Home › Forums › Product Discussion & Questions › BeoLab › Evan’s MK2 BeoLab Pentas

- This topic has 32 replies, 5 voices, and was last updated 2 years, 11 months ago by

Evan.

-

AuthorPosts

-

16 January 2023 at 10:25 #42907

Evan

GOLD MemberHey everyone! It’s been a long time since I’ve written a thread like this but it seems I have some time to do so and I shouldn’t keep all my delicious build photos to myself.

Here is the long (and still running!) saga of my 2022 rescue of a pair of MK2 PentaLabs.

But first some context! I kind of live in two places – San Francisco, CA and Bridgend, Wales. It’s a long story that mostly involves work. Work is speakers, and speakers are life so everything has blended into one and the same. So if some of the details in this story don’t make logical/logistical sense then that is most likely due to my frantic, time-impoverished, trying to keep everyone happy, expat lifestyle I currently find myself in.

Like many of you, I religiously browse Facebook marketplace, craigslist and eBay just looking at all the B&O gear I could buy. I found a listing for a pair of MK2 Pentas in the East Bay area and kept my eye on the listing for a few months. Definitely didn’t need them as I already have a pair of MK3’s (in a storage unit, 2500 miles away, might as well be on Mars) but then again, the bedroom in SF needs some floor-standers for movie watching and to play music from my then recently acquired BS Moment that the PrizeDrawBot himself sent my way. Turns out luck was on my side as the girlfriend and I found ourselves in the east bay at a lunch gathering. This was a group of my girlfriend’s colleagues so I was naturally, silently plotting to grab those Pentas on the way home. And snag them we did. I even planned ahead for this and made sure we took the larger of our cars in order to accommodate them and carry them home.

Naturally the confident seller stated that they were a flawless pair of Pentas that had zero foam rot. The seller was a restauranteur and used them as PA speakers for wedding receptions and that sort of thing so in hindsight they had lived a pretty tough life. We arrived at the restaurant and I shined my phone light through the fret to show him what foam rot really looked like – the surrounds were literally falling out and collecting in a neat pile behind the fret. The seller also decided to stop using the amps themselves and very inconveniently extended a pair of speaker wires through them amp (yes, he fished the wire THROUGH the amp) instead of just disconnecting the amps altogether and running wire out the back. But at any rate, they seemed savable and both made music so I made a deal.

I think in the end I paid $450 for them.

Here they are in our old bedroom connected up to the Moment for sadly what was only a very brief moment. The amp started cutting out on the right BeoLab and I realized that the tweeter wasn’t even playing. So out they went into the garage as I ordered parts and prepared for my departure to Wales.

Location: San Francisco

16 January 2023 at 22:31 #42908Evan

GOLD MemberI quickly ordered all the cap kits from BeoParts and a new set of surrounds from good hifi (I think). Both took a long time to arrive in CA and sadly not soon enough for me to do anything about it. I was flying out to Wales in order to start my next assignment at work.

They stood in the corner of the garage not doing anything for about 3 months.

I finally returned from Wales in November and finally had the chance to sink my teeth into these babies. First things first – lets get the mids out.

Location: San Francisco

16 January 2023 at 22:33 #42909Evan

GOLD MemberAfter taking the mids out and taking those to the office (more about that later), I decided to pull out the crossovers and start there. Lets get started with the fun, easy soldering of putting new caps into the crossover.

Location: San Francisco

16 January 2023 at 22:39 #42910Evan

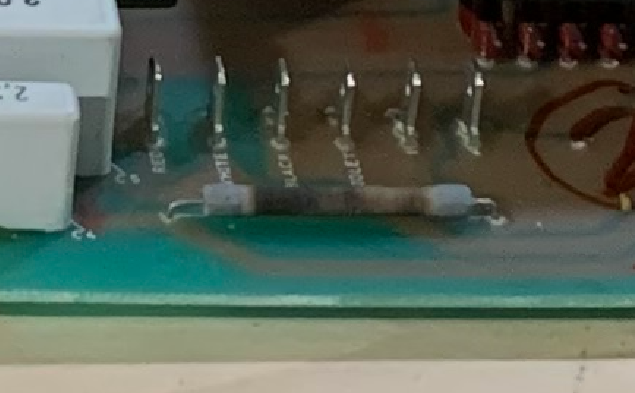

GOLD MemberOne thing I didn’t notice until I started the re-cap was this burned resistor.

I suspect this artifact is evidence to their history of being thrashed in a large restaurant but this seemed to be the limit to the damage on the crossover. Anyway, needed to order this resistor from Mouser and do some waiting. So I moved on to the amps themselves while waiting for a pair of these resistors to arrive.

Location: San Francisco

16 January 2023 at 23:25 #42911Evan

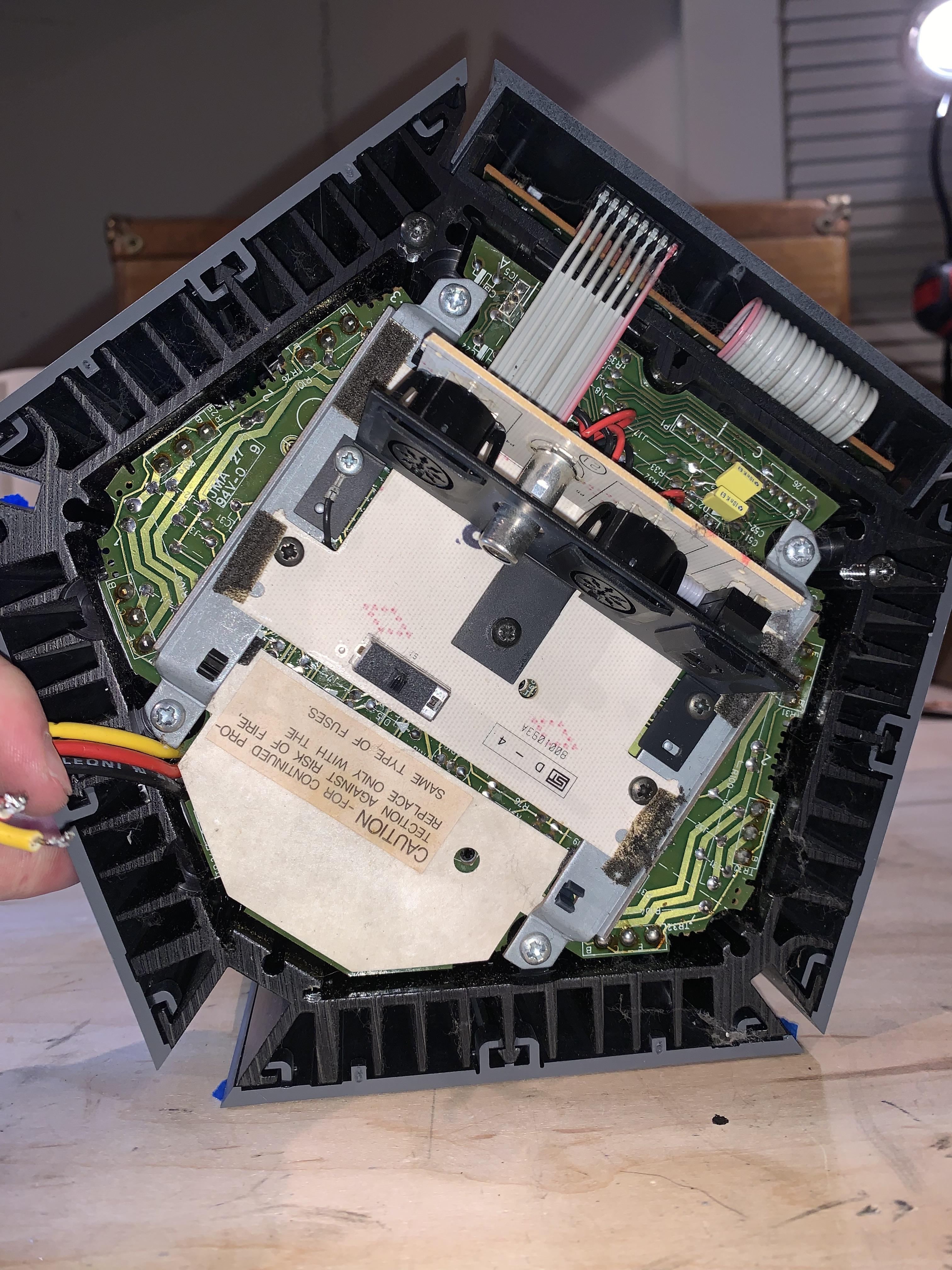

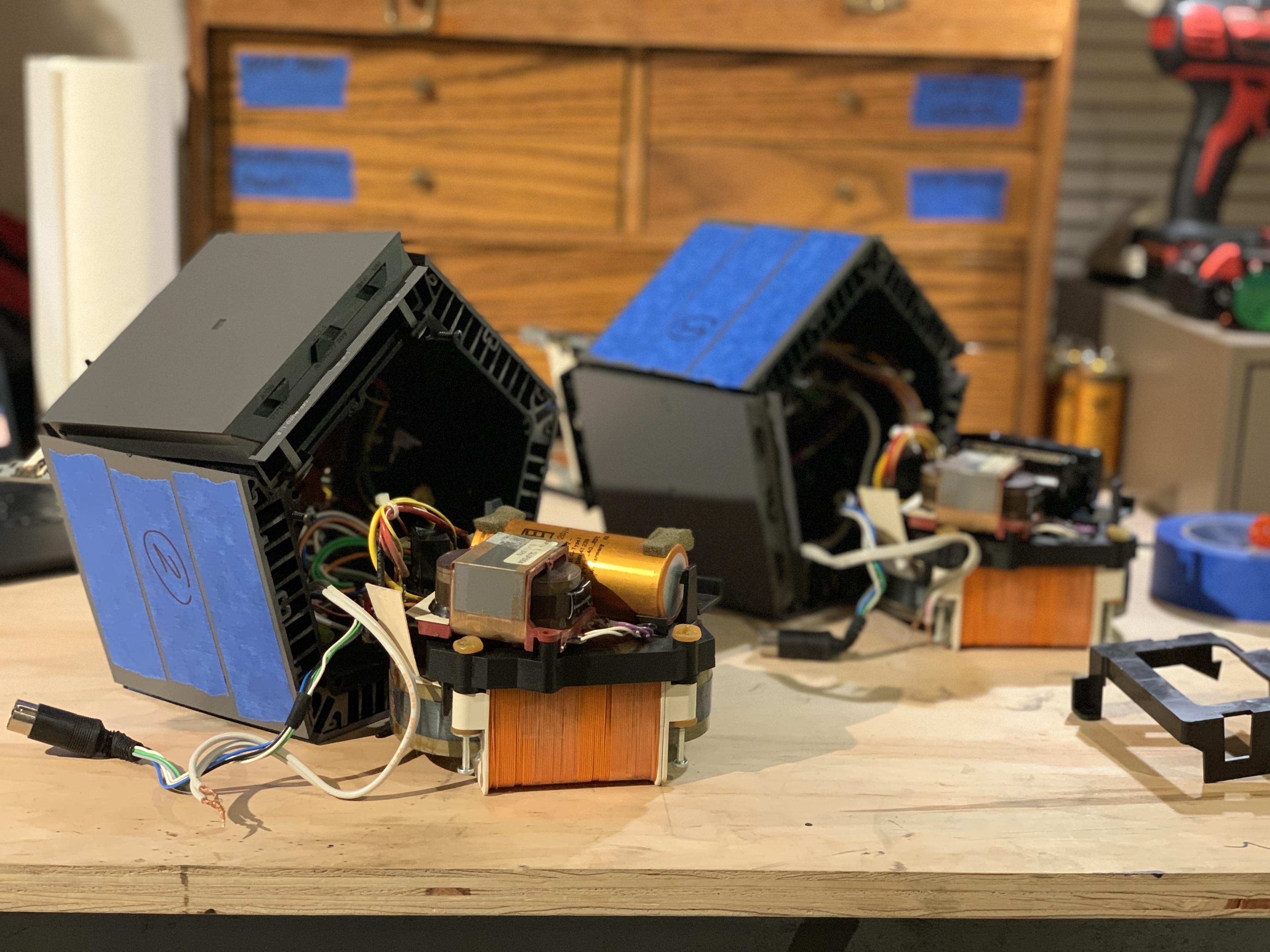

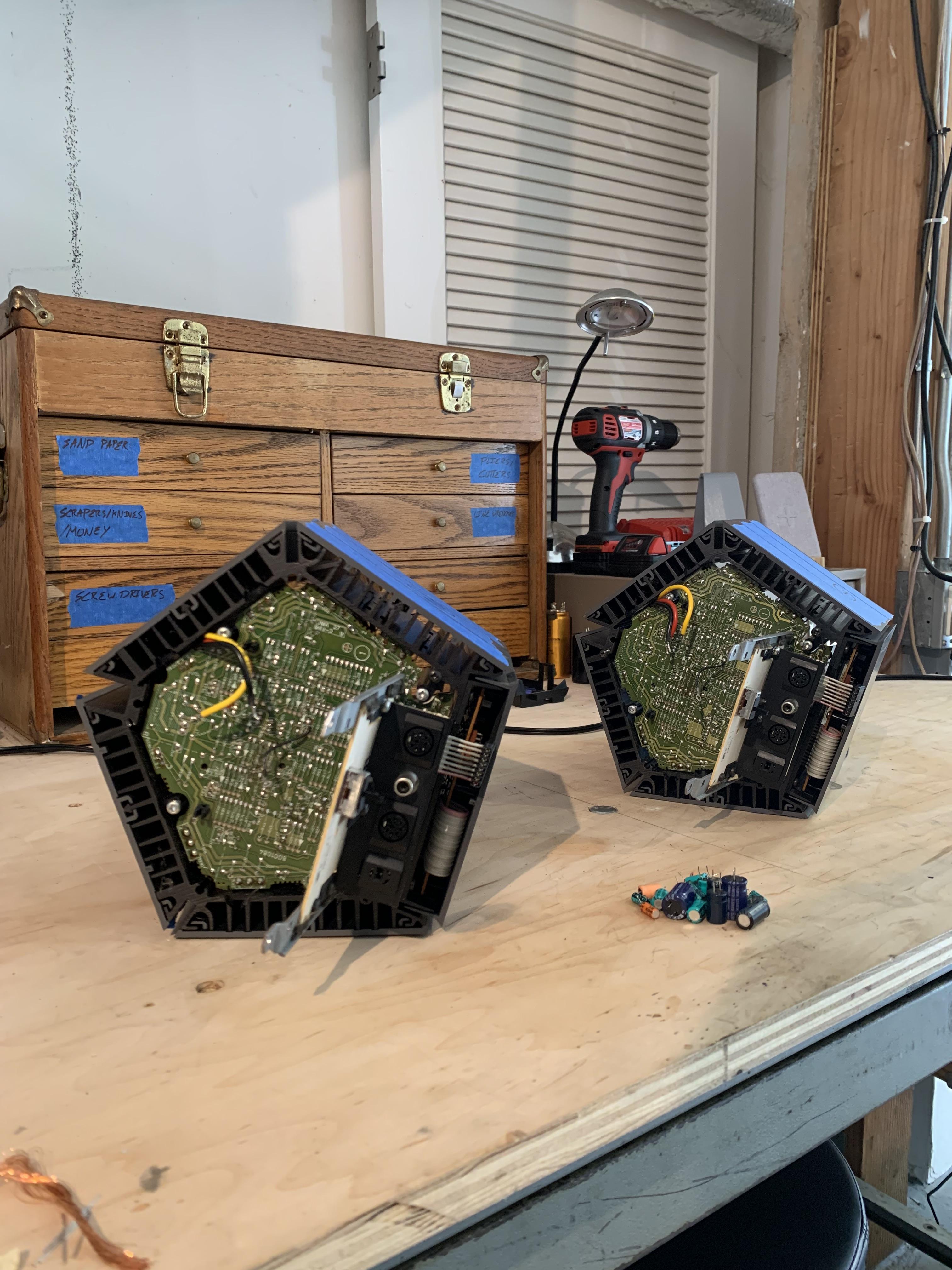

GOLD MemberNow time for the amplifiers. Man do these things need a lot of disassembly before you can really get to the matter at hand. Not to mention the actual task of working inside a pentagonal heatsink. However that was also something to marvel at. The engineer in me is very impressed that this amp even exists. The heat sink is clearly just big enough to hold the transformer and there seemingly isn’t a single right angle among any two components. Packaging this thing mist have been hell. If anyone from the original Penta project team is reading this, I’d love to know more about this. Did you guys/gals use CAD to develop this package?! Even if you did, I’m impressed.

Never mind the poor photo, this was mostly just to keep track of cable routing.

Now that the gray trim pieces and power cord are off, its time to pull out those power supplies.

Location: San Francisco

16 January 2023 at 23:28 #42912Evan

GOLD MemberSee what I mean?? This is amazing. Yes, those power supplies actually fit in there!

This level of disassembly is unfortunately necessary, the power caps (and all other caps to be honest) live in the core of this beast.

Location: San Francisco

17 January 2023 at 00:41 #42913Loving this thread 🙂

Location: Kent, UK

Favourite Product: Beosystem 6500

My B&O Icons:

17 January 2023 at 00:54 #42914Evan

GOLD MemberLoving this thread

Glad you like it! Had to take a lunch break, now back at it.

Location: San Francisco

17 January 2023 at 01:00 #42915Evan

GOLD MemberFirst thing was to get the main power caps swapped out. Seemed easy enough! Turned out, like many things in this amp, to be a highly-tedious process due to the cramped nature of this beast. The cable routings are exact. No real wiggle room to get things in and out and the lack of extra wiring harness made it extremely tough to get the connections made without burning things nearby with the soldering iron.

In the background I was watching the AutoAlex series on his new Jag XJR-6. Highly recommended! Judging by the coffee hardware in the background this was clearly an AM session!

Location: San Francisco

17 January 2023 at 01:03 #42916Evan

GOLD MemberA closer look at what I mean. No slack in the wires and they are nearly tied in knots through those solder lugs. I tried to surgically remove the wiring exactly as it was by de-soldering with a pump and painstakingly maneuvering the wires out but in the end it wasn’t worth it.

In order to get the new caps to fit in the black plastic holder, I needed to add some wire so I soldered on some extensions ultimately.

Location: San Francisco

17 January 2023 at 01:06 #42917Evan

GOLD MemberNew power caps are finally in. I always appreciate finding all the little B&O branding elements throughout old systems like this. I’m guessing these were all made by suppliers but still nice to see.

Location: San Francisco

17 January 2023 at 01:09 #42918Evan

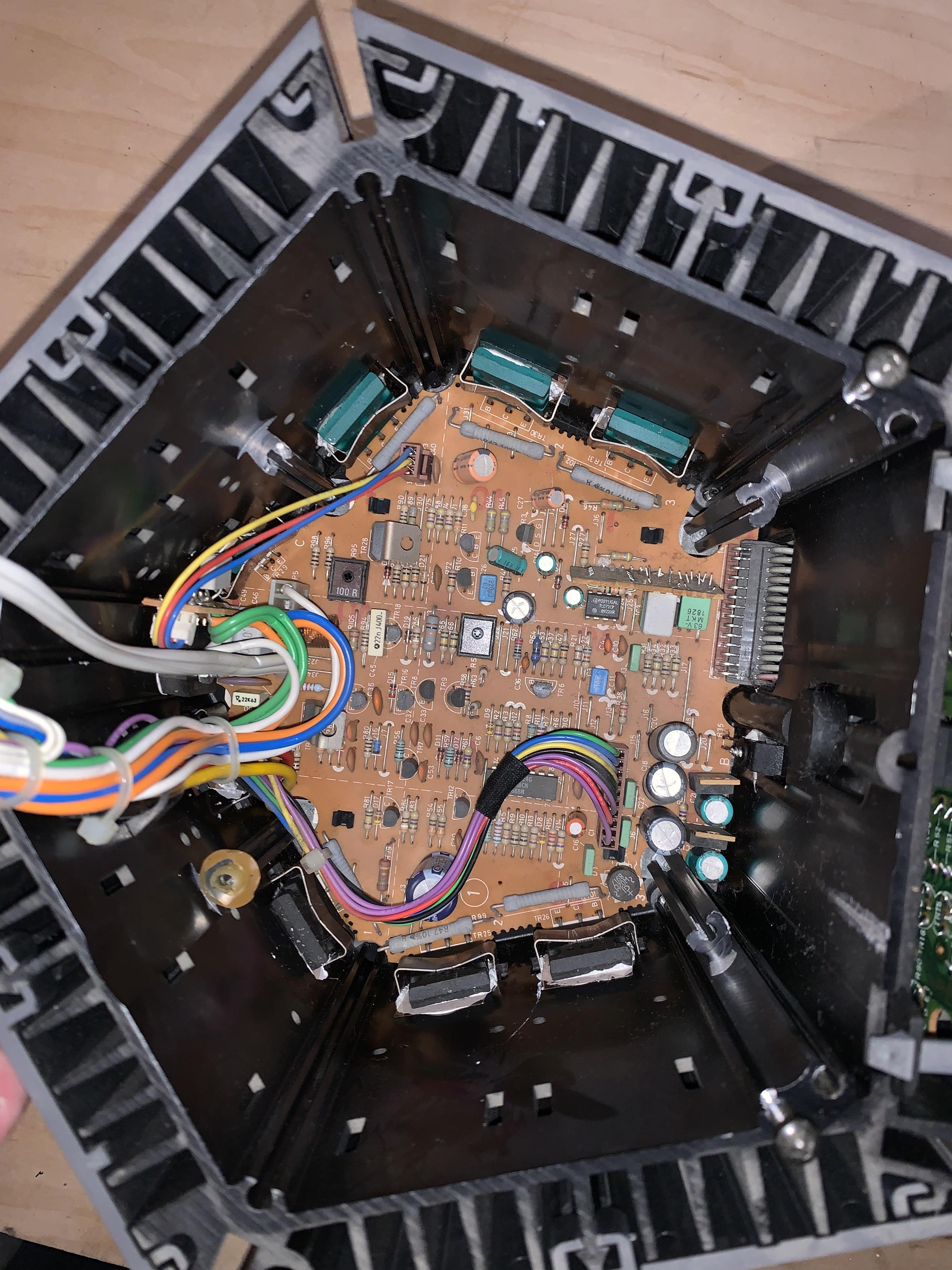

GOLD MemberNow for all the little caps inside plus trimmers and a fresh Burr Brown OPA134 op amp. Hope you like working with a flashlight.

Location: San Francisco

17 January 2023 at 01:12 #42919Evan

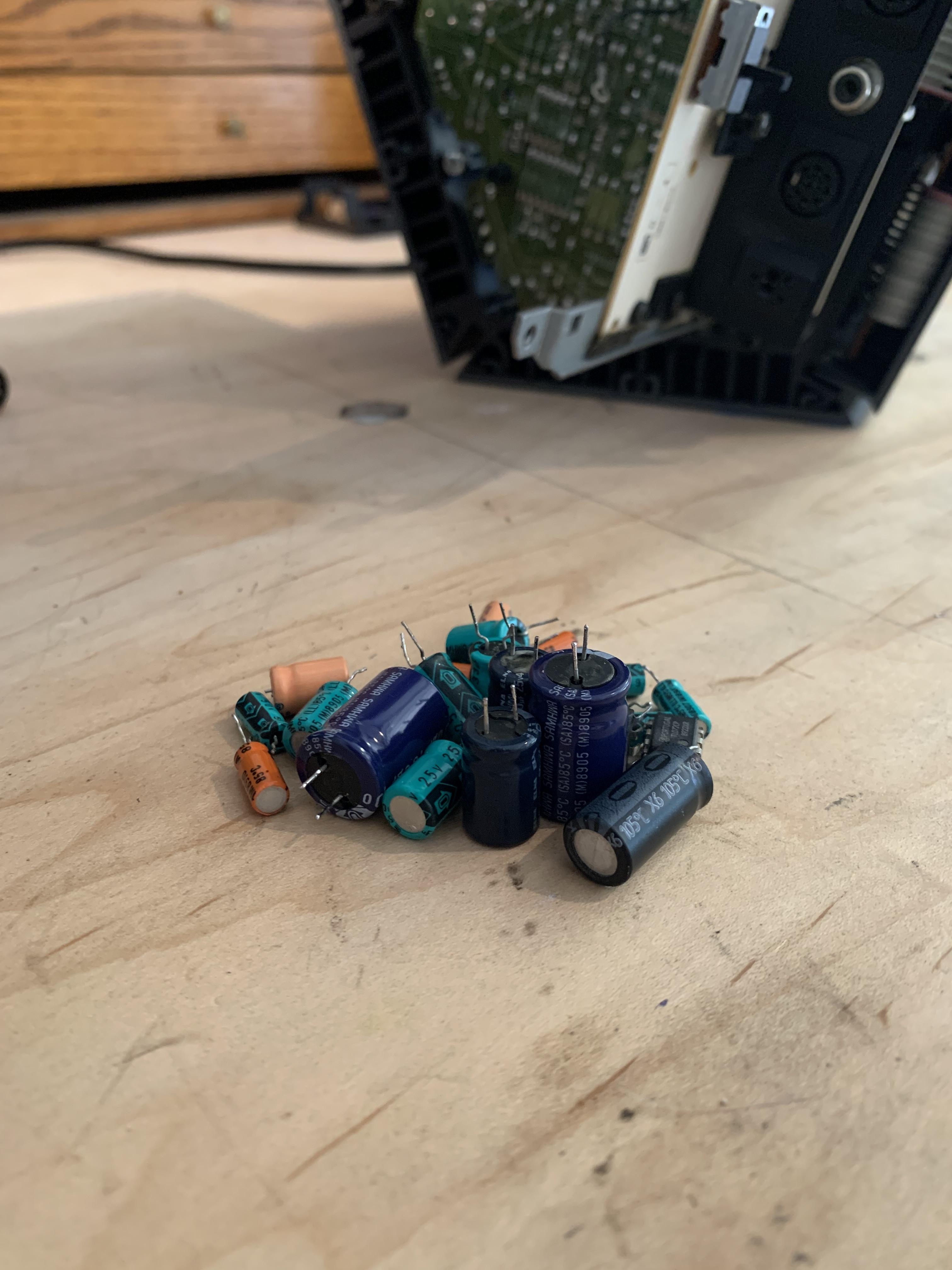

GOLD MemberAfter a few hours, I had a modest pile of old caps out and replaced with fresh electrolytic goodness.

Again – absolutely amazing opportunity to marvel at some truly epic packaging / design engineering.

Location: San Francisco

17 January 2023 at 01:27 #42920Evan

GOLD MemberAfter swapping out all the parts in the amps, I also set the bias voltage and DC offset and called it a day. They seemed to be tip top!

Now to switch tracks a bit and get over to sorting the acoustics. Classic Penta story here – all eight midrange transducers need new foam surrounds.

This particular chapter takes place in the office lab. A lab where new loudspeaker prototypes are brought to life so it is the perfect place to do this kind of work.

Starting with a shop vac, I carefully vacuumed up the large chunks that were basically just falling off. Then alcohol to remove the remaining residue in preparation for the new surrounds.

I’ve never seen such terrible foam rot before!

Location: San Francisco

17 January 2023 at 01:28 #42921Evan

GOLD MemberAbout an hour or so later, I have a full set, ready for the re-foam job.

Location: San Francisco

17 January 2023 at 01:36 #42922Evan

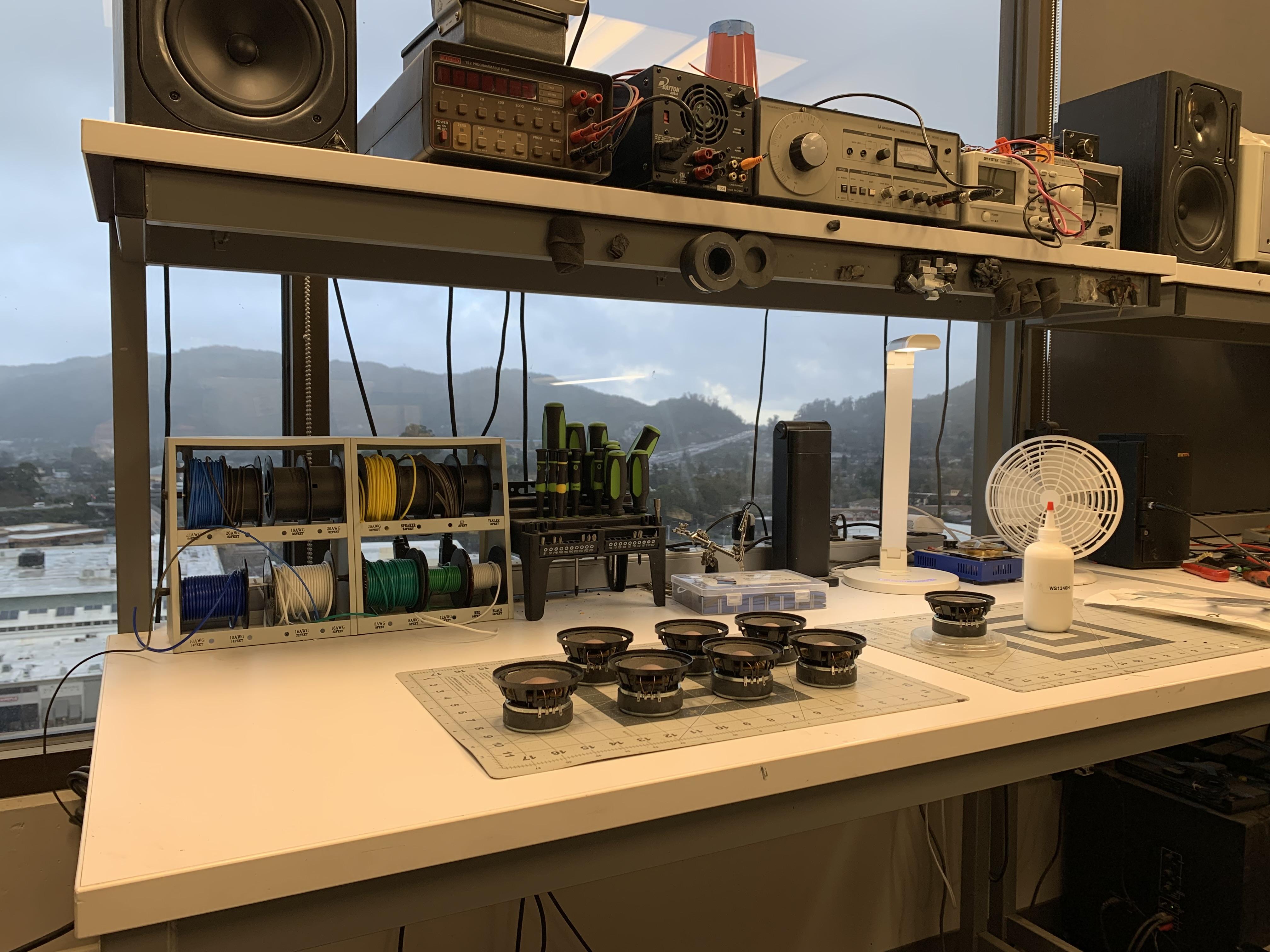

GOLD MemberOne of my favorite view from the office. We are very fortunate that our company values engineers and doesn’t shove the soldering station in the basement somewhere!

This is usually just our random electronics area. Soldering, buzz-up station, general debugging typically goes on here.

Working in a speaker company means we usually have all the tools for the job haha! In this case it was nice to have a small turntable to spin the drivers on when applying the glue for the surrounds.

We had a long, three-day weekend here in the US and everyone but myself cleared out early on Friday. After everyone took off, I connected my phone to the monitors on the shelf, started jamming and getting on with the work.

Location: San Francisco

17 January 2023 at 01:39 #42923Evan

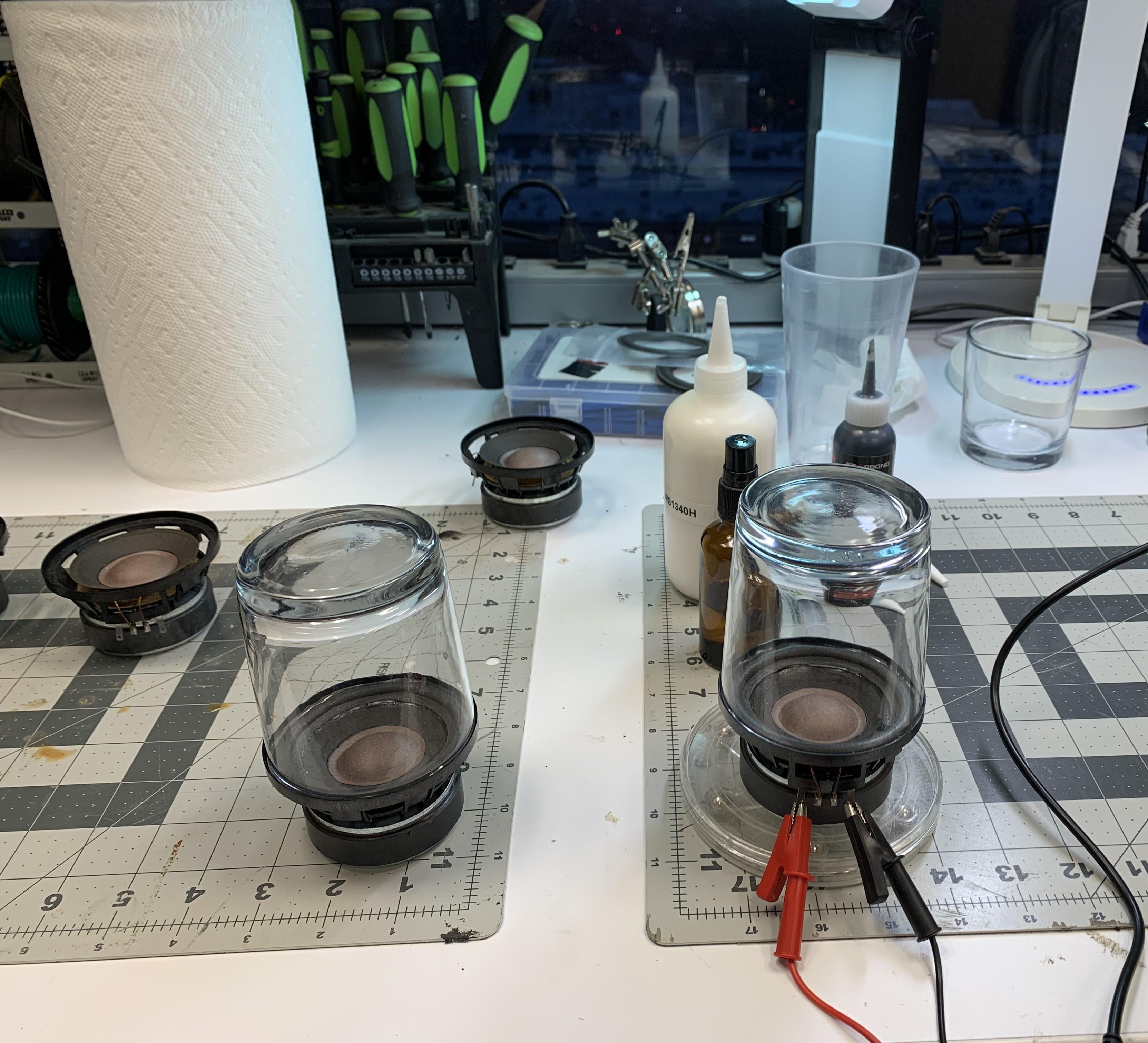

GOLD MemberThings were going well. ….until they weren’t! The outer flange of the surround was starting to wrinkle and not lay flat so I frantically ran around to try and find something to hold them down while the glue set. Luckily we are a well equipped office and have drink vessels of the exact-right size for this job.

While the glueing-up was taking place, I also made sure that I ran some signal through them to ensure no nasty misalignment and coil rubs were to take place.

Location: San Francisco

17 January 2023 at 01:41 #42924Evan

GOLD MemberNow safely back at home, the mids are ready to go back in!!

Location: San Francisco

17 January 2023 at 01:47 #42925Evan

GOLD MemberBefore we put those mids back in, I noticed something that needs mentioning. The gaskets for the mids looked reusable except for one. One was not properly installed in the first place and was too messed up to re-use. I ended up putting on new foam gaskets myself for all drivers. Adhesive foam strips work well for this sort of thing as they can’t move out of the way during installation.

Sealing is an important topic and I suggest those of you reading this to take a closer look at old gaskets and seals in your speakers. Leaks (even small ones) can lead to strange noises and buzzes etc. Most of all they lead to the acoustic system not working/performing as intended.

Location: San Francisco

17 January 2023 at 01:59 #42926Evan

GOLD MemberHere is another great example of deteriorated foam. This is the base of the lower woofer cabinet, I also replaced this on both speakers.

Location: San Francisco

-

AuthorPosts

- You must be logged in to reply to this topic.