Forum Replies Created

-

AuthorPosts

-

If the display is flashing, it means the record is repeated from one time to seven times. If this happens when you only press play once, it’s usually because of a corroded switch.

Location: Copenhagen

-

This reply was modified 1 month, 3 weeks ago by

Location: Copenhagen

Check the bridge rectifier.

Location: Copenhagen

There was a thread in the old forum about how to eliminate this:

There were two situations where you could get this type of problem as I recall and they were:-

Using a Beosound like Ouverture or BS9000 as a master, the amplifier will be turned on a few seconds before the sound is plugged in through the relay; causing a blop in the speakers if they haven’t been turned on for while, say an hour.

When Beolab Penta is connected to Beovision AV 9000 or Avant, a plop could be heard in the speakers when the speakers were muted.

The solution to the first problem was apparently to:-Keep a continious small load on the big 10000µF electrolytic capacitors 6C1 and 6C2 by means of two diodes and a resistor: On PCB1 at the bottom of the amplifier/speaker. You need to put two IN4002 diodes in series with a 2.7 K ohm resister. Place the end of the string with the anodes of the diodes at the plus (+) of 1C18 which is 22 Volts Place the end of the string with the cathodes (and resistor) of the diodes at the minus (-) of 1C20 which is -22 Volts.

The second issue was resolved by:-

The control voltages connecting the speaker signal in Beolab Penta in/out on 22IC2 pins 5/12 are determined by the voltage dividers 22R13 to 22R16. As the control voltages are higher than the supply voltage of 22IC2, a positive DC voltage will occur on the Power Link input. When the Beovision is muted, the speaker signal is pulled to chassis. Thereby a DC loop occurs which results in a plop in the Beolab Penta speakers. The solution is to change 22R13 and 22R15 from 390 Kohms to 470 Kohms.

There are no issues with the damping material.

Location: Copenhagen

It probably resembles the issue I had with my BG7000, and Martin (Dillen) answered that I should clean the switch near the top left of the deck – it’s marked S1. This helped.

Location: Copenhagen

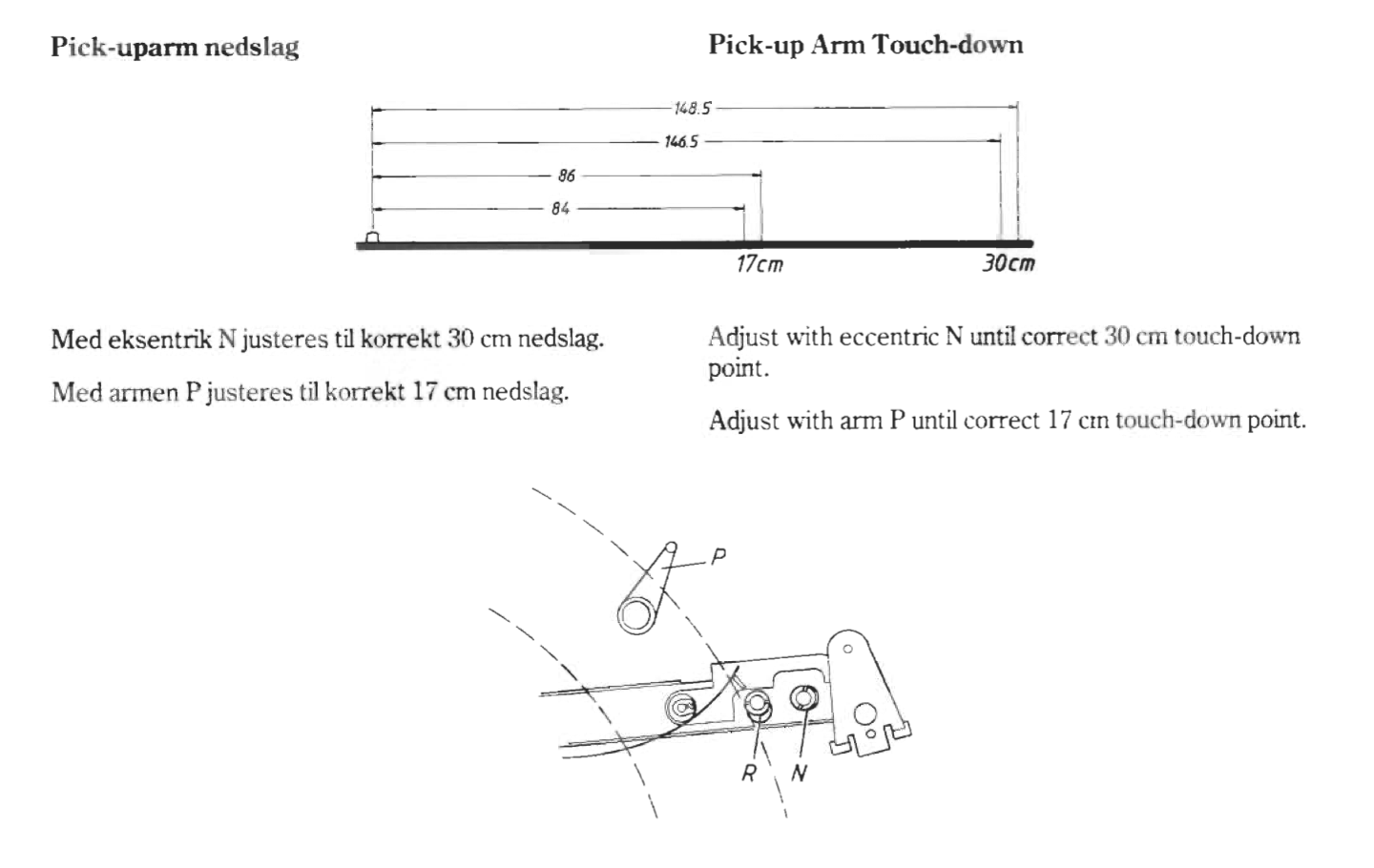

10 February 2025 at 10:57 in reply to: Beogram 1800 not setting down at correct point on record #63661Yes, there is. However, it depends what kind of Beogram 1800 you have. If it is the one from the early 70s, you can look at this post: https://archivedforum2.beoworld.org/forums/p/12303/111377.aspx

If it is a Beogram 1800 from the 80s, the procedure is this:

Location: Copenhagen

Have you pressed the buttons for Speakers down on the front (there are two separate buttons)? Also, the balance pot may need a cleaning.

Location: Copenhagen

Indeed the problem was that I had soldered pin 6 instead of pin 7. Now it works. Time will tell when I revisit that front PLAY button issue. I think the board needs to be positioned very accurately for the pin to hit the conductive spring, so it may just be a matter of misalignment as the board works when I press it with a finger.

Location: Copenhagen

The BG7000 has an RIAA preamp.

Location: Copenhagen

It was a DIN wire that had broken off. Does anyone have a diagram for wires? I have sound in right and left channel now but datalink doesn’t work, so I presume I have soldered the datalink wire (yellow) to the wrong pin.

Location: Copenhagen

Argh – I am getting tired. Now I only have sound in the right speaker.

Location: Copenhagen

Yes, I have all 7 pins.

The switch under the front panel PLAY button was very corroded. I cleaned it but it is falling apart, and I can’t seem to position it correctly for it to work when I press the PLAY front. After fiddling with it for hours, I have decided to accept that it doesn’t work. Can I replace it with another type of tactile switch? It seems to be a rather cheaply made board where a piece of tape was holding the metal plate in place. Any suggestions?

Location: Copenhagen

I spoke too soon. It fixed the issue when pressing the top PLAY button, however, when pressing the front PLAY button, it sometimes only spins the record and moves the arm to the beginning of the record. It also doesn’t turn on the amplifier if it is in standby mode. I can live with it but would love to fix this issue too.

Location: Copenhagen

Amazing. I cleaned S1 and S2 with a fibre brush pen, and now it works as it should again. Thanks, Martin!

Location: Copenhagen

23 January 2025 at 22:19 in reply to: Speech Intelligibility issue with AppleTV and surround settings 5.1 and 7.1 #63036Perhaps the Beolab 14 speakers are not very good for centre speakers.

Regarding the Apple TV – why not set the sound to AUTO? This avoids the Apple TV converting all signals to Dolby 5.1 and will give you an uncompressed multi channel LPCM signal that your TV should be able to convert to the right surround formats.

Location: Copenhagen

First things to check would be the belt for the carriage. And the pulley will most likely be cracked as they all are by this time. Get a new one in metal – some people here sell them.

Location: Copenhagen

First of all, measure the current idle current. If it is already 10mV, this is not where your problem is. You can measure over the points given in the below screenshot (see instructions below).

According to the service manual:

- The unit must be cold and the volume turned all the way down. Speakers must not be connected.

- Select P1 to P5

- Connect a Voltmeter between 3TP200 and 3TP201 and adjust 3R224 to 10mV. Do the same with a Voltmeter between 3TP100 and 3TP101 and adjust R124 to 10mV.

I suggest you either clean the trimpots first with contact cleaner and give them a few turns back and forth (take note of where they were) or that you replace them. They are known to corrode over time.

Regarding the instructions to put a Voltmeter between two resistors – it essentially means to put the probes of your multimeter on the outer legs of the two resistors to be measured. I have marked the points with red and green. The two red points are for R124 and the green points are for R224. Be careful that your probes do not slip.

Attachments:

You must be logged in to view attached files.Location: Copenhagen

Since I finally got around to solve the issue with my Beomaster 7000 not turning on the amplifier section (TR19 was defective), I thought I would continue a little TLC for my Beogram CD7000. I carried out the mechanical adjustments in the service manual as I thought the drive was slightly noisy with some CDs making a whirring sound. That seems to be gone now. Next up was reconfiguring the transformer from 220V to 240V. The hardest part was to get the damn plastic protection cover off. It takes quite a bit of persuasion while pulling outwards at the front and trying to slide it back at the same time. After that I unscrewed the transformer and looked at it. After a short while, I figured out that the jumper needed to be desoldered, moved and then soldered back in the new position. Quite easy. I believe the benefits are that the unit should not heat up as much as before and perhaps also stress components less. That completed the restoration of the Beogram CD7000 that I had previously recapped and changed C2103 in.

Location: Copenhagen

If the other one has no display at all, please check the switch at the bottom of the speaker where you can turn the display off. I think it says Audio/Video – and the idea was to be able to turn of the display in a dedicated cinema room.

Location: Copenhagen

Check the foam in the speaker. If it is gray, it will have started to become a sticky mess that eats away traces at the amplifier section. This is a well-known problem – search in the old forum and you will find lots of info about it.

Location: Copenhagen

-

This reply was modified 1 month, 3 weeks ago by

-

AuthorPosts