 1000px on the largest border. If you have difficulties posting pictures and because I beleive they can really help in that specific topic, please reach any moderator or report the issue in the dedicated topic.

Thank you again.

Location: Paris France

14 June 2022 at 18:58 #34657Pictures never have been easier to insert compared to the previous forum. I’m not aware of size limitation and I always reduce the pictures I post to around 1000px on the largest border. If you have difficulties posting pictures and because I believe they can really help in that specific topic, please reach any moderator or report the issue in the dedicated topic.

I did not add any limitations on size of images that can be uploaded.

However the limitation is the width of the forum itself.

No uploaded images are modified.Location: Hampshire, England

27 November 2022 at 00:20 #34658Thank you for part 1. I could also read that you made some modifications so that the sound does not ‘exit’ the amplifier to go through the blind plug, saving quite a bit of signal path. Any advice on how to do this?

Location: Copenhagen

16 March 2023 at 12:18 #34659Finally got around to removing all of those capacitors.

Apparently C67 and C68 were never fitted from Bang&Olufsen, so I guess they must have suspected that they were not necessary.

I am listening to my BM7000 now, and I agree that it takes away a layer of ‘muffleness’ – it’s like removing a blanket in front of the speakers.

Thank you for suggesting this mod. I wonder why B&O fitted the board with those capacitors in the first place.

Location: Copenhagen

19 March 2023 at 09:17 #34660I also finally got around to adjust the no load current to the specified 11 mV. The trimmers were quite dirty it seemed so I gave them a big splash of contact cleaner, waited some minutes, and then it was possible to adjust the no load current without it jumping like crazy.

However, after I put everything together, I have a rather irritating and interesting problem: After some time, the two buttons on the front panel do not work which means that I cannot turn the BM7000 on with the left button. If I then turn it on with a remote control and turn it off again, the left button will work for some time, after which it gets unresponsive again. Any ideas why?

Location: Copenhagen

25 June 2023 at 21:07 #34661Gspaltenhorn

BRONZE MemberHey everyone, sorry for bringing this topic up again.

I inherited a Beomaster 6500 and am currently trying to restore it. A year ago I switched the 2 big caps of the power supply and now i want to work on the sound, following Die_Bogener´s description. But i have a question about the approach

Open the BM6500. 2 screws on the rear, 2 in the preamp plug section. Remove the black lower plate, 4 + 3 screws. Then you have access to the boards. There is no need to remove the boards out of the cabinet. Just unplug the tuner board, the hinge can be removed or unpluged from the cabinet.

I guess the black lower plate refers to board 5 with the speaker connections. So far so good, but how do you remove the caps on board 3 without taking it out? Did I miss some mechanism like the hinge on the tuner board (board 1)?

Many thanks in advance! And if you have any other tips or suggestions for someone who is just starting of, please share them with me ?

26 June 2023 at 09:33 #34662Die_Bogener

BRONZE MemberThe tuner board has a hinge to open it 90 degrees… and the hinge has a function to remove the tuner board… turn and push/pull axial … no need to open bolts on the hinge.

The tuner can be removed and the master is still working without the tuner, so you can test it on your desk.

The black bottom plate is easy to remove… 4+3 bolts. Then you have access to all other boards from both sides without removing them out of the cabinet.

The defect buttons: check the button on the board. There can be oxyd inside the switch, especially when there was smoking nicotin. Then you need the switches.

Sometimes the connector ob the display board to the cpu board makes problems. I have also seen keramic caps break near the connector because there is sooooo much solder, there is a filter cap row and the thermic expansion makes them crack.

11 January 2024 at 09:14 #34663Marto

BRONZE MemberHello everyone,

I am wondering if it’s going to have Part 2 or maybe more mods for this amp. I also want to thank you Die_Bogener for your advices and great work that you do for this community.

Best Regards

Martin1 May 2024 at 06:33 #32574Dillen

ModeratorThe insulation capacitors are there for a reason.

I would NEVER remove them.

Actually, they are signs of a very high quality circuit design.So what are they, and why are they here?

They are small ceramic capacitors placed in strategic places through the signal path, from the signal path to ground.

They are called insulation caps because they insulate the individual signal path stages HF-wise.

They are here because you cannot put a load on f.e. a power supply, without seeing some kind of reaction on its power output, and

because most OpAmps have a very high slew-rate.If an OpAmp switches fast from off to on (or vice versa), the current it “accellerates” will have to come from somewhere.

In other words, a sudden spike commanded on an OpAmp output will see a corresponding (reverse) spike on its power supply rail(s).

This supply will often be supplying other circuits in the signalpath as well, and these circuits will also see the spike in their supply causing them to instantly produce a spike on their output.

Actually, the OpAmp itself will almost always also cause a spike, as will most semiconductors (and some capacitors).The spike on the power supply rail will of course also affect the very OpAmp that caused it (with a brief delay), and

the (very!) brief power surge will cause a new spike on its output.

The result is a very high frequency “ringing” (fading burst of spikes) until the new current flow situation has settled (throughout

the signal path!).As the spike reaches stages with higher and higher amplification and higher currents involved, the corresonding

spikes on the power supply rails will be larger – again feeding back to the earlier stages.

If the power supplies are not suitably decoupled, due to f.e. tired/sluggish filter capacitors, this could in severe cases end in

self-oscillation and a burned amplifier.Small caps (100nF or so) are often placed directly on OpAmps (and other circuits handling audio signals) power supply pins.

This helps quite a bit when viewed from the power supply side.

But any spike already produced will go on to the next stage, be that tonecontrol, volume or amplification.

If nothing is done, the spike will continue to the next stage and cause the next OpAmp to (attempt) to

reproduce this “signal” which, in case of an amplification stage, would only make matters worse.

The spike will grow through the amplifier, and the more it grows the heavier spikes form on the power supply rail and the

more ringing will be introduced to the signal.This signal could eventually end at the tweeter (as speakers crossovers usually don’t cut off HF), and it can contain quite an amount of energy.

A Zobel-network on the amplifier output would take some of it, but even this small circuit could be put to hard work.

Bad power supply filtering caps (the small 10uF) in f.e. Beomaster 5500 can cause ringing throughout the preamp and output stages,

and the small Zobel network resistor can actually burn from the resulting HF energy contained in the signal.

The output stage will also run warm.Putting an insulation cap (a few pF) on the signal path to ground will drastically improve matters as it will be seen as a

dead short for the very high frequency contained in the bursts.

A capacitance this small will have no influence on anything within the audible frequency range.

Quite opposite in fact, as it will remove spikes and bursts that are not part of the original signal.In some cases, – typically early in the signal path, the OpAmps (or whatever circuit handles the signal) power are fed through

a low-pass filter, often seen as something like 47-100 Ohms in series with the power supply/ies and 100uF to ground.

This is done for all stages individually, of course, – or it would be pointless.

The JAMO Promix 200 which is at first glance simple but, by far, one of the best sounding discoteque mixers, uses this in dozens of places.

Beogram CD5500/6500/7000 does too in the analogue stages.I strongly recommend leaving insulation caps well alone.

It is very high quality circuit design.Martin

-

AuthorPosts

- You must be logged in to reply to this topic.

We can make a simple step by step description how to modify the preamp. Big pictures do not work here… the upload of the circuit plan does not work… Martin

We can make a simple step by step description how to modify the preamp. Big pictures do not work here… the upload of the circuit plan does not work… Martin