Home › Forums › Product Discussion & Questions › BeoGram › Beogram CD-50 – Lower Disc Holder 9132

- This topic has 30 replies, 3 voices, and was last updated 7 months, 2 weeks ago by

Rob Bune.

-

AuthorPosts

-

4 April 2025 at 09:09 #64936

Rob Bune

BRONZE MemberHi Guys,

I’m knew to the Beogram world, a good friend of mine has asked me to take a look at his Cd-50 with a faulty CD tray.

I did some research which led me to replace the black band between the motor and cogs which drives the tray mechanism. this has resolved has resolved the eject/loading issue – so far so good.

However it seems that the clip that holds the spring on the lower disc holder has lost the tabs which the plastic ring that keeps the spring in place have broken. Consequently the spring loader ring won’t stay in play.

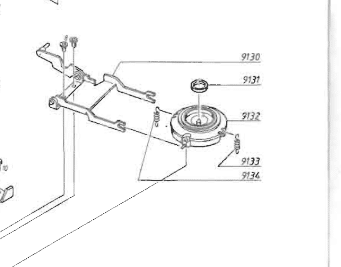

It is not clear from the service manual but I think the part number is 9132 “Disc Holder, Lower”

Would anyone have one of these available of have any suggestions – I don’t really want to buy another unit for parts if possible.

Thanks in advance.

6 April 2025 at 15:39 #65008Dillen

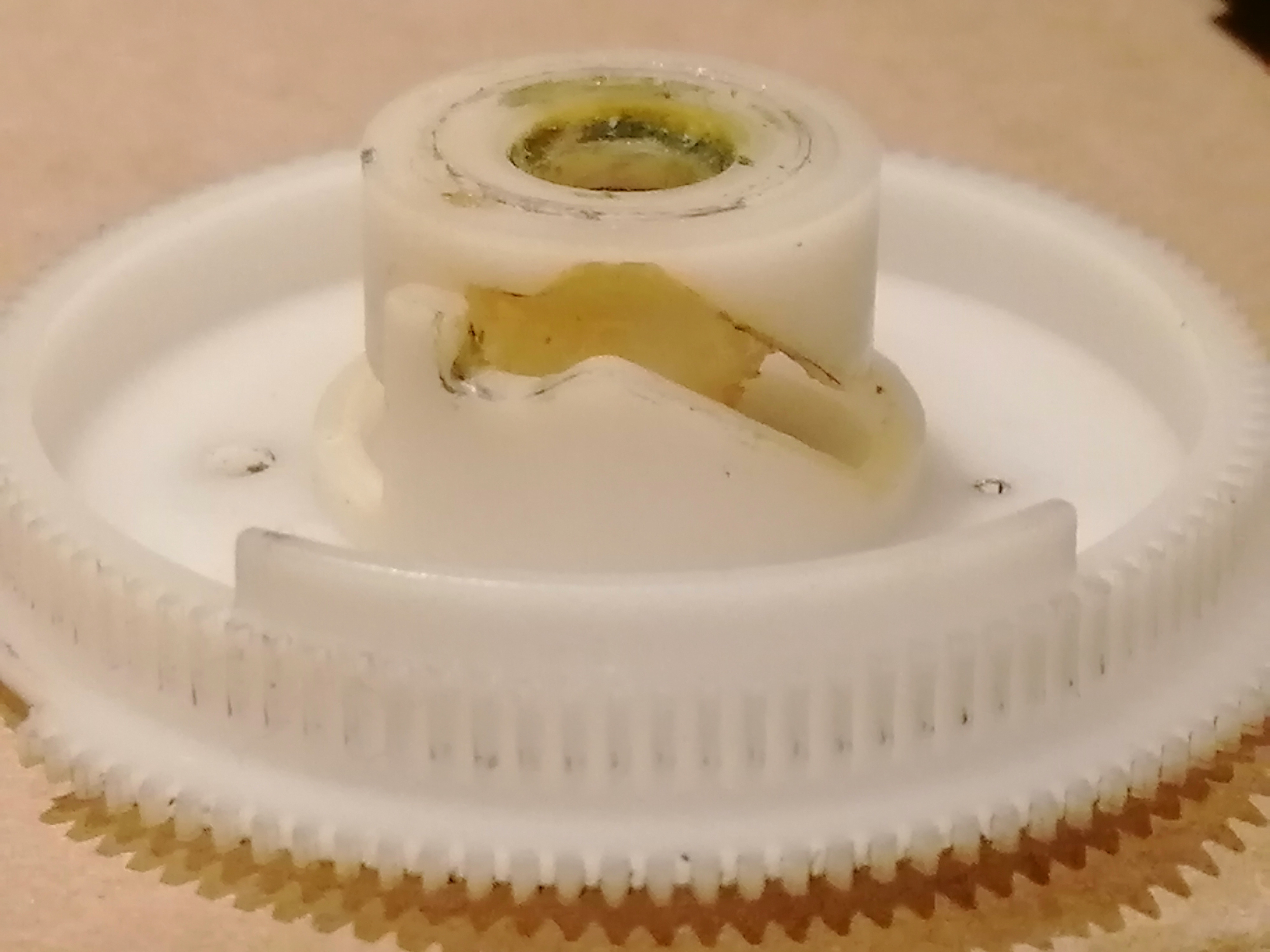

ModeratorThe parts in your photo look intact.

But perhaps that’s merely a photo you found somewhere?

Else – ask at Danish Sound Parts.

They are known to be able to help with many, else impossible, parts.Martin

9 April 2025 at 23:09 #65046Rob Bune

BRONZE MemberIt is my photo, there are two small tabs shown in arrows that are broken. Anyway I sourced that part.

The disc now loads but won’t play. I can here a clicking sound as the motor spins.

When the tray closes the disc raises but drops again at the end of the travel. Seems to be because of the groove on the cog… Is this correct?

Should the disc be picked up when it is raised, because to me it looks as if the disc is just sat in the tray?

I don’t have the CD mechanism screwed down but it lined up with the screw holes and I have tried minor adjustments.

Any ideas? Thanks.

10 April 2025 at 05:37 #65048Madskp

GOLD MemberYou might be able to find some hints in this guide that also has a lot of pictures and recommandations for capacitor replacements

https://beolover.blogspot.com/2021/06/beogram-cd50-typical-restoration-steps.html?m=1

Location: Denmark

10 April 2025 at 11:30 #65050Rob Bune

BRONZE MemberThanks that link is very helpful. It seems the cog is correct and the raiser should dip at the end of the travel. So my issue is that the disc is not being picked up by the motor when it is raised, it simply drops back down as it would when ejecting.

The disc isn’t ever going to clamp.

12 April 2025 at 11:48 #65070Madskp

GOLD MemberSorry I am not able to give you any further input as I have yet to start the repair in my own CD50, but am following with interest.

Location: Denmark

13 April 2025 at 16:52 #65115Rob Bune

BRONZE Memberit seems that this forum’s interest for the CD-50 possibly died a little of late – the archived version has lots of historical posts and contributions from many members who no longer seem to here!

25 May 2025 at 15:21 #65809Rob Bune

BRONZE MemberOk I found the issue, lower disc raiser was a little bent, the disc are now being raised correctly.

However discs don’t seem to be spinning and the laser is making a seeking/scratching sound – exactly like in this video:

https://www.youtube.com/watch?v=bclDp8K4oo4

I have two players doing this 🙂

Any ideas?

Thanks.

26 May 2025 at 07:39 #65819Madskp

GOLD MemberHello again

I am now working on my CD50 and after belt replacement I had some issues with the carrige movement as mentioned in this thread https://forum.beoworld.org/forums/topic/boegram-cd50-carrige-slow/#post-65712

However this is now solved and cam down to adjusting to one misplacement of the camwheel by on tooth, and how much the brass nut on top of the cam wheel was screewd down.

I actually had it playing some tracks on a CD, but after i tried to skip a few tracks it started acting like the one in the video you are linking to.

On thing I will look further into when I have the time is if fine adjustment of the brass nut does any difference.

One thing I notice in the comments to the youtube video is a suggestion about disassembly of the motor and cleaning of it. This might be worth to research further into

Location: Denmark

26 May 2025 at 18:07 #65826Rob Bune

BRONZE MemberYes I saw in the comments to the suggestion that the motor requires cleaning and or lubrication. However the two non-working players that I have both had broken belts, so I am reluctant to believe that 2 players both developed in addition a problem with the motor. Also one player I am repairing for a friend who told me that discs were playing fine before the cd tray stopped ejecting, So unless this two issues are a symptom of one another I am reluctant to start stripping the motor down especially since it appears not not to be a simple job.

I should add that with both players it appears to me that the disc is not actually spinning – the motor is moving but it seems it hasn’t quite grabbed the disc so maybe I will try the adjustments of the copper nut first and also tiny adjustment of the teeth of the main cam.

26 May 2025 at 18:40 #65832Madskp

GOLD MemberYes I saw in the comments to the suggestion that the motor requires cleaning and or lubrication. However the two non-working players that I have both had broken belts, so I am reluctant to believe that 2 players both developed in addition a problem with the motor. Also one player I am repairing for a friend who told me that discs were playing fine before the cd tray stopped ejecting, So unless this two issues are a symptom of one another I am reluctant to start stripping the motor down especially since it appears not not to be a simple job.

Fully understandable. I will also look into other options before trying that. But always a good idea to look into what Others have found in older threads. I will update if I find something relevant.

I should add that with both players it appears to me that the disc is not actually spinning – the motor is moving but it seems it hasn’t quite grabbed the disc so maybe I will try the adjustments of the copper nut first and also tiny adjustment of the teeth of the main cam.

That could be. adjusting the brass nut on my CD50 a little down moved the disc raiser a few millimeters up which seemed to be just what was missing

Location: Denmark

27 May 2025 at 17:42 #65847Madskp

GOLD MemberThis old thread might be worth reading into https://archivedforum2.beoworld.org/forums/t/628.aspx?PageIndex=1Seems to be some succes rate with spindle motor cleaning, but it also sounds like a hard job to disassemble itOne thing I note is in one of the later posts the adjustment of the brass nut on the cam wheel is again mentioned for being responsible in how easy a disc will rotateLocation: Denmark

27 May 2025 at 20:34 #65850Rob Bune

BRONZE MemberSo so progress of sorts.

On player #1 – I still cannot get the disc to clamp properly but I think it is because I am missing the springs which keep the raiser level when it rises.

On player #2 – I played with the brass knob, too tight and discs won’t rise, but I loosened it and the disc is clamped and I can see it spinning. I gave the spindle motor a nudge and it starts to spin – but clearly it has a problem. It is quite noisy. But the TOC seems to be read as I see the correct number of tracks on the display and I can move through the track – but they don’t play. So I believe the issue on this player is the motor.

28 May 2025 at 05:35 #65856Madskp

GOLD MemberGood to hear that the brass knob adjustment had some effect.Even though my CD50 is playing now it still can have time when it spit the disc out at first try. Also on every disc I tried it will start playing 1-2 minuttes into the first track and can sometimes have issues with tracks where it will not play and the counter is just showing the track number. It allways read the TOC though when the disc stays in.Location: Denmark

28 May 2025 at 10:51 #65864Rob Bune

BRONZE MemberPlayer #1 is now playing the discs. With a light source I shone into the side of the player I could see that when the disc was raised there was still a 1-2mm gap between the disc and the grabber. So I further tightened the brass knob and although I was sure the cam could not be any lower it made a difference. the disc now spins and will play the disc seemingly without any issues – although I have not listened to any music only observed.

So a note of warning – the sound heard in the video posted above in my case was not related to the spindle motor issue which the comments suggested was the issue.

Player #2 is still not playing discs but I suspect the issue here is the motor which I probably have nothing to lose in attempting the service.

For the temperamental issues of the player have you tried cleaning the laser lens – and are the cams on the laser housing all complete and lubricated?

28 May 2025 at 18:29 #65880Madskp

GOLD MemberSo a note of warning – the sound heard in the video posted above in my case was not related to the spindle motor issue which the comments suggested was the issue.

Ok good to know. Will experiment a lttle more with the brass know before going into motor issues.

For the temperamental issues of the player have you tried cleaning the laser lens – and are the cams on the laser housing all complete and lubricated?

Laser cleaned and all gears in the laser housing is lubricated. Have not checked for small cracks or missing teeths on the gears, so will also do that.

On your player #1 have you noticed if the CD start the counter at 0.00 or if it is a minute or more into the first track?

Location: Denmark

28 May 2025 at 21:07 #65885Rob Bune

BRONZE MemberOn your player #1 have you noticed if the CD start the counter at 0.00 or if it is a minute or more into the first track?

It starts at 00:00 – the start of the track according to the display. I noticed that on my player #2 i was displaying 00:00 too but would not begin playing the disc.

On player #1 I have made the necessary adjustments to the draw to make it close nicely – I couldn’t figure out why the eject wasn’t working (by pushing the draw fascia) – only manually engaging the micro-switch worked. The fascia of the tray fixes and snaps down on to the hinge (see arrow 1), mine was not fully engaged so when the draw closed the back of the fascia was not making contact with the lever arm for the eject – that took some figuring out. I also managed to find a screw to secure the arm of the tray which had become detached (see arrow 2). Originally it looks like a tiny rivet was used, I found a screw which does the job.

The final job is to add some springs that keep the lower disc raiser level – that might be the most challenging job yet.

29 May 2025 at 20:04 #65924Rob Bune

BRONZE MemberI managed to get player #2 working, or at least playing discs today.

I first removed the laser carriage (via the 4 screws) and wound the white plastic grub screw that comes out of the carriage motor. It took a few turns but eventually the carriage moved about 10mm. I then powered up and the carriage returns to the stop position – which I think proves that the carriage motor is ok.

I then tried to play a disc, I only had 2 of the laser mechanism screws in loose to keep the mechanism in place. Seemed to play ok – I then put all 4 screws in tight and the disc would not play and the disc was lightly knocking or rubbing against something. I noticed that if I loosen the front two screws and lift the mechanism with my fingers by a mm or two the playback works fine and the rubbing stops.

So I think the spindle needs to be adjusted – lifted up so that the disc is spinning a little higher than at present. Perhaps in your case if you have temperamental playback it could be related to this same issue – just try lifting the mechanism once the cd is loaded to see if it makes a difference!

30 May 2025 at 14:01 #65929Madskp

GOLD MemberGreat hint. I will certanly try that the next time I work on it.

One thing I wonder though is if it makes a difference to adjust the spindle height vs. Adjusting the lifting mechanism

Location: Denmark

31 May 2025 at 11:26 #65967Madskp

GOLD MemberI have now tried to lift the Mechanism slightly, and saw an improvement on some CD’s which now starts at 0.00 or 0.03. Tried to adjust the brass know more loosly and that also give this result. However there are still some of the CD’s I am using for testing that starts between 1-2 minutes into track 1, so does not solve every case for me. If I remeber correctly I saw something about CD thickness in one of the older threads. Will have to go back and read up on that

Location: Denmark

-

AuthorPosts

- You must be logged in to reply to this topic.