Home › Forums › Product Discussion & Questions › BeoGram › Bg4002 (ac) not tracking

- This topic has 10 replies, 3 voices, and was last updated 2 years, 2 months ago by

bulldog123.

-

AuthorPosts

-

24 November 2023 at 11:59 #50689

bulldog123

BRONZE MemberTonearm not moving with record. The tonearm does not move freely as the record spins and jumps the grooves. I have checked the sensor and this works – if I nudge toward the left the whole carriage moves. I have checked the pickup and it works fine on another deck. Any ideas gratefully received.

thanks.

24 November 2023 at 13:46 #50690Dillen

ModeratorTracking force set correctly?

Tonearm lowering depth set correctly?Martin

24 November 2023 at 21:47 #50691bulldog123

BRONZE MemberThanks Dillen – thank you for your reply. tracking force measured with scales at 1.2g. Tracking depth was off – it is now correct at o.5mm above low ribs and the tone arm does now move when I rotate the record but….now of course something is wrong with the sensor – when I nudge the tone arm to the left nothing happens – I have tried to adjust the eccentric screw on the shutter position but to no affect. Any other ideas? Could the sensor be playing up?

25 November 2023 at 08:08 #50692Dillen

ModeratorDo you see light inside the shutter house at the foot of the carriage, when the deck is playing?

Martin

25 November 2023 at 08:21 #50693bulldog123

BRONZE MemberYes.

25 November 2023 at 11:24 #50694Dillen

ModeratorYou could put a scope to the output of the tracking opto and follow the signal through the

electronics but, if your deck has not yet been restored with new capacitors etc., I think

that would be the place to start as more issues will almost certainly arise after this one has been fixed.Martin

26 November 2023 at 00:27 #50695bulldog123

BRONZE MemberAlready been re-capped. Will investigate further as suggested. Thank you.

26 November 2023 at 19:42 #50696sonavor

BRONZE MemberAssuming that your Beogram is already electronically restored correctly and that the tracking sensor components are working (lamp and sensor), I would suspect the problem to be a misalignment of the mechanics involved.

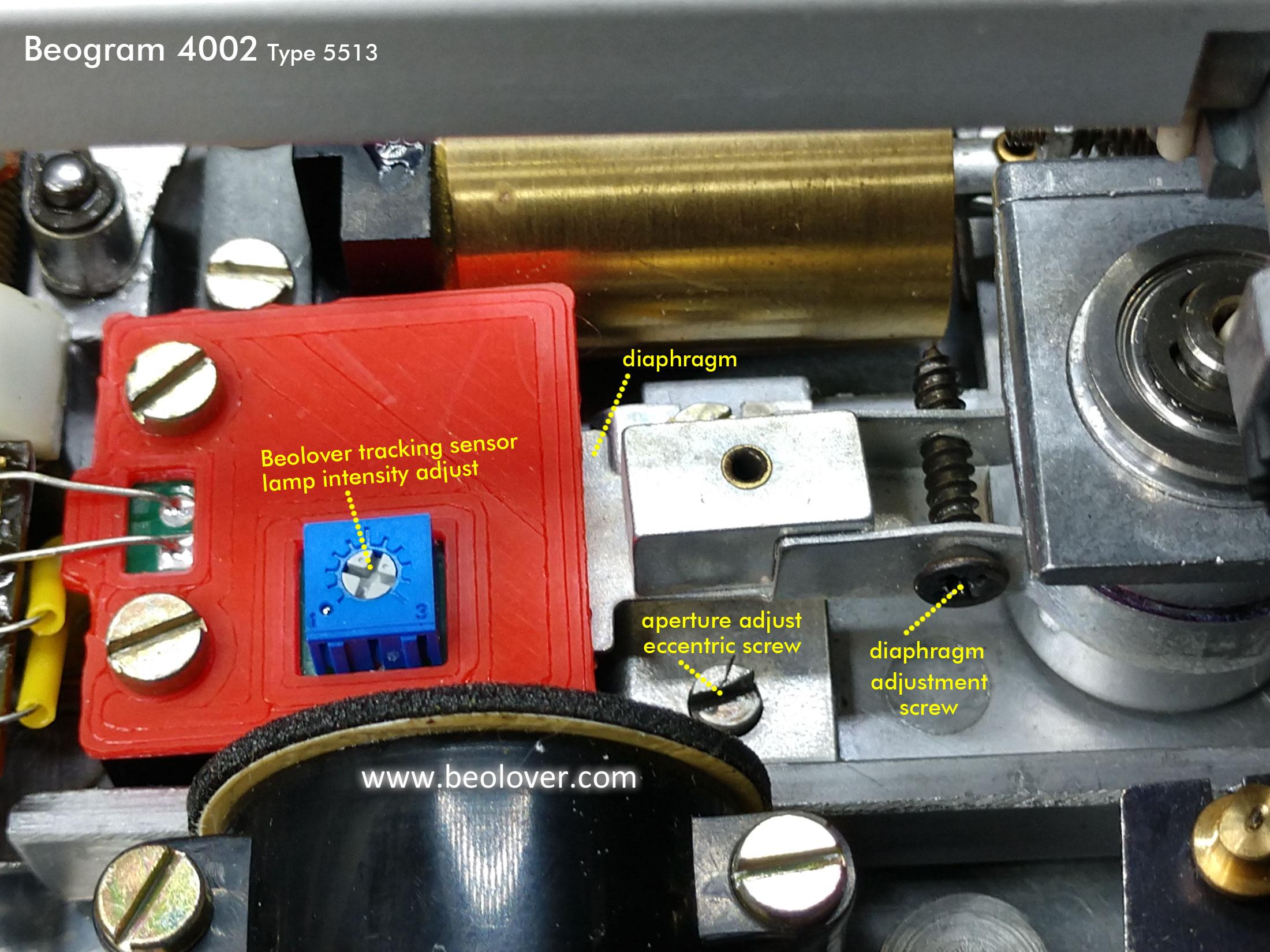

This is a photo I created a while back that shows the mechanical components involved.

Notice the large screw that secures the diaphragm assembly to the base of the tonearm pivot.

That adjustment can get out of position while a Beogram is being worked on and realigning it can be a bit tricky.That assembly bracket can rotate around the tonearm pivot as well as move up and down.

The up and down movement adjusts the height of the diaphram to the sensor housing.

The service manual says that distance should be 1 mm.The left/right rotation of the bracket adjusts the range of the diaphram’s movement across the sensor lamp.

If that position is too far one way or another, the tracking sensor will not work.What I do in this case is try and center everything to return to an initial factory position.

So the diaphram is set above the sensor housing by 1 mm.

The diaphram slot is set to be centered over the sensor housing and the eccentric adjustment screw is set to be centered (so it can be adjusted in either direction later).Getting that initial starting point can take several tries.

I like to get my starting point set where the tracking sensor is already close to being correct just by my setting of the diaphram position.Once I am that close, I can finish the tracking adjustment per the service manual by using the eccentric screw.

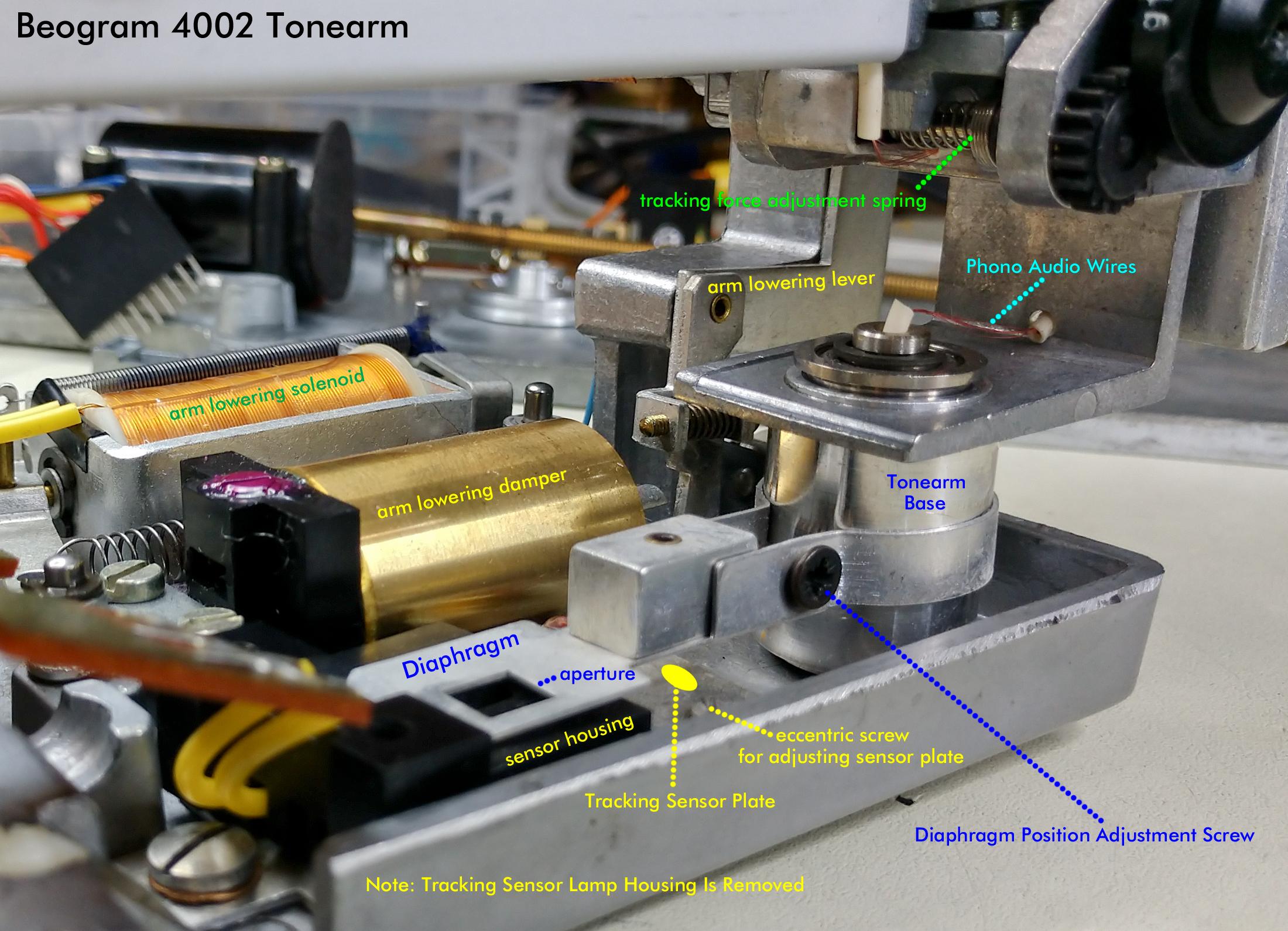

Here is another photo of the mechanical parts. This time with the lamp housing removed.

You have to be patient to get this set right.

After making a change to the position of the diaphram assembly you have to gently tighten the adjustment screws then perform a tracking test.

I just do a crude tracking test with the platter removed and an old cartridge installed in the tonearm.

I move the arm into play position and let the arm drop into “play” position.

It needs to lower straight down and stay in place with no forward movement.

Then you can gently nudge the cartridge towards the center of the record and observe if the tracking sensor detects the movement…and drives the servo to adjust.Like I said to get to that point can take a lot of tries. It also takes quite a bit of patience to tighten the final position back up when you finally have it, without accidentally moving the diaphram. That is easier said than done I am afraid. But you should only have to do this procedure one time. After that any fine tuning can be done with the eccentric screw adjustment. That is why it is important to have that centered to begin with so there is room for adjustment.

Hope that helps and good luck.

-sonavor

26 November 2023 at 23:36 #50697bulldog123

BRONZE MemberThank you Sonavor. Will give that a go. Btw the arm does not drop straight down as you suggest but moves slightly towards the center of the record – how do I fix this?

27 November 2023 at 03:11 #50698sonavor

BRONZE MemberYou will need to fix the arm lowering where it is straight (up and down) before dealing with the tracking.

The arm positioning is also something that I have seen out of alignment.

Interestingly, I have come across several Beogram 400x turntables that have only had one owner. Those were all still in perfect mechanical alignment.

The distance between the tonearm and the stationary (fixed) arm needs to be 7.7 mm.

The tonearm cannot be moved so it is the stationary arm that has to be adjusted if there is an alignment problem that requires an arm re-positioning.The tonearm assembly does have a couple of mechanical adjustments that can mess with the arm lowering negatively. One is the horizontal bar from the back of the tonearm to the stationary arm. That is the bar with the “V” slot the arm lowering lever rests in.

I make sure that is aligned with the arm is raised and the lowering lever in the slot.

Manually moving the lever that the arm lowering solenoid drives to let the arm drop needs to result in the lever lifting straight out of the “V” slot and staying directly above the “V” (not to the right or left of it).

Typically though, I have found that horizontal bar with the “V” slot is okay.More often it is a problem with the positioning of the tonearm counter-weight.

There is a very narrow window the counter-weight can be adjusted to (toward the front or towards the back).

If sticking out too far in the back, the cover for the tonearm assembly will not fit.

If the counter-weight is too close to the back of the tonearm, it will interfere with the lowering.To summarize…

Make sure the stationary arm is parallel with the tonearm and the distance between them is 7.7 mm.

If that is not the case, make the necessary adjustments to the stationary arm position.

It has to be perpendicular to the back guide rail of the tangential arm assembly as well as 7.7 mm (and parallel) to the tonearm.

The service manual shows how to adjust that.

Next, check the tonearm counter-weight position.

Last, make sure the horizontal “V” and arm lowering lever align.Do all of those alignment and adjustments with the tonearm cover removed.

Get everything aligned and working with the tonearm cover off first.These adjustments take patience. There have been a couple I worked on where I started wondering if they actually could be realigned or not. In the end, they always can.

-sonavor

27 November 2023 at 17:48 #50699bulldog123

BRONZE MemberThat is great. Thank you.

-

AuthorPosts

- You must be logged in to reply to this topic.