Home › Forums › Product Discussion & Questions › BeoLab › BeoLab 3500: sometimes responds to remote control, sometimes it doesn’t ?

- This topic has 20 replies, 5 voices, and was last updated 1 year, 5 months ago by

Klaus Stoetzel.

-

AuthorPosts

-

1 February 2024 at 04:37 #52556

The BeoLab 3500 I discussed in another thread, seems to have issues with responding to the remote control.

What I use

- To make it switch to the external audio source, via DIN input, I use the ‘Menu > 4 > 0 > Go’ command.

- I make use of a Beo4 remote control.

What happens/problem

- The BeoLab 3500 sometimes responds correctly to the commands from the Beo4, but also sometimes not. I do not recognize a pattern.

- When I remove the power plug from the BeoLab 3500 and restart it, the above described commands work at least the first time. After that sometimes not, sometimes they do.

What I tried

- I removed the Beo4 batteries and replaced them with fresh new ones. > No change.

- I took another Beo4 remote (also with fresh batteries). > No change.

Question

Who has experienced something like this, or has an idea for solving this issue?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

1 February 2024 at 16:46 #52557B3OHACK3R

BRONZE MemberCould be a slowly dying capacitor.

https://forum.beoworld.org/forums/topic/beolab-3500-remote-ir-not-working/

1 February 2024 at 17:04 #52558Thanks @B#OHACK3R, that’s great info!

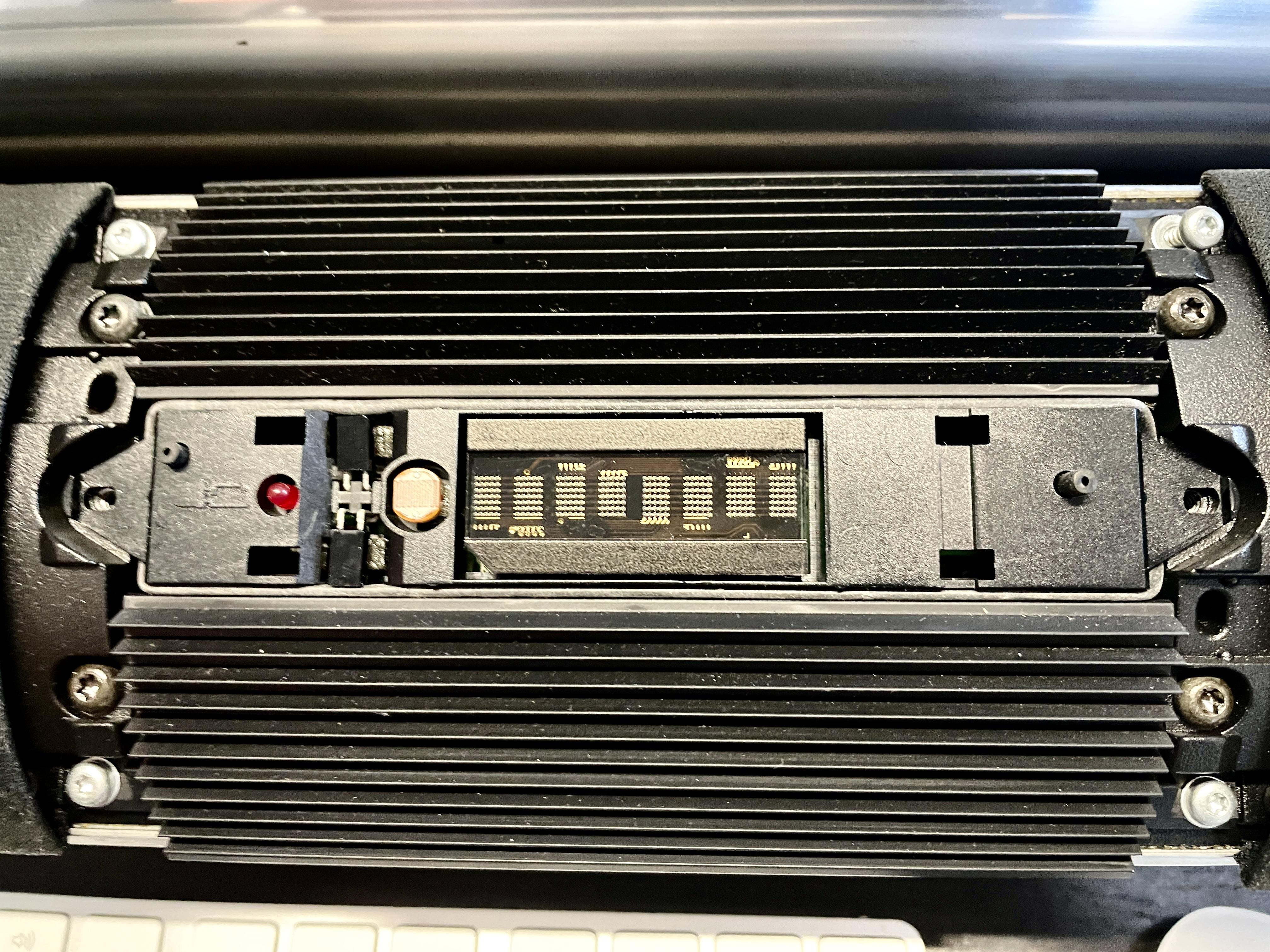

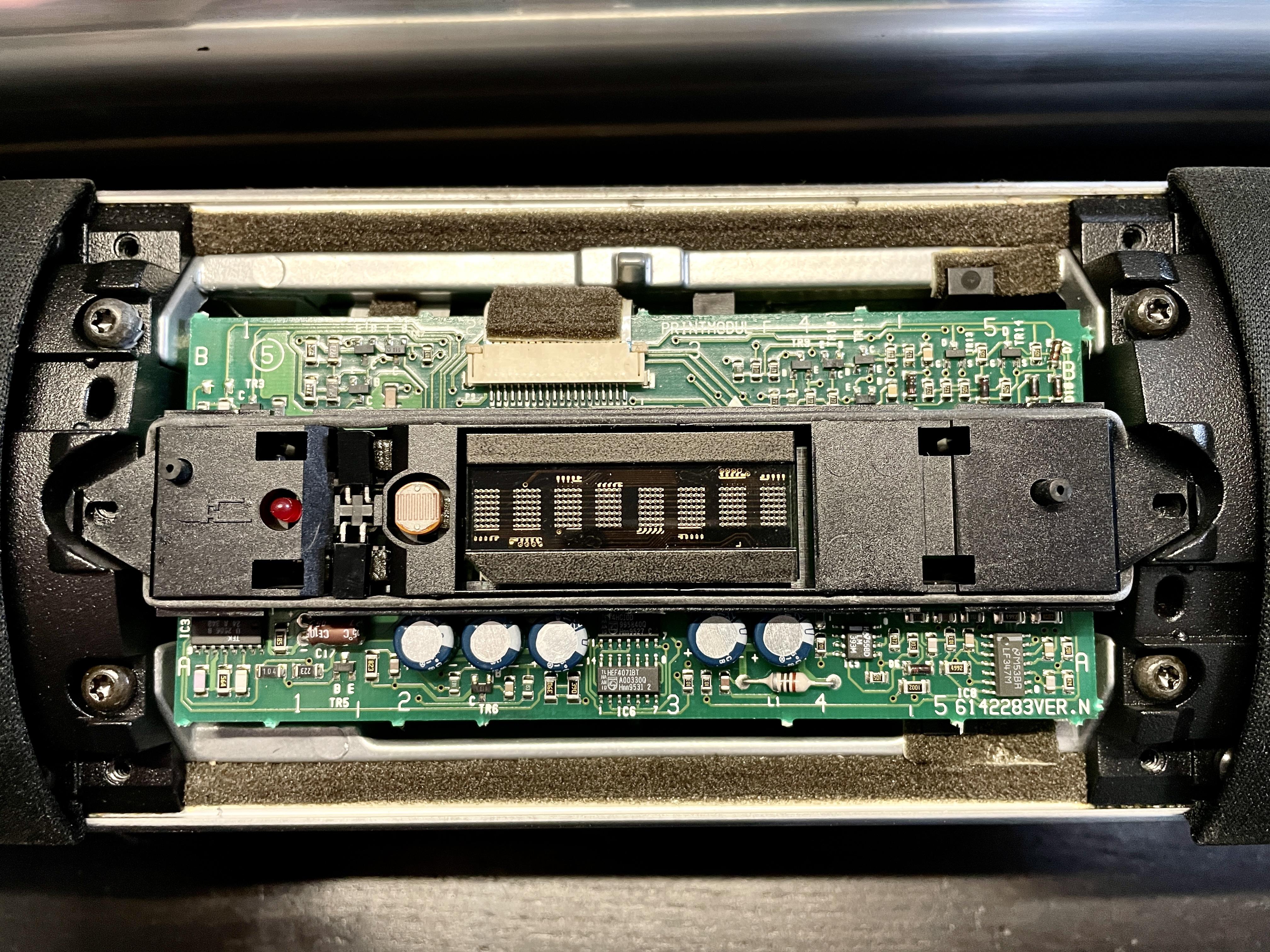

I guess it is a matter of getting the display part out.

Is the PCB with the mentioned IR-receiver chip and capacitors, right behind that?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

1 February 2024 at 17:26 #52559B3OHACK3R

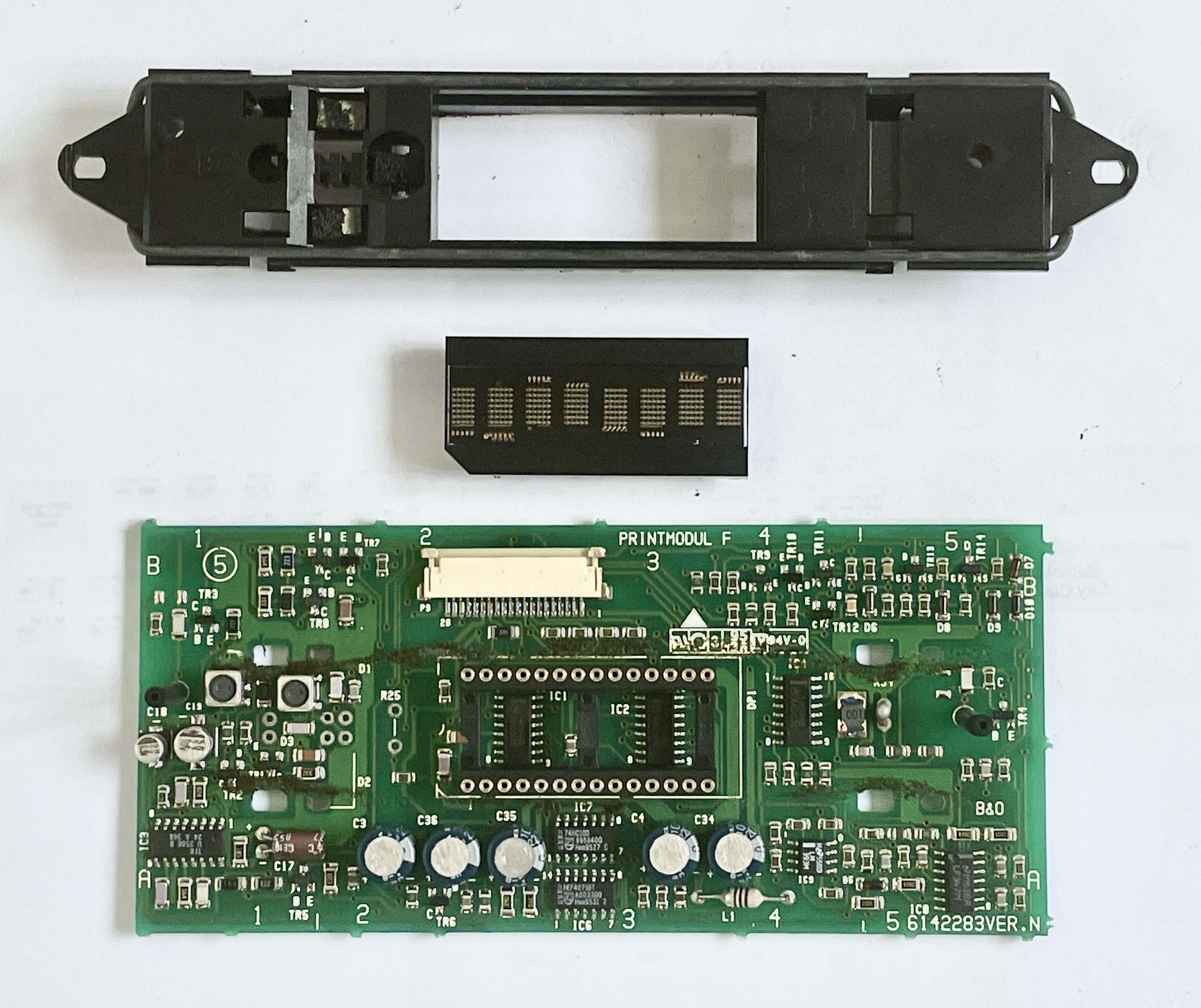

BRONZE MemberYes, getting the display out is a bit tricky.

First you have to remove the whole front PCB which is still pretty easy.The IR related parts are underneath the internal bracket that holds the display in place.

For removing that you have to carefully desolder the red LED, the photo-resistor and the two IR sensors.

Then you can slowly pull it off and get access to the caps. There is also some sticky foam touching that board. Better remove it and give it a proper clean afterwards to prevent future damage.2 February 2024 at 11:35 #52560Good that you mention that B3OKACK3R.

Two questions:

- Are the capacitors to be replaced electrolytic’s or SMD’s?

- Do you happen to have a picture of how that PCB looks like?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

2 February 2024 at 12:15 #52561Who has experienced something like this, or has an idea for solving this issue?

I just wondered if you have tried IR control of the BL3500 in a normal setup (connected to an Audio/Videomaster via ML). I ask this because I have have such intermittent problems with ‘Test Mode’ with other products, using cleared by removing power. The MENU 04 GO command is effectively such a Test Mode. Perhaps IR sensitivity is reduced in Test Modes – this would make sense in a workshop where several B&O products are placed.

I would probably attempt a more ‘normal’ IR test before stripping it down.

Location: Warwickshire, UK

My B&O Icons:

2 February 2024 at 15:01 #52562B3OHACK3R

BRONZE MemberAre the capacitors to be replaced electrolitics or SMC’s?

Yes, they are all SMD while the components you have to desolder for removing the display are through-hole ones.

Do you happen to have a picture of how that PCB looks like?

Unfortunately no, sorry. Forgot to take pictures during that repair.

I would probably attempt a more ‘normal’ IR test before stripping it down.

Good point regarding possible issues with test mode in general. Nevertheless the IR reception “strength” itself cannot be adjusted in hardware. It could just ignore certain commands due to software flaws etc. in that mode.

2 February 2024 at 15:24 #52563Thanks for your comment Guy, nice hearing from you again!

I haven’t exactly tried what you described. Though I have tested both Beo4’s on a BeoSound Ouverture for normal operation. Both Beo4’s and the Ouverture responded well to remote control operation, each time.

Concerning the Test Mode on the BeoLab 3500, I wasn’t aware that this is a testmode command set. I just use this command to activate the DIN connector for audio input (MCL set).

But I must also add that I have been using another BeoLab 3500 (currently not in my house) this way for 2 years. It always responded well to this type of remote control operation. So my guess is that the comment by B3OHACK3R could help solve this.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

3 February 2024 at 12:35 #52564Concerning your remark to get to the components to be replaced:

“The IR related parts are underneath the internal bracket that holds the display in place.

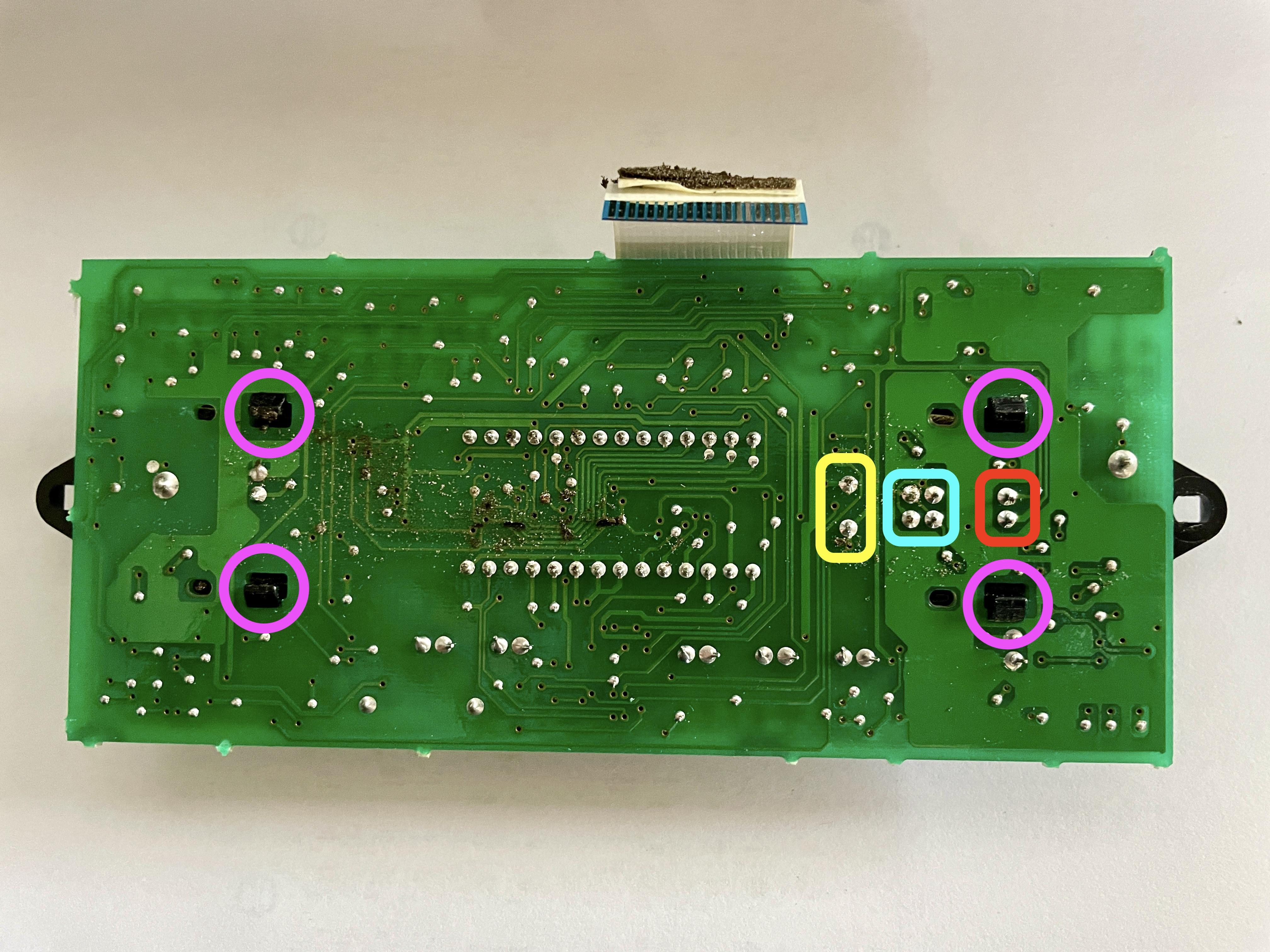

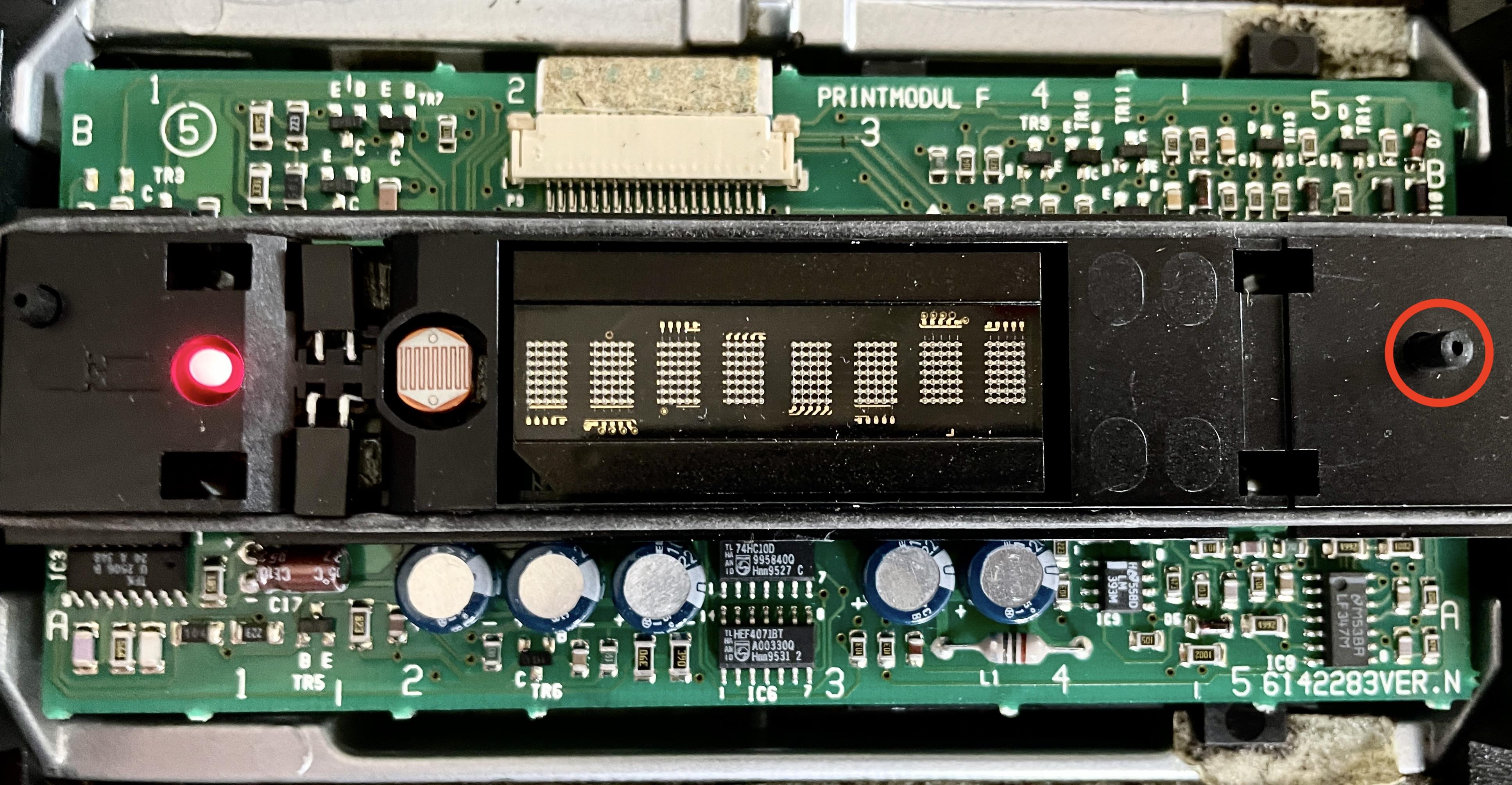

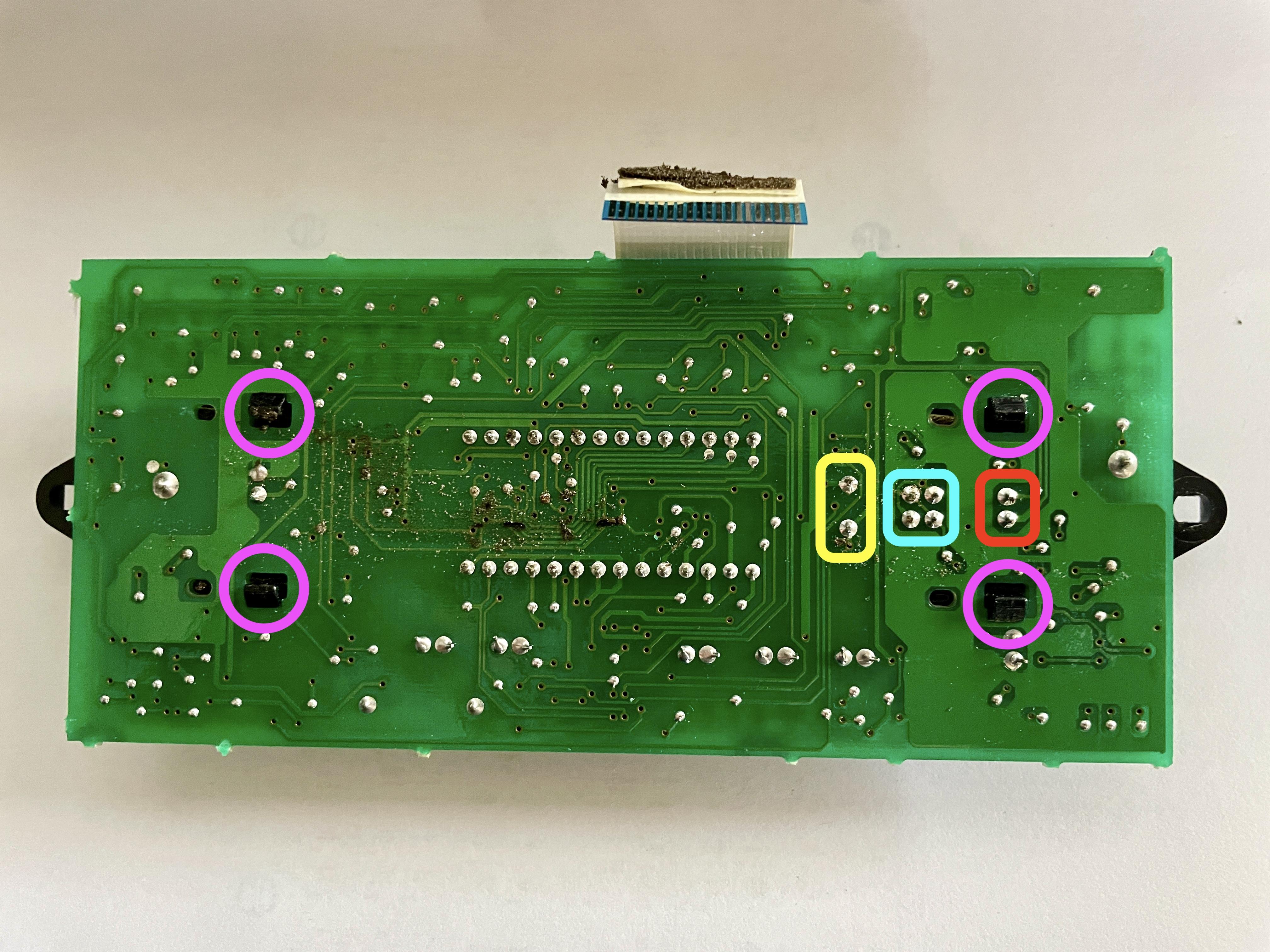

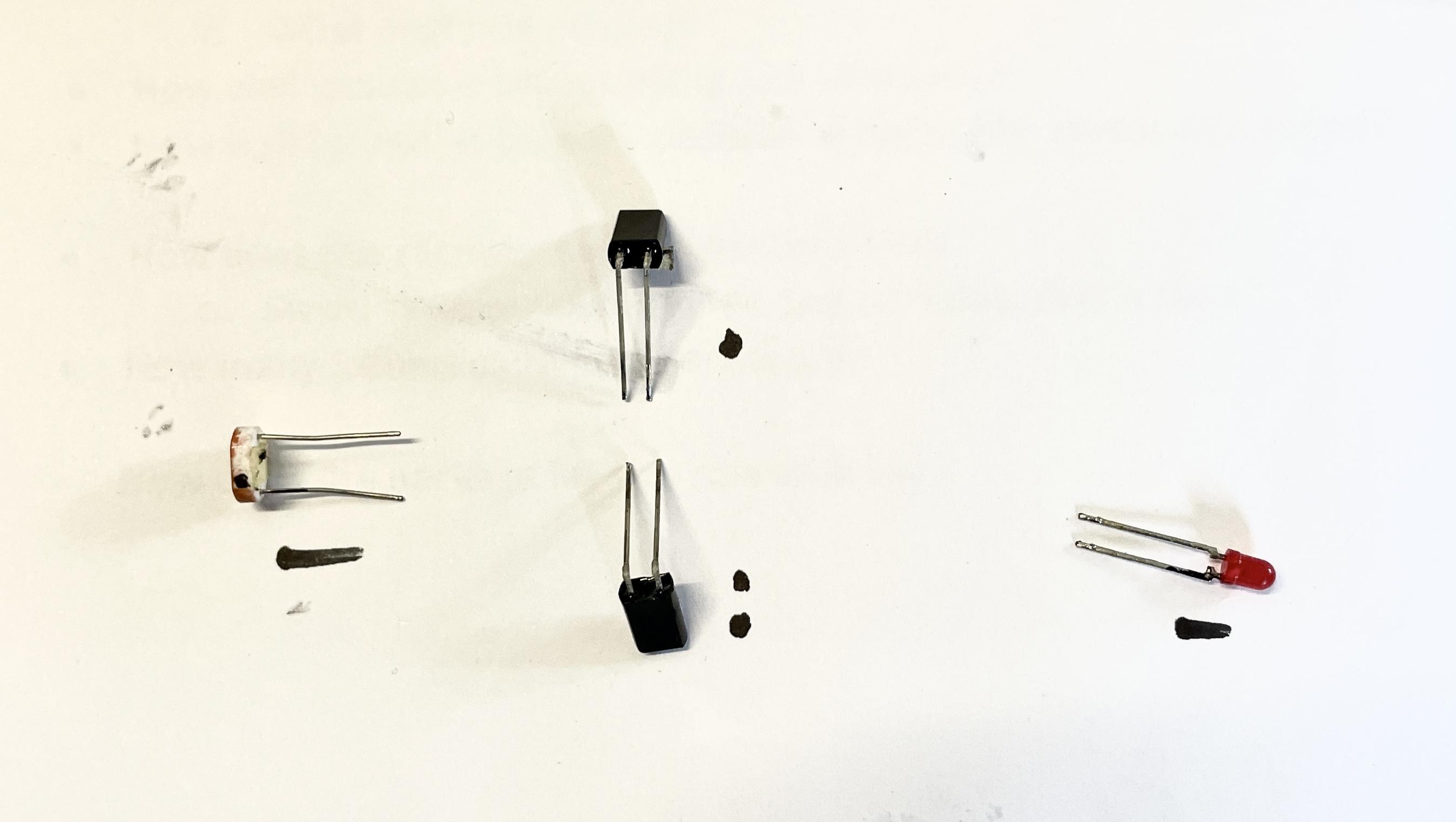

For removing that you have to carefully desolder the red LED, the photo-resistor and the two IR sensors.”I think what you mean is: (see 1st picture below)

- De-solder the 2 points in the yellow square for the photo resistor.

- De-solder the 4 points in the blue square (the legs of the two IR-sensors.

- De-solder the 2 points in the reed square for the photo resistor.

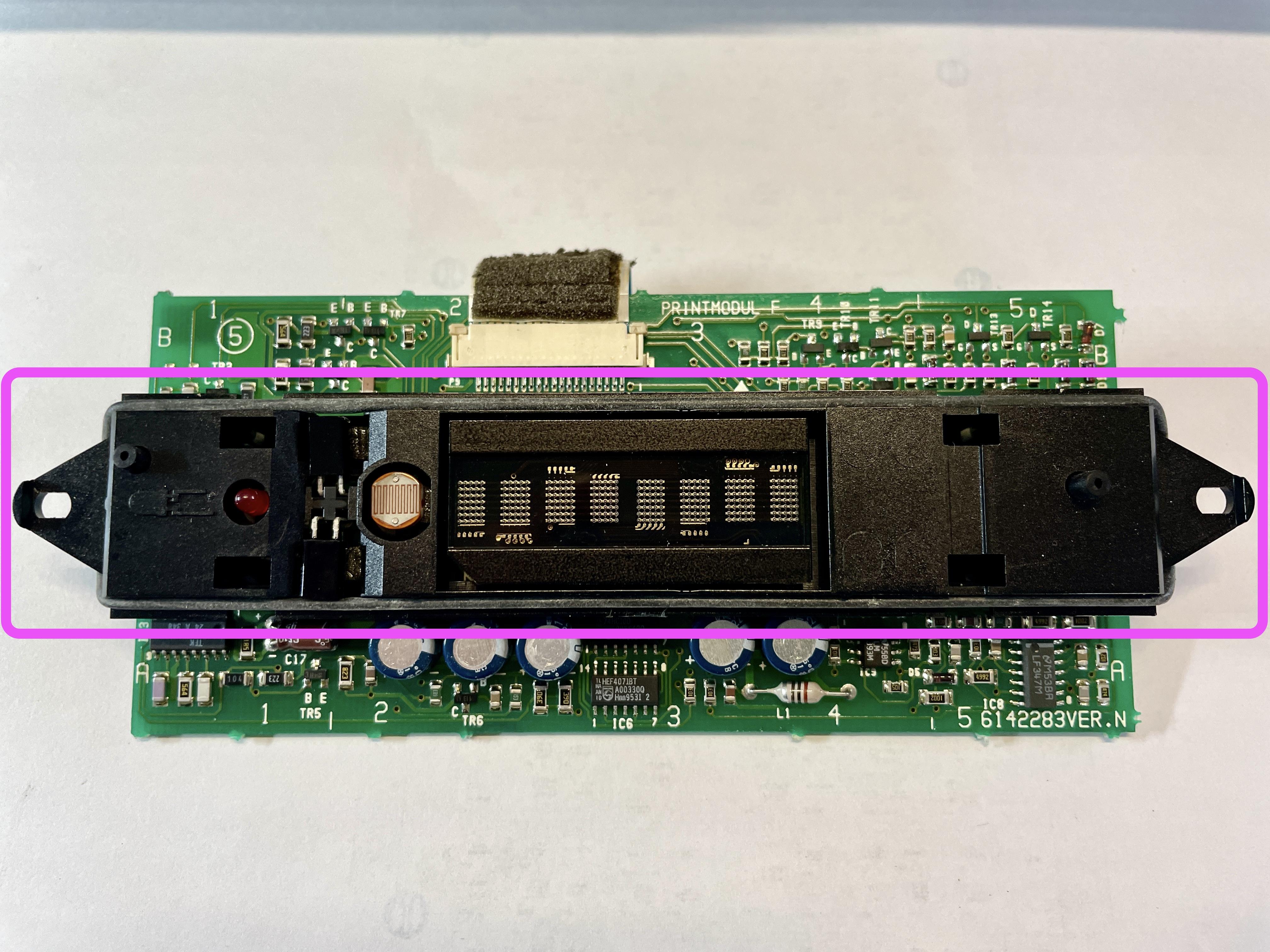

- De-clip the 4 plastic feet from the PCB and lift the plastic bracket at the front to access the components underneath. (2nd picture below)

Is this the right understanding?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

3 February 2024 at 16:08 #52565B3OHACK3R

BRONZE MemberYes, exactly. Sounds good.

Don’t forget to mark the polarity of the components when desoldering them. The photoresistor won’t care but the LED certainly will and the two black IR sensors probably as well.Be careful when removing the black plastic frame. It’S a bit tricky as the display will come off as well. It’s plugged into a two row pin socket connector on the bottom. So disengage the four clips from the bottom and then gently pull it up. You will need some force.

Now when I look at the picture – you might also get away with just replacing C17. It’s a dual footprint. It can either be an SMD or a THT part. Mine was SMD – if yours is THT like in the picture you might be able to replace it using a small tip for your soldering iron. Nevertheless then you are missing out two SMD electrolytic caps that are under the plastic frame. Lower left area close to the red LED in your second picture.

I don’t know which cap is actually causing the problem. I just replaced all three of them and since then everything is working well again.9 February 2024 at 14:07 #52566Here’s an update.

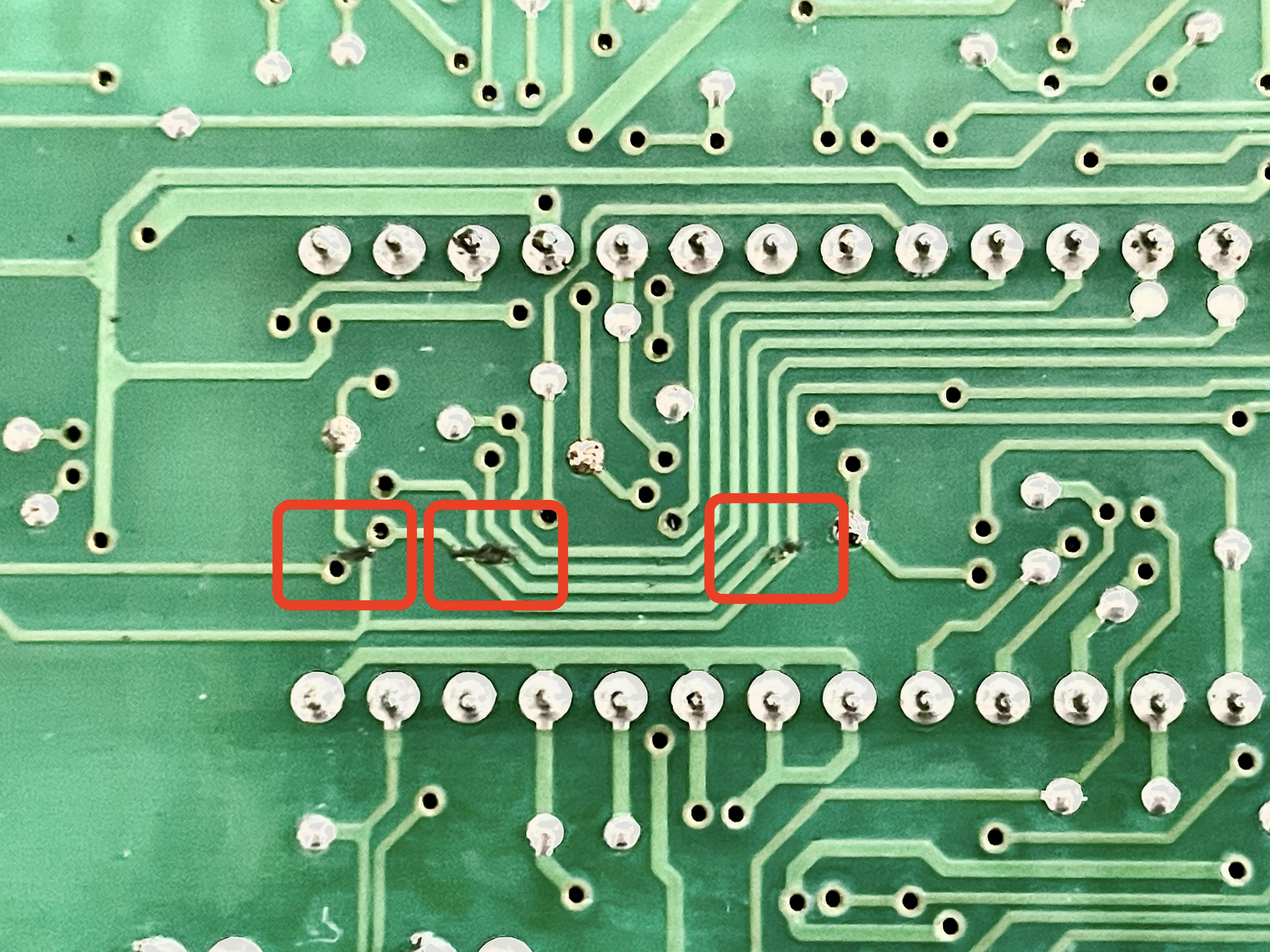

Before moving on I decided to check the IR-PCB and it’s traces more closely.

I found some foam remains sticking to and covering 2 or more traces (see 1st picture).So I decided to clean them first, which went pretty easy. And after cleaning I placed the board back and tested it again with the remote. It did not solve my issue; the BeoLab 3500 still doesn’t not respond to the Beo4.

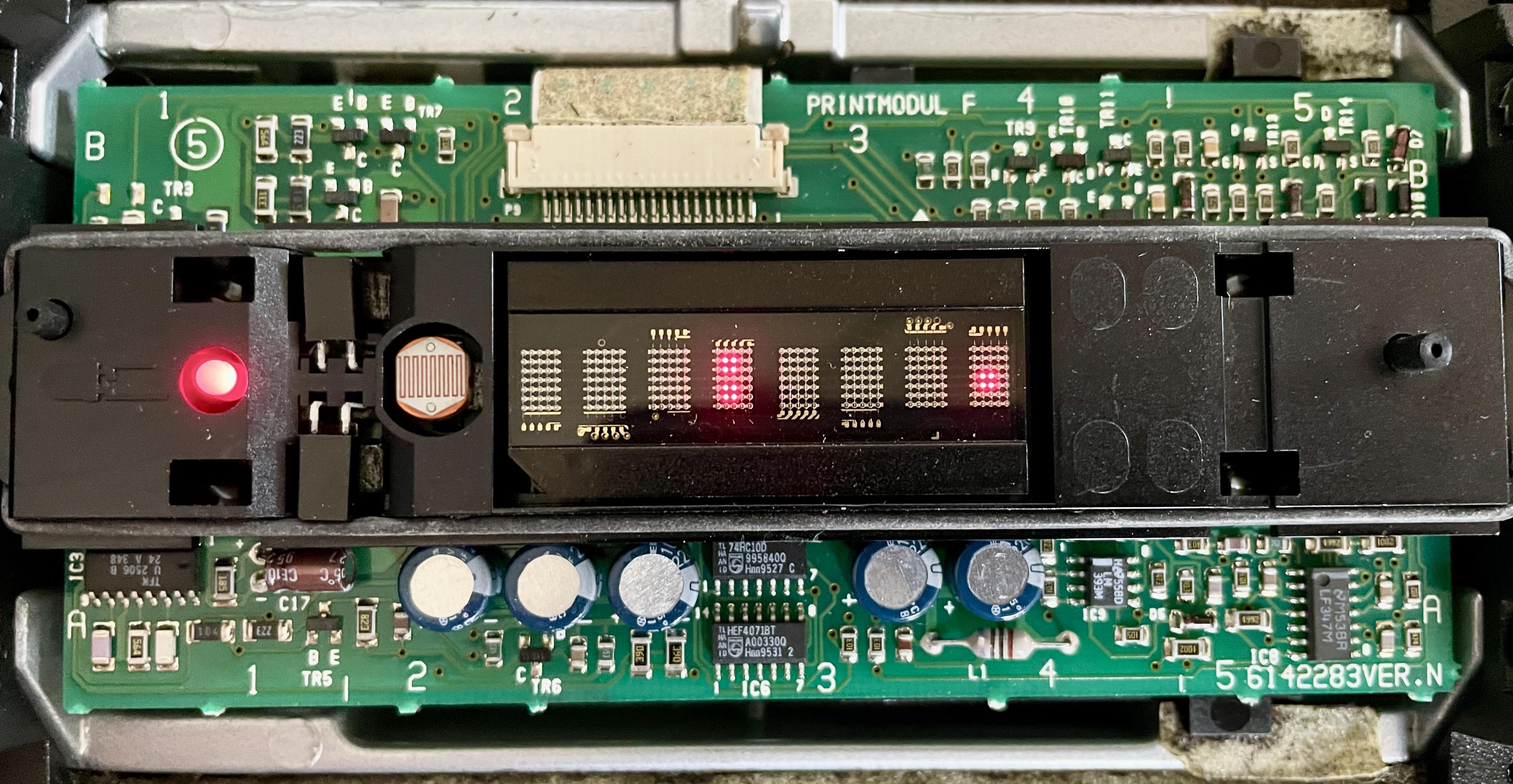

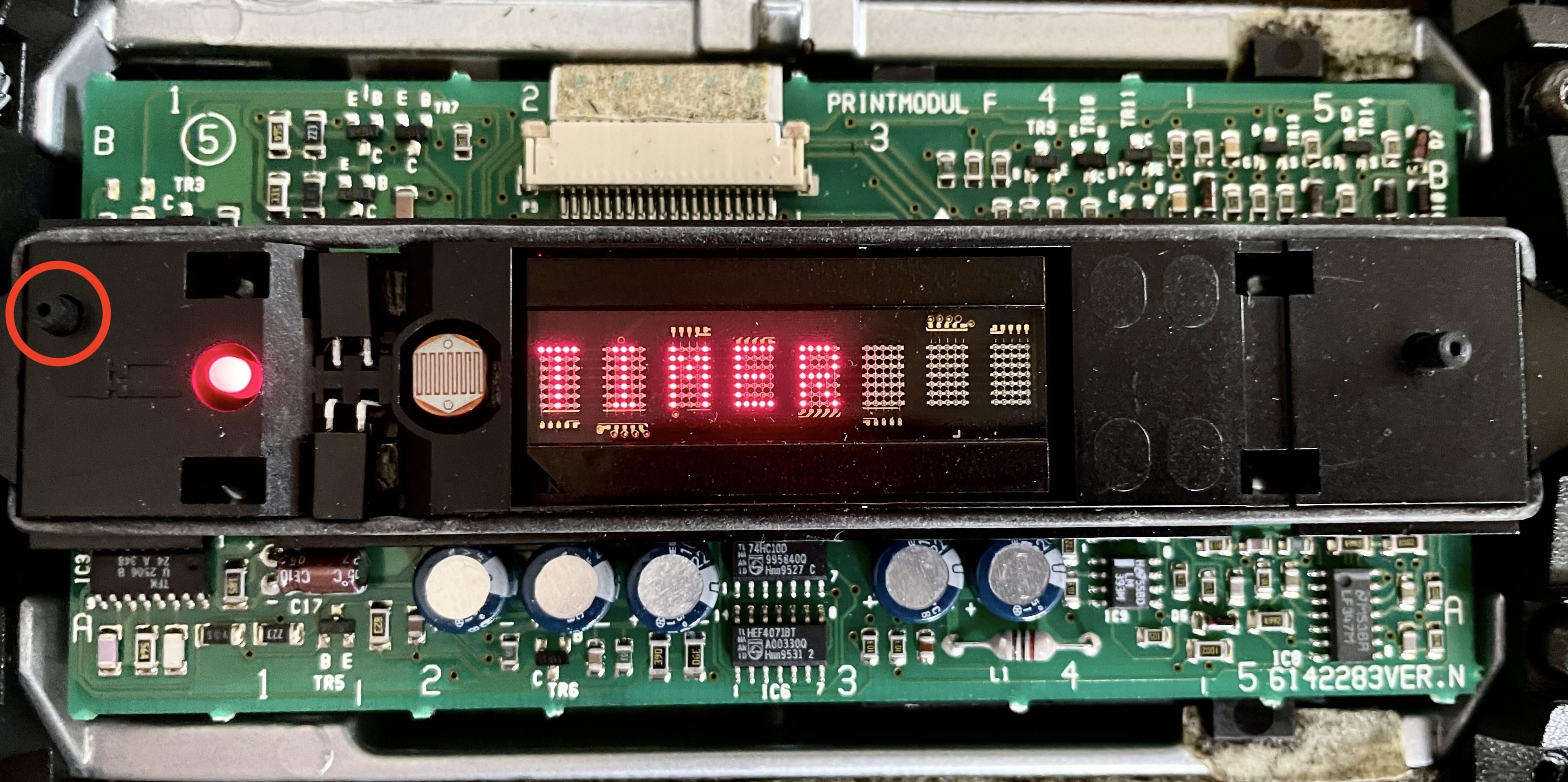

Also I would like to share what the display looks like. here’s some pictures:

(1) Display after Power On: It shows ‘:’ in the 4th segment and ‘*’ in the 8th segment.

(2) Display after pressing the Right button: all segments are blank and sometimes the red LED stains On but sometimes it goes Off.

(3) Display after pressing the Left button: the segments show ‘TIMER’.

Maybe this gives more information for additional diagnoses.

Question:

- Does this change anything for what I am about to do?

(I am about to do what B3OHACK3R advised me to do, read above)

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

10 February 2024 at 14:06 #52567B3OHACK3R

BRONZE MemberGreat, thanks for adding the pictures. Will for sure help others in the future.

I think to remember that my unit says “TIMER ON” and “TIMER OFF” when pressing that touch button. Can’t test that currently. It is mounted in a pretty inaccessible location.

Otherwise it’s looking identical.If you want to be really sure if the problem comes from the IR receiver circuit you have to probe it with an oscilloscope. In the BeoLink Active service manual you’ll find the schematic of the silver IR eye. It uses the same IR receiver chip so the circuit should be pretty much the same. You should be able to probe the outgoing (demodulated) IR signal on pin 7 of the U2506B chip.

10 February 2024 at 15:25 #52568Ok, thanks @B3OHACK3R !

In that case I will proceed with what you advised me to with exchanging components on the board.

Will be continued …

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

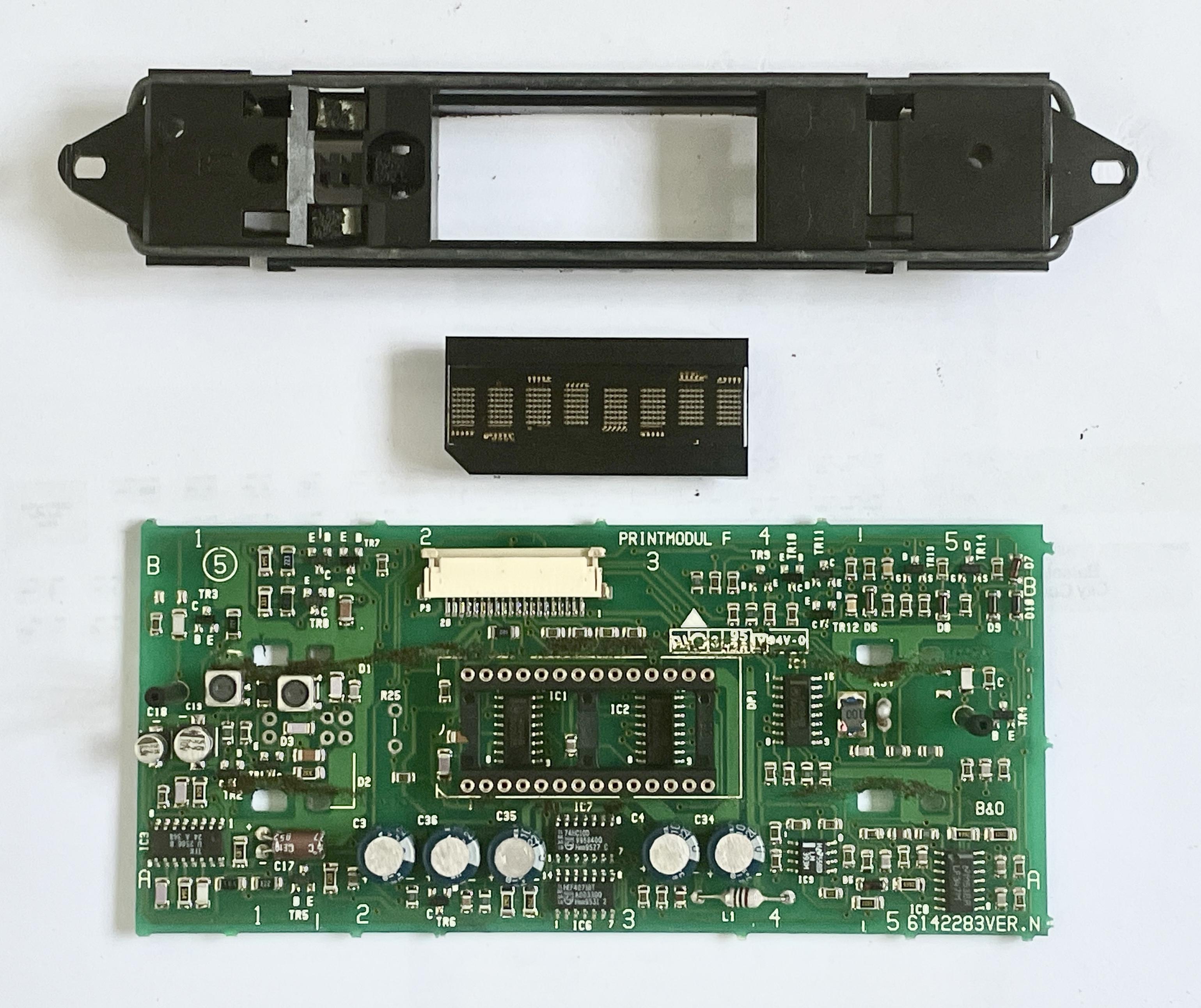

12 February 2024 at 13:13 #52569Update

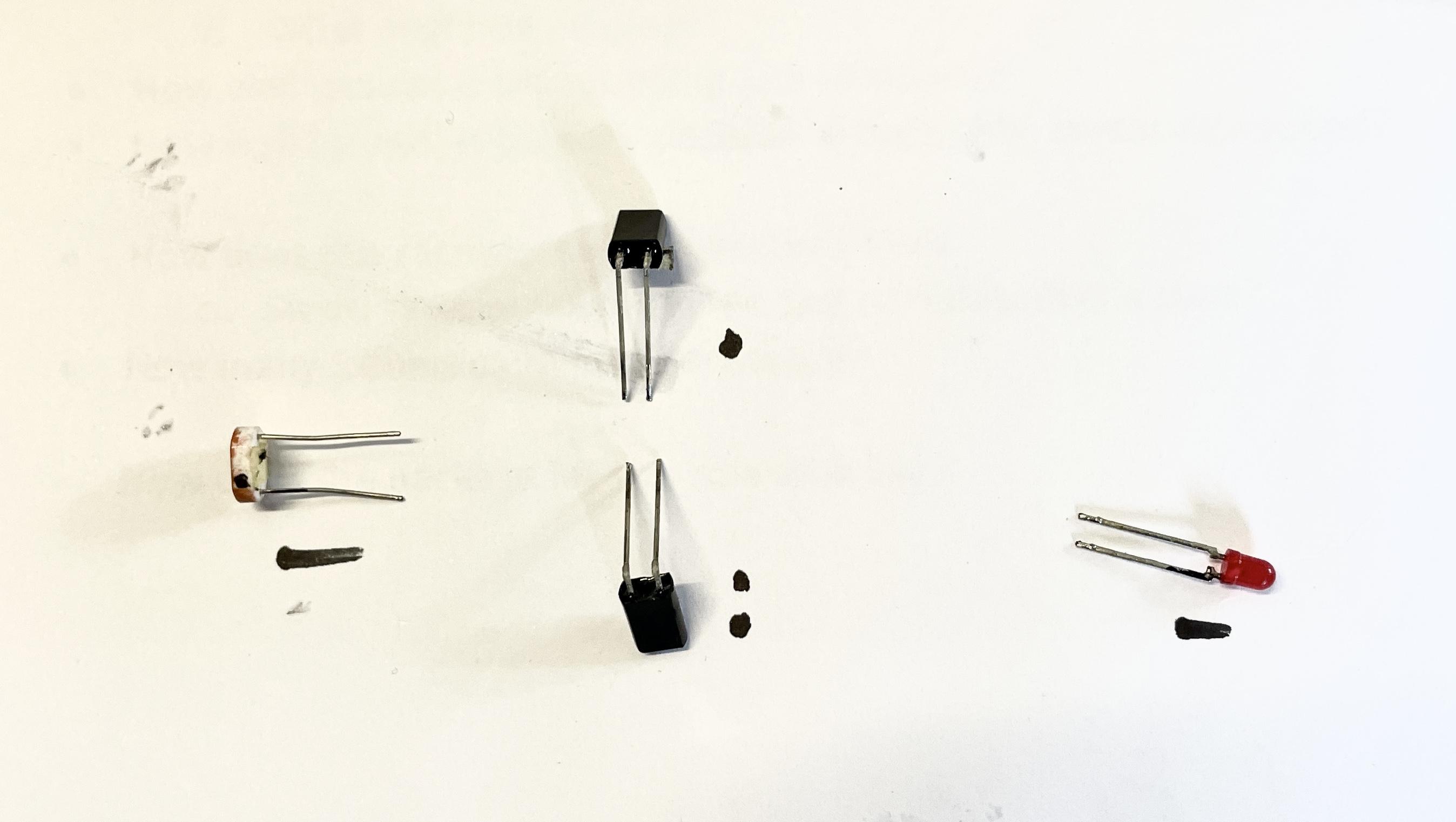

I have now de-soldered the light and IR-sensors and the LED. I took pictures and marked the legs to remember their position on the PCB.

Pulling the plastic panel from the PCB, indeed needed some force. But for anyone doing the same, be careful to lift the panel in an even, horizontal movement. Especially for the LCD-block in the middle; it sits with 26 pins in a foot socket on the PCB. So this way you can keep the legs all straight.

Replacing capacitors

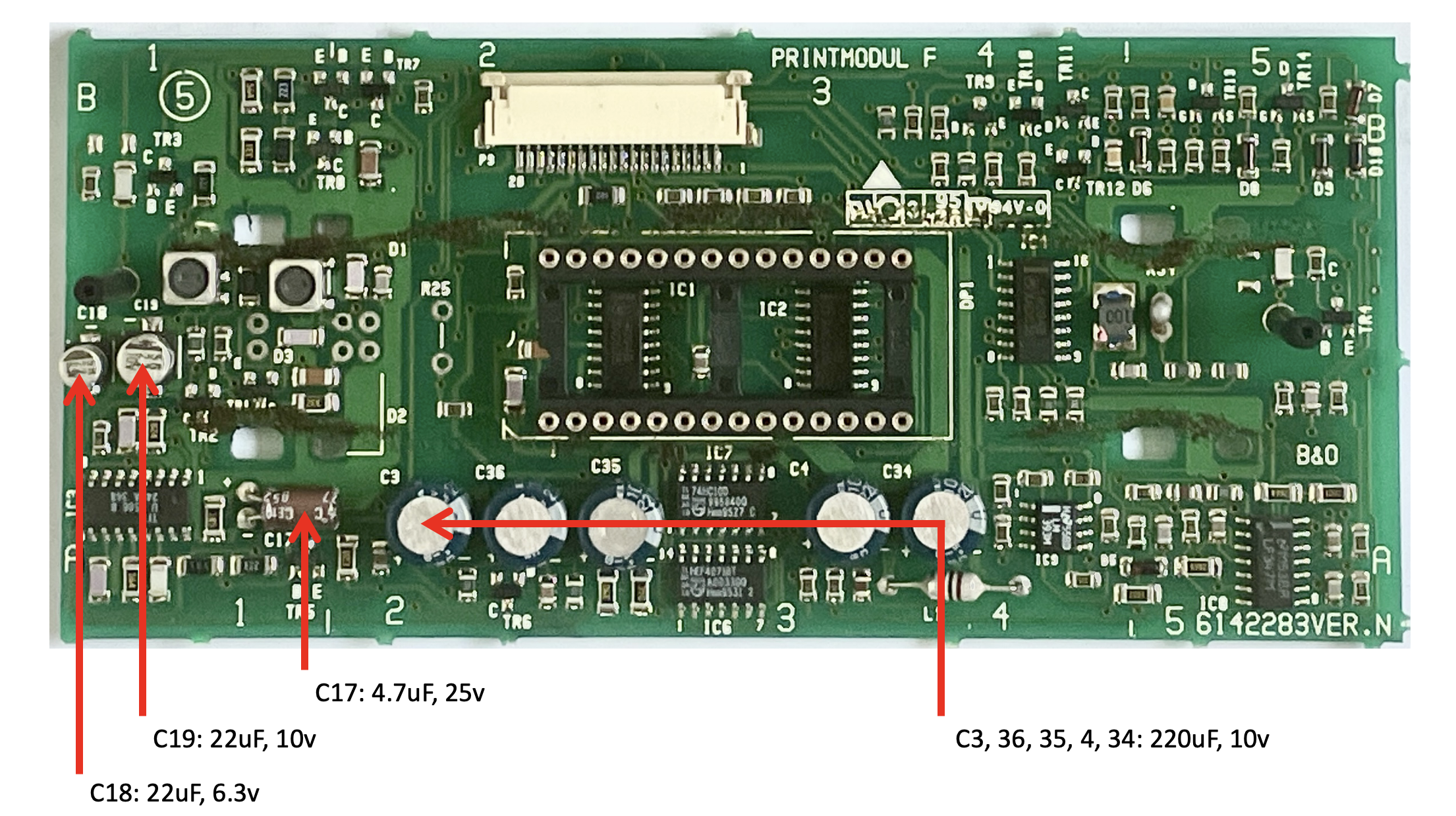

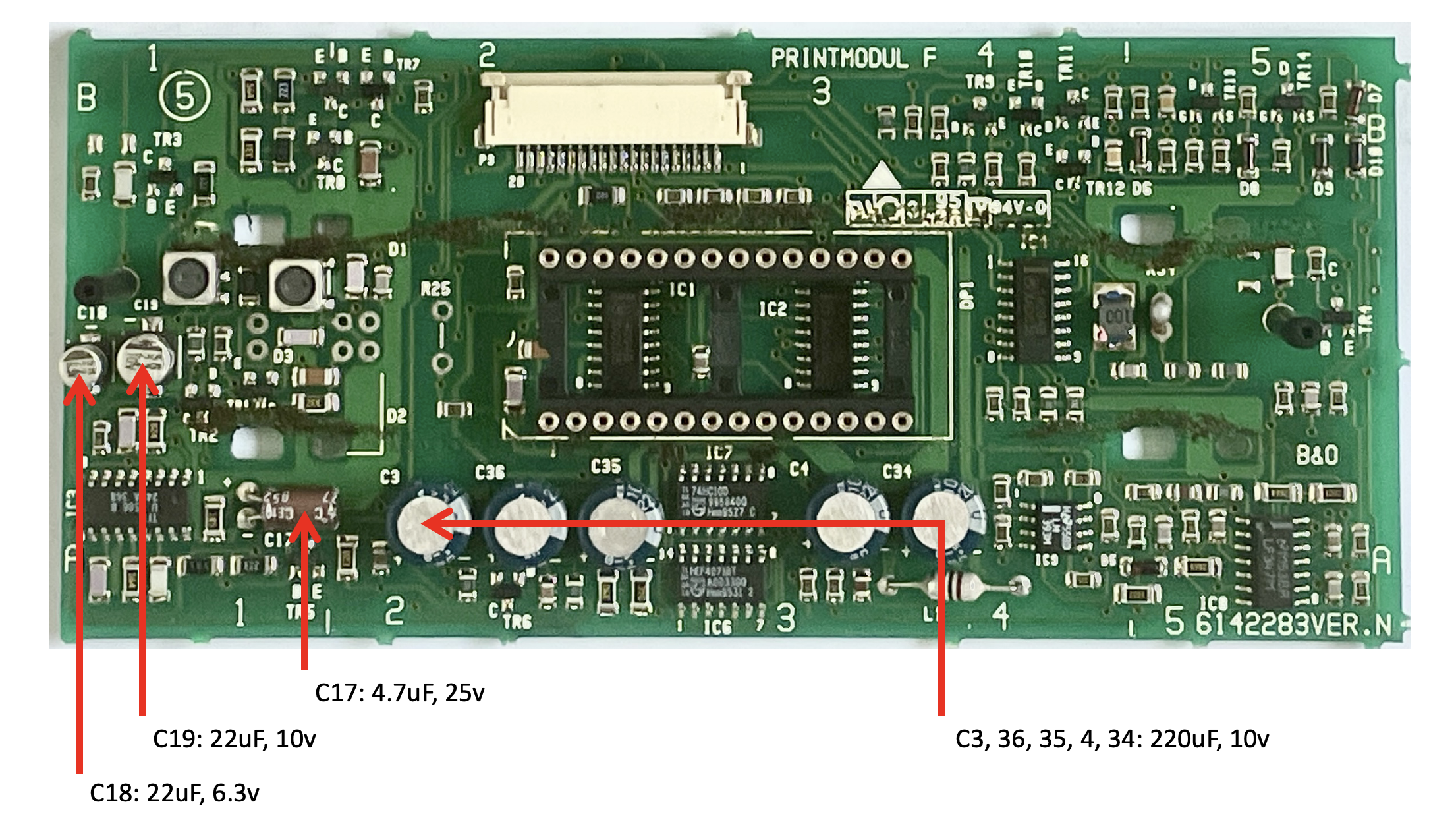

I found these capacitors on the PCB:

Questions

- If I understand wel, C18, 19 and 17 will have to be replaced, right?

- C3, 36, 35, 4 and 34 can stay in place?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

12 February 2024 at 13:21 #52570B3OHACK3R

BRONZE MemberNice progress.

If I understand wel, C18, 19 and 17 will have to be replaced, right?

Yes, exactly!

C3, 36, 35, 4 and 34 can stay in place?

Yes, I doubt that they have something to do with the IR reception. At least I haven’t touched mine.

12 February 2024 at 13:22 #52571Great & thanks!

I will now first get the components for C18, 19 & 17 and replace them.

And then make a test.To be continued …

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

12 February 2024 at 16:44 #52572Another and final update.

I have just replaced the capacitors C18, 19 and 17. After removing C17 and measuring its values on my capacitor tester, I noticed it was still ok. But anyhow while doing, I replaced it with a new one.

C18 & 19 I replaced with regular electrolytic capacitors. The voltage a bit higher than spec. but still small enough to fit.

Result after testing

Everything works fine again!

Like always, you need to know what you are doing. But this appeared to be very do-able.

For anyone else who needs to do the same. Here are some helpful steps.

Step 1 – Shift the two speaker covers from the middle to each respective side: appr. 1 cm. This will show the two black screws left and right in the middle. Removing those two screws will enable the IR-cover to be removed.

Step 2 – Next the two ribbon panels above and under the IR-panel have to be removed. Each has two light silver screws. Remove them and remove both panels.

Step 3 – On the top of the PCB, just slightly left from the middle, is a flat cable and its connector on the board. Push the two lock sliders on the side of the connector up to unlock it. Gently and evenly, pull the flat cable out. The whole PCB can now be lifted out.

Step 4 – To whole plastic panel that sits on the PCB has to be removed, to get access to the components underneath. To do so, four components have to be de-soldered:

a. Yellow = the red LED.

b. Blue = the two IR-sensors. The two top pins for the top sensor, the two bottom pins for the bottom sensor.

c. Red = for the light sensor.

d. Purple = push the clips (two-by-two) inwards to release the plastic panel from the board.Att! Be aware of the position of the components and their legs, removing them. When re-soldering them, the position of the legs has to be right. I marked them both on paper and a leg.

Be aware that to separate the panel from the PCB, some force is needed. Make sure to push/lift the panel even and in a horizontal movement upwards. The display module (block in the middle of the picture below) has two rows of 12 and (resp.) 14 pins. When the panel has been lifted off, the LCD module may come loose. Be aware of its position, especially the cut corner on the left bottom side.

Capacitor replacement

For solving the IR-issue, capacitors C17, C18 & C19 will have to be replaced.After the replacement, just work in the opposite order as described above.

It makes sense to first reassemble the PCB with its plastic bracket, the LCD module, and putting back the light & IR sensors and the red LED.

Then connect the flat cable and make a test.

If right, everything else can be put together again.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

12 February 2024 at 21:54 #52573B3OHACK3R

BRONZE MemberPerfect! Happy to hear that it worked for you.

Likely many of the BL3500 will have exactly the same issue sooner or later. Would be a shame not fixing them. They are looking really nice and have a decent sound.

So thanks for publishing that how-to guide. Something I obviously missed in my other thread. 🙂13 February 2024 at 11:24 #52574Thanks for all your help B3OHACK3R !

I couldn’t have don it without. 🙂

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

13 February 2024 at 14:17 #52575Madskp

GOLD MemberVery nice writeup of the procedure.

I will indeed save that for further reference

Location: Denmark

-

AuthorPosts

- You must be logged in to reply to this topic.