Home › Forums › Product Discussion & Questions › BeoLab › BeoLab 8000: Broken plastic leg supporting PCB > which glue ?

- This topic has 14 replies, 6 voices, and was last updated 11 months, 3 weeks ago by

LeHe.

-

AuthorPosts

-

7 August 2024 at 12:07 #58082

BRONZE Member

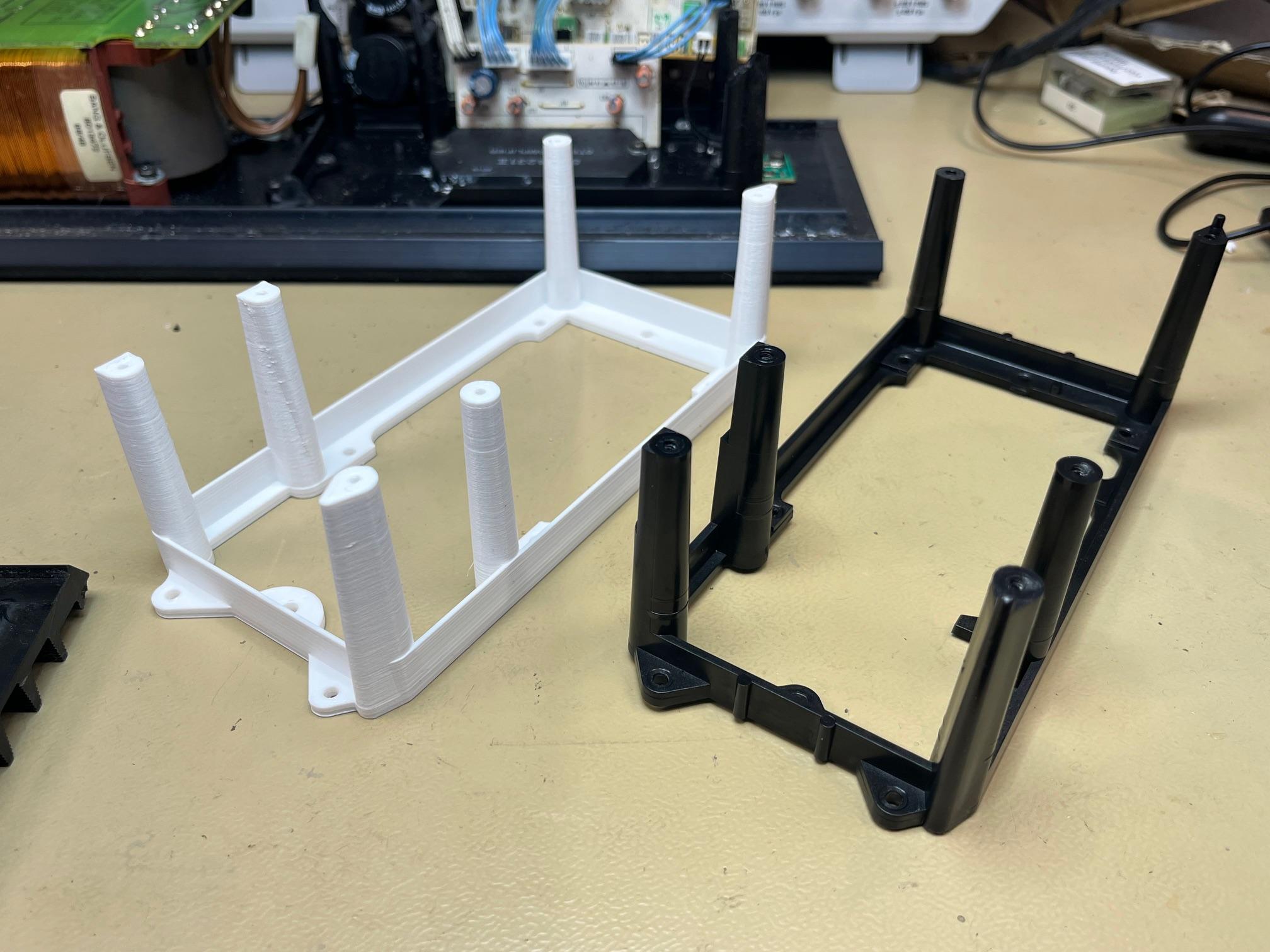

BRONZE MemberThe older series of BeoLab 8000 (09xx, 10xx) have plastic legs supporting the PCB, that have become brittle overtime. And sometimes easily break apart when working on the screws that hold the PCB to these legs. See picture.

I have tried to glue the broken part back using super glue. But it does not work well, the glue does not keep the parts together well. So I am looking for glue that works better.

Question

What glue works best for this purpose, with tis kind of plastic?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

7 August 2024 at 13:01 #58085Glueing will not work. The first screw that enters, will break it again.

Reproducing these:

Or at the PSU side:

Location: Utrecht

7 August 2024 at 15:03 #58090Glitch

BRONZE MemberThe 3D printed part is a great solution!

If you still want to try repairing the old part, a stronger glue, added reinforcements, or a combination of both might work. Below are a couple (of many ways) to do this.

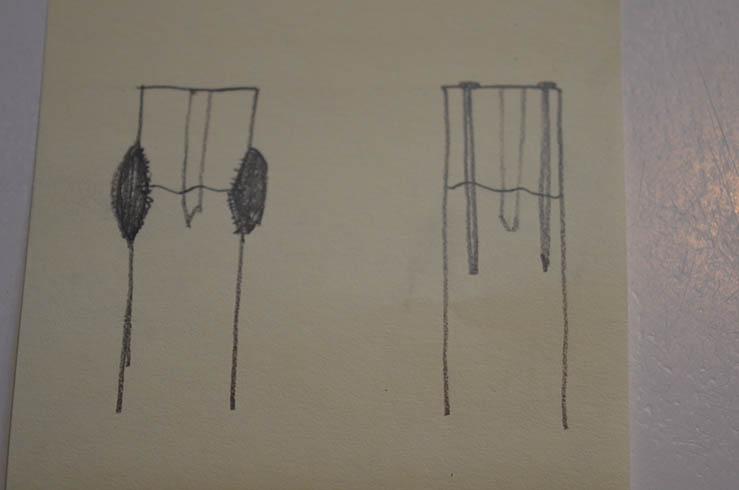

In the first picture. The outside of the post is roughed up so a mechanical bond with the glue can be made. My favorite glue for this type of repair is original JB Weld. In this repair the epoxy itself provides all of the strength.

In the second picture, metal pins are heated and pushed into the plastic. The melted plastic holds the pins in place and the metal provides the strength. Another option could be to glue a thin walled metal tube over the post.

For any repair, be sure that you clean out any material that may have gotten into the screw hole. Lubricating the screw can also reduce the stress on the repaired part.

None of these options will look as good as the 3D printed part, but once the speaker is reassembled nobody but you will know.

Glitch

7 August 2024 at 15:53 #58092My experience with glueing the parts together with supports around etc is, that the plastic is so brittle and it easily breaks again at another place along the pillar.

To prevent breaking I always start to search for the thread and use some grease or just wetting the screw to carefully turn the screw with the minimal amount of force back in its place.

Location: Utrecht

8 August 2024 at 09:05 #58096 BRONZE Member

BRONZE MemberThanks BeoBuddy !

I agree on the ‘brittleness’. The material all over is quite vulnerable after all these years. After it happened with one screw, I put just a bit of WD40 in the other screw holes. Keeping the screw vertical and screwing slowly works quite well. Anyhow, if one screws slowly without too much of resistance, it works well.

For all other cases, it is indeed better to create new brackets/stands. I think I might also do this on my 3D printer.

===

By the way, did you see my PM to you?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

28 December 2024 at 12:18 #61991jaspers1996

BRONZE MemberHi Beobuddy,

Are these models available somewhere? Would be of great help to me, thanks!

17 February 2025 at 16:26 #63852LeHe

BRONZE MemberJaspers1996,

You can buy them for your Beolab 8000 at http://www.dksoundparts.com ( circa € 20,- a piece)

My B&O Icons:

17 February 2025 at 17:20 #63854 BRONZE Member

BRONZE MemberThanks @Jaspers1996

I have a 3D printer, so having a 3D model would be my preference.

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

1 March 2025 at 17:57 #64246Frog

GOLD MemberYes, agree. A STL would be great.

13 March 2025 at 14:20 #64482LeHe

BRONZE MemberFor most people who overhaul their own Beolab 8000 once it seems to me more convenient and much cheaper to just buy a new holder, versus the cost of purchasing a 3D printer or commissioning someone who has one and who first has to create an STL file

My B&O Icons:

13 March 2025 at 14:26 #64483Frog

GOLD MemberYou are forgetting those who already have a 3D printer – like me.

13 March 2025 at 14:47 #64484LeHe

BRONZE MemberOk, certainly true, but who will make the STL file first, still seems more expensive than simply buy 2 print holders for € 40,- for that one time or it has to be about numbers (business)

My B&O Icons:

13 March 2025 at 15:04 #64485Frog

GOLD MemberThe STL file is already there. Just not in the public domain.

13 March 2025 at 15:21 #64486 BRONZE Member

BRONZE MemberWhere can I find it Frog?

Location: The Netherlands

Favourite Product: BeoSound 9000

My B&O Icons:

13 March 2025 at 15:42 #64487LeHe

BRONZE MemberIt looks like Beobuddy has an STL file that he used to print the white version at the beginning of this article.

So ask him to provide it.

The black one in the same picture next to the white is the injection-molding machine version from the supplier I mentioned earlier

My B&O Icons:

-

AuthorPosts

- You must be logged in to reply to this topic.