Home › Forums › Product Discussion & Questions › BeoGram › Tips for adjusting BG4000 platter height

- This topic has 10 replies, 4 voices, and was last updated 1 year, 10 months ago by

-

AuthorPosts

-

1 March 2024 at 16:32 #54089

GOLD Member

GOLD MemberLocation: Netherlands

5 April 2024 at 08:24 #54088etype76

BRONZE MemberHi,

I’ve been trying to get the platter on a new to me BG4000 level with the surrounding plates. Wondering if any of you experienced Beoworlders have any golden tips on this matter. I’ve got the top part of the platter and the right side kind of flush but the lower half of the platter is sitting too high.

How sensitive are the adjustment screws? I mean am I working in half/quarter turns or am I turning them fully? Do I tighten the nuts after until they snugly lock? I’ve read the couple of lines in the service manual and watched a beolover video but still having a go at it.

tia

6 April 2024 at 10:09 #54090etype76

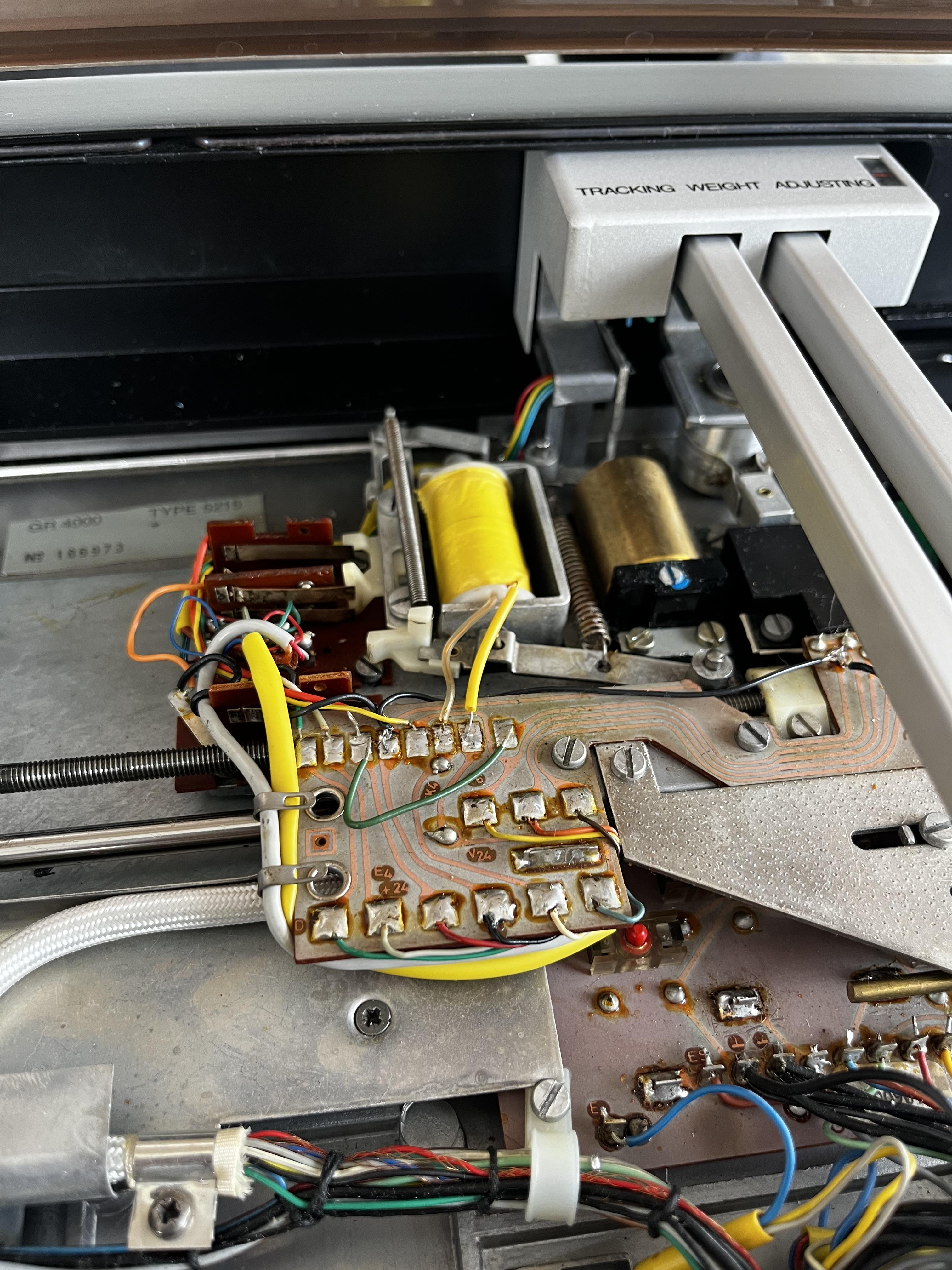

BRONZE MemberSome progress has been made. The platter is sitting much flusher with the surrounds. There is a scraping sound when the tonearm reaches just past halfway point. At first I thought it was the stylus in the groove but I can hear the sound even when the tone arm is raised over the record.

6 April 2024 at 10:42 #54091Dillen

ModeratorSolenoid leads touching the platter underside?

Martin

6 April 2024 at 11:00 #54092etype76

BRONZE MemberI’ll check tomorrow. The sound is intermittent with the rotation of the platter. I also think the sub chassis might need raising as it may be touching the bottom even though there is a 1mm or so play when I push the platter down at the spindle. But a gentle side to side wiggle of the platter I can hear/feel some friction.

thx7 April 2024 at 03:52 #54093etype76

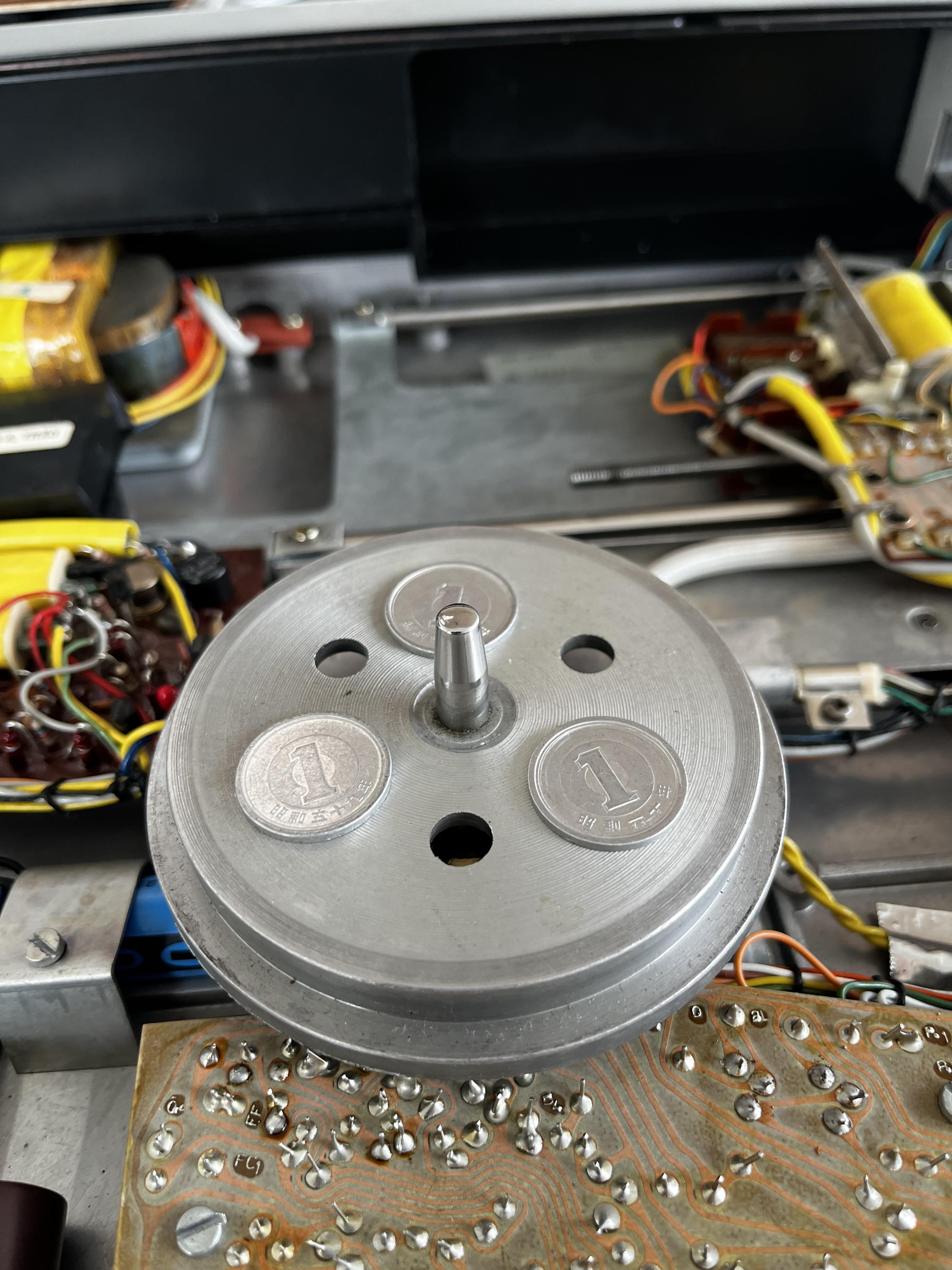

BRONZE MemberI think you’re right, Martin. With the plates off again I can hear the noise begin when the “guts” of the tonearm assembly are fully under the platter. An inspection doesn’t show anything specific sticking up although I expect it to be the thickly shielded yellow cable. I’m not messing with those! As a test, I place 3 thin coins on the platter hub to shim it up and the noise disappeared. I also adjusted the springs again and the floating chassis feels better now with the platter bouncing back to centre suggesting it has fully cleared the bottom. I have leveled the platter with the surrounds too. For now, I’ll keep the coins in place.

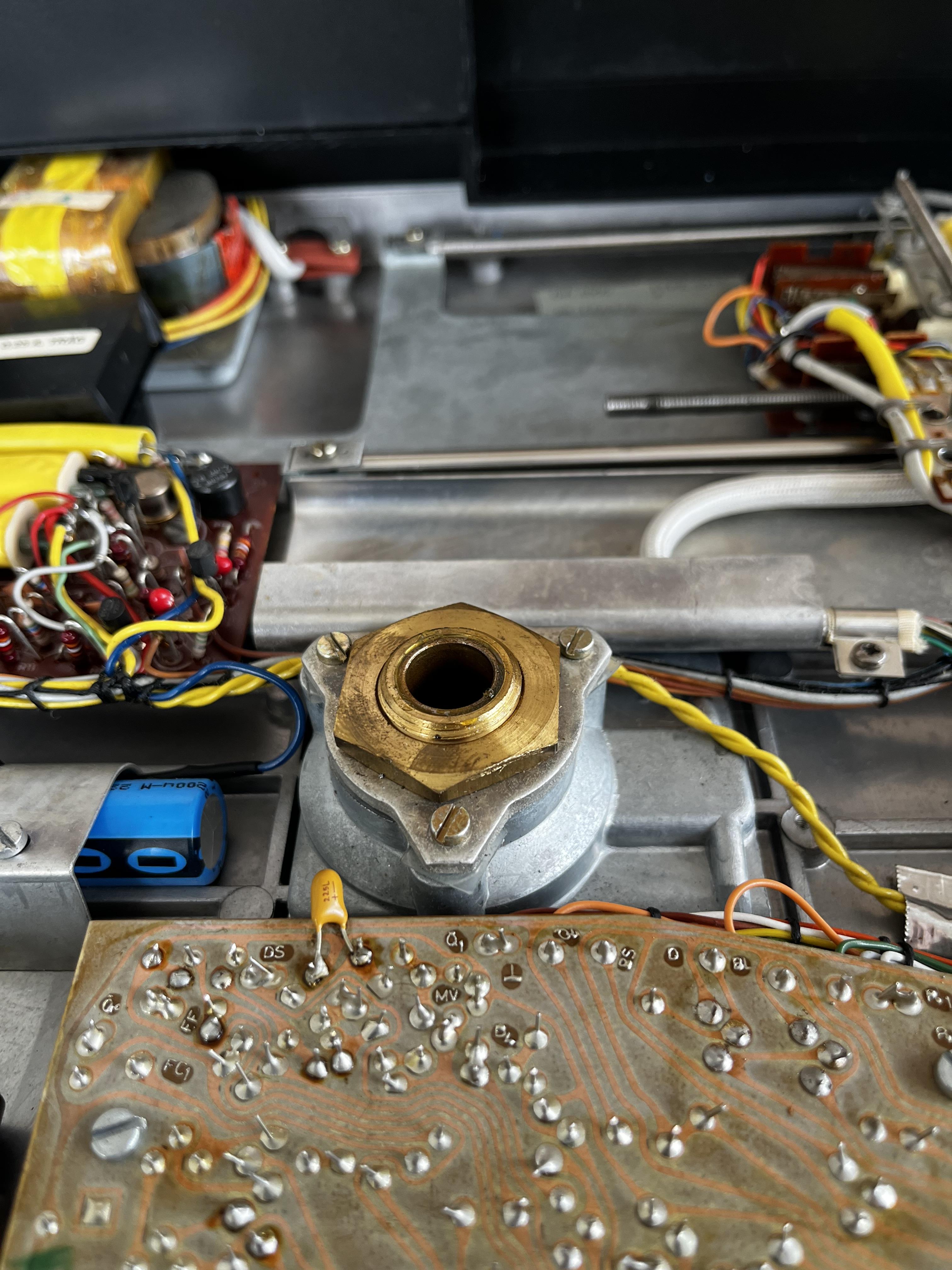

I notice that the bearing on this 4000 is different from the manual. It’s a brass fixture so am not sure if the vertical height can be adjusted there.

7 April 2024 at 06:43 #54094 BRONZE Member

BRONZE MemberI have seen the braided cable rise up out of the curved channel as approaching the spindle if it is twisted. Also the bearing height is adjustable. The brass bearing is threaded and with a large locking nut on top. However, that rarely ever is the problem.

7 April 2024 at 09:04 #54095etype76

BRONZE MemberThank you for the input! I’ll take another look at that. I did check it and it looked quite snug in there but not sure when the carriage is under the platter.

I have also noticed that the arm drops too quickly, no damping. This drop causes some pop on touch down and lift off. This seems more pronounced after raising the platter height today.

8 April 2024 at 03:40 #54096 BRONZE Member

BRONZE MemberThe screw in the black bottom of the damping cylinder controls the rate of descent.

9 April 2024 at 08:45 #54097etype76

BRONZE MemberI adjusted the screw on the cylinder, gave it 4 slight turns totalling a quarter turn in all. I don’t notice any difference at record level but when I removed the platter the arm is definitely lowering gently just not the short distance to the LP surface. The arm also springs back up very quickly. Should I go further and keep turning the damper cylinder screw?

Another odd thing is that the scraping sound has disappeared now, even after removing those coins so whatever was the obstruction has cleared.

9 April 2024 at 14:30 #54098 BRONZE Member

BRONZE MemberThe damping cylinder only slows lowering. Raising should be quick. You can turn it more to slow it further. It simply won’t lower if too much.

-

AuthorPosts

- You must be logged in to reply to this topic.