Home › Forums › General Discussion & Questions › General Discussion & Questions › Beogram motor bearings issue

Tagged: Beogram 5244 motor noise

- This topic has 11 replies, 3 voices, and was last updated 1 year, 7 months ago by

RIB2906.

-

AuthorPosts

-

17 June 2024 at 14:56 #56545

RIB2906

BRONZE MemberHi everyone, can anyone help me with this please? Previous advice has been most helpful.

I have been renovating my 1975 vintage Beogram 2000 (5244) and also a 1203 which I bought for spares. I now have them both working pretty well and the 1203 which was in poor cosmetic condition is much improved. The only remaining issue is the sound of the motor which is audible in both cases. I’m thinking of replacing the motor bearings which are available but I cannot see how to remove the old bearings for replacement. I’d really appreciate advice on how to do this. Any suggestions on appropriate tools would also be very helpful. Many thanks, Richard.

19 June 2024 at 22:43 #56617RIB2906

BRONZE MemberMartin, I’m wondering if you could help me here please? I recall your advice earlier to replace the bearings, which I really appreciated. I need a steer on how to remove the old bearings and whether there is an appropriate removal tool for these which are the 3mm drive shaft size. Help!

20 June 2024 at 13:11 #56625 BRONZE Member

BRONZE MemberMaybe you get some more information in this discussion:

https://archivedforum2.beoworld.org/forums/t/10293.aspx

Lot to read and some pictures.

Kind regards

Christian

20 June 2024 at 14:59 #56627Dillen

ModeratorA photo or two showing how far you’ve come would help us suggest the next step.

Martin

20 June 2024 at 16:58 #56629RIB2906

BRONZE MemberHi Christian and Martin,

Thank you both for responding on this. I have now watched (and saved!) one of the you tube videos which shows me exactly how to access both the bottom and top bearings for the motor. It appears more straightforward than I thought so I will access and lubricate the 2 bearings on the 1203 and if that quietens the motor I’ll repeat it on the 2000/ 5244. I have also now checked using noise cancelling headphones that the noise is not transmitted with the output signal and pleased to say it is not. It’s just ambient and slightly annoying close to the deck but a bit less with the lid on. I really appreciate your help and think I now have the answers I was looking for. If cleaning and lubing the bearings does not work then I’ll buy and fit new ones.

Thanks again!

Richard

20 June 2024 at 17:33 #56630Dillen

ModeratorRemember lubricating should be with an oil suitable for use with sinter-bronze. It needs to have the

right additives. Lubrication is done with the bearings submersed in the oil, while vacuum is pulled to get

the air out of the pores in the bearing metal. Then leave them submersed without vacuum for 24 hours to allow

oil to suck in.

If not oiled correctly the bearings will only run fine for a short time (hours or days).

Factory new bearings, pre-oiled and ready to fit is available from Danish Sound Parts.

I would recommend that as it also includes new reservoir felts and takes wear to the old bearings out of the equation.Martin

20 June 2024 at 21:24 #56636RIB2906

BRONZE MemberThank you for that advice Martin. That is information way beyond my knowledge and it seems lubricating the bearings may be of limited benefit. May I ask please if I should order Beoparts (now: Danish Sound Parts) “Motor bearings set for Beogram & Beocenter motor with 3mm spindle and one collared bearing” for both types 1203 and 2000/5244? It may be that I need to first take apart the two motors to check whether or not they each<!–more–> require one collared bearing.

Thank you,

Richard

21 June 2024 at 07:49 #56641Dillen

ModeratorMost likely not the set with the collared bearing.

As mentioned in the bearings sets descriptions, you will have to look at the motor to see

which set is needed.Martin

23 June 2024 at 15:21 #56953RIB2906

BRONZE MemberHi Martin,

I have checked the motors and you are quite right, all 4 bearings are non-collared so I have ordered 2 pairs to replace them. May I please ask 2 (last?) questions?

1 you mentioned I should use “oil suitable for use with sinter-bronze. It needs to have the

right additives.” Can you recommend one that I should use? I’m thinking of using WD40 white lithium grease spray, would that be OK?2 Should I spray the oil into the new reservoir felts? Many thanks, Richard.

23 June 2024 at 21:15 #56960Dillen

ModeratorIf you order bearings from Danish Sound Parts, you will not need to add any oil.

They come pre-oiled, ready to mount. That also goes for the reservoir felts.

Just clean the motor spindle thoroughly, as any remains of old lubricants will be in the way,

and make sure the spindle is centered in the motor so it runs freely without rubbing on anything.You can read more here:

https://www.dksoundparts.com/product/motor-bearings-set-for-beogram-motor-with-3mm-spindle/Martin

10 July 2024 at 13:42 #57336RIB2906

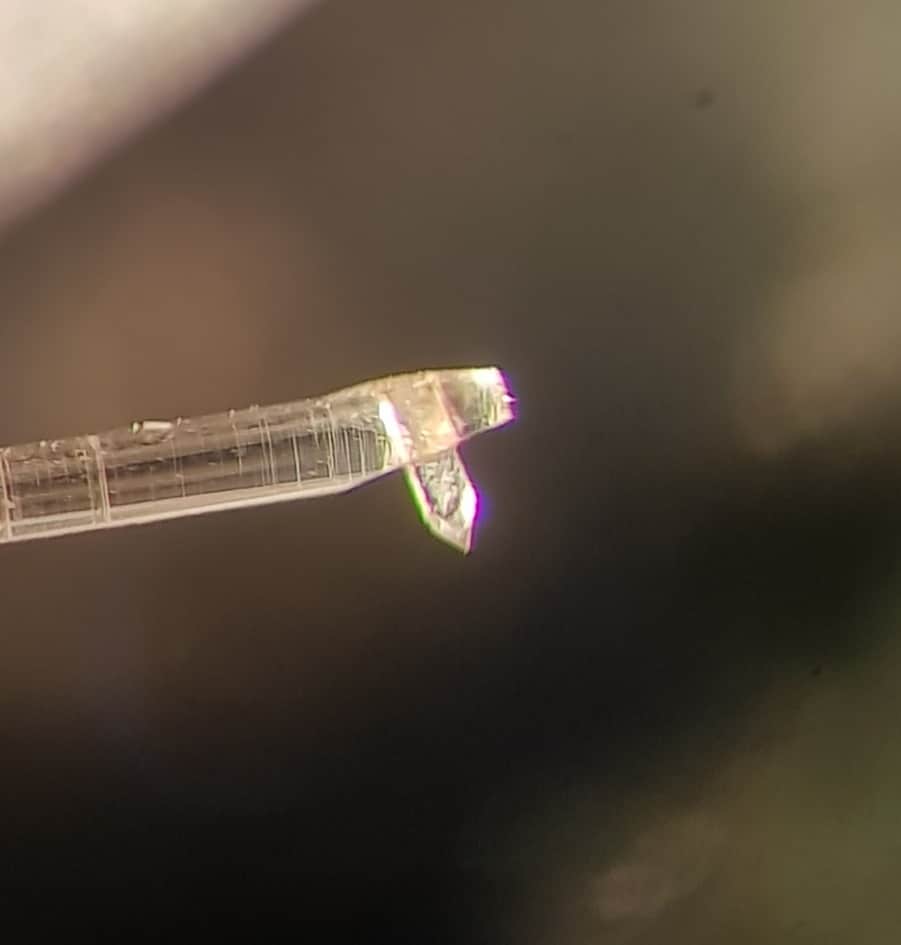

BRONZE Member- Hi Martin, I’m pleased to say that I’ve now completed changing the bearings on both decks and they are running smoothly at the right speed. They are however both still making a (lower) level of ambient noise which sounds like the motor running and the idler wheel against the drive cone. I’m attaching two short recordings of the sound from close by and then at 1m distance to demonstrate the attenuation. I’d appreciate you experienced opinion here as I can’t now judge how much drive noise there was before the 2000 deck hit problems. I can only compare with my recent Pro-Ject deck which is near enough silent. Given these B&O decks are nearly 50 years old, do you think I should expect to hear some ambient drive noise or is there a likely cause I can address? I have changed bearings, belts, idler wheels and lifter pads so not sure what more I can do! Many thanks, Richard

<!–more–>

10 July 2024 at 14:33 #57337RIB2906

BRONZE MemberAttachments second try….

-

AuthorPosts

- You must be logged in to reply to this topic.