Home › Forums › Product Discussion & Questions › BeoGram › Beogram CD 5500 – needs a push?

- This topic has 7 replies, 3 voices, and was last updated 2 years, 5 months ago by

Storck.

-

AuthorPosts

-

21 September 2023 at 12:20 #49271

Storck

BRONZE MemberI have replaced all rubber parts (including the suspension/rubber dampening for the CD mechanism) and replaced all caps with Dillens kit.

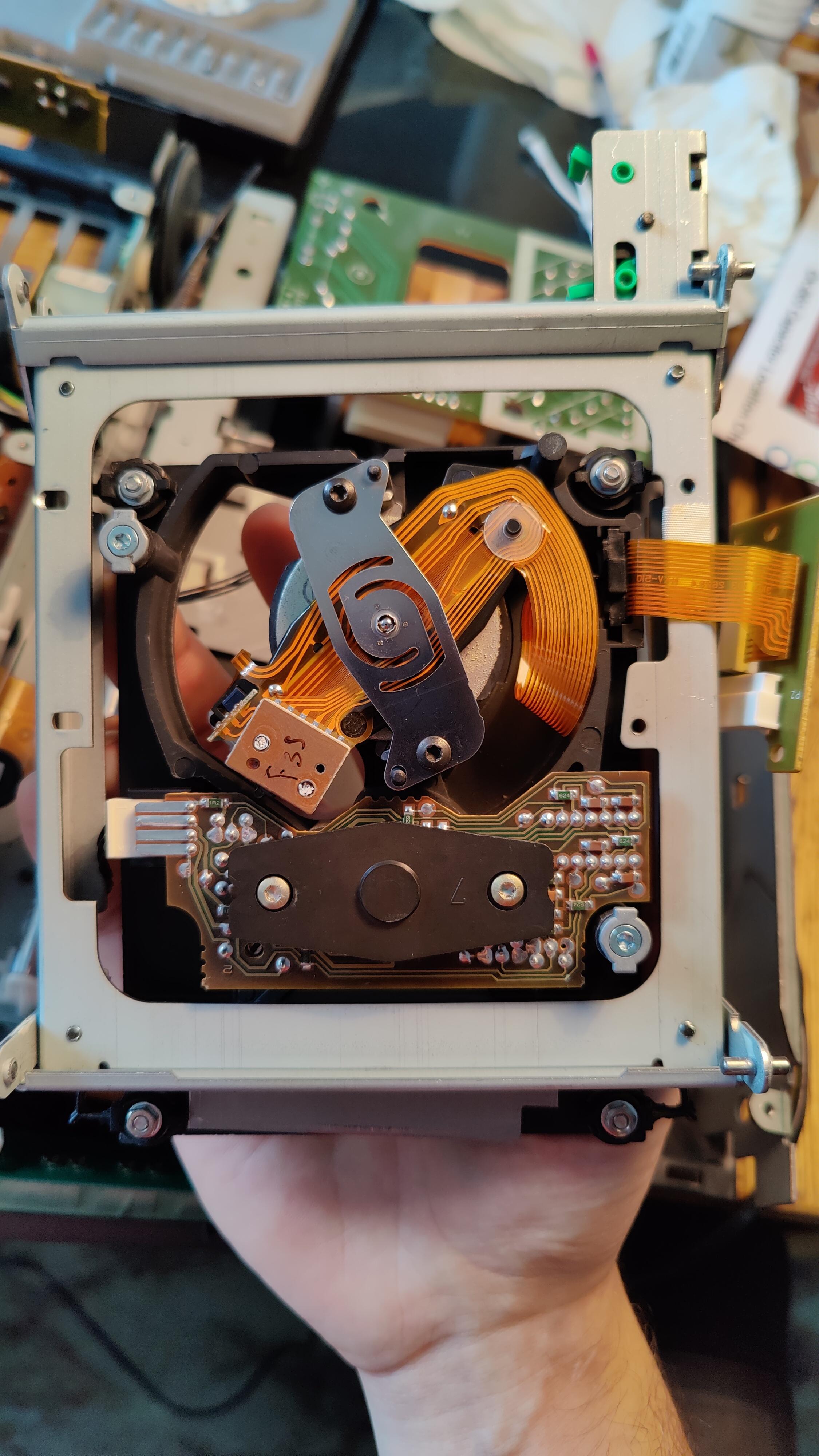

the unit works like a charm IF I push the back of the CDM4 down against the chassis like the picture shows. If I don’t, it makes a scraping noise and goes into standby.

It doesn’t work if I tilt the whole unit to the same angle as if I were to push it down.

It doesn’t work if I lift the front of the CDM4 to the same angle as if I were to push the back.

In service mode 3 the disk spins without any problem, regardless of angle or where I push, so it must be a problem with the RAFOC/laser focus.

Could it be some grounding or connectivity issue? I’ve cleaned all PCB connections.

Is there a specific trick to installing the four rubber disc drive suspensions? I just replaced them and adjusted the screws until the disc drive was leveled.

Focus and laser current are correct.

This is driving me crazy! I can’t come up with a single possible reason for the issue, which makes it hard to troubleshoot.

21 September 2023 at 12:40 #49272Die_Bogener

BRONZE MemberRemove the clamp for the center of the CD. This is probably the scrapping noise.

The metal clamp can be adjusted on the side.

The complete sliding unit has a excentric adjustment on the left side near the transformator. There shoud be a damping rubber band around, 2mm rubber ring… if that is lost, the slide moves too far inside and the clamp will make contact/noise.

21 September 2023 at 13:05 #49273Dillen

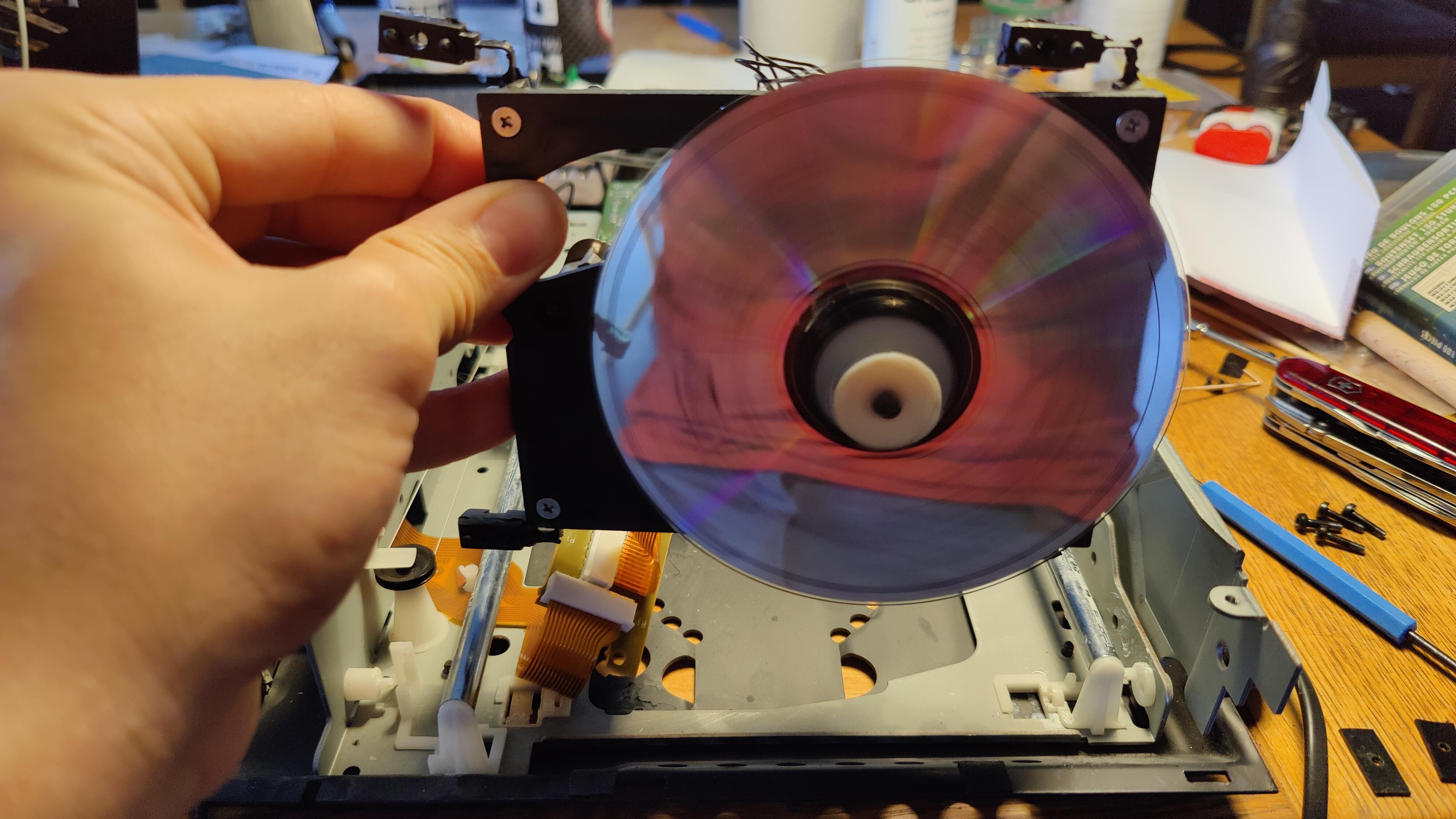

ModeratorCan you tell if the disc is scraping on the alu tray?

I have noticed, in some decks, a little more height is needed for the suspension rubbers in order for the disc to fully clear the tray.

If so, you can fit a thin washer (0,5mm or so) under the rubber parts, between the

rubber parts and the drive base chassis to lift the (rubbers and) drive slightly with respect to the alu tray.

This will also solve the noise issue, if it’s the clamp scraping on its metal bracket as it will also be lifted by this.New suspension parts, that I am currently working on, will be corrected for this.

Martin

21 September 2023 at 15:25 #49274Storck

BRONZE MemberI tried to remove the clamp – same problem.

It’s not a issue with the Disc drive motor. In service mode 3 the disc spins perfect and quietly regardless of how and where i push/move/angle the unit.

The noise must come from the swing arm/laser.

I just can’t see what possibly could be effected by pushing the back of the unit down, nothing seems to touch anything, and the swing arm moves without friction either way.

21 September 2023 at 15:56 #49275Dillen

ModeratorBad, or badly seated, ribbon cable?

Martin

21 September 2023 at 16:14 #49276Storck

BRONZE MemberI removed and cleaned all ribbon cable connections, also ohm-measured from the servo board to the solder points on the swing arm with good results.

21 September 2023 at 17:10 #49277Storck

BRONZE MemberThe search continues…

It works more or less reliably in vertical positions.

I found one video with the same problem, but he just replaced the focus unit.

21 September 2023 at 21:43 #49278Storck

BRONZE MemberPROBLEM SOLVED:

I was about to give up, but as a last desperate attempt I removed the RAFOC-unit. I didn’t wanna do this at first since I didn’t wanna mess with the angle setting.

Anyway, after removing it, cleaning it, and dipping the two bearing balls in silicone oil it works like a charm!

Thank you so much for your suggestions and help Die Bogener and Dillen.

-

AuthorPosts

- You must be logged in to reply to this topic.