Home › Forums › Product Discussion & Questions › BeoCenter › Beocenter 2200 Tone arm lowering problem

- This topic has 3 replies, 4 voices, and was last updated 8 months, 1 week ago by

omminp.

-

AuthorPosts

-

31 October 2024 at 19:08 #60614

Ördög

BRONZE MemberGreetings!

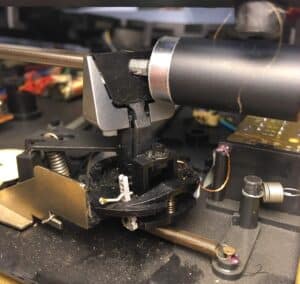

I’m having some trouble with my Beocenter 2200. The tone arm doesn’t lower enough to make contact with the vinyl.

The counterweight is set correctly and when I took the player apart and fumbled a bit with the plastic pieces with a spring attached, the tone arm started to move correctly. The thing is that this wasn’t a permanent fix and the tone arm again doesn’t lower enough to play.

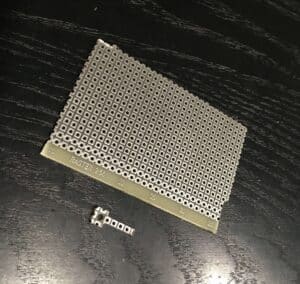

Here’s a pic and a video from the part I mean. In the video the tone arm works correctly.

Attachments:

You must be logged in to view attached files.25 May 2025 at 16:11 #65810Lorenz Hilf

BRONZE MemberI have the same Problem. The pastic Box seems to block the tonearm from moving freely up and down. Have you managed to solve the issue?

29 May 2025 at 07:55 #65897Dillen

Moderator21 June 2025 at 06:43 #66560omminp

SILVER MemberI found this to be helpful as well. https://www.vintage-radio.net/forum/showthread.php?t=176737

In my case, the mechanism lost the plastic ears on both sides. I used the bent wire idea from the attached thread and held it in place with a match stick beside it in the hole. This is for the right hand side looking from the back, and allows for operation of the mechanism without fouling on any other parts.

For the left hand side one, I used a zip tie. The one I had was 1.5mm wide, and needed to be reduced in width to 1.2mm to fit the hole. I removed the zipper tongue with a sharp blade. Then fitted the modified zip tie and used the zipper part from a second tie to secure it so the 2 parts of the mechanism were parallel.

The zip tie has advantages – it is flexible so easier to fit through the hole in the mounting plate, and if the zip is overtightened, the zipper part can be cut off using miniature side cutters leaving the styrup part intact for another try.

With these 2 fixes, the arm works perfectly again. Thanks to Martin for his initial inspiration.

-

AuthorPosts

- You must be logged in to reply to this topic.