Home › Forums › Product Discussion & Questions › BeoGram › Beogram4000 start issues

- This topic has 10 replies, 4 voices, and was last updated 2 years, 8 months ago by

sonavor.

-

AuthorPosts

-

11 June 2023 at 05:55 #47102

alf

SILVER MemberHi All,

I am over my Beogram 4000 now for a considerable time and can not find the problem.

what happens here:

activate ON, the platter starts at 45 !!

The carriage does not automatically move in to the drop-down point, however I can manually switch to 33 and move the carriage forward, activate arm lowering and it plays as normal.

i have been through the training manual and fault-finding flowchart in the SM.

the SI circuit had a wrong BC183B fitted which is wrong – why and how that got in….no idea.

i felt unsure about the correct replacement: BC184 or BC149 ? i chose the BC184 typ and it was working fine.

now its back to the previous issue described ?? i have checked as per flowchart but obviously missed something fishy in there……but what ?

can someone provide any other pointers than the fault-finding chart suggests ?

as always, thanks for your help

ALF

13 June 2023 at 01:49 #47103alf

SILVER MemberHi,

i revisited the adjustment of the platter motor as the table seem to have 45rpm locked in ?

yes, I can operate a speed change manually, but….

adjusting the motor as per SM I set all trimmers – 4VR1/2, 1VR1/2/3 – in their center position.

I can adjust the corresponding 33rpm voltage at about 15V at 42Hz, 45rpm at about

15V at 53Hz – not 59Hz as the training manual suggests.

checking the SI signal I should see 6V after a 10ms delay…..what I am getting though

is just under 2V which is obviously far too low……but why ????

6V are present at the suppy, 1TR20 measures fine 1C15 is 10uF / 16V – no 6V cap at hand.

the 24V supply is on the low side at about 23.4V ?!

would really appreciate some input

thanks guys

ALf

13 June 2023 at 13:08 #47104If I read the schematics correctly, the fault could be between 1TR2 and 1TR3. So start by testing those two transistors.

Location: Copenhagen

14 June 2023 at 02:57 #47105alf

SILVER MemberThank you for your input, I will test those two transistors.

just a brief recap:

i verified 6V at The C of 1TR20, but when measuring the SI on the mainboard the max I see is 2V ?

i assume this is the signal 3IC4 is receiving ?

it seems the logic has locked-in the 45rpm as the platter starts only with 45 when ON is activated.the components of the SI circuit are working ! The. Platter motor adjustment is another matter but should not interfere with the start-up of the carriage, moving in !

i hope my explanation didn’t lead to misunderstandings here.

any help is most welcome ?

ALF

14 June 2023 at 07:30 #47106alf

SILVER MemberTested the mentioned transistors – off board ! – and both tested fine.

obviously one other (or more) component(s) is faulty as this issue was not a gradual decline but appeared suddenly.

at this stage I want to rule out a contact issue as the table performs normal once the carriage has moved in via FE to its drop-down point.

ALF

14 June 2023 at 09:10 #47107Hi Alf

Do I understand right? You are measuring 6 V at C of 1TR 20 and 2 Volt at SI on the mainboard?

If so it seems that you have a broken trace between these points.

SI is connected to several IC’s on the logic board under the button plate.

Have already had broken wireconnections b etween mainboard and logicboard, maybe you have a closer look there.

Kind regards

Christian

14 June 2023 at 10:45 #47108alf

SILVER MemberHello Christian,

thank you for your reply – very sorry to say you just missed out on a 10/10,

But a 9/10 for inspiration isn’t too bad either I thought ?!

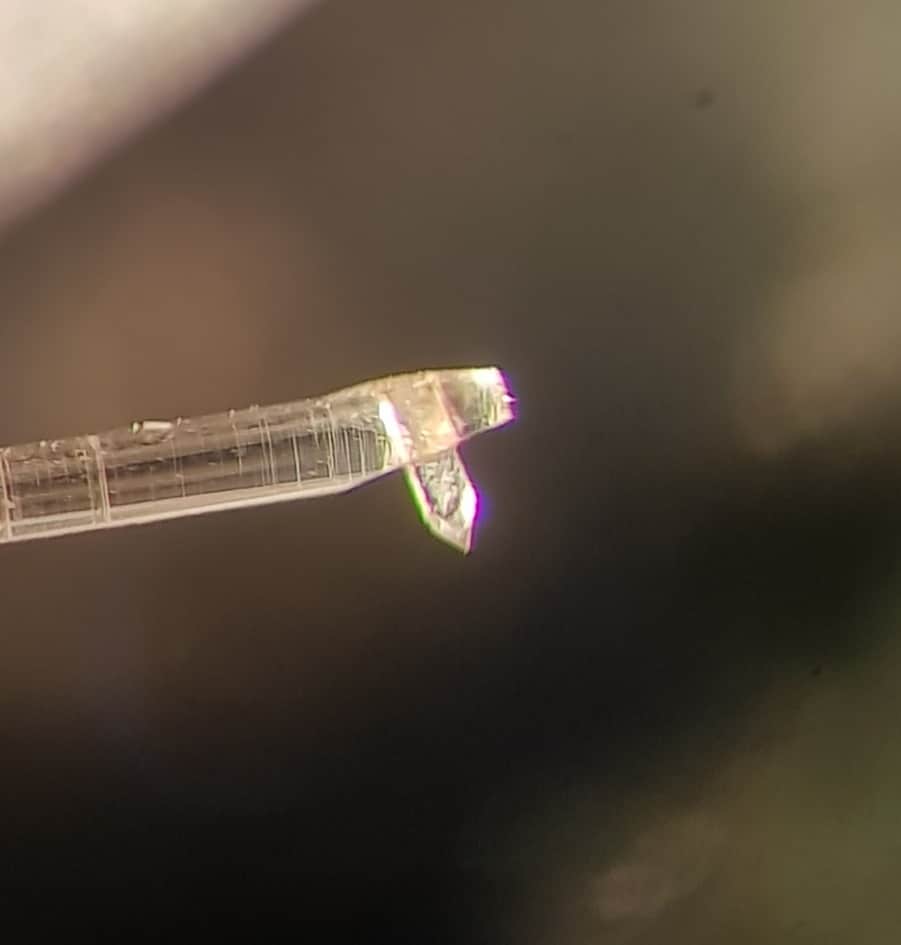

I did check that 1cm track under the magnifier, than clean that short track with a fiber glass pen as well and still did not see any damage…..which sidetracked me.

assuming that there may be a wire issue further on stopped me for now but thanks to

you I simply connected a short wire jumper between SI and C of 1TR20…..success ??

and now the platter starts at 33rpm as it should.

many thanks again ?

ALF

14 June 2023 at 10:52 #47109Congrats, issue solved

14 June 2023 at 13:09 #47110Nice!

Location: Copenhagen

14 June 2023 at 13:32 #47111alf

SILVER MemberThanks Filip,

my thoughts precisely – nice to see the carriage moving correctly again.

always interesting how many challenges this table can throw at you……

ALF

14 June 2023 at 16:07 #47112sonavor

BRONZE MemberWhile we definitely come across plenty of failed, original components (due to age and whatever ordeals they have suffered), the number one cause of faults is still a broken connection. Either a bad solder joint, a broken trace/pad or a faulty connector pin.

Those are often pretty difficult to find…so nice work in solving the problem.

-sonavor

-

AuthorPosts

- You must be logged in to reply to this topic.