Home › Forums › Product Discussion & Questions › BeoMaster › Beomaster 1600 Type 17xx Clutch Washer Replacement

- This topic has 8 replies, 4 voices, and was last updated 3 months, 2 weeks ago by

Dillen.

-

AuthorPosts

-

26 August 2023 at 09:43 #48523

jfrancis49

MemberHello All,

I have resolved a couple of the more difficult issues with renovating a Beomaster 1600 (the belt driven controls Beomaster receiver), namely replacement belts and the plastic wheels that run the belts. I have found a source for the belts that can be cut to size and I have found someone to 3D print the roller wheels with my design modifications, so they are less likely to break at the shaft in the future.

What I could use some help with is how to replace the clutch washers in the controls. I have Martin’s (Dillen) replacement washers and know that the clear plastic housing needs to come apart to replace the rubber washers. What I am looking for is any insight into what needs to happen to get to the washers that need replacement. I am a little hesitant to take everything apart that doesn’t need taken apart. If anyone has done this before and give some advice I would appreciate it.

I will post pictures of my redesigned roller wheels and belts soon. Also there are a number of sources out there for the belts I found that can be ordered online to cut down.

John

27 August 2023 at 15:47 #48524Dillen

ModeratorThe small “couplings” or what shall we call them are held by snapping in to indentations in the hexagonal shaft.

Just pull.Martin

27 August 2023 at 20:30 #48525jfrancis49

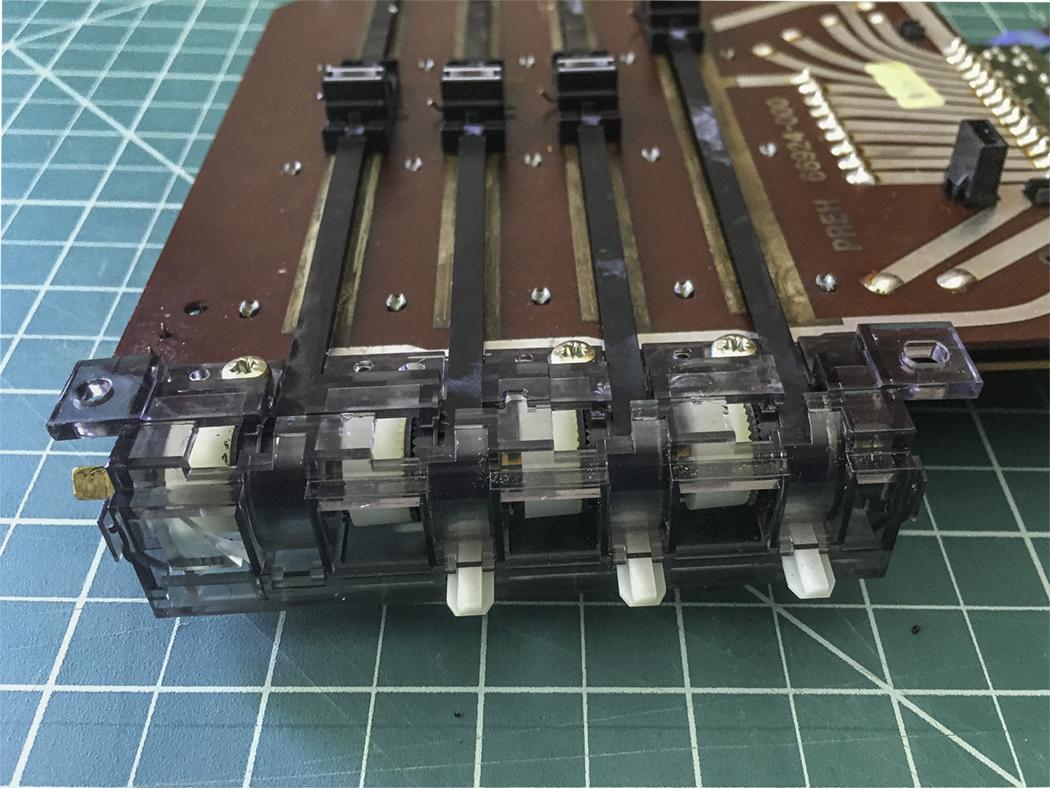

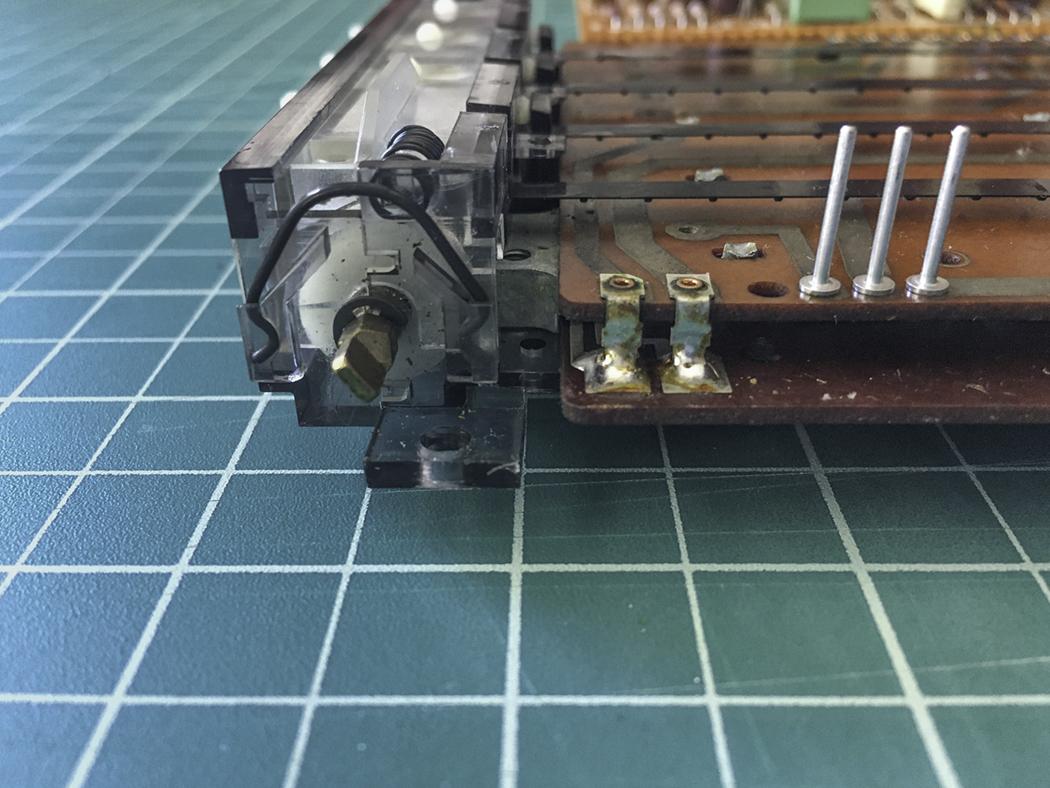

MemberThanks for the reply Martin. I believe I understand that the couplings are the white disks shown in the photo here. But my guess is I need to disassemble this further than I have. Should I remove the screws shown in the first image and the plastic cover and the two clips that would be on each end of the clear plastic enclosure shown in the second image?

Thanks again,

John

30 August 2023 at 09:50 #48526Dillen

ModeratorYou must take off the black bands (pull them a little to release them from the potentiometer slider).

Then take off the two wire springs, one each end, and open the clutch box.Martin

30 August 2023 at 23:37 #48527jfrancis49

MemberThanks Martin, that was a big help! I now have the left side controls taken apart.

John

31 August 2023 at 08:23 #48528orava

BRONZE MemberWhat kind and from where did you find replacement belts?

I have one 1600 in my refurb cue.1 September 2023 at 00:19 #48529jfrancis49

MemberHello Orava,

There are different places on the internet you can find them, I am not sure the moderators want us to post sources. But if you do a search for “Industrial Drive Timing Belts HTD 3M Pitch Timing Belt Width 30mm Open-Ended Transmission Synchronous Belts” you will find several sources, it is branded 3M but made most likely in China. It is available in different lengths and I would get more than you think you need. You will have to cut the 30mm to around 27-28mm width and cut the length based on an old 1600 belt. Getting a clean cut between the belt ribs for a good splice is the tricky part. That is why I would get more than I need. If done cleanly and straight you then use Gorilla Super Glue Gel and clamp it for 24 hours. I have done two belts and the seem is invisible. You can use WD-40 and a cotton swab to remove small amounts of visible glue.

I plan on posting pictures of the belts when I get the clutch washers installed. I have everything apart replaced the clutch washers, but am having issues putting the rod and parts back in the plastic housing.

John

15 October 2025 at 20:23 #70496David Moultonbark

BRONZE MemberHi, appreciate this is an old post but I am after the a couple of clutch washers. Is Martin (Dillen) still able to supply? If so how do I get I touch. Thanks

Favourite Product: Beocord9000

2 November 2025 at 07:00 #70847Dillen

ModeratorContact Danish Sound Parts.

I hardly ever use the message system here.But the washers are usually not the root cause. It’s the sliding plastic coupler – something that is being worked on every now and then.

It’s a fantastic and unique receiver, but a goofy construction.Martin

-

AuthorPosts

- You must be logged in to reply to this topic.