Home › Forums › Product Discussion & Questions › BeoGram › Beogram 9500 – adjusting the set-down position

Tagged: Beogram 9500

- This topic has 5 replies, 2 voices, and was last updated 1 year, 3 months ago by

-

AuthorPosts

-

13 November 2024 at 16:36 #60911

GOLD Member

GOLD MemberI have just got my hands on a BG9500 as a restoration project. The problem turned out to be that the ‘wire drive’ that drives the tonearm had come loose, due to the hook you connect both ends of the wire drive to being broken off. I managed to glue it back into position, and re-thread the wire drive successfully (and I was quite proud of myself too!).

However, sometimes when starting to play a 12″ record, the set-down position is just short of where it should be, and the arm slips off the edge of the record.

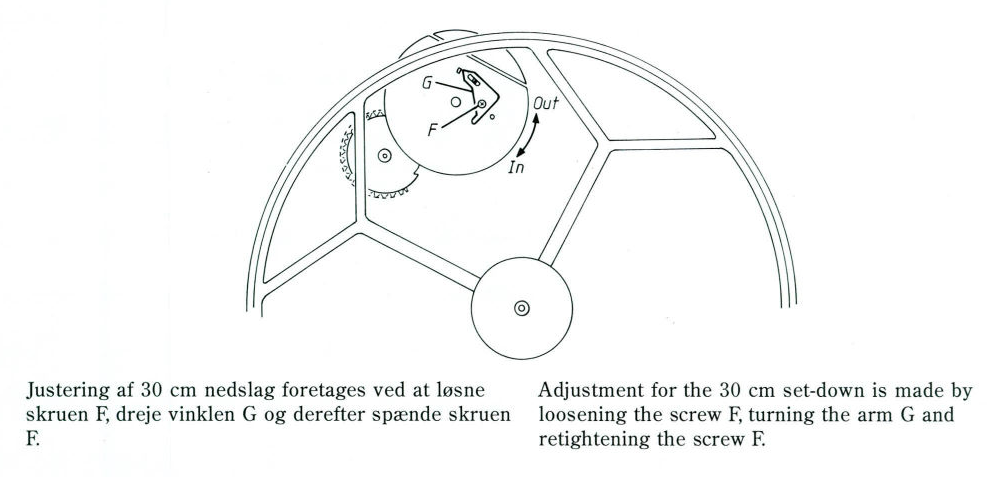

I have found the instructions for adjusting this in the service manual (image below), but before I start, I wonder if anyone has any experience of this, and can offer any tips? I just want to avoid any common pitfalls.

I have not yet tested the 7″ set-down position (I don’t play many singles!) but that looks much easier to adjust.

Location: Liverpool

My B&O Icons:

14 November 2024 at 08:52 #60926Dillen

ModeratorWhen the problem was with the string drive, it’s much more likely that the offset is

between the carriage and the string rather than between parts of the mechanics.

Adjust the black excentric at the foot of the carriage.Martin

14 November 2024 at 08:57 #60927 GOLD Member

GOLD MemberThanks. The little plastic hook that I had glued back in place came loose again, so this time I’ve added a little plastic ‘buttress’ of my own making and glued it back on so it should have a firmer hold. I also got the positioning of the hook more precise this time. When the glue dries I’ll refit the wire drive and give that a try (I saw the adjustment method you mention in the service manual but it said that was more for 7″ records).

Location: Liverpool

My B&O Icons:

14 November 2024 at 11:21 #60929 GOLD Member

GOLD MemberThanks for the advice @Dillen, the glue dried, and the hook I had glued back on seems firmly fixed this time, so I reattached the wire drive, adjusted the eccentric a little, and the set-down position now seems to be good for both 12″ and 7″ records. The sound quality seems to be as good as my BG3000 so I’ll keep using it for a while in place of my BG3000, to make sure it continues to work. I’ve never restored a Beogram before so I’m quite proud of myself!

The only thing I do notice is that when I press Play, the platter seems to spin slowly for 2 or 3 revolutions, but by the time the arm has set down, it has reached the right speed. I’m assuming that this means the belt is worn, so I’ll get a new one – they do them quite cheap on Beoparts Shop (or Danish Sound Parts, as they are now calling themselves).

Location: Liverpool

My B&O Icons:

14 November 2024 at 18:35 #60937Dillen

ModeratorTypical symptom of a slipping belt.

With the Beogram unpowered and platter lifted off, put a finger on top of the

motor pulley, rotate the subplatter (“skeleton” platter) by hand and feel for friction.

There should be a fair amount of friction. If the belt doesn’t “bite” the pulley but instead just

“skates” on it, replace the belt.Yes, Danish Sound Parts is both Danish, Parts and Sound.

Martin

14 November 2024 at 18:53 #60940 GOLD Member

GOLD MemberThanks for the advice – I’ve performed that test and there is no real friction there at all. I performed the same test on my BG3000 just for comparison and there is plenty of friction there, so I see exactly what you mean. I’ve ordered a new belt.

Location: Liverpool

My B&O Icons:

-

AuthorPosts

- You must be logged in to reply to this topic.