Home › Forums › Product Discussion & Questions › BeoCenter › Beocenter 9300 Tape Deck Belts Replacement

- This topic has 5 replies, 3 voices, and was last updated 3 years, 6 months ago by

Beowolf.

-

AuthorPosts

-

22 July 2022 at 10:25 #36299

Beowolf

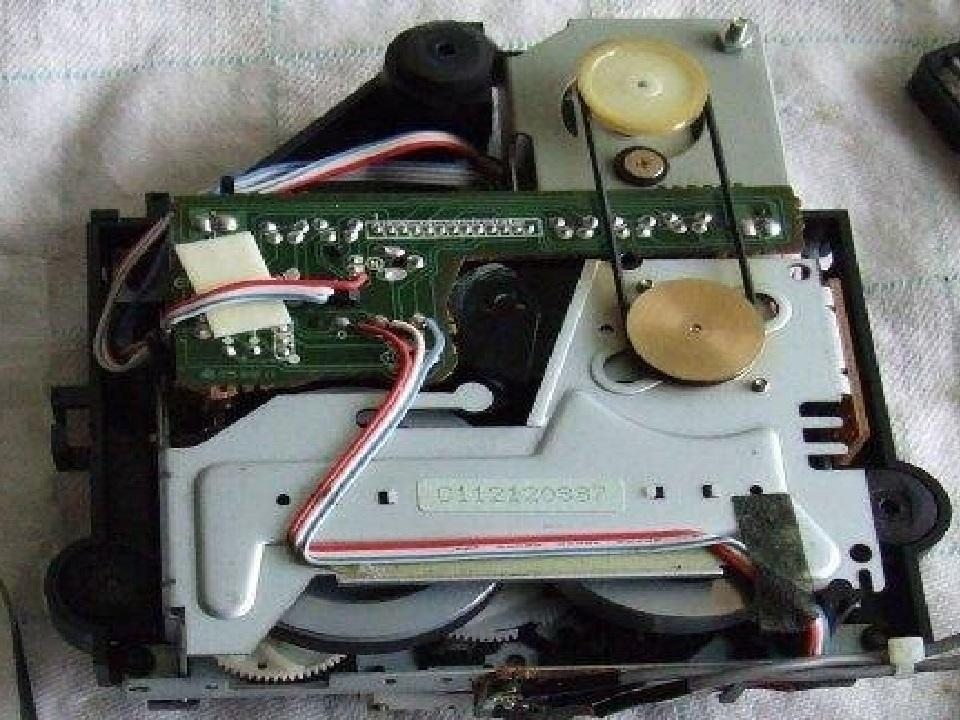

BRONZE MemberI have a Beocenter 9300 that works great except for the tape deck. It doesn’t move at all when trying to play a tape. FF and RW also do nothing. I plan to replace all 3 belts in the deck (the belt that drives the hub was already broken). The 2 smaller belts are easy enough to access, but I cannot seem to figure out how to access the larger wide flat belt inside the deck.

Rather than making a big mess and taking apart too many screws and components, is there a straightforward way to access the larger belt?

I know this is a pretty common procedure on the Beocenters, but I can’t find clear instructions or a tutorial on the best way to go about it.

Any guidance would be greatly appreciated!

23 July 2022 at 07:18 #36300snorre

BRONZE Memberhello beowolf,

I think this video will help you : https://www.youtube.com/watch?v=JnAD5PbyBGA

It shows a belt change on a BC2500, but the tape deck on your 9300 is very similar, except the motor in the BC9300 is mounted in a different place and with an additional belt.

best regard from germany

Andree

23 July 2022 at 14:12 #36301Beowolf

BRONZE MemberThanks for your reply, Andree. The video is very helpful!

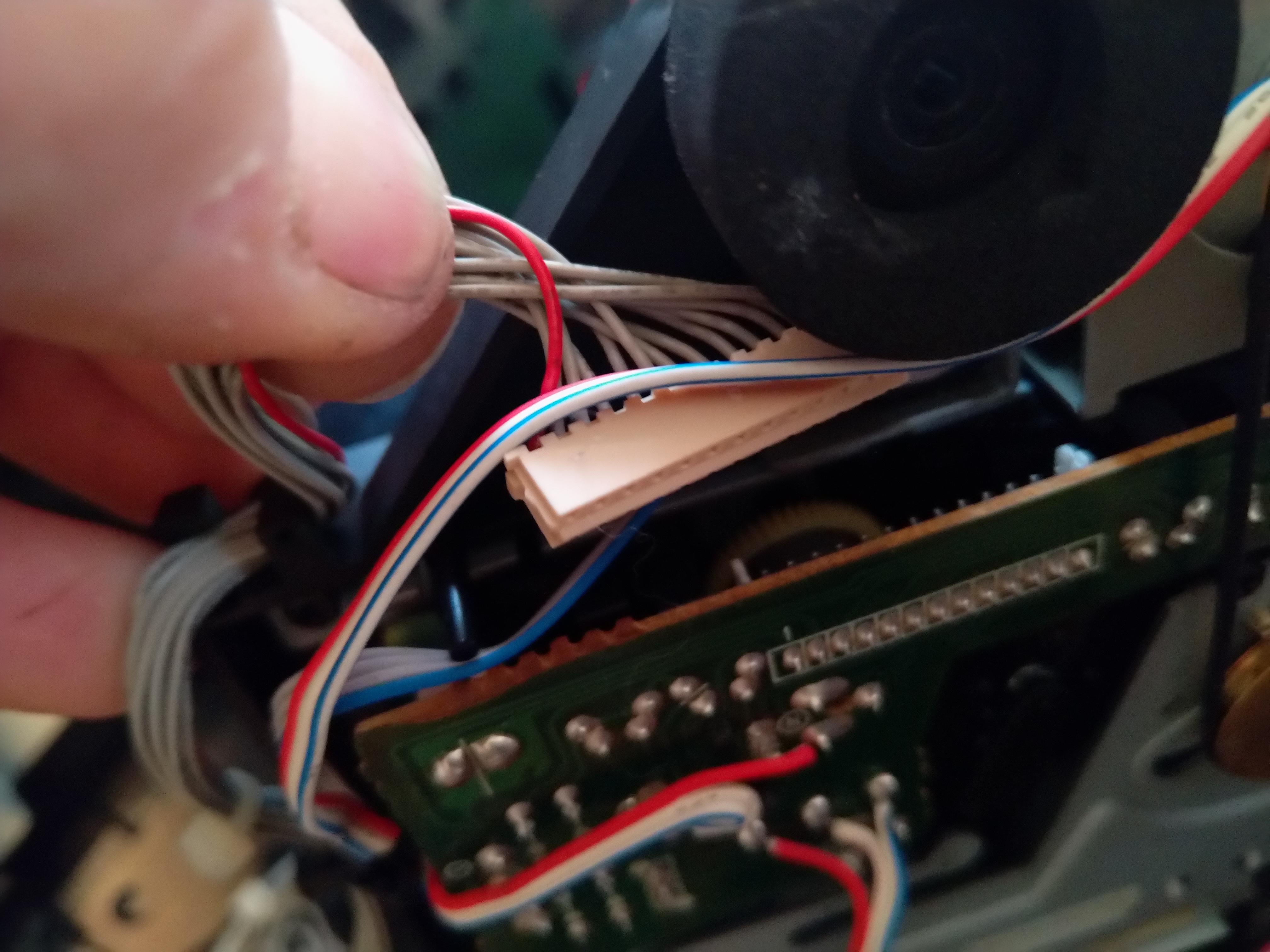

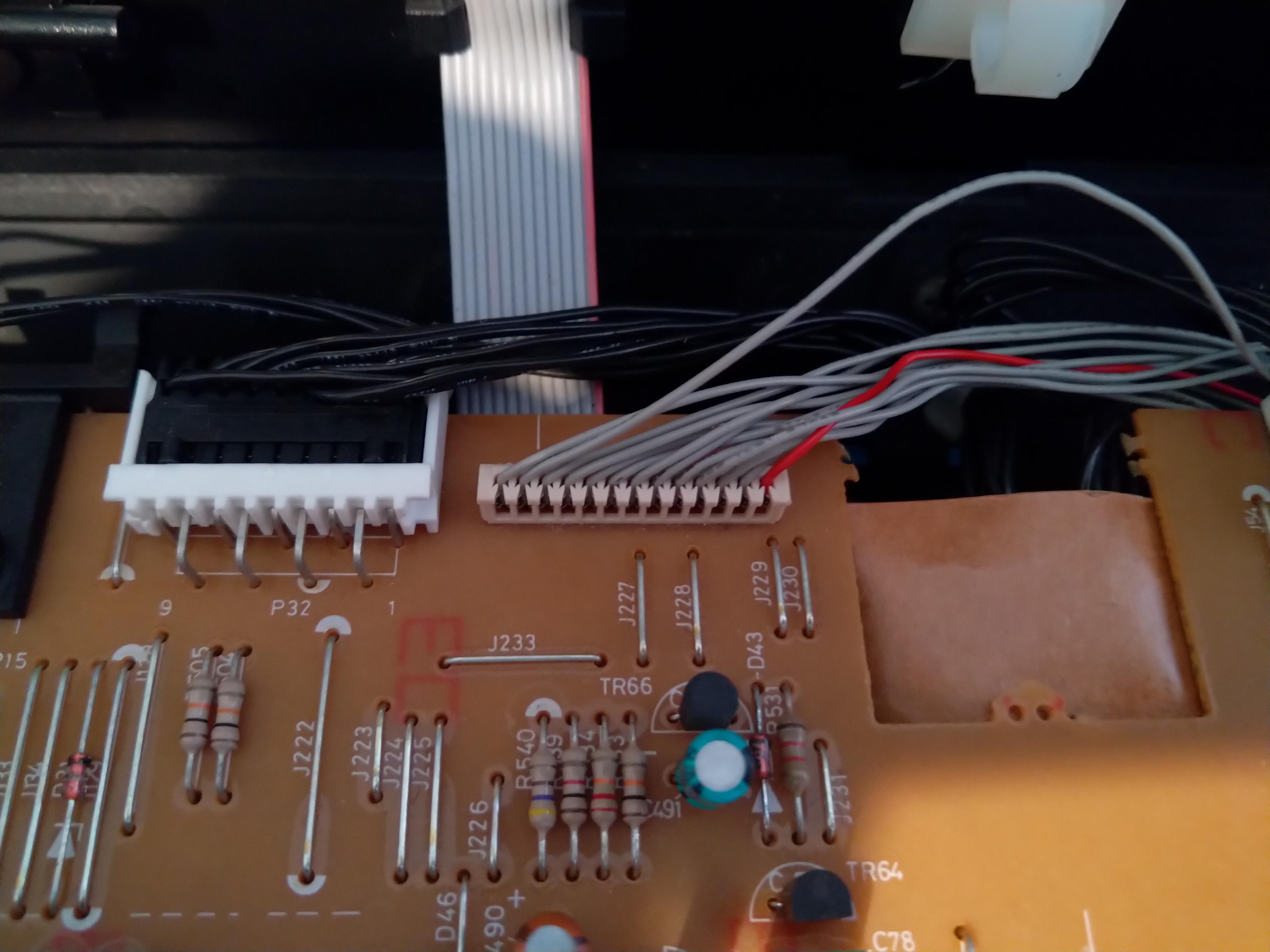

Do you happen to have any advice on the best way to remove the tape deck from the unit so it can be worked on more freely away from the unit? Some of the cables have clips that can be easily removed to free the deck from the PCB, but there is one group of maybe 8 or 10 wires that are soldered to a connector on the PCB which are the main issue.

Unfortunately, I didn’t think to take pictures of this when I had the unit open, but I was working on it still connected to the PCB, which was a bit limiting for working on the deck.

Thanks again!

23 July 2022 at 21:10 #36302Have a closer look, pretty sure all looms will unplug, there is one tricky loom plugged in under an RF shield which can be either unsoldered or pried up at one end, then un-plug the loom, Be careful not to bend the shield out of shape too much ( it stops the sliding door opening if it’s not put back in original position)

good luck, I’m going to do some work on a 9500 soon which should be very similar I can take some photos if it helps.

Regards Brad

23 July 2022 at 21:48 #36303Apologies for the last comments Are you referring to this loom pictured, is so yes it is soldered to the PCB but un-plugs from deck

23 July 2022 at 23:21 #36304Beowolf

BRONZE MemberThanks for the info. I’ll take another look the next time I open up the 9300. It would make sense to come off fully, and I hope it does because I have a few BCT’s that will need this procedure!

-

AuthorPosts

- You must be logged in to reply to this topic.